FirstCall™ Liq x Liq Medical Gas Manifold

Operating & Maintenance Manual

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN599800AV • 15 January 2021

Page 4 of 24

Responsibilities

Information contained in this manual pertains to

the Powerex FirstCall™ medical gas manifold system.

The manifold system will operate as described in this

manual when operated and serviced in compliance

with the instructions.

Installer Responsibilities

The manifold should be handled, installed, and tested

per the recommended practice as described within this

manual. Should any repair or replacement become

necessary, contact Powerex for original equipment or

replacement parts.

User Responsibilities

The manifold should be tested and examined

periodically according to facility codes. Any parts which

are found to be damaged, corroded, contaminated, etc.

should be replaced.

Introduction

Safety Guidelines

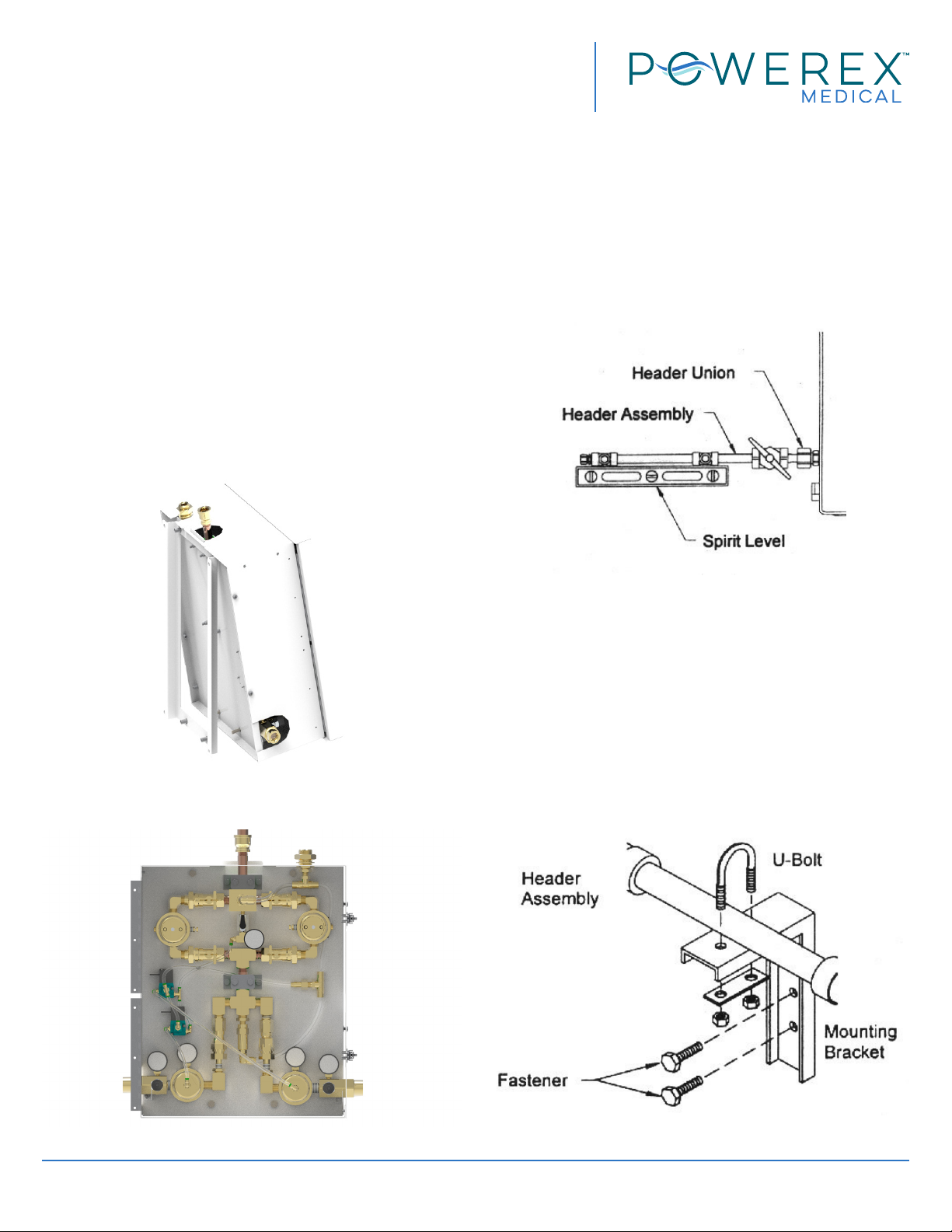

Installation of the Powerex FirstCall™ Manifold

involves installing the manifold cabinet, headers, and

making the necessary conduit, plumbing and electrical

connections. All installation and testing should be done

in accordance with NFPA 99.

Electrical power intended for the

manifold to be installed should be

disconnected prior to installation.

This device should only be installed

by qualied personnel. Installation

should not be attempted by anyone not having general

experience with the installation of devices of this nature.

Failure to follow the following

instructions can result in personal

injury or property damage:

• Never permit oil, grease, or other combustible

materials to come in contact with cylinders,

manifold, and connections. Oil and grease may

react with explosive force when ignited while in

contact with some gases – particularly oxygen and

nitrous oxide.

• Cylinder and master valves should always be

opened very slowly. Heat of recompression may

ignite combustible materials creating an explosive

force.

• Pigtails should never be kinked, twisted, or bent

into a radius smaller than 3 inches. Mistreatment

may cause the pigtail to burst.

• Do not apply heat. Oil and grease may react with

explosive force when ignited while in contact with

some gases – particularly oxygen and nitrous

oxide.

• Cylinders should always be secured with racks,

chains, or straps. Unrestrained cylinders may fall

over and damage or break o the cylinder valve

which may propel the cylinder from its current

position.

• Oxygen manifolds and cylinders should be

grounded. Static discharges and lightning may

ignite materials in an oxygen atmosphere, creating

a re or explosive force.

• Welding should not be performed near nitrous

oxide piping. Excessive heat may cause the gas to

dissociate, creating an explosive force.

• Remove all protective caps prior to assembly.

The protective cap may ignite due to heat of

recompression in an oxygen system.

General Instructions/Location & Shelter

Manifolds should be installed in accordance with

guidelines stated by the NFPA, CGA, OSHA, and all

applicable local codes. Central supply systems and

cylinders should not be placed in a location where the

temperature will exceed 125°F (51.6°C) or fall below

-20°F (-29°C). A manifold placed in an open location

should be protected against weather conditions.

During winter, protect the manifold from ice and

snow. In summer, shade the manifold and cylinders

from continuous exposure to direct sunlight. The ow

capacity of nitrous oxide and carbon dioxide manifolds

depend upon ambient temperature and the number of

cylinders on line. Contact your gas supplier to determine

the vaporization rate of Carbon Dioxide and Nitrous

Oxide cylinders for the ambient temperature climate

at the installation site. Leave all protective covers in

place until their removal is required for installation.

This precaution will keep moisture and debris from the

piping interior.