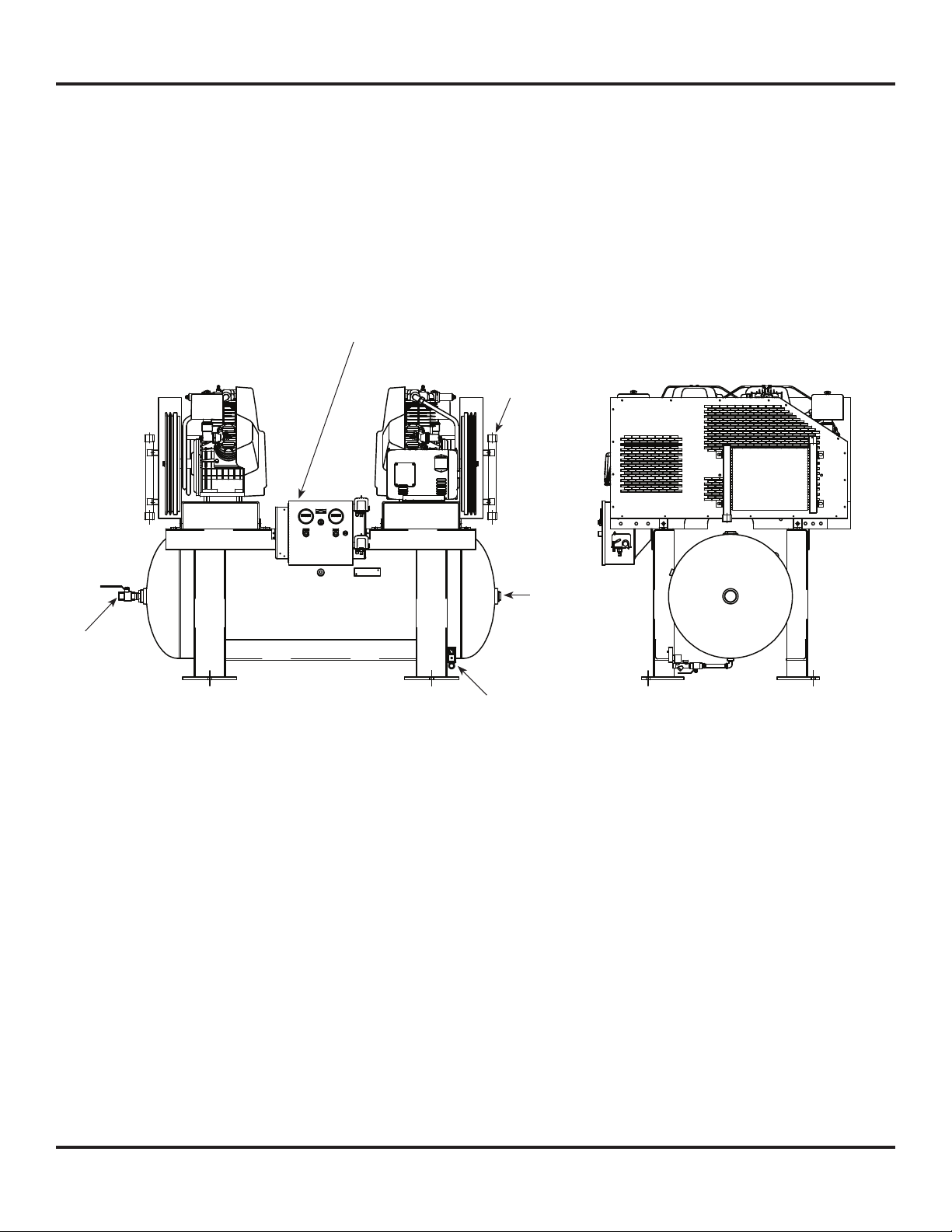

Oilless Tankmount Duplex

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

1-888-769-7979 • www.powerexinc.com

IN256905AV 1/14

Description

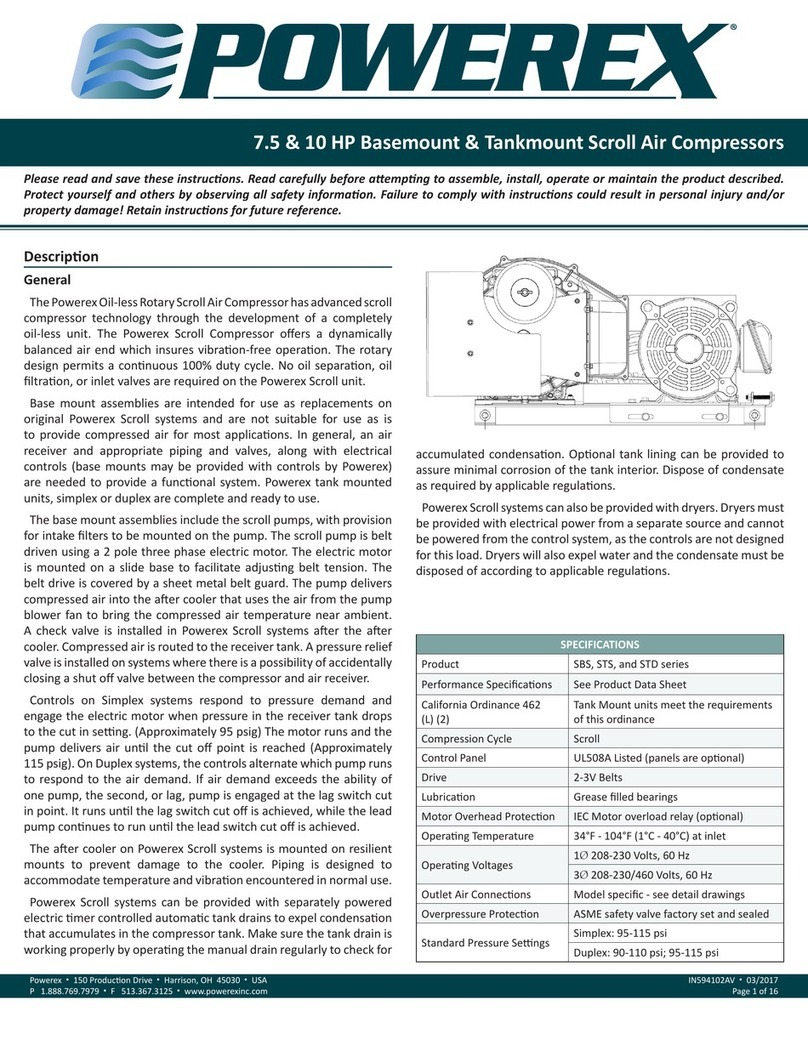

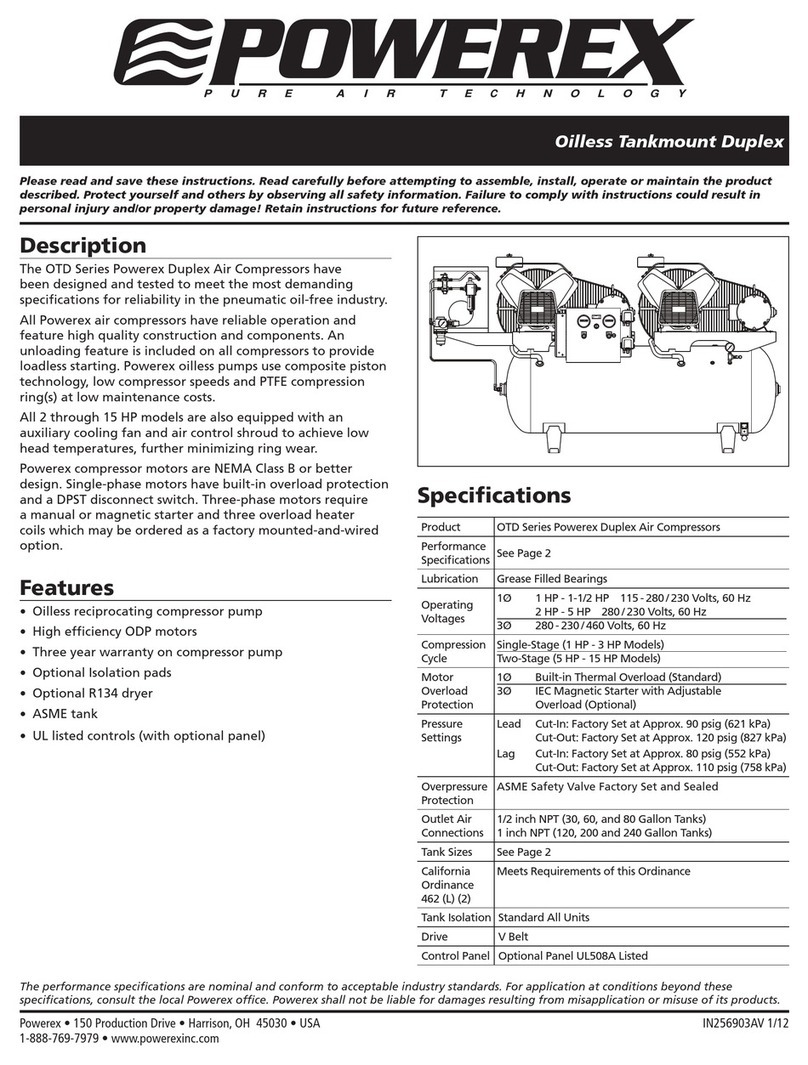

The OTD Series Powerex Duplex Air Compressors have

been designed and tested to meet the most demanding

specifications for reliability in the pneumatic oil-free industry.

All Powerex air compressors have reliable operation and

feature high quality construction and components. An

unloading feature is included on all compressors to provide

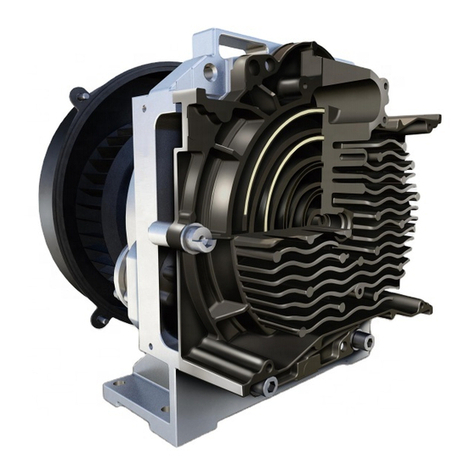

loadless starting. Powerex oilless pumps use composite piston

technology, low compressor speeds and PTFE compression

ring(s) at low maintenance costs.

All 2 through 15 HP models are also equipped with an

auxiliary cooling fan and air control shroud to achieve low

head temperatures, further minimizing ring wear.

Powerex compressor motors are NEMA Class B or better

design. Single-phase motors have built-in overload protection

and a DPST disconnect switch. Three-phase motors require

a manual or magnetic starter and three overload heater

coils which may be ordered as a factory mounted-and-wired

option.

Features

• Oilless reciprocating compressor pump

• High efficiency ODP motors

• Three year warranty on compressor pump

• Optional Isolation pads

• Optional R134 dryer

• ASME tank

• UL listed controls (with optional panel)

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Powerex office. Powerex shall not be liable for damages resulting from misapplication or misuse of its products.

Specifications

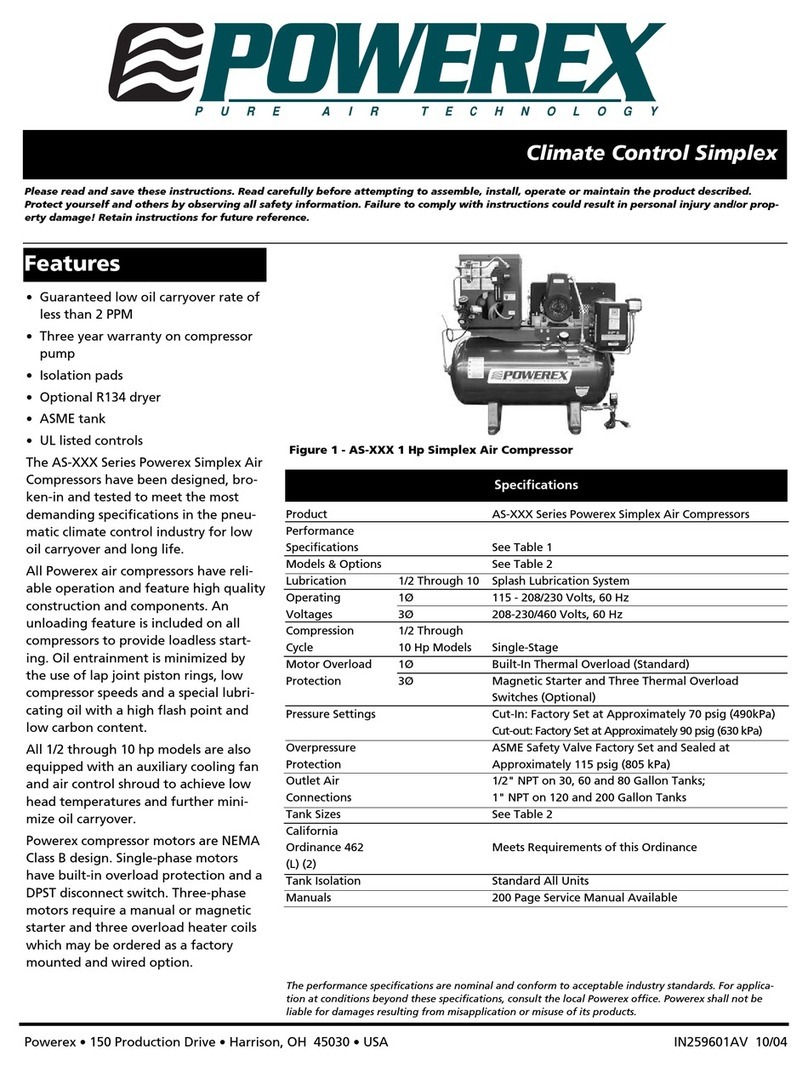

Product OTD Series Powerex Duplex Air Compressors

Performance

Specifications See Page 2

Lubrication Grease Filled Bearings

Operating

Voltages

1Ø 1 HP - 1-1/2 HP 115 - 280 / 230 Volts, 60 Hz

2 HP - 5 HP 280 / 230 Volts, 60 Hz

3Ø 280 - 230 / 460 Volts, 60 Hz

Compression

Cycle

Single-Stage (1 HP - 3 HP Models)

Two-Stage (5 HP - 15 HP Models)

Motor

Overload

Protection

1Ø Built-in Thermal Overload (Standard)

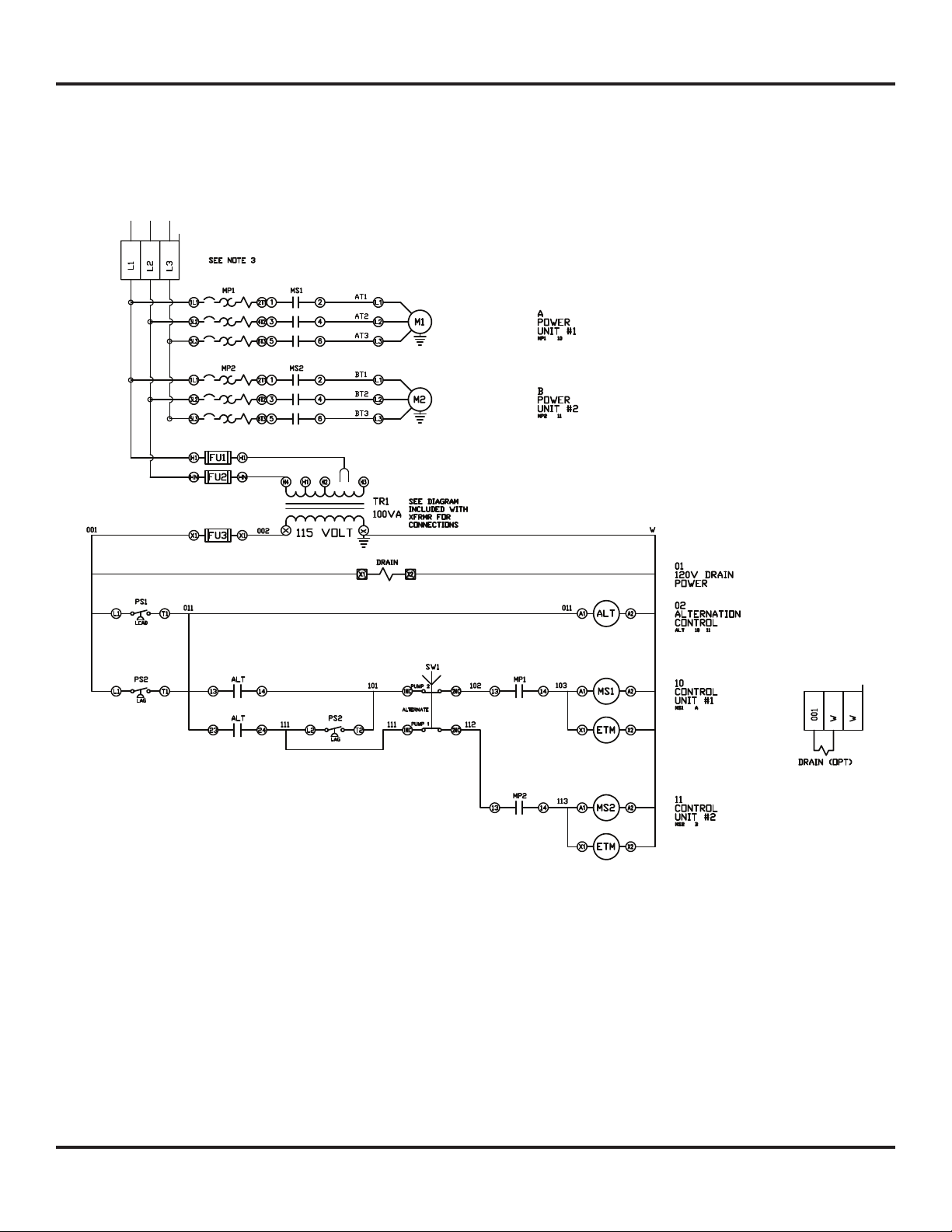

3Ø IEC Magnetic Starter with Adjustable

Overload (Optional)

Pressure

Settings

Lead Cut-In: Factory Set at Approx. 90 psig (621 kPa)

Cut-Out: Factory Set at Approx. 120 psig (827 kPa)

Lag Cut-In: Factory Set at Approx. 80 psig (552 kPa)

Cut-Out: Factory Set at Approx. 110 psig (758 kPa)

Overpressure

Protection

ASME Safety Valve Factory Set and Sealed

Outlet Air

Connections

1/2 inch NPT (30, 60, and 80 Gallon Tanks)

1 inch NPT (120, 200 and 240 Gallon Tanks)

Tank Sizes See Page 2

California

Ordinance

462 (L) (2)

Meets Requirements of this Ordinance

Tank Isolation Standard All Units

Drive V Belt

Control Panel Optional Panel UL508A Listed