Powercraft 3

5. Store idle tools

When not is use, tools should be stored in dry, high,

or locked-up place, out of reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for which

it was intended.

7. Use right tool

Don’t force small tools or attachments to do the job

of heavy duty tool. Don’t use tools for purposes not

intended.

8. Dress properly

Do not wear loose clothing or jewelry. They can be

caught in moving parts. Rubber gloves and nonskid

footwear are recommended when working out-

doors. Wear protective hair covering to contain long

hair.

9. Use safety glasses

Also use face or dust mask if cutting operation is

dusty.

10.Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and sharp

edges.

11.Secure work

Use clamps or a vise to hold work. It’s safer than using

your hand and it frees both hands to operate tool.

12.Don’t overreach

Keep proper footing and balance at all times.

13.Maintain tools with care

Keep tools sharp and clean for better and safer per-

formance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically

and, if damaged, have repaired by authorized service

facility. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean and free

from oil and grease.

14.Disconnect tools

When not in use, before servicing, and when chan-

ging accessories such as blades, bits and cutters.

15.Remove adjusting keys and wrenches

Form the habit of checking to see that keys and adjus-

ting wrenches are removed from tool before turning

it on.

16.Avoid unintentional starting

Don’t carry plugged-in tools with finger on switch. Be

sure switch is off when plugging in.

17.Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

18.Stay alert

Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

19.Check damaged parts

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to deter-

mine that it will operate properly and perform its

intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged

should be properly repaired or replaced by an autho-

rized service center unless otherwise indicated

elsewhere in this instructions manual. Have defective

switches replaced by an authorized center. Do not

use tool if switch does not turn it on and off.

20.Warning

The use of any other accessory or attachment other

than recommended in this operation instructions or

the catalog may present a risk of personal injury.

21.Have your tool repaired by an expert

This electric appliance is in accordance with the rele-

vant safety rules repairing of electric apliances may be

carried out only by experts otherwise it may cause

considerable danger for the user.

22.Connect the dust extraction device

Whenever there are facilities for fitting a dust extrac-

tion system, make sure it is connected and used.

BEFORE USING THE MACHINE

1. Check the following

•Make sure that your machine is correct for your power

supply.

•Make sure the socket is earthed;

•Make sure the cable and socket are in good condition,

i.e. not frayed or damaged.

2. Do not use long extension cables

Use only earthed extension cables.

3. A grinding stone is fragile

The stone is easily damaged when being dropped, hit,

etc. Always grind with the face of the grinding stone,

never the sides. A cracked grinding stone must be

replaced immediately. Due to the high rotational

velocity the stone might disintegrate, causing acci-

dents.

4. Always wear safety glasses when grinding

5. Never operate the grinding machine without the

guard in place.

6. Make sure the guard and the tool rest are properly

adjusted and secured.

7. The maximum clearance between the tool rest and

the grinding stone must never exceed 1-1.5 mm.

8. Use the stone only for its intended purpose, e.g. for

grinding tools, never for heavy-duty construction

work.

Use only grinding stones that state the following:

•Name of the manufacturer;

•Binding material;

• Dimensions;

•Maximum speed.

9. Never rebore the arbor hole in the grinding stone to

widen the diameter.

10. The maximum admissable rotational velocity of the

grinding stone may not exceed the velocity mentio-

ned on the stone.

11. For safe grinding it is best to bolt the machine to the

bench.

BEFORE YOU OPERATE THE MACHINE

1. Make sure the switch is “OFF” before you plug in the

machine.

2. Keep the cable away from moving parts.

IMMEDIATELY SWITCH OFF THE MACHINE

WHEN

•Interruption in the mains plug, mains lead or mains

lead damage.

•Defect switch.

•Smoke or stench of scorched isolation.

6Powercraft

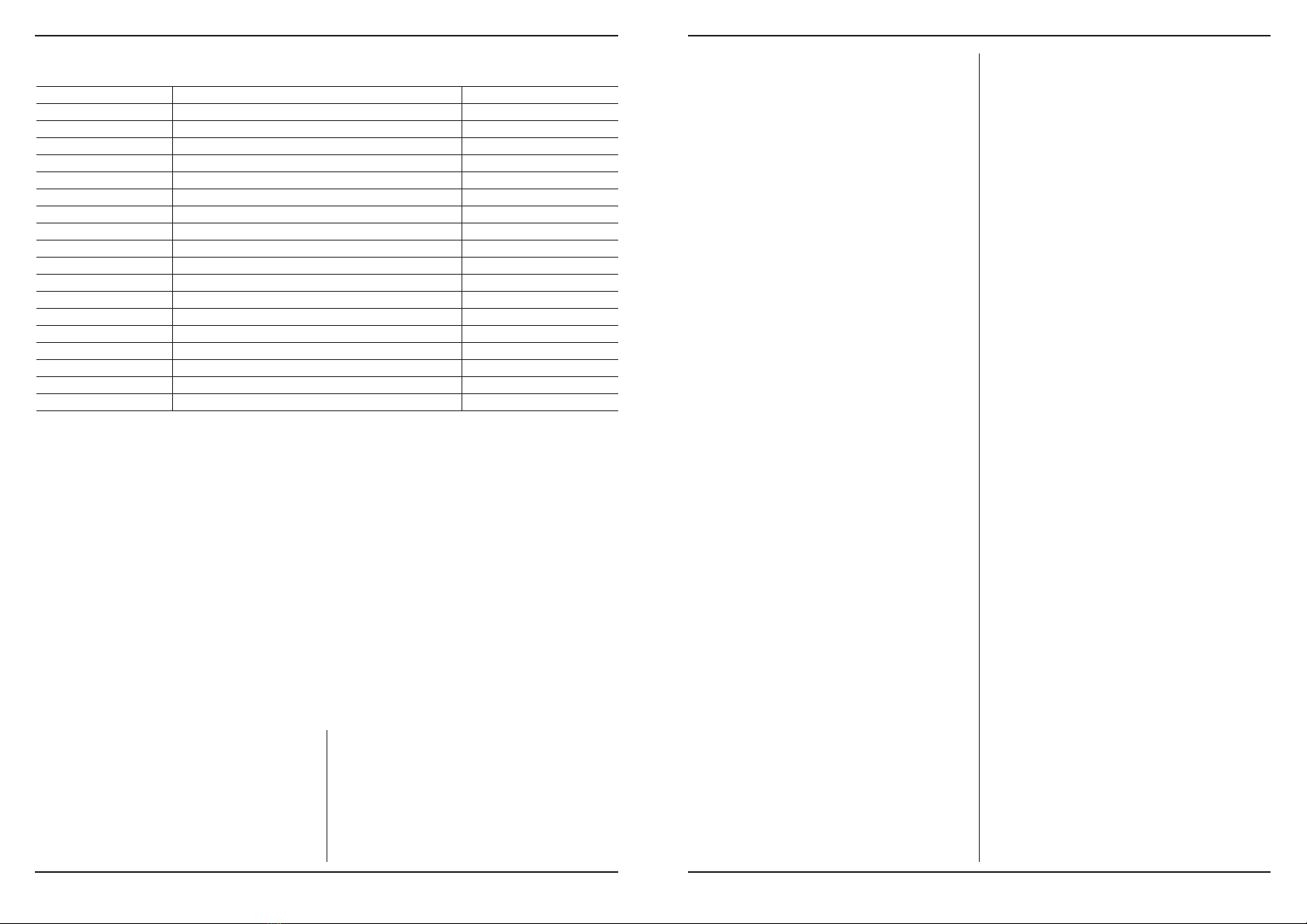

SPARE PARTS

REF NR DESCRIPTION POWERCRAFT NR

015 - 020 BOLSTER THREADED COMPLETE 209860

023 PRESSING PLATE 209861

024 SPRING 209862

025 BUSHING 209863

026 UPPER ARM 209864

028 SAW BLADE HOLDER (UPPER) 209865

033 + 034 CONNECTION PLATE + BEARING 209866

039 LOWER ARM 209867

041 SAW BLADE HOLDER (LOWER) 209868

042 - 044 AIR HOSE + PLASTIC PLATE 209869

047 TRANSPARENT GUARD 209870

049 GAS BAG 209871

052 CAM 209872

055 TABLE INSERT 209873

056 MOTOR 209874

065 SUPPORT FRAME 209875

069 - 072 MITRE GUIDE COMPLETE 209876

SWITCH 209877