1

www.prbx.com 2022.07.21

Specifications are subject to change without notice.

Table of Contents

1. Assembling and Installation Method ......................................................... 1

1.1 Mounting method ................................................................................... 1

1.2 Isolation from conductive enclosure.................................................... 2

1.3 Installation to fulfil EMC requirement.................................................. 2

2. Derating........................................................................................................... 2

2.1 Derating curve by input voltage............................................................ 2

2.2 Temperature measuring point.............................................................. 2

3. Wiring............................................................................................................... 3

3.1 Wiring input connector .......................................................................... 3

3.2 Wiring output terminal ........................................................................... 3

3.3 Wiring function connector..................................................................... 4

3.4 Jumper factory setting........................................................................... 4

3.5 Output ripple and ripple noise measurement.................................... 4

4. Functions ........................................................................................................ 4

4.1 Input voltage range................................................................................. 4

4.2 Inrush current limiting............................................................................ 4

4.3 Over current protection.......................................................................... 5

4.4 Over voltage protection.......................................................................... 5

4.5 Thermal protection ................................................................................. 5

4.6 Output voltage adjustment.................................................................... 5

4.7 Remote ON/OFF..................................................................................... 6

4.8 Remote sensing....................................................................................... 7

4.9 Adjustable constant current range ...................................................... 7

4.10 Power good (PG)................................................................................... 8

5. Series / Parallel Operation........................................................................... 8

5.1 Series operation...................................................................................... 8

5.2 Parallel operation .................................................................................... 9

5.3 Redundancy operation.........................................................................10

6. Life Expectancy and Warranty...................................................................11

6.1 Life Expectancy .....................................................................................11

6.2 Warranty .................................................................................................11

7. Options..........................................................................................................11

7.1 Option -N: with Metal cover ................................................................11

7.2 Option -O: with Active ORing..............................................................11

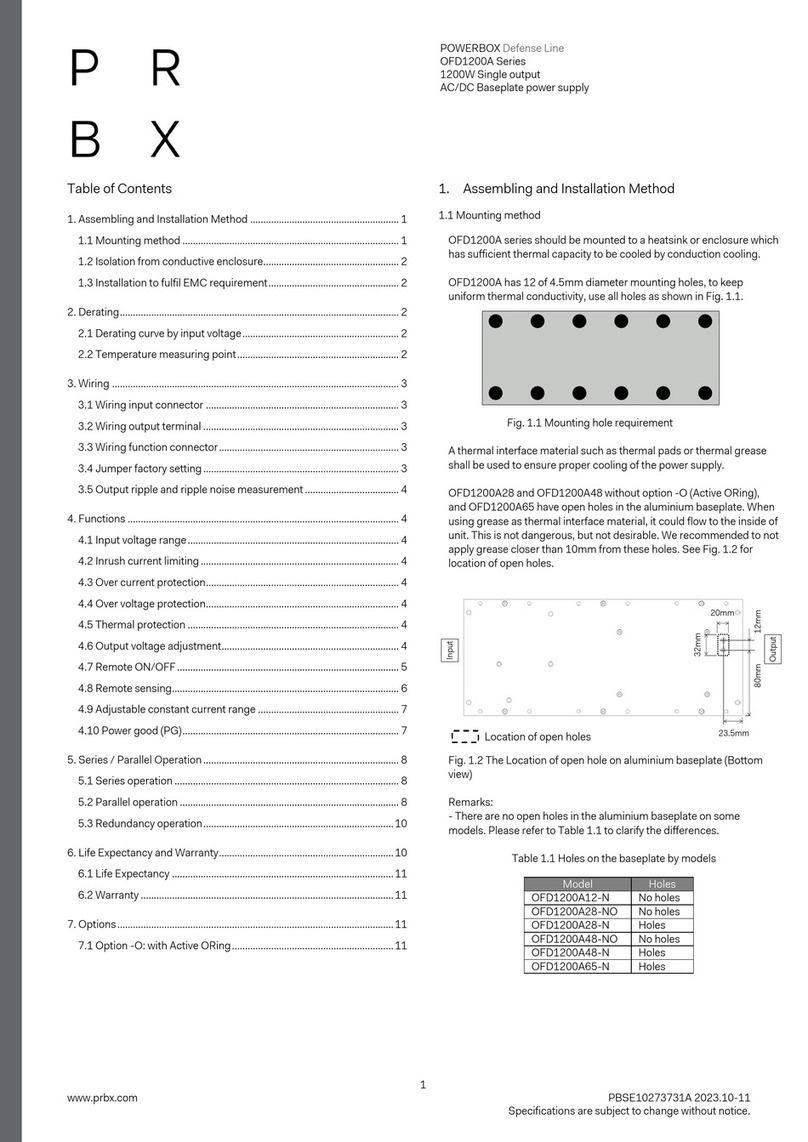

1. Assembling and Installation Method

1.1 Mounting method

OFI1200A series should be mounted to a heatsink or enclosure which

has sufficient thermal capacity to be cooled by conduction cooling.

OFI1200A has 10 of 4.5mm diameter mounting holes, to keep uniform

thermal conductivity, use at least 6 mounting holes as shown in Fig.

1.1. Using all 10 mounting holes is recommended.

Minimum Recommended

Fig. 1.1 Mounting hole requirement

A thermal interface material such as thermal pads or thermal grease

shall be used to ensure proper cooling of the power supply.

OFI1200A28 and OFI1200A48 without option -O (Active ORing), have

open holes in the aluminium baseplate. When using grease as thermal

interface material, it could flow to the inside of unit. This is not

dangerous, but not desirable. We recommended to not apply grease

closer than 10mm from these holes. See Fig. 1.2 for location of open

holes.

Fig. 1.2 The Location of open hole on aluminium baseplate (Bottom

view)

Remarks:

- There is no open holes in aluminium baseplate on units with option -

O.