2ENGLISH

SPECIFICATIONS

Model 5201N / 5201NA

Blade diameter 260 mm

Max. Cutting depth at 90° 97 mm

at 45° 64 mm

No load speed (min-1)3,700

Overall length 445 mm

Net weight 8.3 kg

• Duetoourcontinuingprogrammeofresearchanddevelopment,thespecicationshereinaresubjecttochange

withoutnotice.

• Note:Specicationsmaydifferfromcountrytocountry.

Symbols

Thefollowingshowthesymbolsusedfortheequipment.

Besurethatyouunderstandtheirmeaningbeforeuse.

Readinstructionmanual.

Wearsafetyglasses.

Intended use

Thetoolisintendedforperforminglengthwaysand

crosswaysstraightcutsandmitrecutswithanglesin

woodwhileinrmcontactwiththeworkpiece.

Power supply

Thetoolshouldbeconnectedonlytoapowersupplyof

thesamevoltageasindicatedonthenameplate,and

canonlybeoperatedonsingle-phaseACsupply.This

toolshouldbegroundedwhileinusetoprotecttheoper-

atorfromelectricshock.Useonlythree-wireextension

cordswhichhavethree-pronggrounding-typeplugsand

three-polereceptacleswhichacceptthetool'splug.

SAFETY INSTRUCTIONS

WARNING! When using electric tools, basic safety

precautions, including the following, should always

be followed to reduce the risk of re, electric shock

and personal injury. Read all these instructions

before operating this product and save these

instructions.

For safe operations:

1. Keep work area clean.

Clutteredareasandbenchesinviteinjuries.

2. Consider work area environment.

Donotexposepowertoolstorain.Donotuse

powertoolsindamporwetlocations.Keepwork

areawelllit.Donotusepowertoolswherethereis

risktocausereorexplosion.

3. Guard against electric shock.

Avoidbodycontactwithearthedorgroundedsur-

faces(e.g.pipes,radiators,ranges,refrigerators).

4. Keep children away.

Donotletvisitorstouchthetoolorextensioncord.

Allvisitorsshouldbekeptawayfromworkarea.

5. Store idle tools.

Whennotinuse,toolsshouldbestoredinadry,

highorlockedupplace,outofreachofchildren.

6. Do not force the tool.

Itwilldothejobbetterandsaferattheratefor

whichitwasintended.

7. Use the right tool.

Donotforcesmalltoolsorattachmentstodo

thejobofaheavydutytool.Donotusetoolsfor

purposes not intended; for example, do not use

circularsawstocuttreelimbsorlogs.

8. Dress properly.

Donotwearlooseclothingorjewellery,theycan

becaughtinmovingparts.Rubberglovesand

non-skidfootweararerecommendedwhenwork-

ingoutdoors.Wearprotectinghaircoveringto

containlonghair.

9. Use safety glasses and hearing protection.

Alsousefaceordustmaskifthecuttingoperation

isdusty.

10. Connect dust extraction equipment.

Ifdevicesareprovidedfortheconnectionofdust

extractionandcollectionfacilitiesensuretheseare

connectedandproperlyused.

11. Do not abuse the cord.

Nevercarrythetoolbythecordoryankittodis-

connectitfromthesocket.Keepthecordaway

from heat, oil and sharp edges.

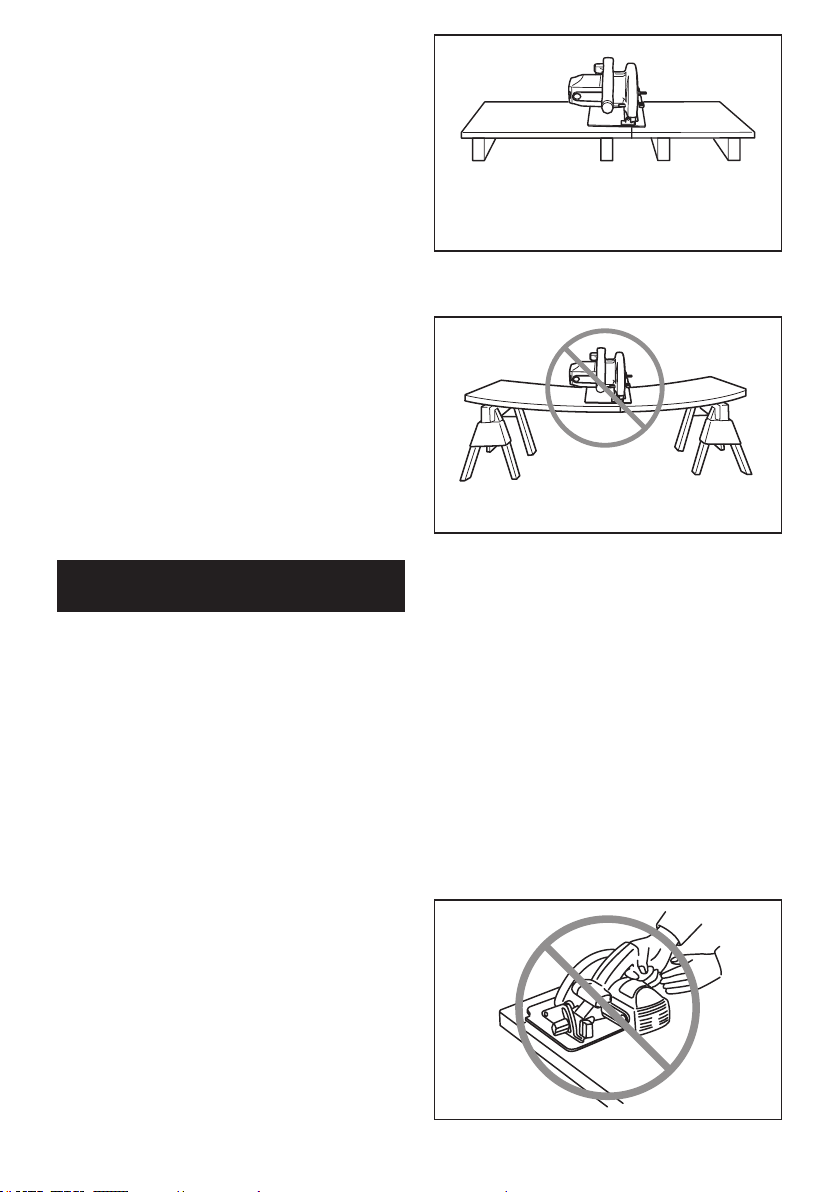

12. Secure work.

Useclampsoravicetoholdthework.Itissafer

thanusingyourhandanditfreesbothhandsto

operate the tool.

13. Do not overreach.

Keepproperfootingandbalanceatalltimes.

14. Maintain tools with care.

Keepcuttingtoolssharpandcleanforbetterand

saferperformance.Followinstructionsforlubrica-

tionandchangingaccessories.Inspecttoolcord

periodicallyandifdamagedhaveitrepairedbyan

authorizedservicefacility.Inspectextensioncords

periodicallyandreplace,ifdamaged.Keephan-

dlesdry,cleanandfreefromoilandgrease.

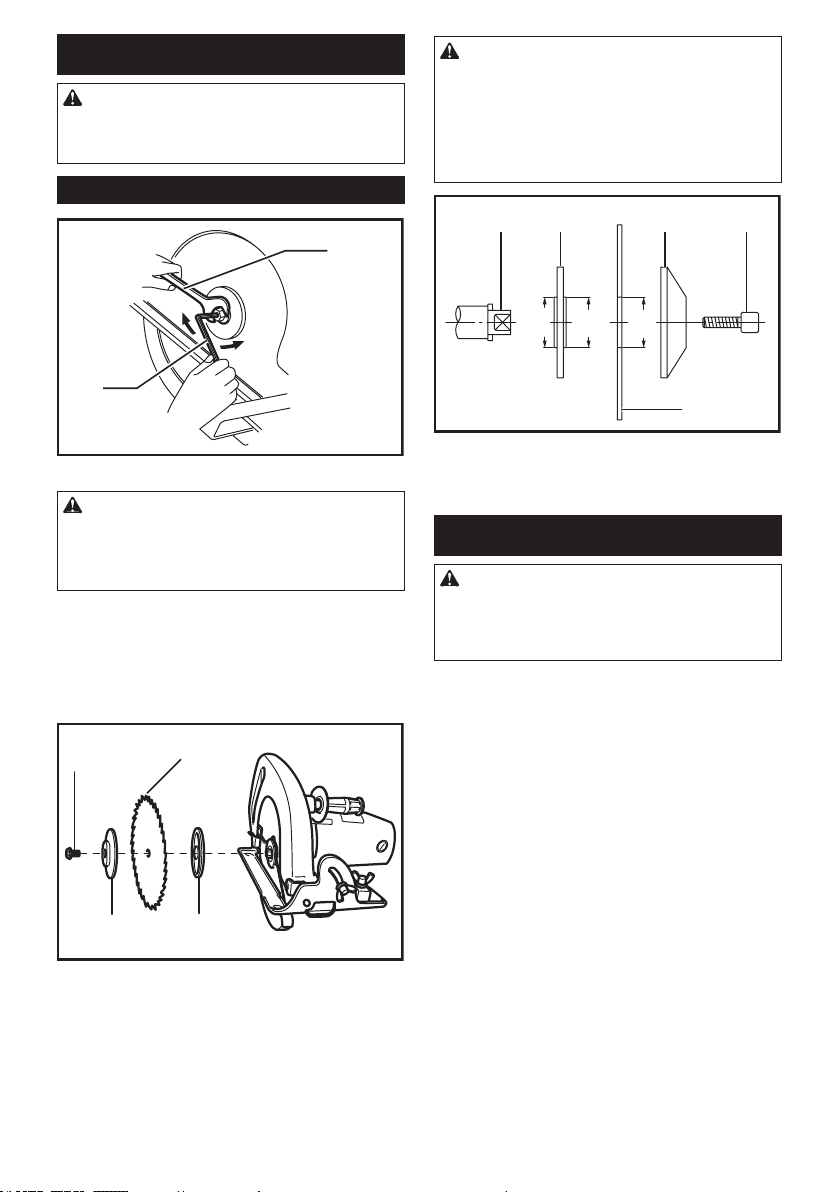

15. Disconnect tools.

Whennotinuse,beforeservicingandwhenchang-

ingaccessoriessuchasblades,bitsandcutters.

16. Remove adjusting keys and wrenches.

Formthehabitofcheckingtoseethatkeysand

adjustingwrenchesareremovedfromthetool

before turning it on.

17. Avoid unintentional starting.

Donotcarryaplugged-intoolwithangeronthe

switch.Ensureswitchisoffwhenpluggingin.