64111-0034 —May 2015

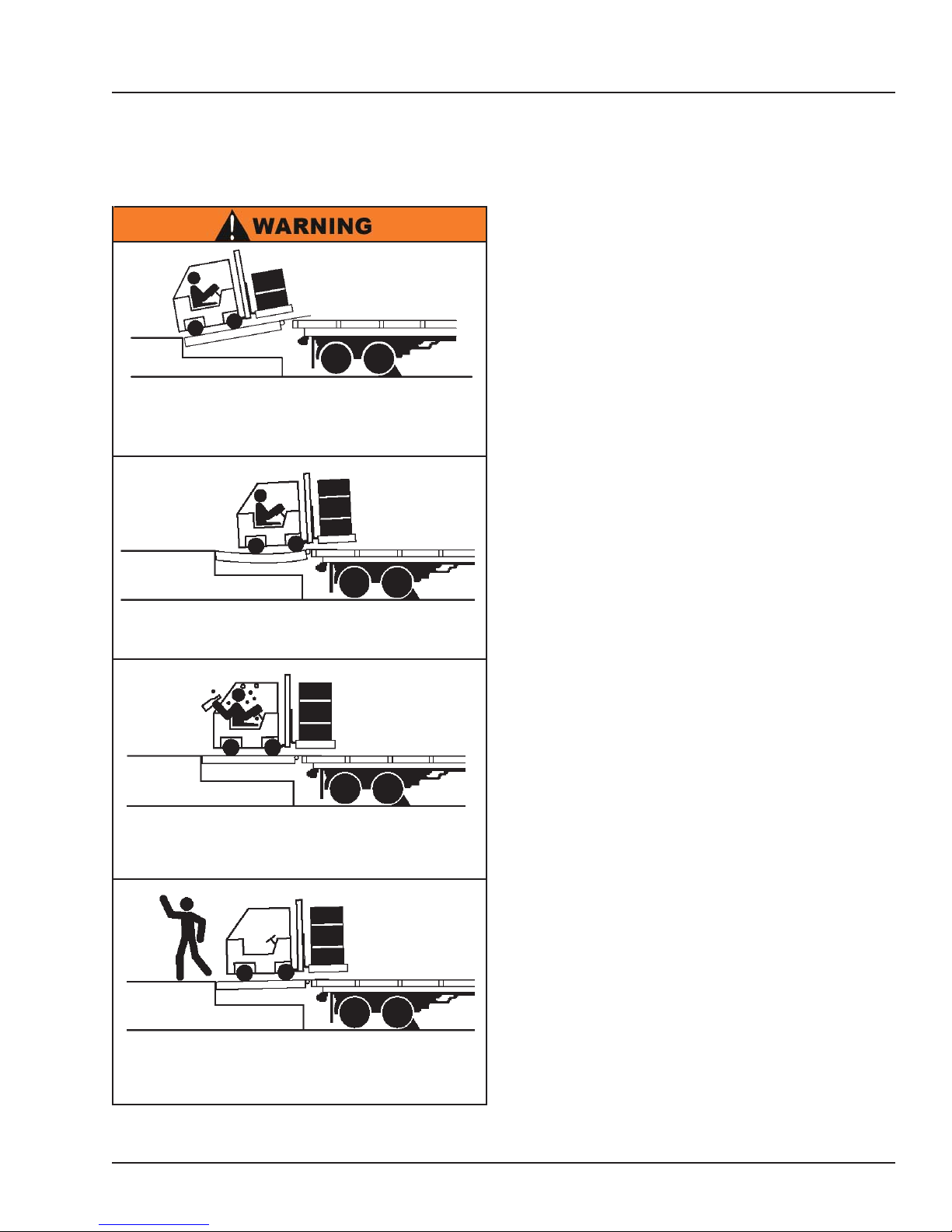

OWNER’S/USER’S RESPONSIBILITIES

1. The owner/ user should recognize the inherent dangers of the interface between the loading dock and

the transportation vehicle. The owner/ user should, therefore, train and instruct all operators in the safe

operation and use of the loading dock equipment in accordance with manufacturer’s recommendations and

industry standards. Effective operator training should also focus on the owner’s/user’s company policies

and operating conditions. Maintaining, updating and re training all operators on safe working habits and

operation of the equipment, regardless of previous experience, should be done on a regular basis and

should include an understanding and familiarity with all functions of the equipment. Owner’s/user’s shall

actively maintain, update and retrain all operators on safe working habits and operations of the equipment.

2. The manufacturer shall provide to the initial purchaser all necessary information regarding Safety

Information, Operation, Installation and Safety Precautions, Recommended Initial and Periodic Inspections

Procedures, Planned Maintenance Schedule, Product Specifications, Troubleshooting Guide, Parts

Break Down, Warranty Information, and Manufacturers Contact Information, as well as tables to identify

the grade(slope) for all variations of length or configuration of the dock leveling device and information

identifying the maximum uncontrolled drop encountered when sudden removal of support while in the

working range of the equipment.

3. It is recommended that when the transportation vehicle is positioned correctly in the dock opening and in

contact with both bumpers, there shall be a minimum of 4.00 inches (100mm) overlap of the leveling device

and the transportation vehicle at all times during the loading and unloading process.

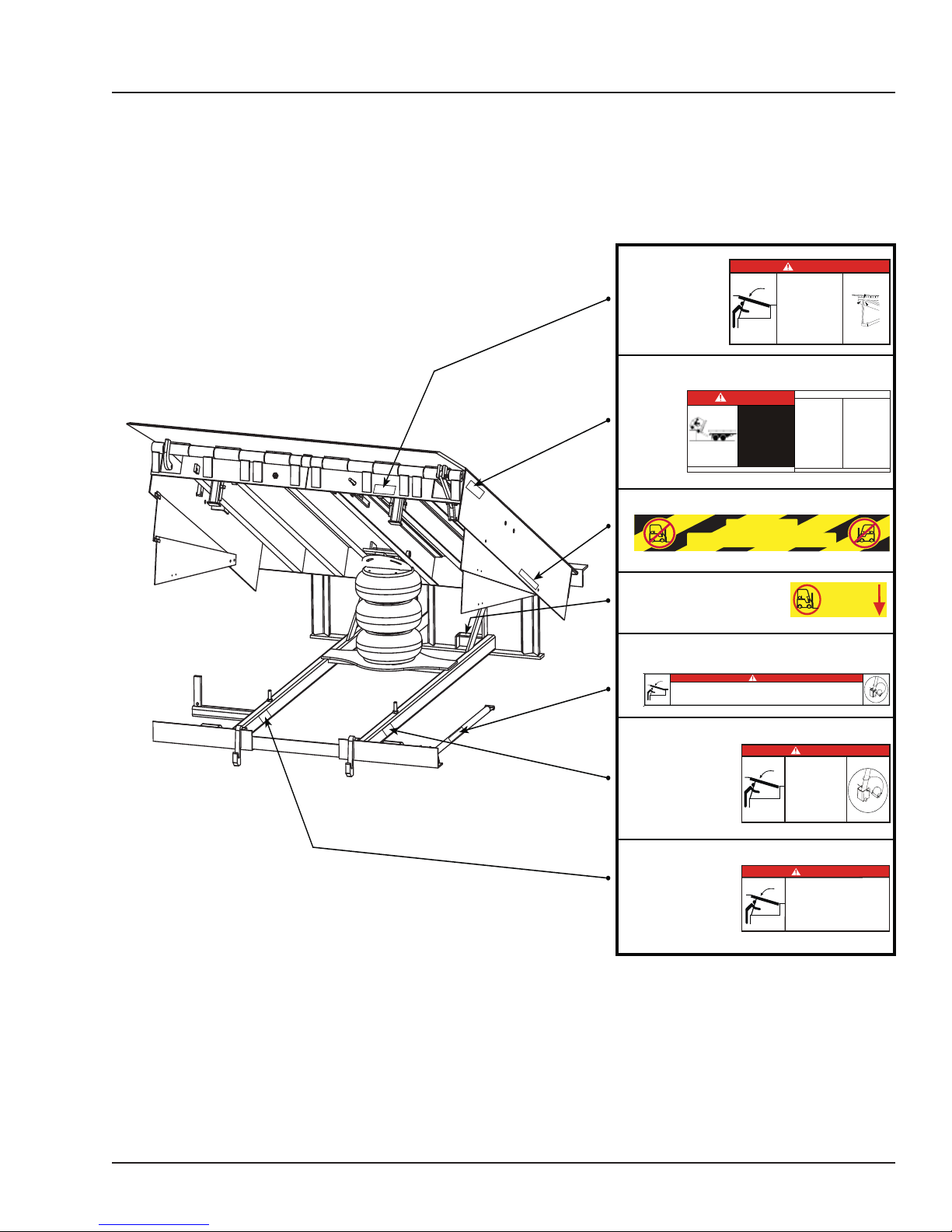

4. The Owner/User must review all name plates, placards, decals, instructions and posted warnings and

place the same in view of the operator or maintenance personnel for whom such warnings are intended

for. Contact manufacturer for any replacements.

5. Manufacturer’s recommended periodic maintenance and inspection procedures in effect at the date of

shipment shall be followed at all times. Written documentation of maintenance, replacement parts or

damage should be retained. In the event of damage notification to the manufacturer is required.

6. Loading dock equipment that has been structurally damaged or has experienced a sudden loss of main

support while under load (such as what might occur when a transport vehicle pulls out from under the

leveling device) shall be removed from service, inspected by a manufacturer’s authorized representative,

and repaired or replaced as needed before being placed back in service.

7. Any modifications or alterations of loading dock equipment shall only be done with prior written approval

from the manufacturer and the same shall be at least as safe as the original equipment was prior to the

modification and shall also satisfy all safety requirements of the manufacturer for the particular application

of the leveling device.

8. When industrial moving devices are being used in the loading or unloading of product from the

transportation vehicle, this vehicle shall have the brakes and wheel chocks applied appropriately or all

other positive restraining device shall be fully utilized. It is recommended that transport vehicles with air-

ride suspension systems shall have its air exhausted prior to performing loading and unloading operation

to minimize transport vehicle bed drop.

9. Loading dock safety equipment should never be used outside of its intended use, vertical working range,

or capacity. Please consult the manufacturer if you have any questions as to the use, vertical working

range or capacity of the equipment. Only properly trained and authorized personnel should operate the

equipment.

10. When selecting loading dock safety equipment, it is NOTICE to consider not only present requirements but

also future plans and any possible adverse conditions, environmental factors or usage.