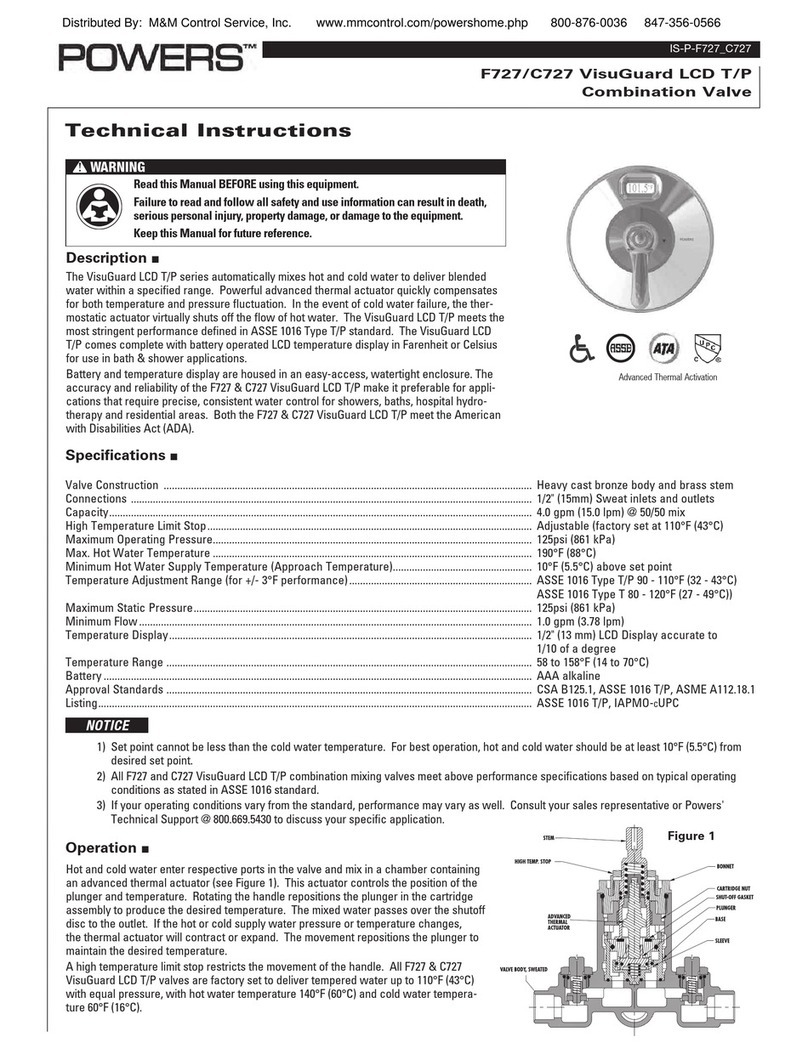

The Series e427 and e428 HydroGuard valves automatically

mix hot and cold water to deliver blended water at any desired

temperature within a specified range. The assembly contains

an advanced thermal actuators which maintains the selected

water temperature within rigid tolerances despite temperature

and pressure fluctuations in the water supply.

Construction features include a built-in shutoff valve for delivery

water, a poppet type mixing valve, a concealed adjustment for

raising and lowering the temperature range, and corrosion

resistant parts.

The Series e427/e428 HydroGuard is simply constructed. All

parts are accessible from the front, to facilitate cleaning and

maintenance.

The Series e427/e428 HydroGuard is preferred for a wide variety

of applications because of its accuracy, reliability, and economy

of water and energy. It is chiefly used in showers, baths, hospital

hydrotherapy and residential areas, where precise, consistent

water temperature is required.

Maximum Hot Water Supply Temp. . . . . . . . . . . . . . 190°F (88°C)

Minimum Hot Water Supply Temp. . . . 10°F (6°C) above set point

Maximum Operating Pressure . . . . . . . . . . . . . . 125 psi (861 kPa)

Temperature Range (standard) . . . . . . . . . . . 90-110°F (32–43°C)

(low temperature) . . . . . . . . . . . . . . . . . . . . . 60-100°F (16–38°C)

(high temperature) . . . . . . . . . . . . . . . . . . . 100-160°F (38–71°C)

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1⁄2″NPT

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 gpm (0.90 l /s)

Minimum Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 gpm

Maximum Static Pressure . . . . . . . . . . . . . . . . . 125 psi (861 kPa)

Finish . . . . . . . . . Chrome Plated on e428, Rough Bronze on e427

Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ASSE 1016

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . CSA B125 Certified

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 lbs.

Adherence to these guidelines and recommendations promotes

safe product use and ensures proper valve performance.

1. Thermostatic water mixing valves are control devices which must

be cleaned and maintained on a regular basis. Powers specifies

periodic maintenance at least once a year or immediately after

any changes are made to the plumbing system. Although annual

cleaning is recommended, frequency of cleaning depends on

quality of local water conditions. Refer to Preventive

Maintenance on page 2 for recommended cleaning procedure.

2. Locate the valve as close as possible to the fixture being

supplied to avoid waste of energy and water.

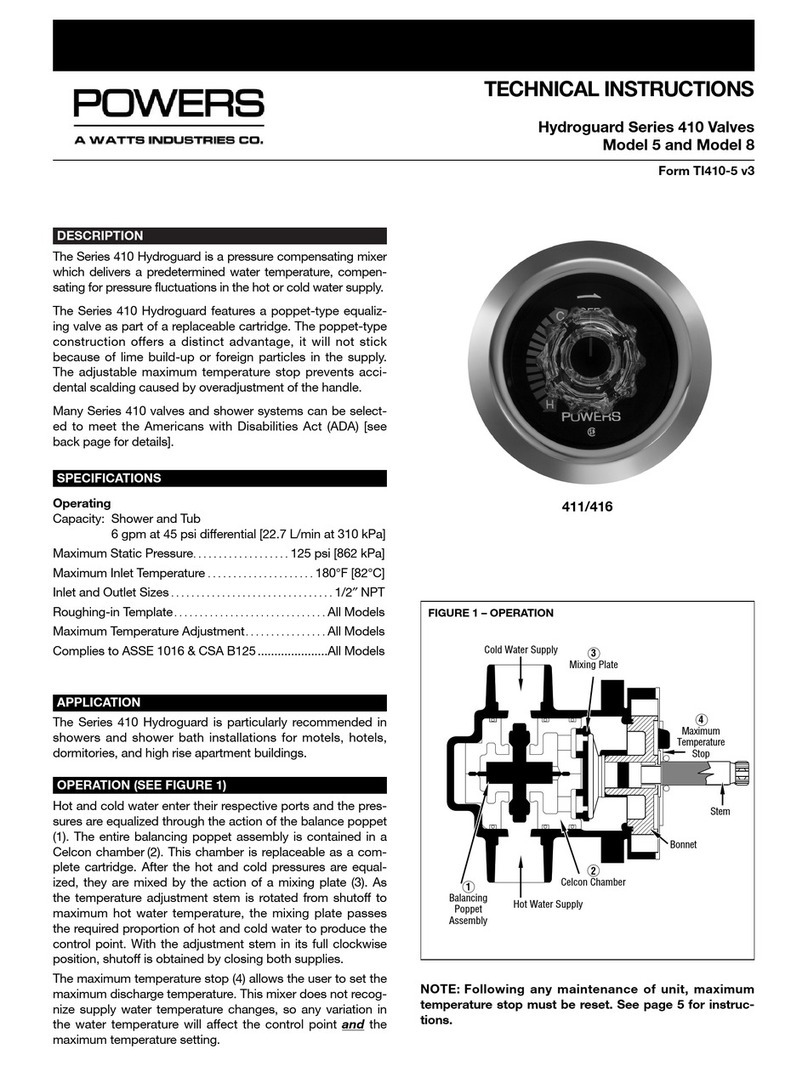

Hot and cold water supplies enter the e427/e428 HydroGuard

through their respective inlet ports. Hot and cold water mix in the

chamber containing the cartridge and thermal actuator assemblies.

The resulting mixture flows across the thermostatic motor, and the

motor positions the valve assembly to maintain the desired delivery

water temperature. Delivery water temperature can be varied by

turning the adjustment handle. Turning the handle counterclock-

wise raises the temperature of the delivery water, and turning the

handle clockwise lowers the temperature. Turning the handle com-

pletely clockwise seats the shut off valve and completely stops

the flow. At the same time the hot water disc seats, preventing

crossflow of the water supplies. Valve (without checkstops) does

not prevent crossflow if left in open position and a downstream

shutoff valve is used. If the temperature of the mixture is higher

than the temperature setting, the advanced thermal actuator

expands and forces the valve assembly to move toward the hot

water seat. The reverse occurs when the mixture temperature is

lower than the temperature setting. A change in water temperature

of either hot or cold water supply will cause the advanced thermal

actuator to reposition the valve assembly to maintain the desired

delivery temperature.

EVERY 12 MONTHS:

• Open up the checkstops and check for free movement of

the poppet. To access the checkstops, remove the handle

assembly and trim plate.

• Before servicing the valve, turn off the water supply upstream

OR close the checkstops. To close the checkstops, turn the

adjustment screw fully clockwise on each checkstop.

• Remove the valve bonnet and rinse all grit and impurities from

the cartridges.

• Winterize valves that are used outdoors. Remove and store

the internal components and drain all water from the valve.

EVERY 3 MONTHS:

• Every three months, check the maximum temperature setting.

NOTE: Before servicing checkstops or piping, always turn

off the upstream water supply.

e427

e428

DESCRIPTION SAFETY AND PERFORMANCE GUIDELINES

OPERATION

PREVENTIVE MAINTENANCE

SPECIFICATIONS

TECHNICAL INSTRUCTIONS

HydroGuard®e427/e428

Thermostatic Mixing Valves

Form TI e427 v2