Model 100 Powerjack

2

To Use:

1. Only push against a stationary surface such as a wall stud. When between wall

studs, push against a board long enough to span the distance of the studs so as to

prevent breaking through the drywall.

2. Ratchet the lever handle until faceplate contacts the stationary surface

3. Continue to ratchet until the fl oor catch draws the fl oor tight for nailing

4. The Powerjack 100 can be left in place, hands free, while that section of fl ooring

is being nailed down.

To release the Powerjack 100, push the handle to the full forward position.

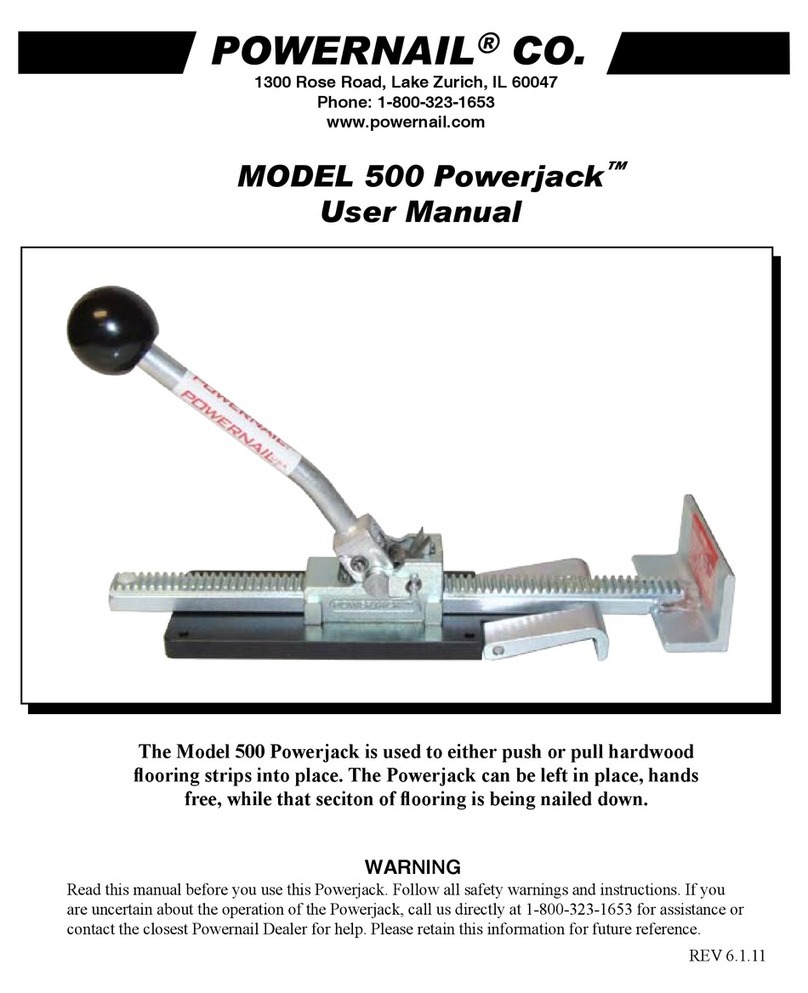

The POWERJACK Model 100 is designed to pull fl ooring strips into place and hold

them tightly for hands-free nailing.

Easy to operate! Use the lever handle to ratchet the faceplate against a stationary

surface. Continue to ratchet until the fl oor catch draws the fl ooring to the desired

position. The POWERJACK can be left in place while you nail down the fl ooring

strip. To release the POWERJACK, simply push the handle to full forward position.

The Model 100 POWERJACK sits on top of your fl ooring and gains leverage against

a wall, a wall-stud, or the toe kick of cabinetry (see picture 1).

When a stud location cannot be determined, a board long enough to span the distance

of the studs should be used to prevent breaking through the drywall (picture 2).

When not near a wall, a temporary anchor point such as a two-by-four fi xed to the

sub fl oor can be used (see picture 3).

Powerjacks® are constructed in the USA and are made

of the best materials available.