SAFETY

5

4111-0006 — Sept 2010

Safety Decals

Every 90 days (quarterly) inspect all safety labels and tags

to ensure they are on the dock leveler and are easily leg-

ible. If any are missing or require replacement, please call

1-800-643-5424 for replacements.

CRUSH HAZARD

Maintenance prop must

support leveler behind bar.

Do not force maintenance

prop forward of bar to

support lip. Refer to

owner’s/user’s manual for

proper use. Failure to

comply will result in

death or serious injury.

DANGER

1751-0727

Unsupported dock leveler

ramps can lower unexpectedly.

Before allowing vehicle to leave

the dock always:

!Ensure that no equipment,

material or people are on the

dock leveler.

!Return the dock leveler to its

stored position at dock level.

Failure to follow posted instructions will result in death or serious injury.

SAFETY INFORMATION

Call 262.255.1510 for replacement placards, warning labels, or owner’s/user’s manuals.

Operation

1. Read and follow all instructions and

warnings in the owner’s/user’s

manual.

2. Use of dock leveler restricted to

trained operators

3. Always chock trailer wheels or

engage truck restraint before

operating dock leveler or beginning to

load or unload.

4. Never use hands or equipment to

move the ramp or lip

5. Before activating dock leveler:

¥Ensure trailer is backed in against

bumpers.

¥Remove any end loads if required.

¥Check trailer alignment to avoid lip

interference. If lip does not lower to

trailer bed, reposition vehicle.

6. Ensure that truck bed supports

extended lip or the leveler frame

supports the ramp before driving on

ramp.

7. Stay clear of hinges and front and

sides of moving dock leveler.

8. Never use damaged or

malfunctioning dock leveler. Report

problems immediately to supervisor.

Maintenance/Service

1. Read and follow all instructions,

warnings and maintenance schedules

in the owner’s/user’s manual.

2. Maintenance/Service of dock leveler

restricted to trained personnel.

3. Place barriers on the driveway and on

dock floor to indicate service work is

being performed.

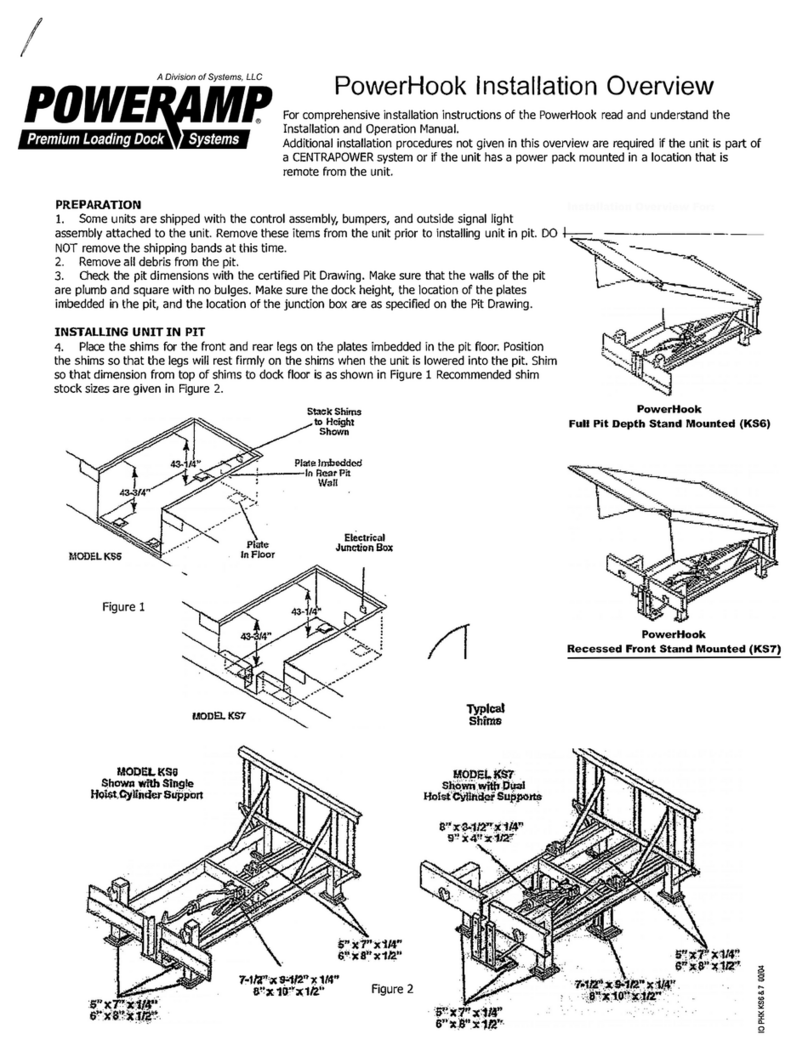

4. DO NOT ENTER PIT unless dock

leveler is securely supported by

maintenance prop.

5. If electrically powered turn off and use

OSHA lockout/tagout procedures.

DANGER

DO NOT

FORK THIS SIDE

FORK

HERE

CRUSH HAZARD

Do not work under dock leveler unless this maintenance prop has been secured in the

upright position. See owner’s/user’s manual for proper procedures. Failure to comply

will result in death or serious injury.

DANGER

1751-0788

CRUSH HAZARD

Open the pin latch and insert

through the maintenance

prop housing and prop

completely. Close the pin latch

to secure prop. Use every

time dock leveler is serviced.

Failure to comply will result

in death or serious injury.

DANGER

1751-0789

CRUSH HAZARD

DO NOT ENTER PIT unless dock leveler is

safely supported by maintenance prop. Place

barriers on driveway and dock floor to indicate

service work being performed. Refer to

owner’s/user’s manual for proper maintenance

procedures. Failure to comply will result in death

or serious injury.

DANGER

1751-0726

1751-0727

1751-0730 (x2)

1751-0788

1751-0789

1751-0726

CRUSH HAZARD

Do not remove main springs until leveler is safely supported by

maintenance prop. Main springs contain stored energy. Be sure

springs are fully unloaded and ends are loose before removal. Refer

to owner’s/user’s manual for proper maintenance procedure. Failure

to comply will result in death or serious injury.

DANGER

1751-0728

1751-0728

(decal placed in same position on both sides)

(decal placed in same position on both sides)

(decal placed in same position on both sides)

1751-0329 (x2)

1751-0330 (x2)