Powermat Charging Spot 3.1 User manual

Other Powermat Batteries Charger manuals

Powermat

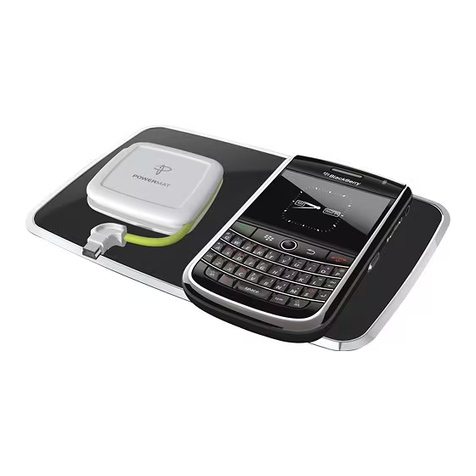

Powermat 2X User manual

Powermat

Powermat PMR-NOK1-EU User manual

Powermat

Powermat 2X User manual

Powermat

Powermat 2X User manual

Powermat

Powermat Home & Office Mat User manual

Powermat

Powermat Home & Office Mat User manual

Powermat

Powermat Charging Spot 4.0 User manual

Powermat

Powermat Powermat Wireless Charging User manual

Powermat

Powermat Receiver Back for Nintendo DSi User manual

Powermat

Powermat Powermat Wireless Charging User manual