MM430_For_PS-Sheet_Test_1.pd

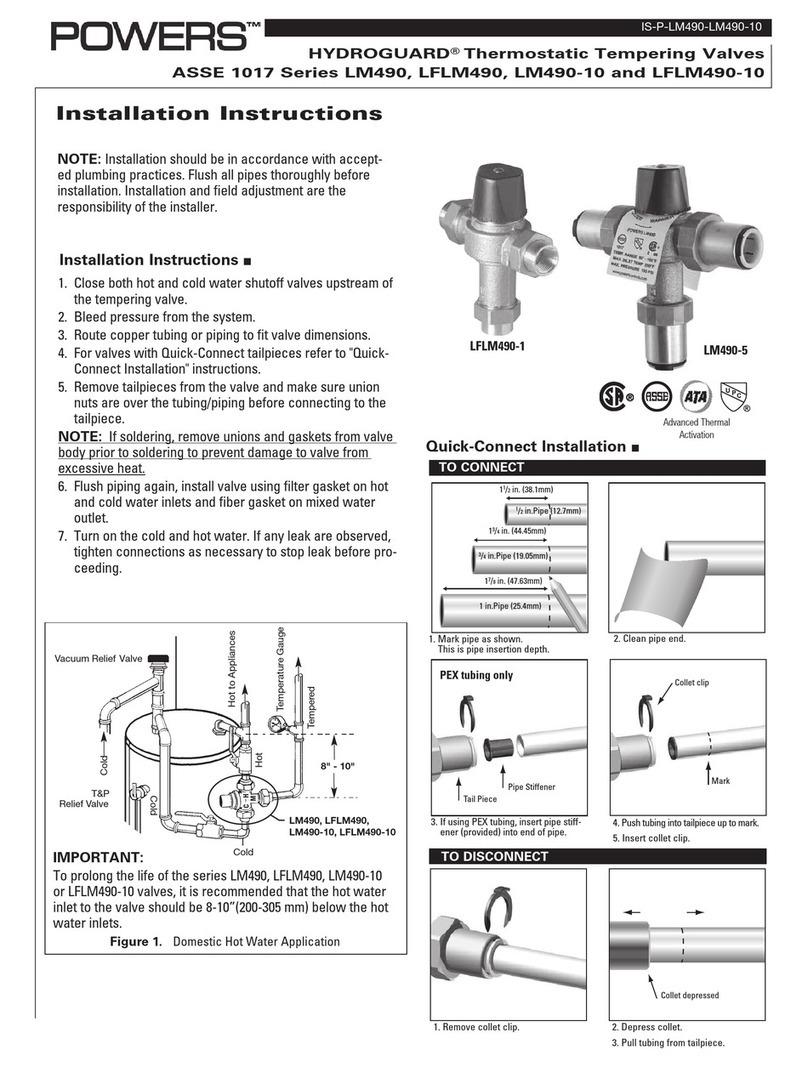

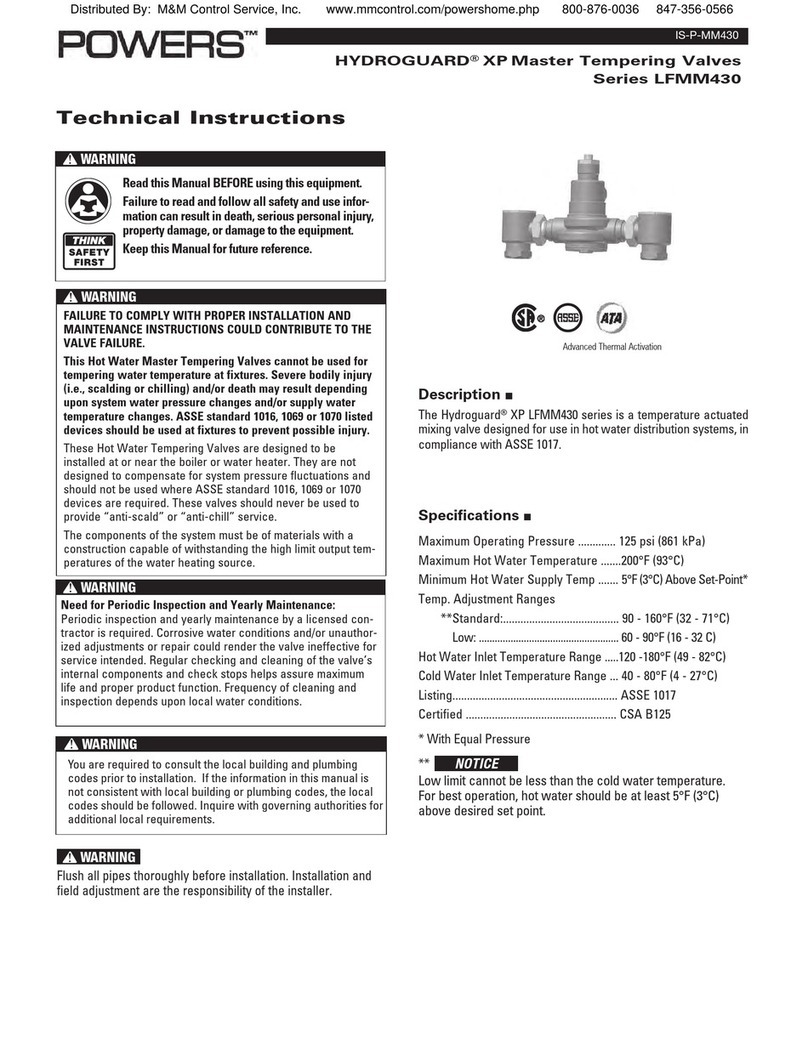

The Hydroguard® XP MM430 and LFMM430 series is a tem-

perature actuated mixing valve designed for use in hot water

distribution systems, in compliance with ASSE 1017.

Description n

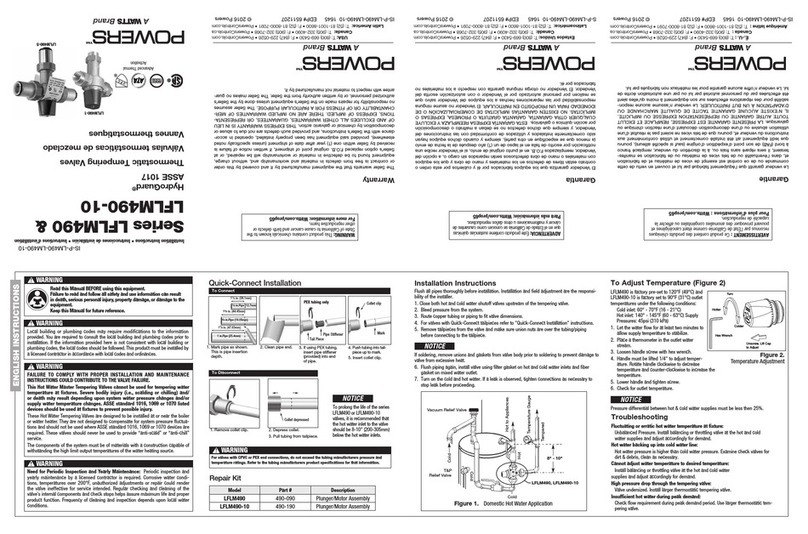

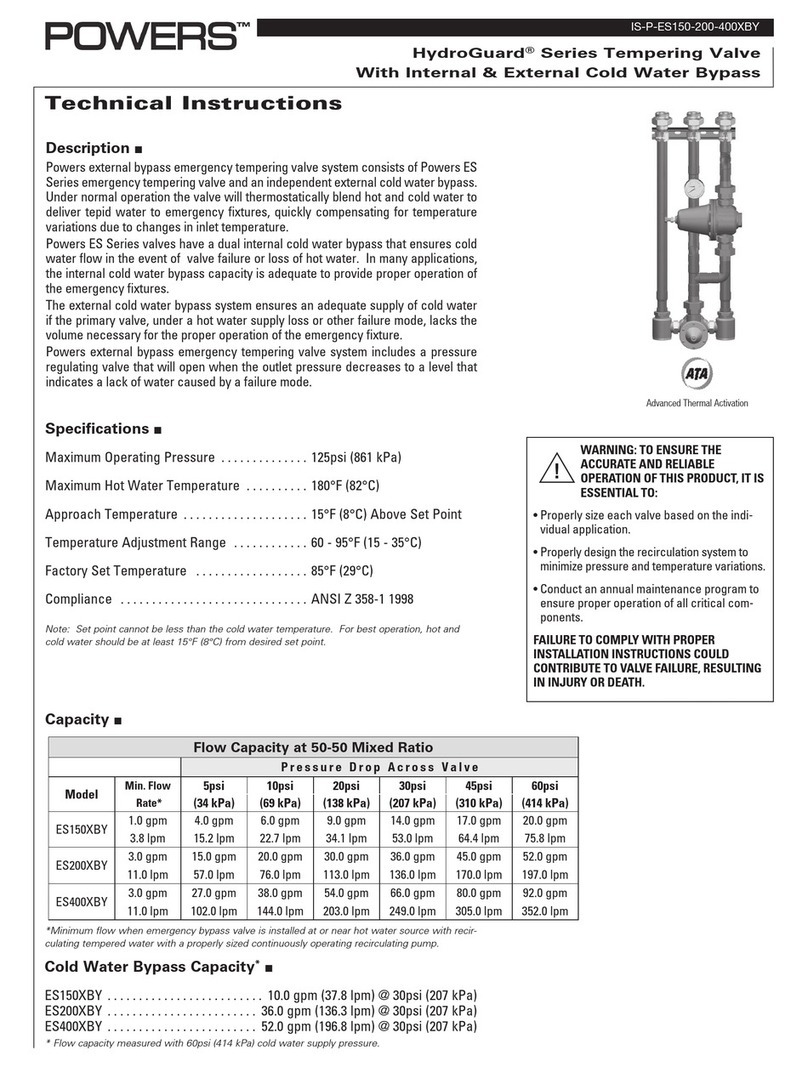

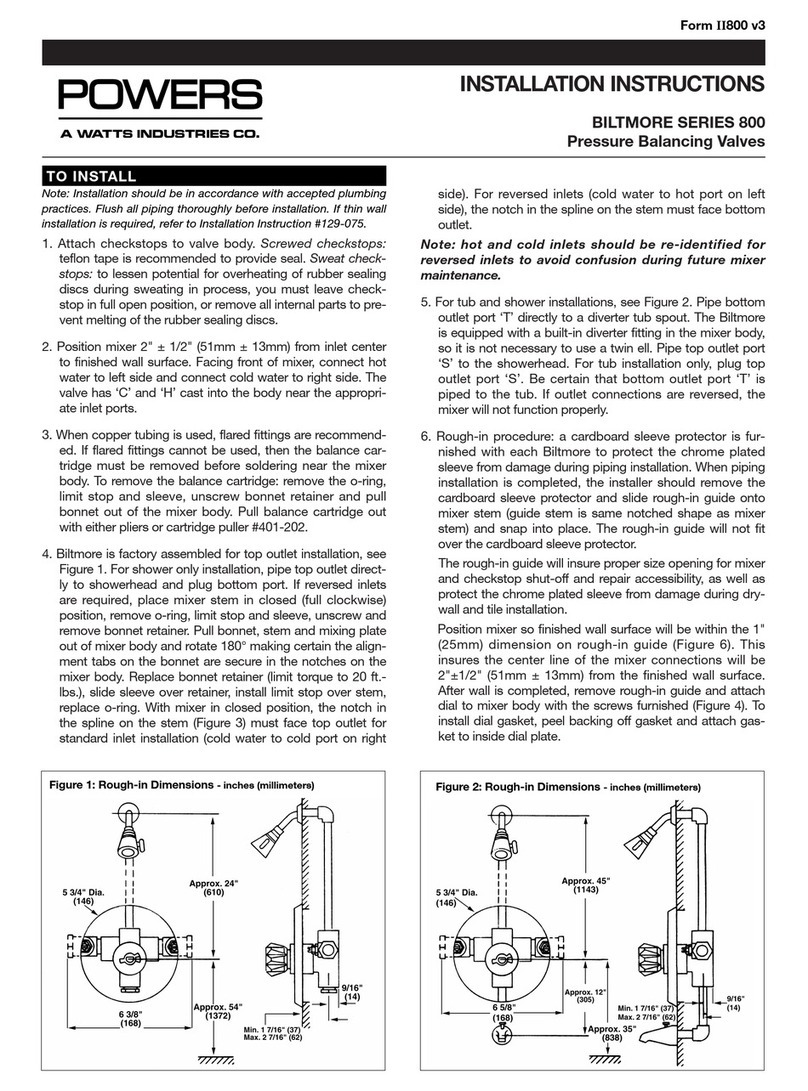

Table 1, Capacity Tables, present the Hydroguard discharge capacity in gpm and l/m for various pressure differentials (the dif-

ference between the lowest inlet pressure and the discharge pressure at the Hydroguard).

Capacity n

Maximum Operating Pressure ............................. 125 psi (861 kPa)

Maximum Hot Water Temperature ...................... 200°F (93°C)

Minimum Hot Water Supply Temp . ..................... 5°F (3°C) Above Set-Point*

Temp. Adjustment Ranges ** Standard: .............. 90 - 160°F (32 - 71°C)

Low: ......................... 60 - 90°F (16 - 32 C)

Hot Water Inlet Temperature Range ................... 120 -180°F (49 - 82°C)

Cold Water Inlet Temperature Range ................. 40 - 80°F (4 - 27°C)

Listing ........................................................................ ASSE 1017

Certified .................................................................... CSA B125

* With Equal Pressure

** NOTE: Low limit cannot be less than the cold water temperature.

For best operation, hot water should be at least 5°F (3°C) above desired set

point.

Specifications n

* Minimum flow when Hydroguard is installed at or near hot water source with recirculated tempered water with continuously operating recirculating pump.

HYDROGUARD® XP Master Tempering Valves

Series MM430 and LFMM430

Technical Instructions

Flow Capacity at 50-50 mixed ratio

Pressure Drop Across Valve

Model Min. Min. Flow 5psi 10psi 20psi 30psi 45psi 60psi 70psi

Flow Rate* to ASSE 1017 CV(34 kPa) (69 kPa) (138 kPa) (207 kPa) (310 kPa) (414 kPa) (517 kPa)

MM431 and

LFMM431

0.5 gpm 3 gpm 6.32 14 gpm 20 gpm 28 gpm 35 gpm 42 gpm 49 gpm 53 gpm

1.89 lpm 11 lpm 53 lpm 76 lpm 106 lpm 132 lpm 159 lpm 185 lpm 201 lpm

MM432 and

LFMM432

0.5 gpm 4 gpm 9.49 21 gpm 30 gpm 42 gpm 52 gpm 64 gpm 74 gpm 79 gpm

1.89 lpm 15 lpm 80 lpm 114 lpm 159 lpm 197 lpm 242 lpm 280 lpm 299 lpm

MM433 and

LFMM433

0.5 gpm 5 gpm 16.44 37 gpm 52 gpm 74 gpm 90 gpm 110 gpm 127 gpm 138 gpm

1.89 lpm 19 lpm 140 lpm 197 lpm 280 lpm 341 lpm 416 lpm 481 lpm 522 lpm

MM434 and

LFMM434

0.5 gpm 7 gpm 21.50 48 gpm 68 gpm 96 gpm 118 gpm 144 gpm 167 gpm 180 gpm

1.89 lpm 26 lpm 182 lpm 257 lpm 363 lpm 447 lpm 545 lpm 632 lpm 681 lpm

MM435 and

LFMM435

0.5 gpm 10 gpm 31.00 69 gpm 98 gpm 139 gpm 170 gpm 208 gpm 240 gpm 259 gpm

1.89 lpm 38 lpm 261 lpm 371 lpm 526 lpm 644 lpm 787 lpm 908 lpm 980 lpm

IS-P-MM430

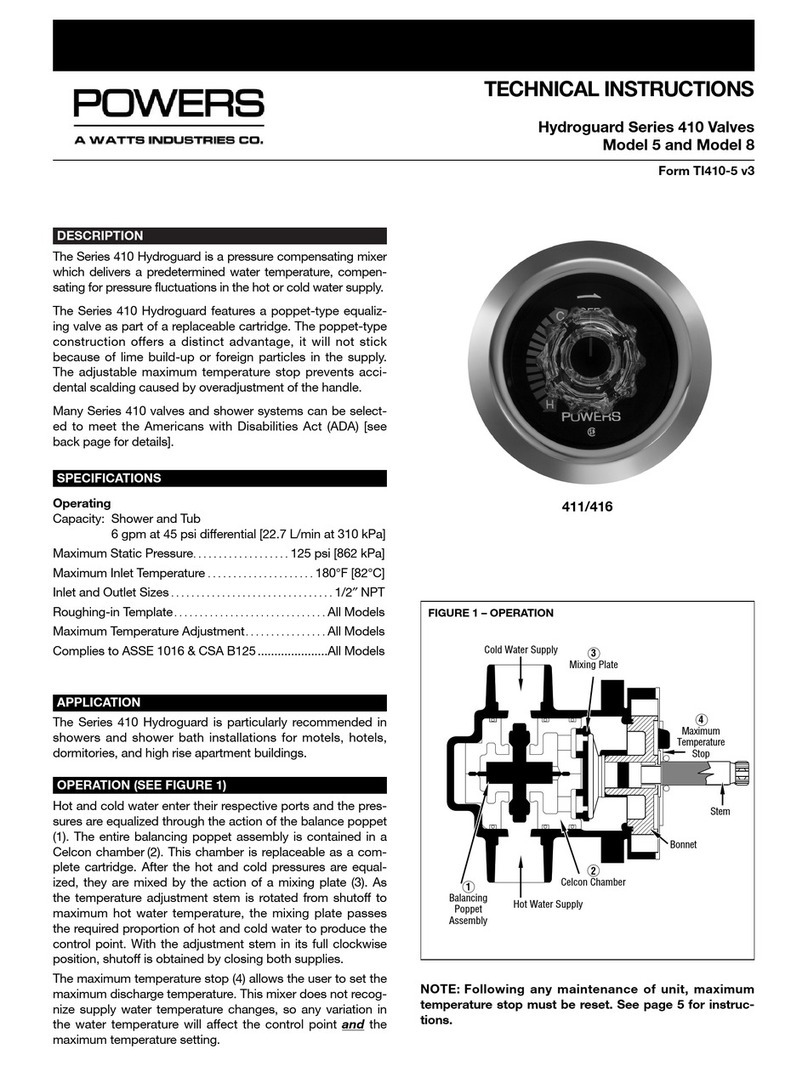

Advanced Thermal Activation

WARNING

!

TO ENSURE THE ACCURATE AND

RELIABLE OPERATION OF THIS PRODUCT,

IT IS ESSENTIAL TO:

• Properly size each valve based on the

individual application.

• Properly design the recirculation system

to minimize pressure and temperature

variations.

• Conduct an annual maintenance pro-

gram to ensure proper operation of all

critical components.

THIS VALVE MUST BE USED IN

CONJUNCTION WITH TEMPERATURE

ACTUATED POINT-OF-USE DEVICES

THAT COMPLY WITH ASSE 1016, 1069, OR

1070.

FAILURE TO COMPLY WITH PROPER

INSTALLATION INSTRUCTIONS COULD

CONTRIBUTE TO VALVE FAILURE,

RESULTING IN IN JURY OR DEATH.