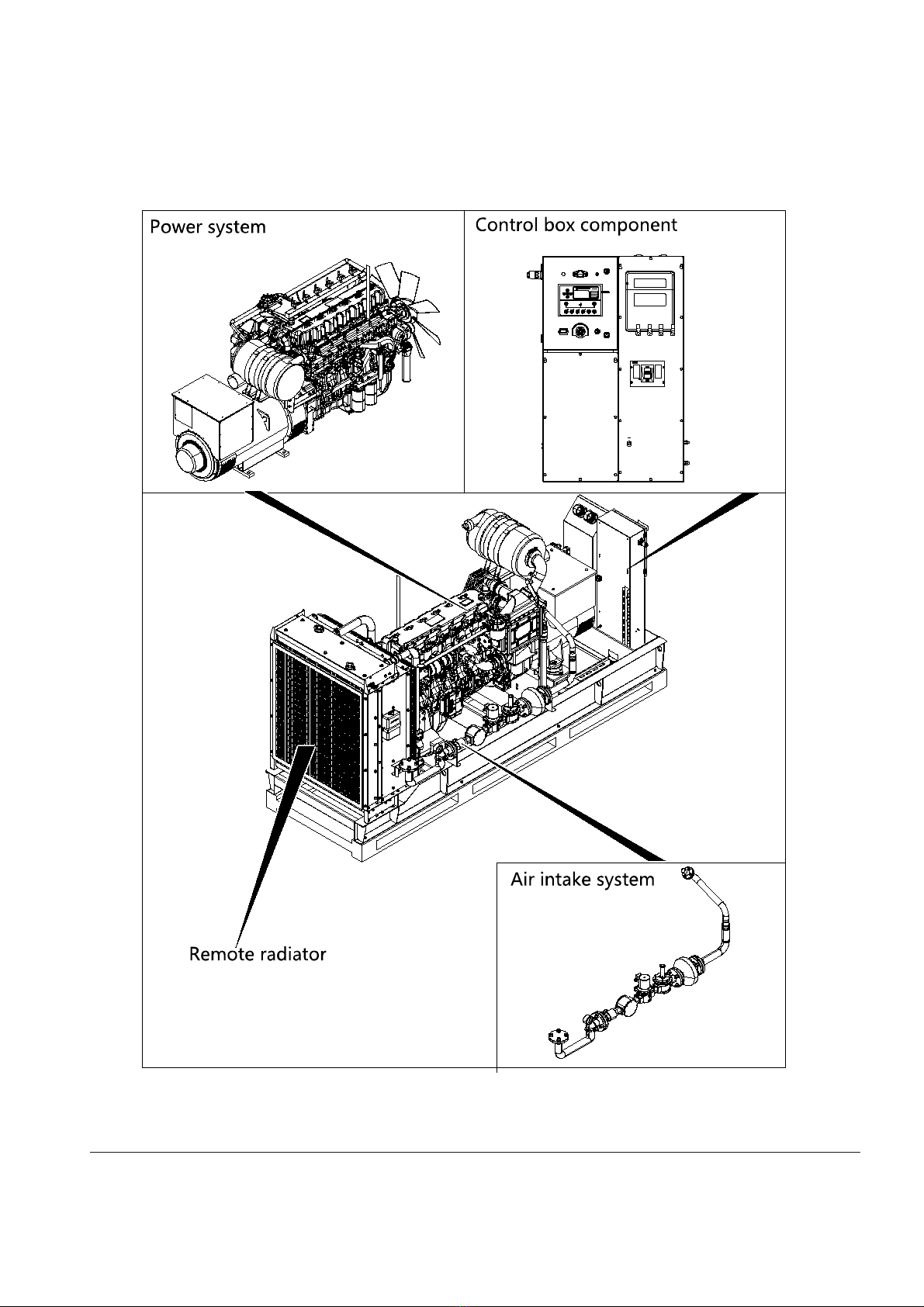

Biogas

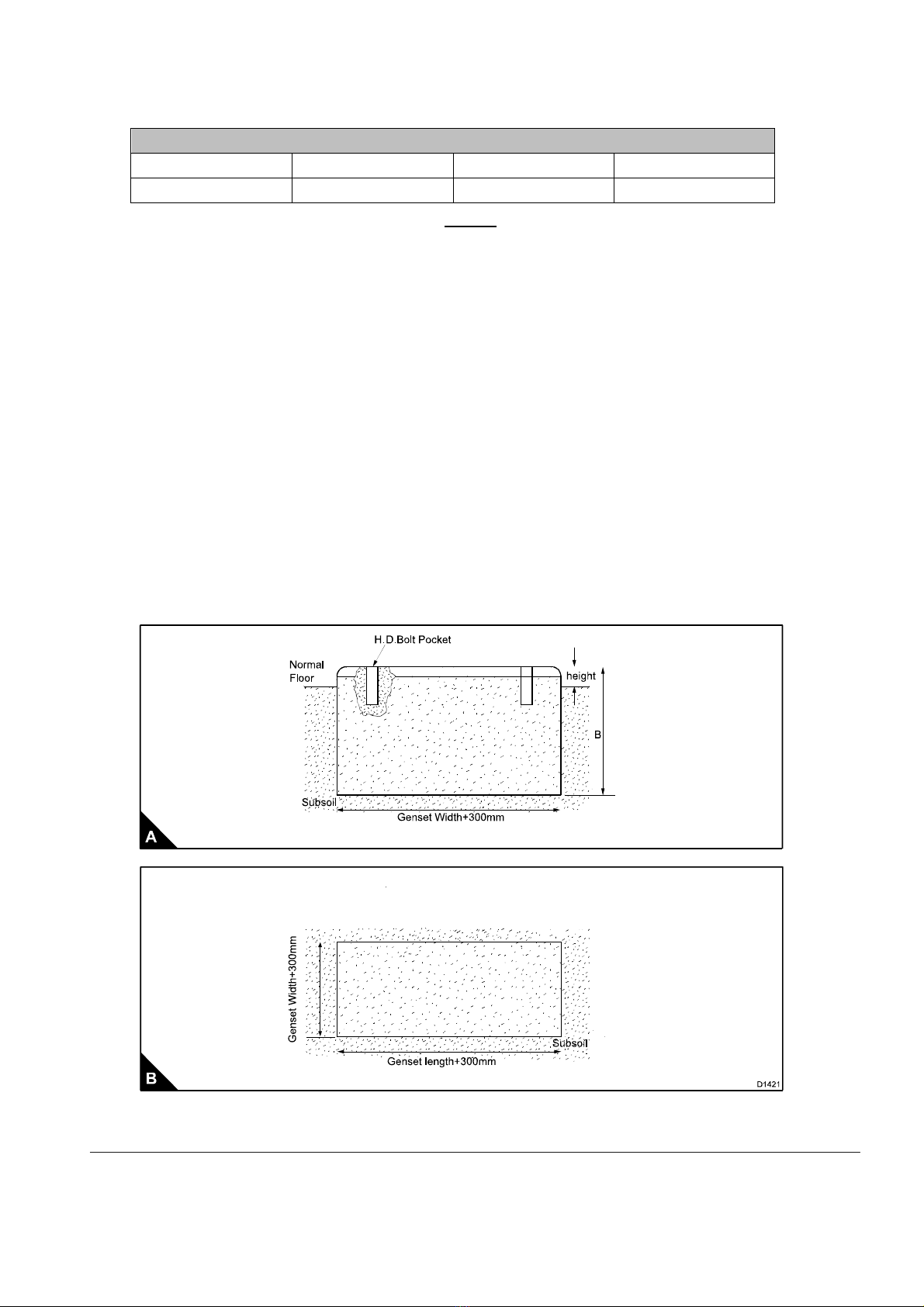

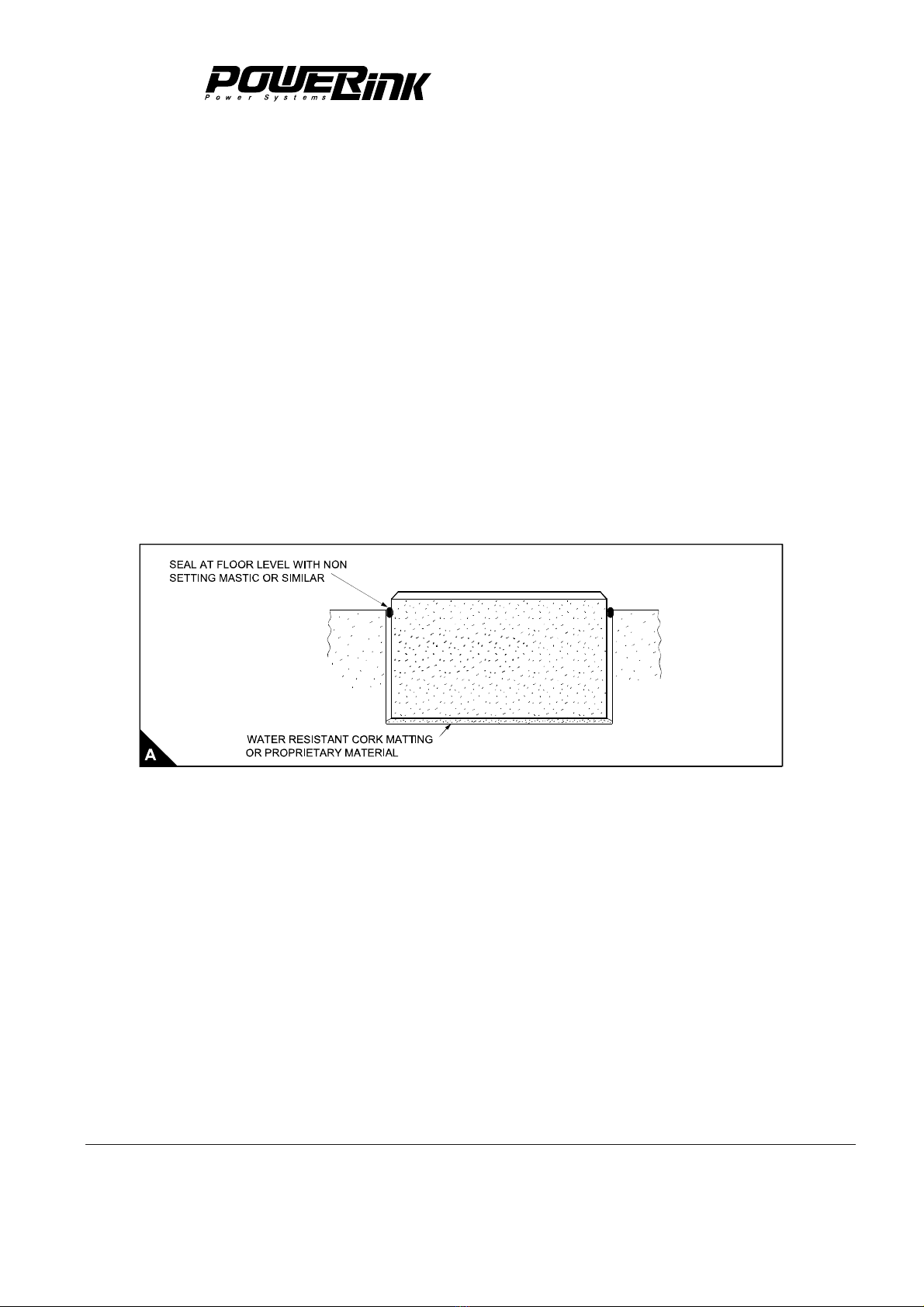

Type of foundations:

The genset room floor/foundation where the undebased/bearers are fixed is of great

importance as it must:

Never use rigid connection between the foundation and genset room.

The surface of the foundation should be oil-water proof, and equipped with drainage

If the genset is set on the floor, the load carrying capacity of floor should be fitted to the static load

and dynamic load of genset.

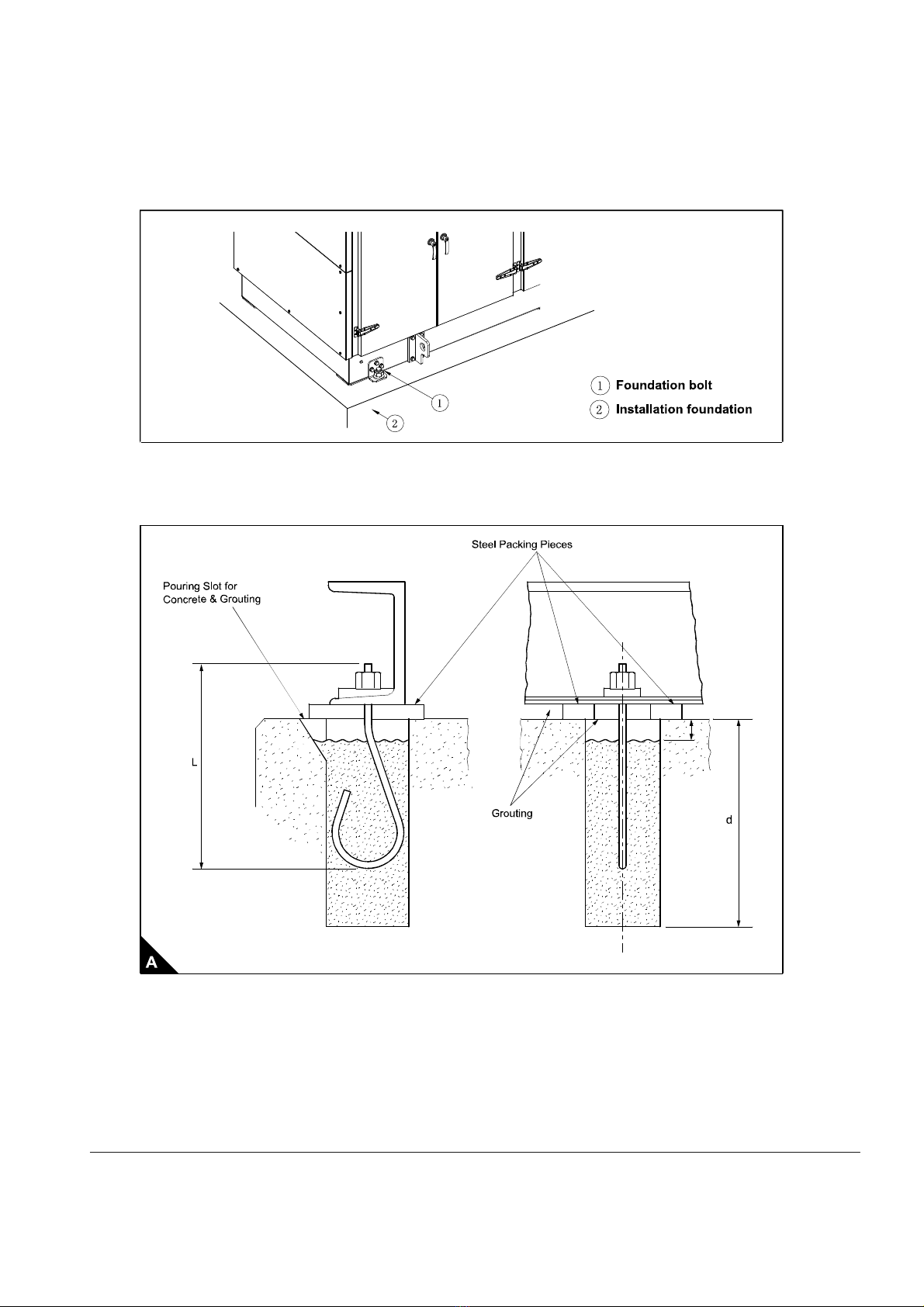

Using shims between the genset mounting feet and the undebased/bearers. The dimensions

of the shims (or packing pieces) should not be less than the mating area of the genset

mounting feet. At least four fitted bolts (minimum quality 8.8 steel) must be used in the genset

mounting feet. Where it is not possible to use a fitted bolt, the mounting feet should be

dowelled to the undebased/bearers using one dowel in each foot at diagonal corners.

The surface of the foundation should be flat. The safe loading capability of the geological

material should be carefully evaluated when selecting the foundation for installing. We advise

adopting concrete as the material of foundation.

SBL=9.81

SB--Weight of the load on the foundation (kg)

TW--Weight of the genset and foundation (kg)

L--Length of the foundation (m)

W—Width of the foundation (m)

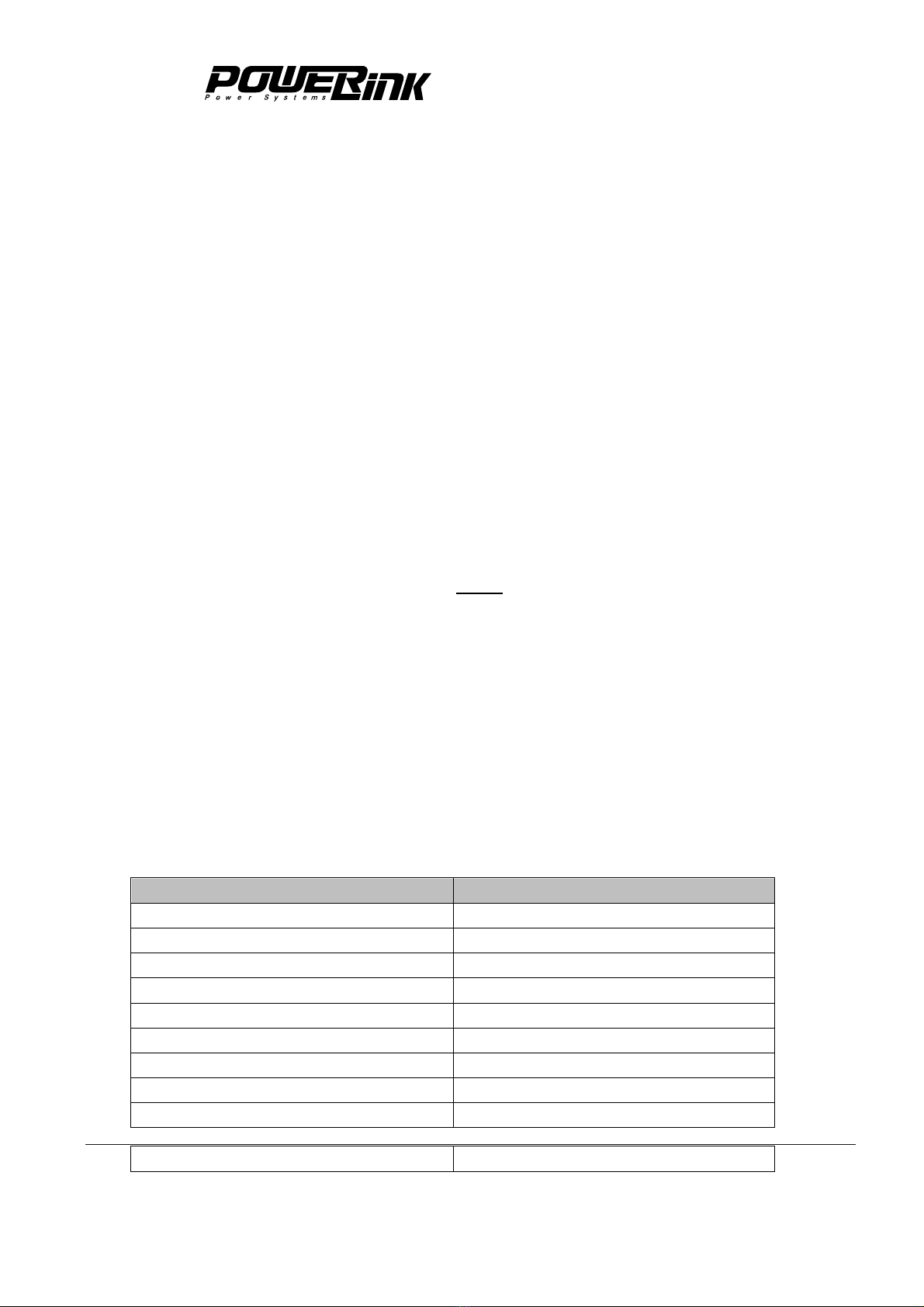

Subsoil-site:

The site subsoil must have a bearing strength capable of supporting the weight of the

complete genset plus the concrete foundation on which it will stand.

If the bearing strength of the subsoil is in doubt advice should be taken from a qualified civil

engineer to enable the type and size of concrete foundations to be determined.

Geological Material Max Load(kg/m²)

Granite 244000-977000

Oil shale 98000-146000

Rock 78000-98000

Soft Rock 49000-98000

Tamped gravel 49000-59000

Pebble and gravel 39000-49000

Tamped sandy clay 28900-39000

Sandy clay 20000-39000

Sand 10000-20000

Soft clay 10000