T

TH

HE

E

W

WO

OR

RL

LD

D

L

LE

EA

AD

DE

ER

R

I

IN

N

C

CO

OM

MP

PA

AC

CT

T

M

MA

AT

TE

ER

RI

IA

AL

L

H

HA

AN

ND

DL

LI

IN

NG

G

S

SO

OL

LU

UT

TI

IO

ON

NS

S

8 of 21 Sept/20

GeneralOverview

PowerHandling’s product line and features are constantly being updated and improved so please check

for more information and updates at www.powerhandling.com.

PowerHandlers are broadly categorized into two types of machines, with an optional third being

a combination of both of these:

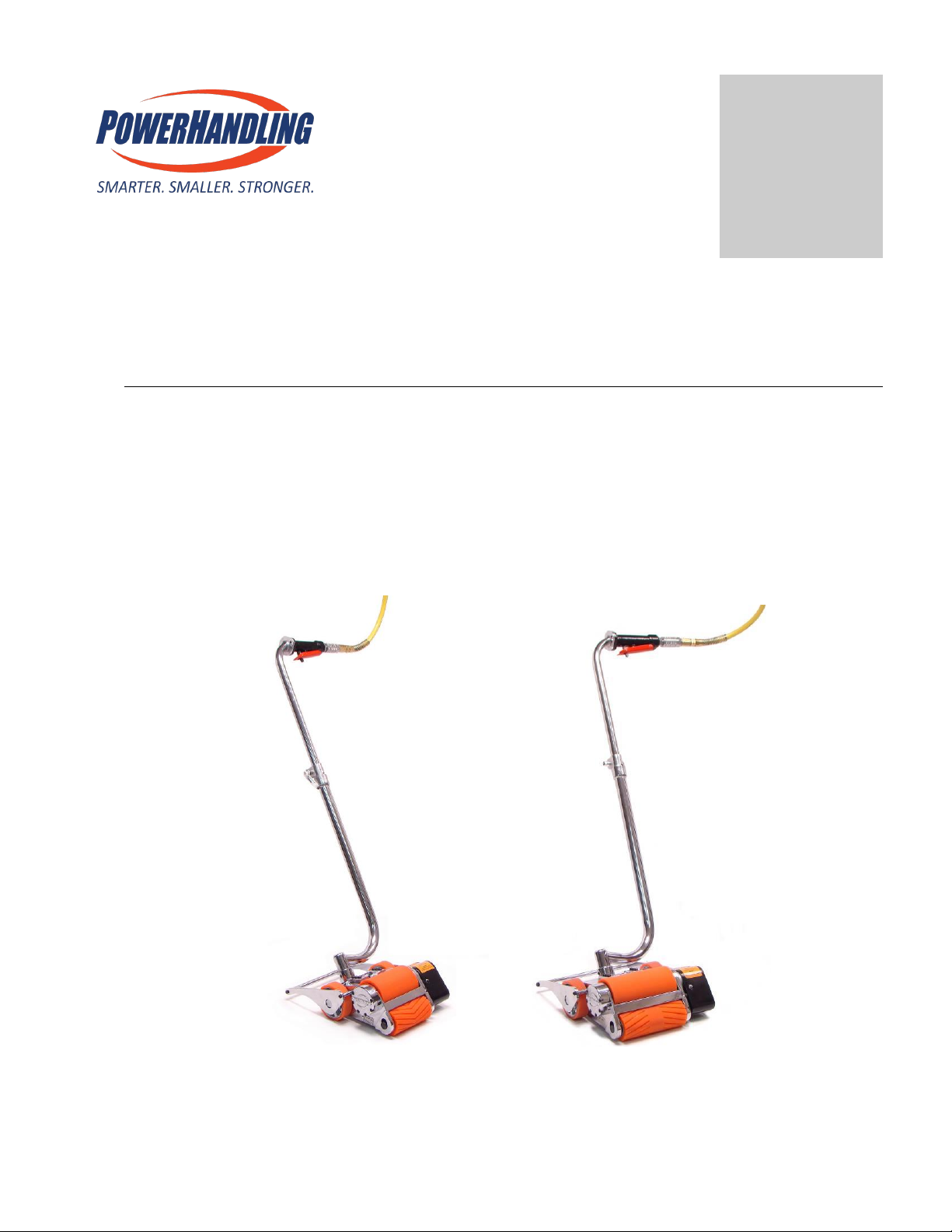

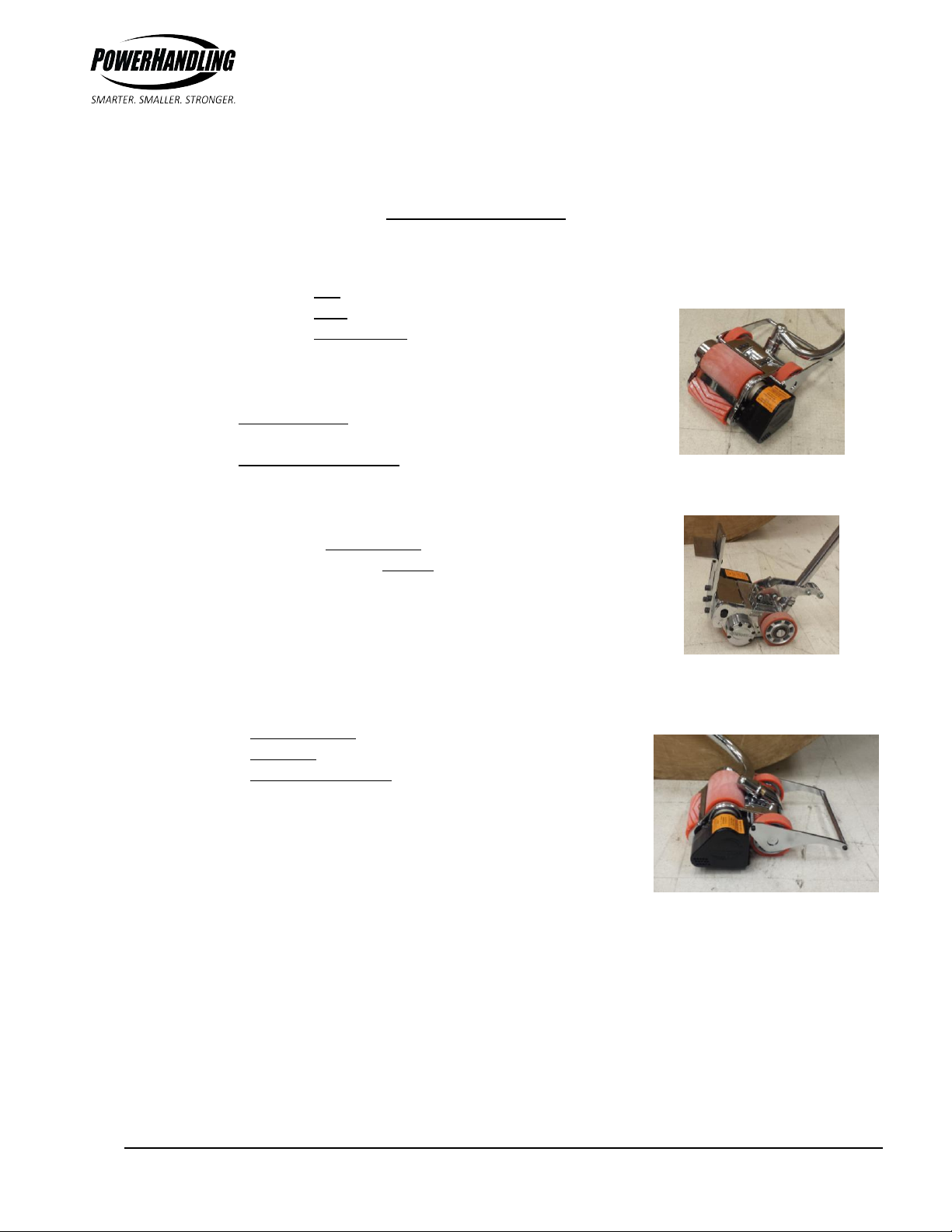

othose that Roll( Fig. 1) (such as paper rolls, cable reels or vehicles) or

othose that Push (such as trolleys, carts etc), or

othose that Roll and Push(Fig. 2) (being a rolling model with a

Hybrid or Pusher Bracket).

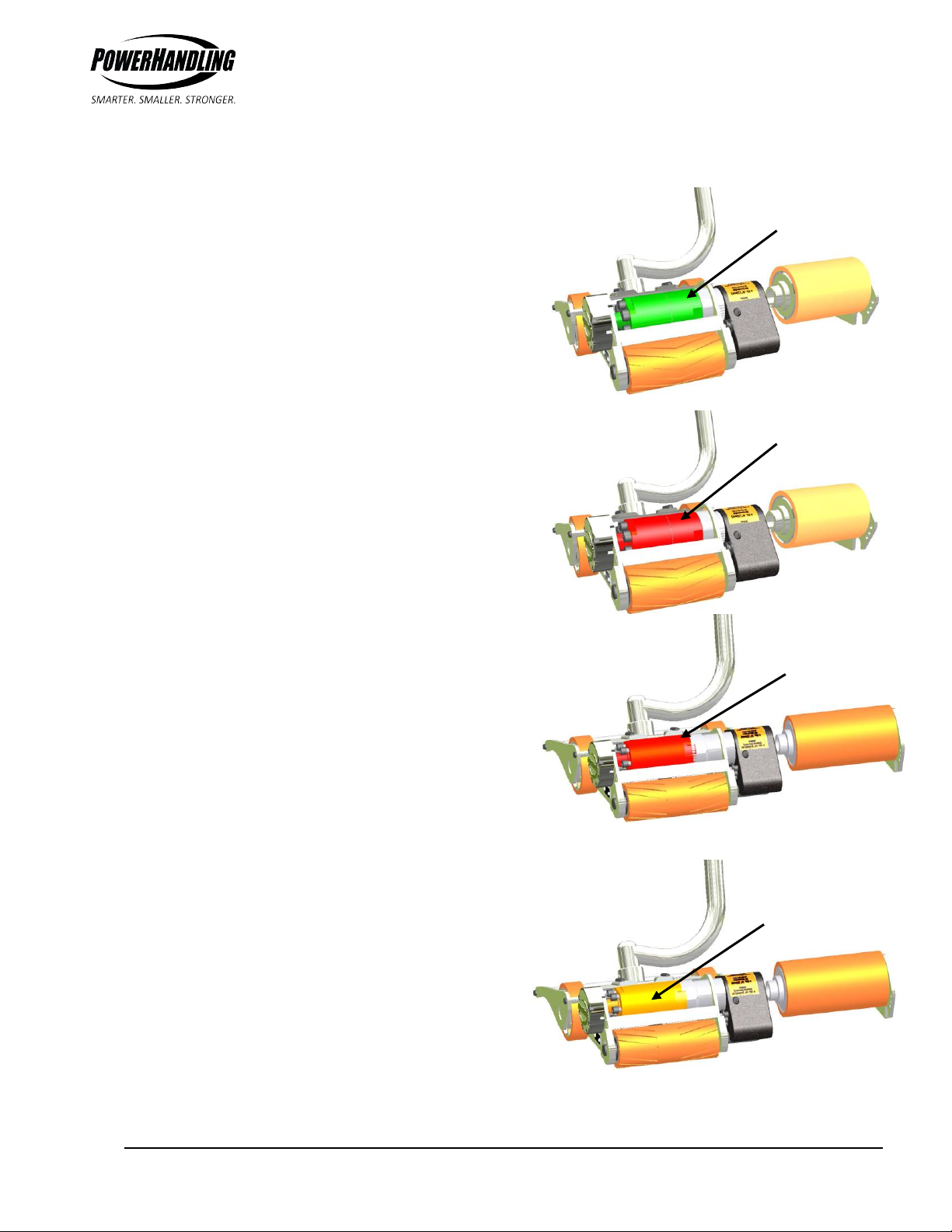

Beyond this distinction there are models powered by:

oCompressed Air –having an airline connected into the back

end of the handle grip throttle; or

oRechargeable Batteries –having two battery packs, one on

the machine and one on a charger (so the machine is never “down” for recharging).

Further model distinctions apply according to:

othe size and power output of the motor, and

othe reduction of the gearing, the latter tailoring a

PowerHandler for higher torque or for higher speed to better

match the requirements of the application. In each case an

increase in one results in a corresponding reduction in the

other.

Finally, models can be further customized according to the handle assemblies and other

attachments, etc. For example ‘Roller’ models can be configured with:

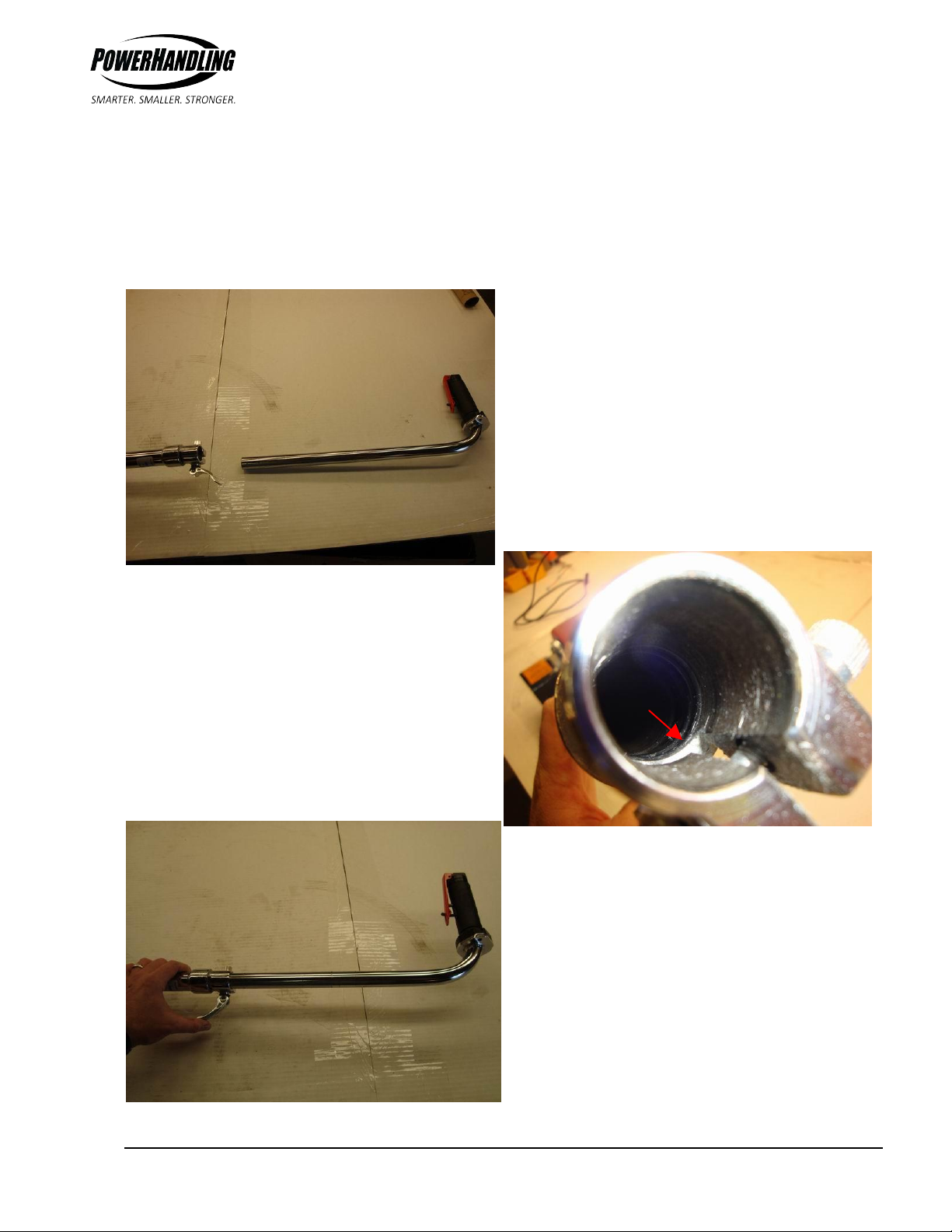

oa Center Straight handle shaft (C), a

oa Swiveling handle shaft (S) or a

oa Swiveling & Pivoting handle shaft (SP)(Fig. 3).

To overcome the inertia of a heavy load, PowerHandlers require a

significant amount of traction –both with the load itself and the ground

on which it’s being moved. Regardless of the amount of power (or

specifically ‘torque’) generated, the load will not move without the

necessary traction.

PowerHandlers gain this traction by directing the weight of the load down onto the drive roller to generate

the traction that is required. In the case of moving cylindrical loads, small diameter / lighter loads can in

fact be more of a problem than larger heavier loads as the weight transfer onto the drive roller is not as

good. This problem will be apparent if the drive roller is observed to slip or spin against the load rather than

wedging in under the load and rotating it. (Please refer to the “Trouble-Shooting” section for suggestions on

how to address this issue).