TI410-5 v3 Page 4

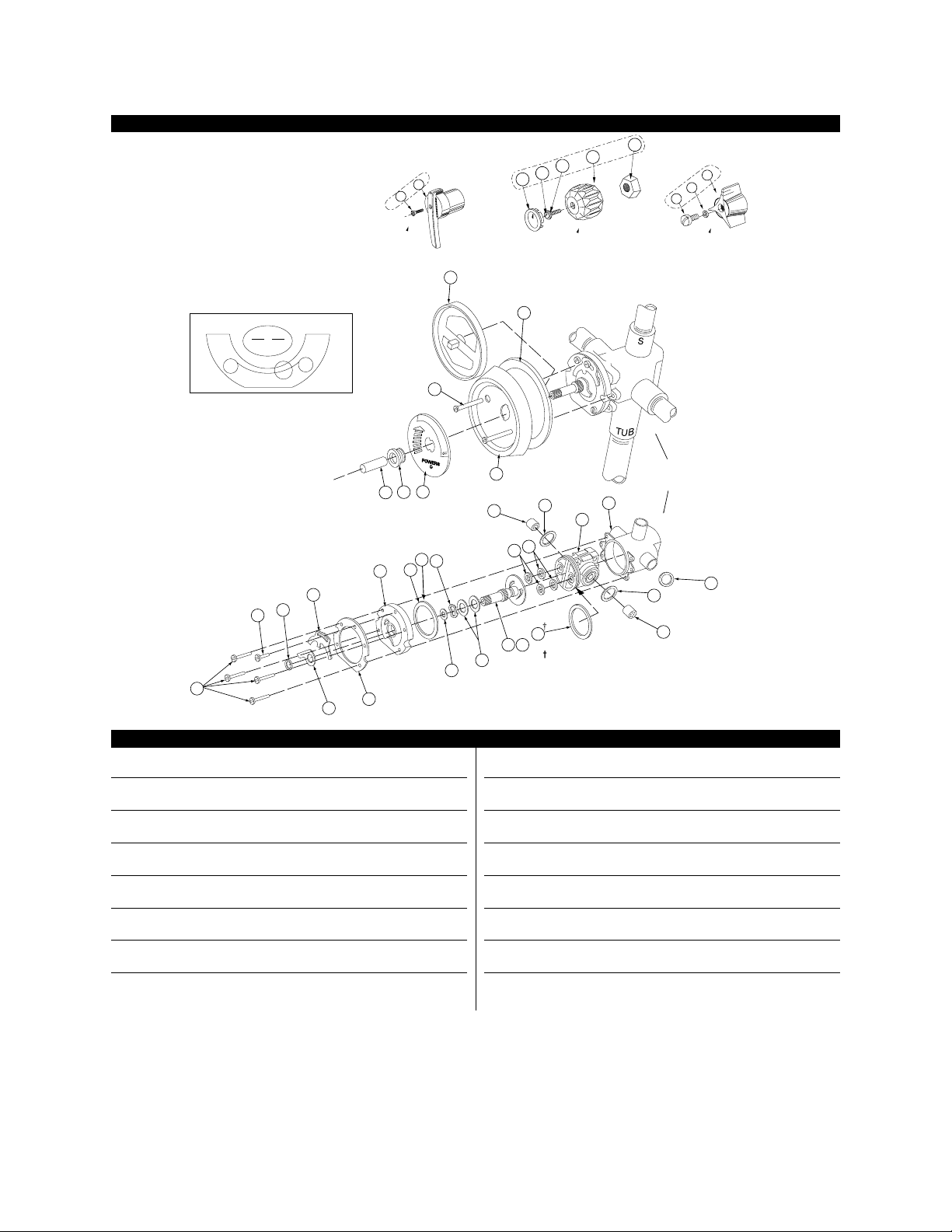

PARTS – SERIES 410 HYDROGUARD

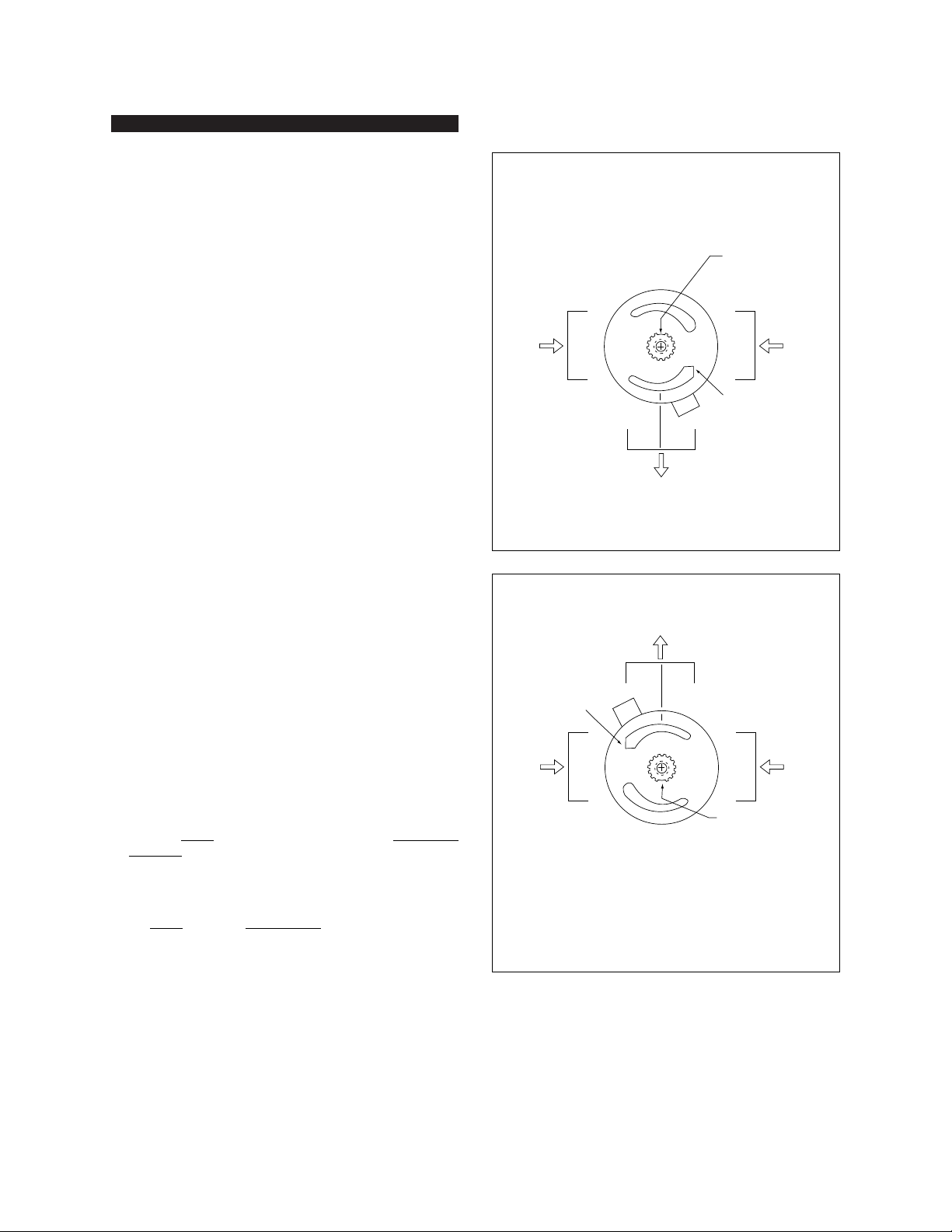

Series 410 Hydroguard Pressure equalizing mixer. Poppet-type construction. Adjustable maximum temperature stop.

Item Part Description Part No. Quantity Material

2a-2b Lever Handle Assembly (410 Model 8) see kit #410-448

2a Lever Handle Screw (8-32 x 1-1/4") * 1 C.P. Brass

2b Lever Handle * 1 C.P. Zinc

4a-4e Acrylic Handle Assembly (410 Model 8) see kit # 410-447

4a Plug Button and Insert 420-314 1 C.P. Brass

4b Acrylic Handle Screw (8-32 x 3/4") 034-515K 1 C.P. Brass

4c Washer 227-197 1 Neoprene

4d Control Knob/Sleeve Assembly 420-310 1 Acrylic and Brass

4e Acrylic Handle Insert 420-125 1 C.P. Zinc

5a-5d Tri-Handle Assembly (All 410 Models: 1-8) see kit # 410-565

5a Tri-Handle Screw 030-070 1 C.P. Zinc

5b Washer 046-008K 1 C.R. Steel

5c Tri-Handle 410-191 1 C.P. Brass

5d Plug Button (not shown) 410-195 1 --

6 Sleeve 401-267 1 C.P. Copper

7 Retainer for Brass Stamped Standard Dial see kit # 410-367

7a Retainer for Brass Stamped Deluxe Dial 410-417 1 Rubber

8 Dial Insert (Model 5) (not shown) 410-374 1 Aluminum

Graphic Insert (not shown) 410-442 1

9 Screws (2) see kit # 420-216

10 Dial Plate see kit # 410-445

10a Gasket see kit # 410-570

10b Rough-in Guide (All Models) 401-178 1 -

11 Bonnet Screws (10-32 x 1") (4) 030-885 4 Stainless Steel

12 Adjustment Stop Screw (10-32 x 5/16") 030-884 1 Stainless Steel

13 O-Rings (3/8" x 1/2" x 1/16") (2) see kit # 410-182/410-570/410-378 1

14 Maximum Temperature Stop 401-218 1 Brass

15 Adjustment Stop 401-278 1 Stainless Steel

16 Support Ring 410-377 1 Stainless Steel

17 Bonnet 401-162 1 Noryl

17a Bonnet for 414 Valve (not shown) 410-393 1 Noryl

18 Bonnet Gasket (Rainbow Style) see kit # 410-182/410-378

18a Bonnet O-Ring (Models 1-3 only) (not shown) see kit # 410-182/410-378

19 Wavy Washer see kit # 410-378/410-369

20 Flat Washers (4) see kit # 410-368/410-378

21 Throttling Stem see kit #410-378

21a Throttling Stem for 419 Valve (not shown) 410-378A 1 Brass Stem Celcon Plate

22 Shut-off Discs (2) see kit # 410-570/378, 182, 183, 401-175

23 Quad Rings (2) see kit # 410-570, 182, 183, 401-175

24† O-Ring (1-3/4" x 1-7/8" x 1/16")† see kit # 410-570, 182, 183, 401-175

25 O-Rings (1-3/4" x 1-3/16" x 3/32") (2) see kit # 410-570, 182, 183, 401-175

25A O-Ring (oversized) see kit # 410-570

26 Balance Chamber (3-port valves) see kit # 410-183

Balance Chamber (4-port valves) see kit # 401-175

27 Body, 4-Port N/A

Body, 3-Port (not shown) N/A

† For use on 4-port mixers only. No discharge will occur when used in 3-port mixers.