AC variable frequency drives are commonly used with various types of motors to

form reliable variable speed drive systems. Problems with these drive systems can

occur when an application requires a deceleration rate faster than what can be

managed by the drive alone, or when motor speeds exceed the synchronous speed

set by the output frequency of the drive (which is called an overhauling load

condition). Both of these conditions create regenerated power which flows from the

motor back into the drive, causing its DC Bus to rise. To manage the regenerated

power and avoid shutting the drive down due to an over-voltage trip, this power must

be dissipated by an external braking resistor.

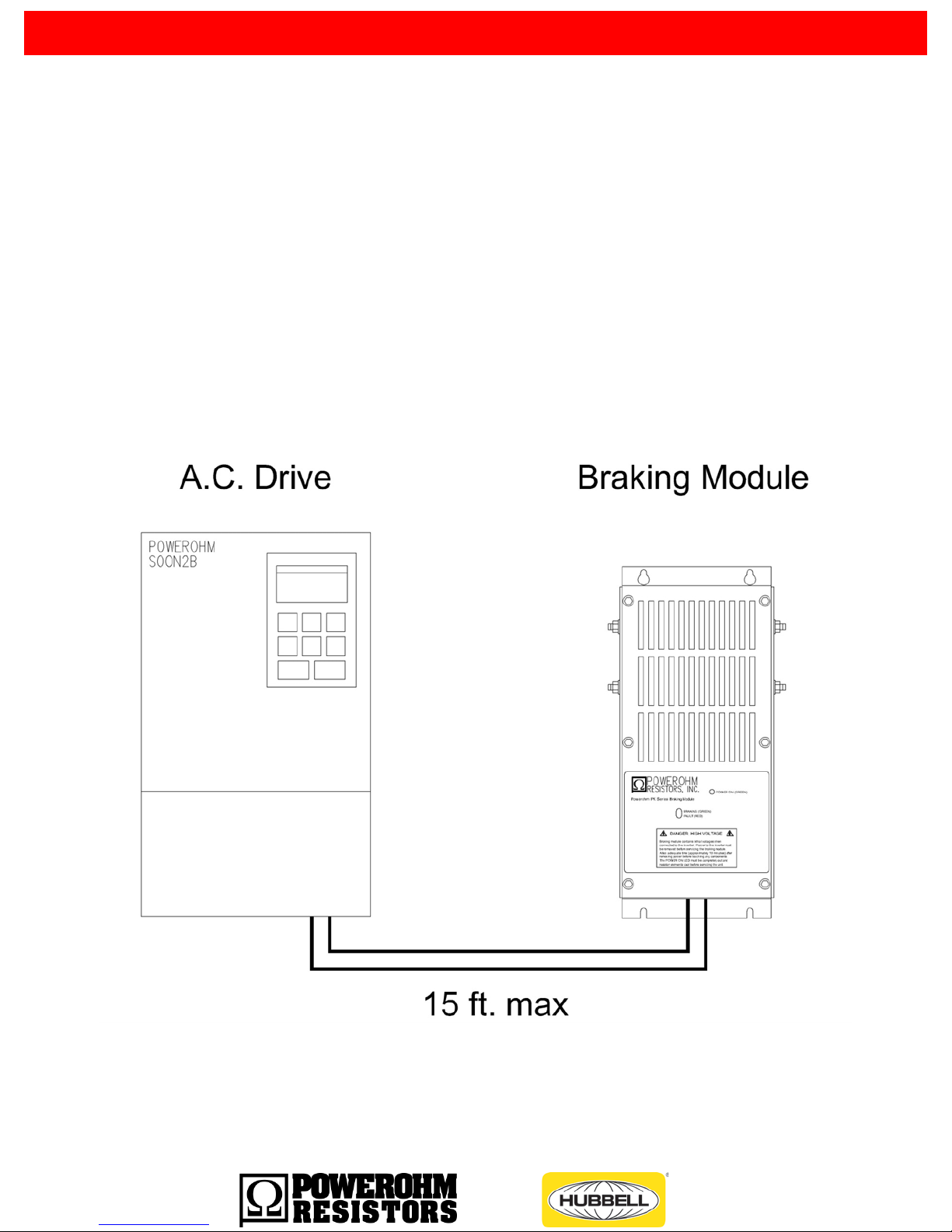

PowerOhm Braking Modules can be used in conjunction with any AC drive to

monitor the DC bus of the drive and activate an internal braking resistor as

needed not only to avoid over-voltage trips, but to greatly improve the performance

of the drive system.

The products covered in this manual are intended to be used with Listed inverter

drives. The input of the DBU is only to be connected across the DC bus of the

inverter drives. Conductors for connection of the DBU shall be according to the

NFPA 70 (National Electric Code) and the drive instructions.

Inspection upon Receipt

Upon receipt of your PowerOhm Braking Module, be sure to carefully unpack the module and

inspect the unit carefully for any shipping damage. The module contains electronics that can be

damaged by static electricity, so handle in accordance with industry standards. Check for loose,

broken or otherwise damaged parts due to shipping. Report any shipping damage immediately

to the freight carrier. Be sure to verify that the part number and ratings listed on the nameplate

match the order specification and the capabilities of the drive system.

The ratings listed on the nameplate are critical – installing and energizing the incorrect

part number could damage the braking module and/or the drive!

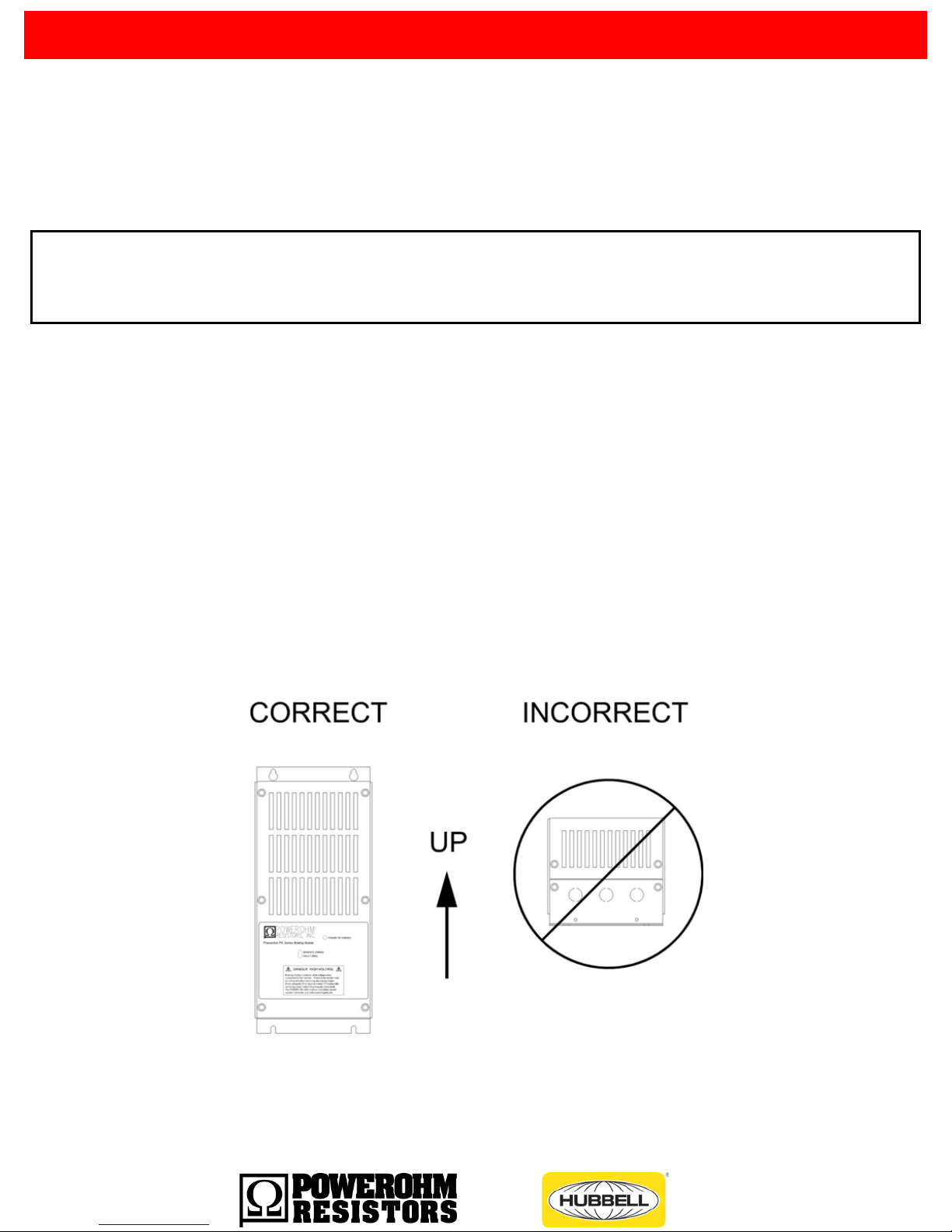

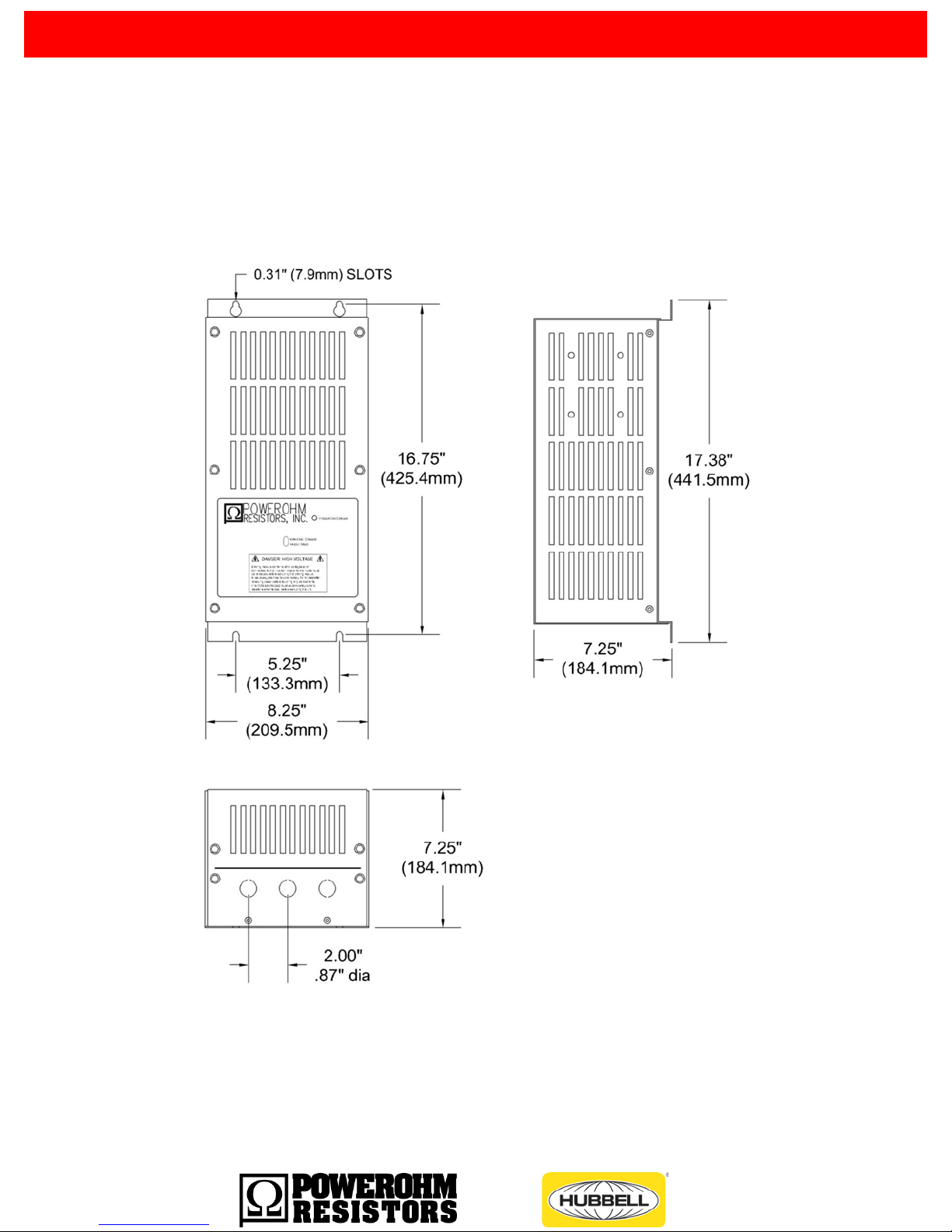

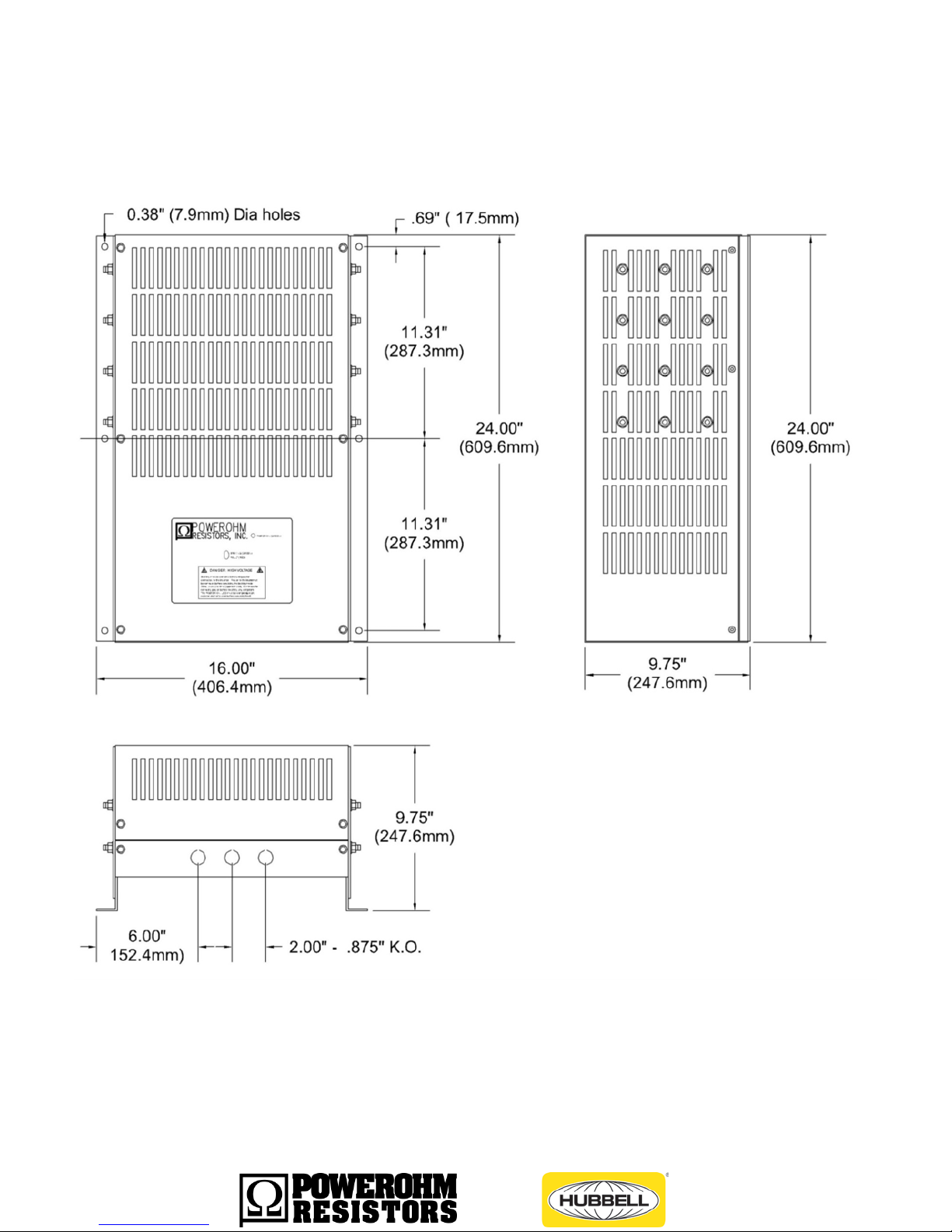

Product Overview