2

2 HP - 5 HP Scroll Enclosure Air Compressors

6. Never install the compressor outside.

7. For 3 and 5 HP single phase models it is recommended that

additional tank volume be added. 3 HP single phase models

need a minimum of 30 gallons air capacity to limit the number of

starts-per-hour to 14 maximum. 5 HP single phase models need a

minimum of 60 gallons air capacity to limit the number of starts-

per-hour to 10 maximum.

VENTILATION

1. If the scroll compressor is located in a totally enclosed room, an

exhaust fan with access to outside air must be installed.

2. Never restrict the cooling fan exhaust air.

3. Vent the exhaust air outside to prevent the compressor from

operating at high temperatures and shutting down.

4. Never locate the compressor where hot exhaust air from other

heat generating units may be pulled into the unit.

WIRING

All electrical connections must be performed by a qualied electrician.

Installations must be in accordance with local and national electrical

codes.

1. Make sure power source is the same voltage as the unit’s required

voltage

2. Use solderless terminals to connect the electric power source.

3. Remove the two left panels.

4. Pull the electric cable through the electric source inlet and

connect to the primary side of the contact blocks.

5. Since loosening of wires is possible in shipment, tighten all wire

terminals prior to starting the unit.

PIPING

General Guidelines

1. Make sure the piping is lined up without being strained or

twisted when assembling the piping for the scroll compressor.

2. Appropriate expansion loops or bends should be installed at the

compressor to avoid stresses caused by changes in hot and cold

conditions.

3. Piping supports should be anchored separately from the

compressor to reduce noise and vibration.

4. Never use any piping smaller than the compressor connection.

5. Use exible hose to connect the outlet of the compressor to the

piping so that the vibration of the compressor does not transfer

to the piping.

Compressor Specications

Remote Intake Piping

Powerex Compressor Systems with pipe thread connectors on the

intake lters are intended for installation with remote air intake. Piping

for the remote intake system must be installed at the nal operating

site.

Under some conditions, the intake piping may facilitate the

condensation of humidity in the intake air stream into liquid water.

The intake lters supplied by

Powerex will not stop ingestion of liquid

water by the pumps. Liquid water going into the pumps will damage the

pumps and void the warranty.

Always install drip legs with sucient capacity to capture liquid water

in the intake piping before the air lters. Drip legs must be sized with

low enough air velocity to make sure they are eective at capturing

liquid water in the intake air and must be maintained (drained) at

frequent intervals to make sure they remain eective.

SAFETY VALVES

Tank mounted compressors are shipped from the factory with safety

valves installed in the air receiver manifold. The ow capacity of the

safety valve is equal to or greater than the capacity of the compressor.

1. The pressure setting of the safety valve must be equal or less than

the maximum working pressure of the air receiver.

2. Safety valves should be placed ahead of any possible blockage

point in the system, i.e. shuto valve.

3. Avoid connecting the safety valve with any tubing or piping.

4. Manually operate the safety valve every six months to avoid

sticking or freezing.

Operation

BEFORE START UP

1. Make sure all safety warnings, labels and instructions have been

read and understood before continuing.

2. Remove any shipping materials, brackets, etc.

3. Conrm that the electric power source and ground have been

rmly connected.

4. Check the belts for tightness.

5. Be sure all pressure connections are tight.

6. Check to be certain all safety relief valves, etc., are correctly

installed.

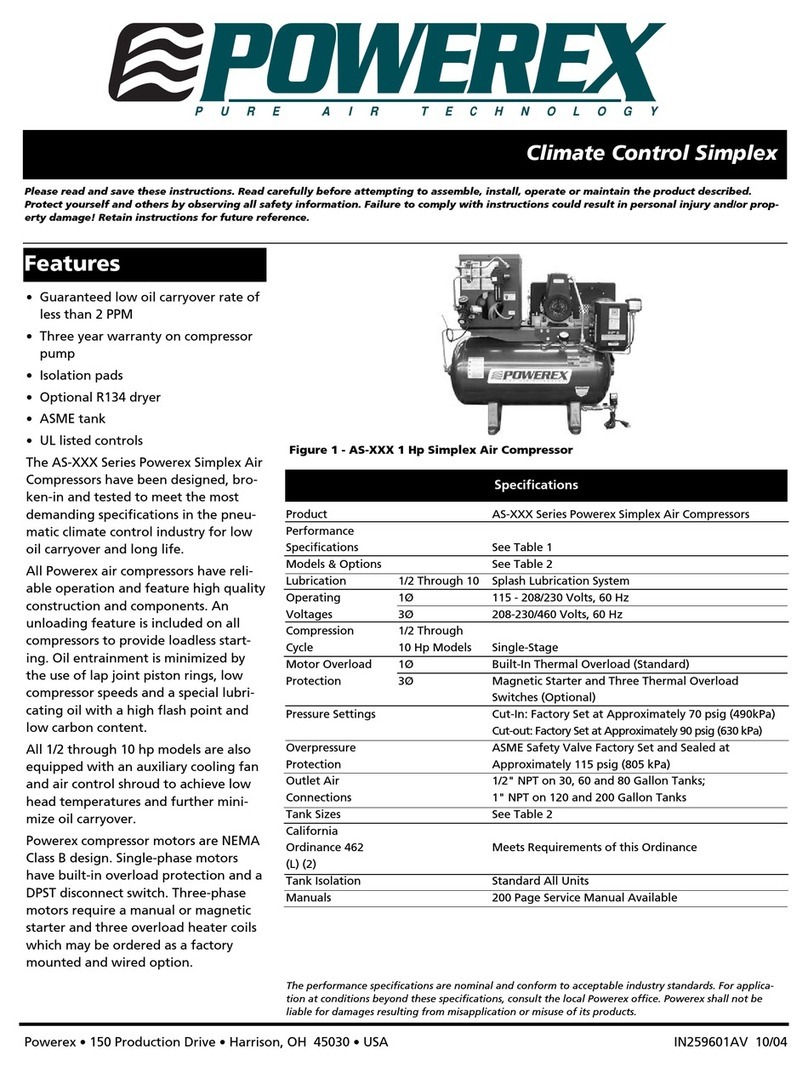

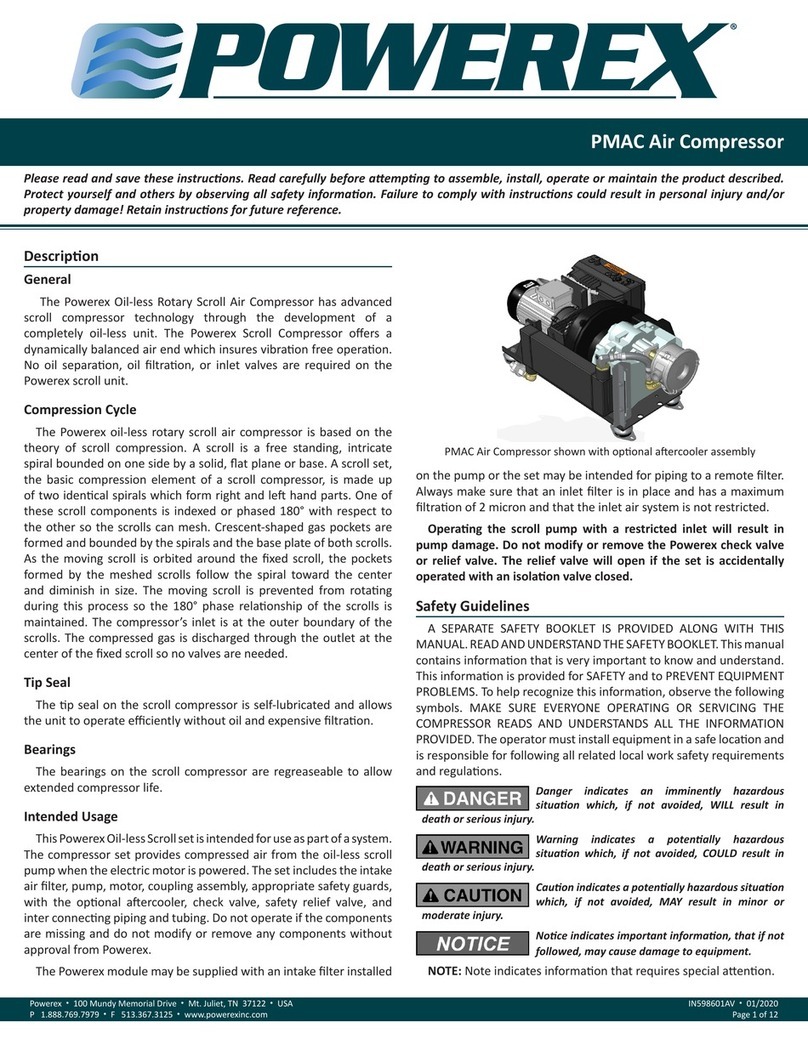

Model SES02 SES12 SES03 SES13 SES05 SES15

HP 235

Phase 3Ø 1Ø 3Ø 1Ø 3Ø 1Ø

Voltage 208 -230/ 460/575 230 208 -230 /460/ 575 230 208-230 /460/ 575 230

Amps See wiring diagram for amp rating

Air End SLAE03EB SLAE03EB SLAE05E (SLAE05EHP)

Control System Pressure Switch Pressure Switch Pressure Switch

Discharge Pressure (PSIG) 95 - 115 (115 - 145 optional) 95 - 115 (115 - 145 optional) 95 - 115 (115 - 145 optional)

Air Delivery (CFM) 6.0 @ 100 PSIG and (4.6 @ 145 PSIG) 8.8 @ 100 PSIG and (7.1 @ 145 PSIG) 15.2 @ 100 PSIG and (12.5 @ 145 PSIG)

Compressor Speed (RPM) 2200 (1850) 3140 (2770) 3250 (3250)

Discharge Temp. Ambient temp. + 30 °F Ambient temp. + 30 °F Ambient temp. + 30 °F

Noise level dB(A)

[1.5m from front] 49 49 51

Dimensions In Inches (L x W x H) 34 x 21 x 32.5 34 x 21 x 32.5 34 x 21 x 32.5

(Items in paranthesis high pressure information)