Intake section of the duct should

be larger than the dimension of

compressor exhaust shown below:

WIRING

All electrical hook-ups must be per-

formed by a qualified electrician.

Installations must be in accordance

with local and national electrical codes.

1. Use solderless terminals to connect

the electric power source.

2. For 15 - 20 HP remove front panel.

For 10 HP see upper right side of

enclosure, remove rectangle panel.

3. For 15 - 20 HP remove the rectangle

electrical box cover located beneath

air inlet filter on the right front of

the unit.

4. Connect the power inlet cable to

the inlet power junction block locat-

ed on the inlet side of all starter

connections.

Consult your NEC and local codes for

wire size

PIPING

These units do not include air receivers.

Air receiver can be purchased separate-

ly. Please consult our distributors. Use

Chart 2 as a guideline for sizing the air

receiver.

1. Make sure the piping is lined up

without being strained or twisted

when assembling the piping for the

scroll compressor.

2. Appropriate expansion loops or

bends should be installed at the

compressor to avoid stresses caused

by changes in hot and cold condi-

tions.

3. Piping supports should be anchored

separately from the compressor to

4

Scroll Enclosure Air Compressors

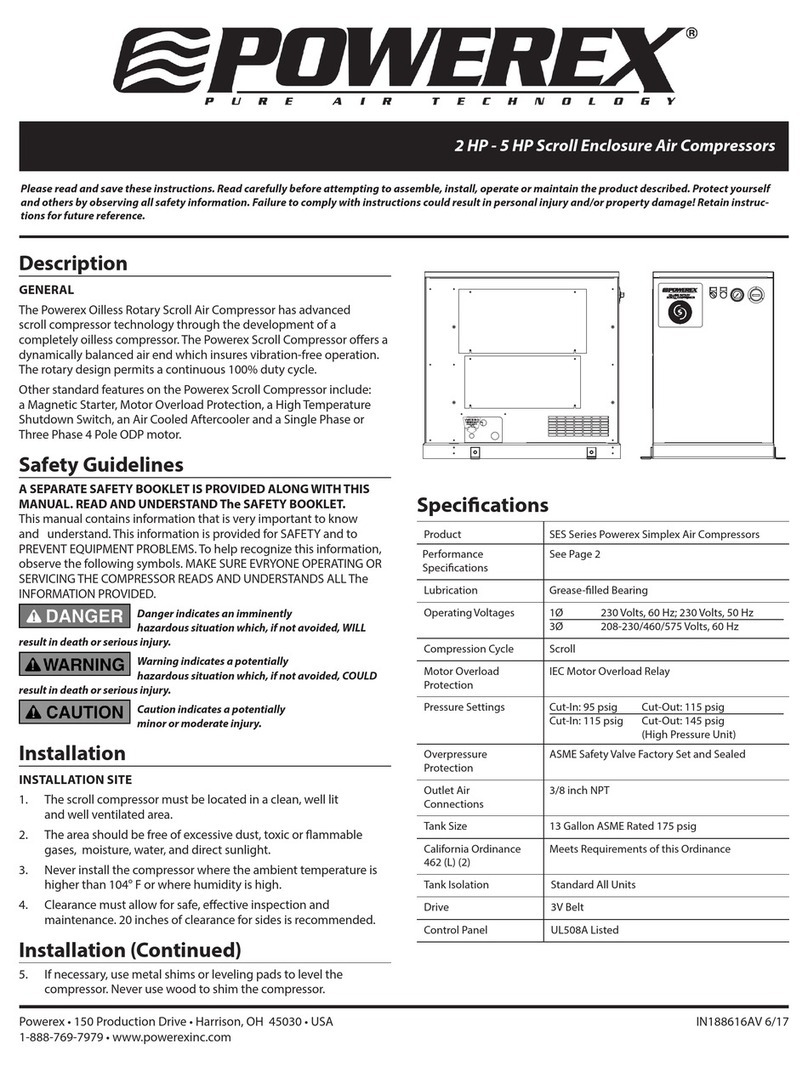

INSTALLATION SITE

1. The scroll compressor must be locat-

ed in a clean, well lit and well venti-

lated area. Contaminated area can

clog intake filter and/or intake

metal mesh.

2. The area should be free of excessive

dust, toxic or flammable gases and

moisture.

3. Never install the compressor where

the ambient temperature is higher

than 104oF or where humidity is

high. High humidity will cause elec-

trical short circuit and rusting of

components.

4. Clearance must allow for safe, effec-

tive inspection and maintenance.

24” of clearance for sides, 40” clear-

ance from the top is recommended.

5. If necessary, use metal shims or lev-

eling pads to level the compressor.

Never use wood to shim the com-

pressor.

VENTILATION

1. If the scroll compressor is located in

a totally enclosed room, an exhaust

fan with access to outside air must

be installed.

2. Never restrict the cooling fan

exhaust air.

3. Vent the exhaust air outside to pre-

vent the compressor from operating

at high temperatures and shutting

down.

4. Never locate the compressor where

hot exhaust air from other heat

generating units may be pulled into

the unit.

SUGGESTED VENTILATION SYSTEM

1) The following ventilation capacity

is designed to keep the tempera-

ture rise inside the room to be max.

10°F. Since the calculation is based

on zero static pressure, the actual

ventilation capacity should be larg-

er than the figure in Chart 1.

2) Install the exhaust duct in order to

minimize the pressure lost of the

ducting. Keep the distance

between the inlet duct and the

compressor exhaust to be at least

12 inches for ease of maintenance.

reduce noise and vibration.

4. Never use any piping smaller than

the compressor connection.

5. Use flexible hose to connect the

outlet of the compressor to the pip-

ing so that the vibration of the

compressor does not transfer to the

piping.

SAFETY VALVES

Tank mounted compressors are shipped

from the factory with safety valves

installed in the air receiver manifold.

The flow capacity of the safety valve is

equal to or greater than the capacity of

the compressor.

1. The pressure setting of the safety

valve must be at least 10 psi less

than the maximum working pres-

sure of the air receiver.

2. Safety valves should be placed

ahead of any possible blockage

point in the system, i.e. shutoff

valve.

3. Avoid connecting the safety valve

with any tubing or piping.

4. Manually operate the safety valve

every six months to avoid sticking or

freezing.

BEFORE START UP

1. Make sure all safety warnings,

labels and instructions have been

read and understood before contin-

uing.

2. Remove any shipping materials,

brackets, etc.

3. Confirm that the electric power

source and ground have been firmly

connected.

4. Check the belts for tightness.

5. Be sure all pressure connections are

tight.

6. Check to be certain all safety relief

valves, etc., are correctly installed.

7. Securely mount all panels and

guards.

8. Check that all fuses, circuit breakers,

etc., are the proper size.

9. Make sure the inlet filter is properly

installed.

10. Confirm that the drain valve is

closed.

Operation

Ventilation 2825 3885 5300

Capacity (cfm)

Exhaust Dimension for all Models

13" x 5.6"

Model 10 HP 15 HP 20 HP

Installation

Chart 1

10 20 gallons

15 30 gallons

20 40 gallons

HP Air Receiver Min. Capacities

Chart 2