Prior to Installation

1. Flush all piping thoroughly before installing.

2. Make sure all ball valve handles are in “OFF” position.

3. In order to make any temperature adjustment to the valves, you must open end-of-line fixtures to ensure you have

adequate flow across the valve.

4. Use a thermometer at the showerhead or install an in-line thermometer at the point-of-use.

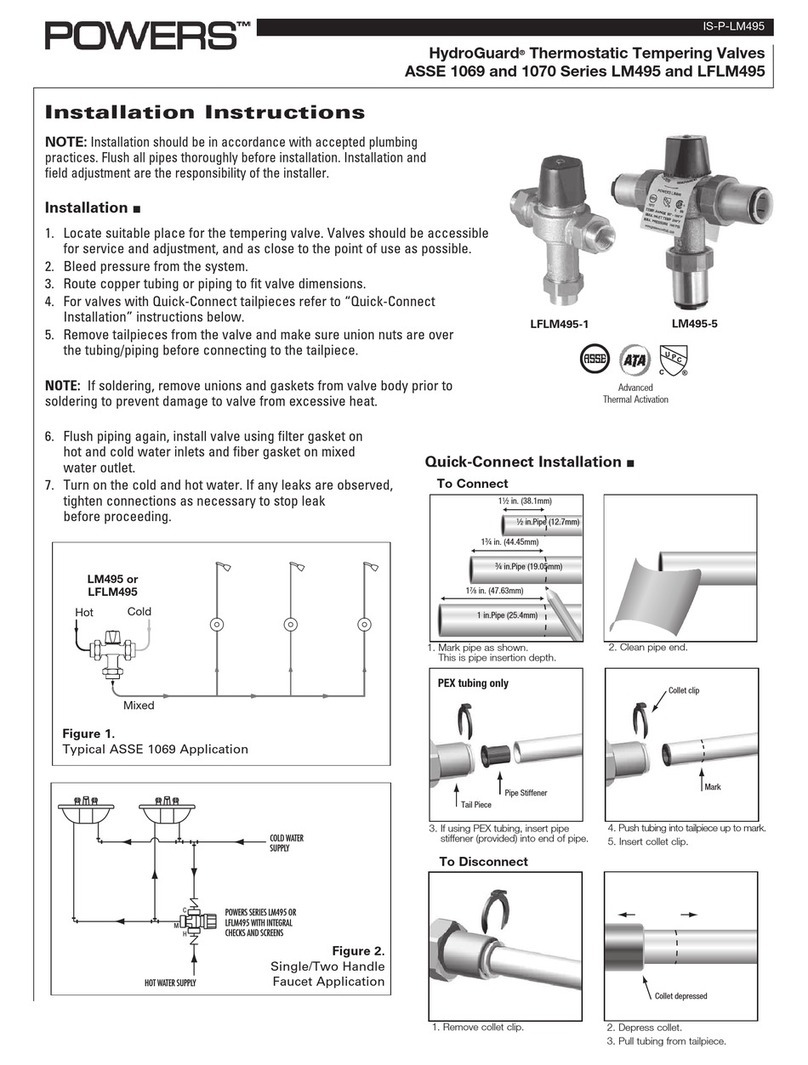

5. Typical piping diagrams are shown on page 4, for other alternatives or special circumstances,

contact Powers’ Technical Support Department at 1.800.669.5430.

Set Up Procedure

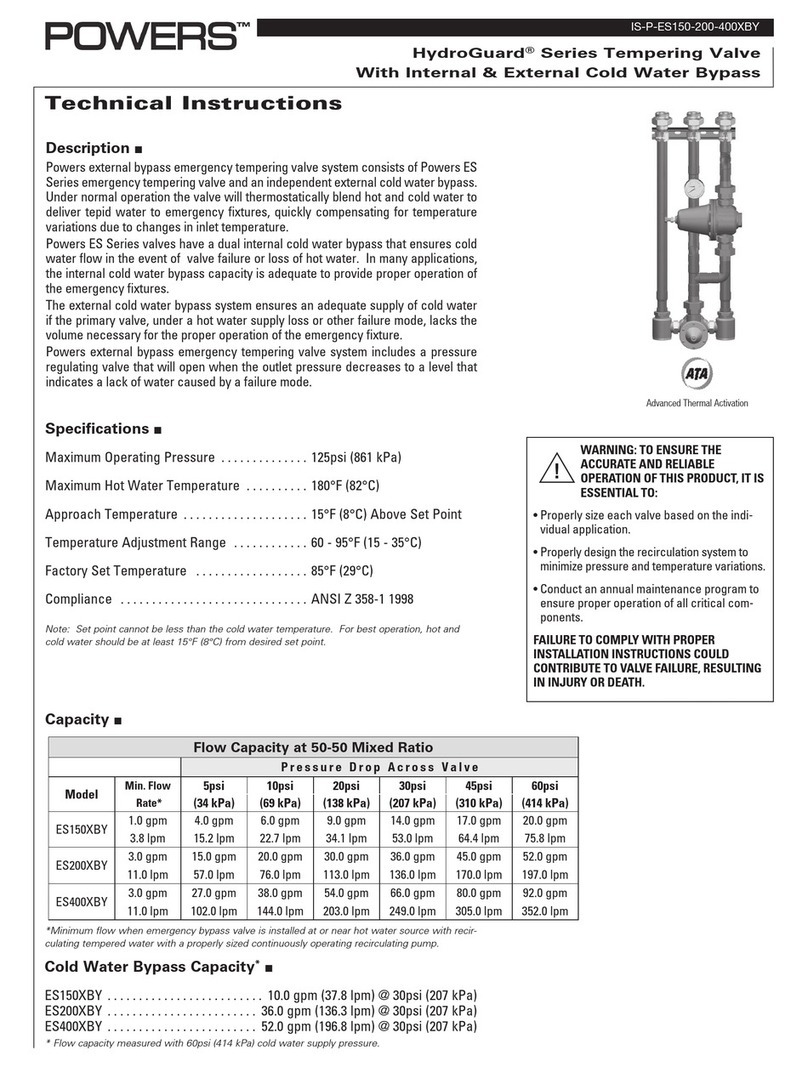

You must follow these procedures in order to properly adjust your High Capacity System. You need flow greater than the minimum

shown in table 1 across the valve in order to set a maximum temperature.

1. Close the ball valve on the outlet of the low flow valve.

2. Open the ball valve at the discharge of the high flow valve.

3. Open enough fixtures to meet the minimum flow requirement as per

table 1.

4. Set valve temperature (refer to enclosed TI if required).

5. For “HL” only. For “DV” skip to #6. Set the PRV as follow for a 15 psi

differential.

a) Loosen the locknut at the top of the PRV. This must be all the way

out or you will be limiting the range of the adjustment.

b) Adjust the PRV so the outlet pressure gauge (top) reads 15 psi less

than the supply pressure gauge (bottom). Turning the adjustment nut

clockwise will increase outlet pressure (decrease the differential)

across the PRV (allowing the PRV to open sooner). Turning the adjust

ment nut counter-clockwise will decrease outlet pressure (increase

the differential) across the PRV (allowing the PRV to open later).

6. Close the ball valve at the discharge of the high flow valve.

7. Open the ball valve on the outlet of the low flow valve.

8. Open enough fixtures to meet the minimum flow requirement as per table 1.

9. Set the temperature for the low flow valve (refer to TI if required).

10. Open the ball valve at the discharge of high flow valve.

11. Open additional fixtures to develop a 20 psi differential between the supply and outlet pressure gauges (table 1).

12. Verify temperature remains at set point.

13. Gradually start to close fixtures to verify that the temperature remain constant through the full range of flow.

14. For any problem, refer to troubleshooting section of the document or contact Powers’ Application Department.

Troubleshooting

Outlet temperature is too hot with low flow:

1) The temperature of the low flow valve was not properly set. Refer to set up procedure and reset the maximum

temperature of the low flow valve.

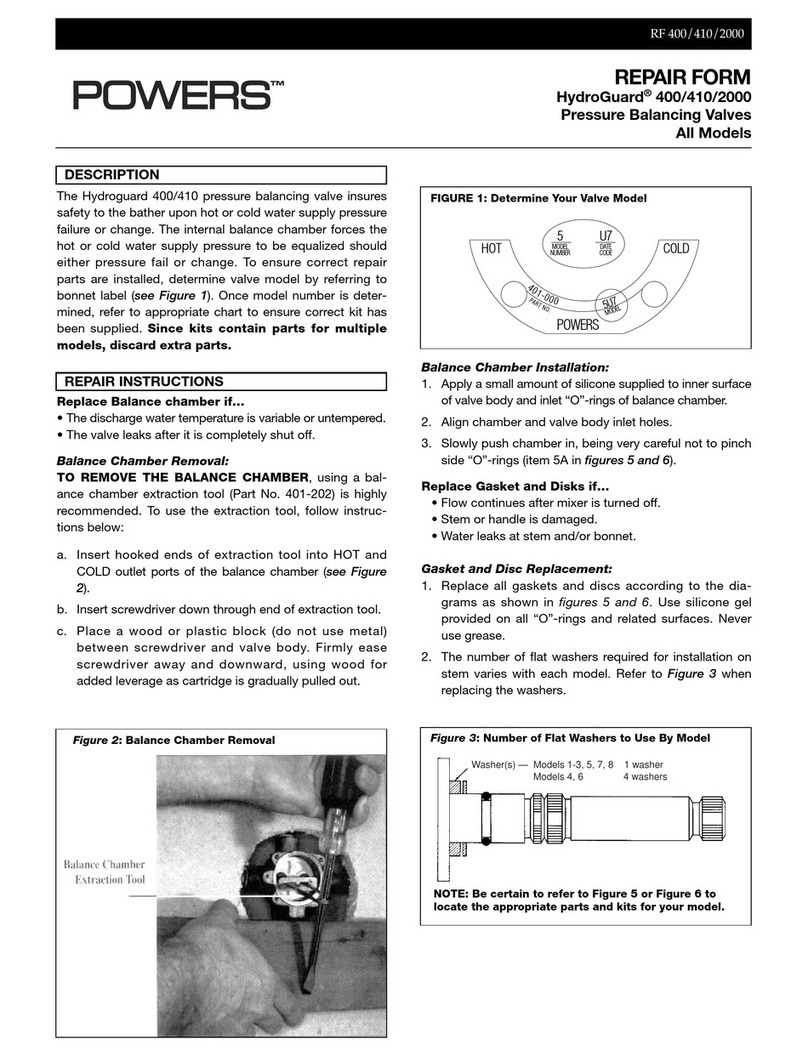

2) The thermal actuator of the low flow valve is not working properly. Test and replace accordingly to the TI 1430

technical instructions enclosed.

Outlet temperature is too hot with a high flow:

1) The temperature of a high flow valve was not properly set. Refer to set up procedure and reset the maximum

temperature of the high flow valve.

2) The thermal actuator of the high flow valve is not working properly. Test and replace accordingly to the TI 430

technical instructions enclosed.

4

Form PS/TI 2-Valve HCS Series 1430 v4 0530

Installation and Troubleshooting