Before disassembling, make certain both hot and cold water supplies

are shut off.

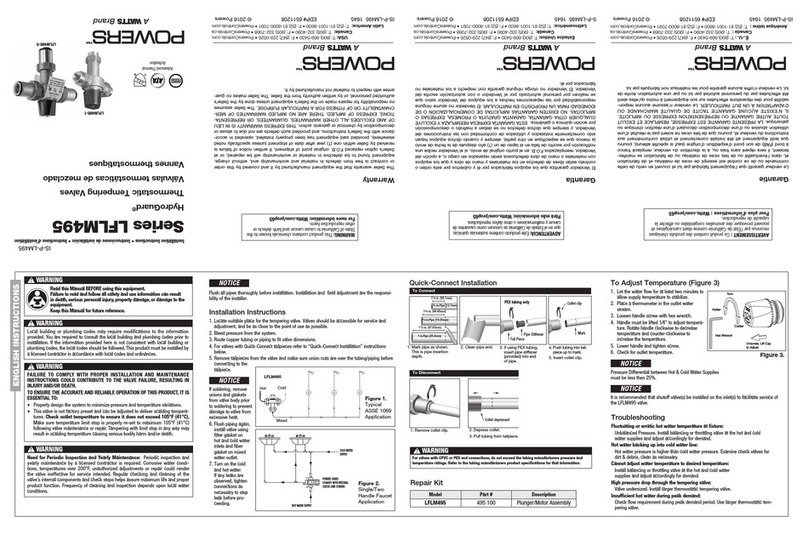

Checkstop Disassembly

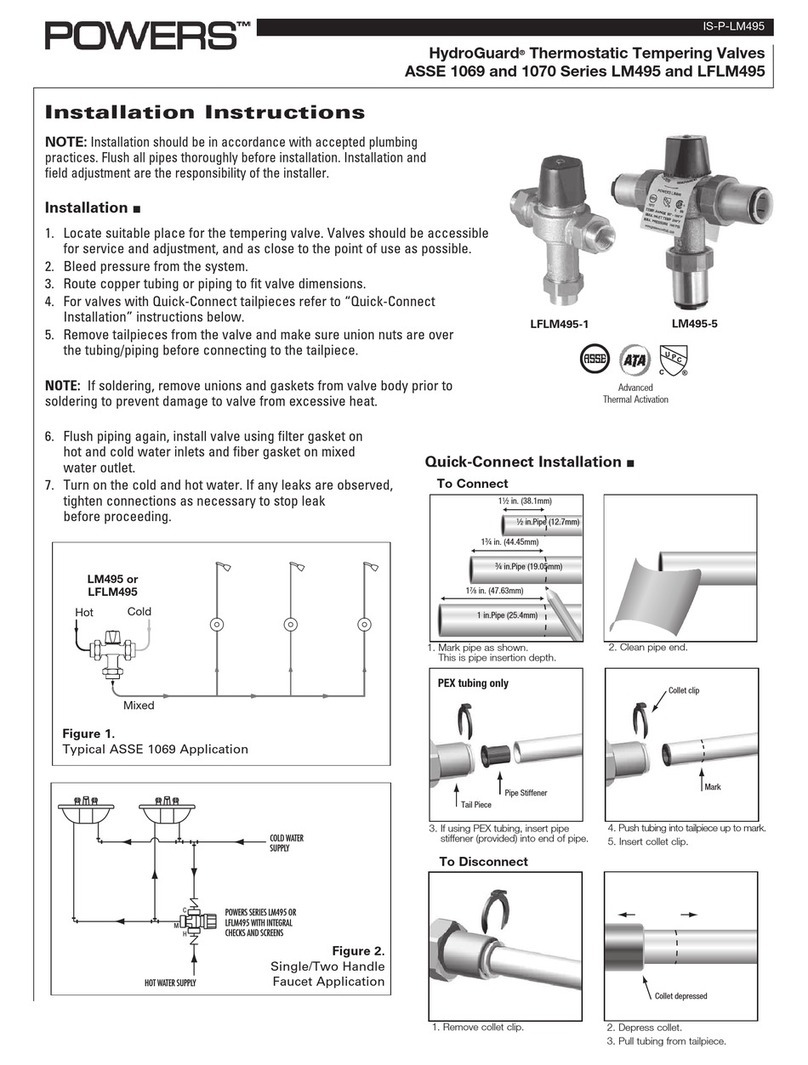

1. Remove bonnet with socket wrench.

2. Lift out strainer screen.

3. Reassemble in reverse order.

Valve Disassembly

To Remove Thermal Actuator from Top

1. Loosen locknut.

2. Remove bonnet and pull out overload assembly by using

standard pliers.

3. Lift out thermal actuator by using a needle nose plier.

4. Reassemble in reverse order.

Servicing n

5. When desired temperature is set, tighten the locknut. Turn

re-circulation pump back on. Close open fixtures.

Temperature Adjustment n

Temperature setting for LFSH1430 Series Valves:

1. Turn off re-circulation pump (if one is in the system).

2. Open up enough fixtures to meet minimum flow requirement of:

LFSH1432 = 1 gpm (4 Lpm)

LFSH1434 = 1 gpm (4 Lpm)

LFSH1435 = 5 gpm (19 Lpm)

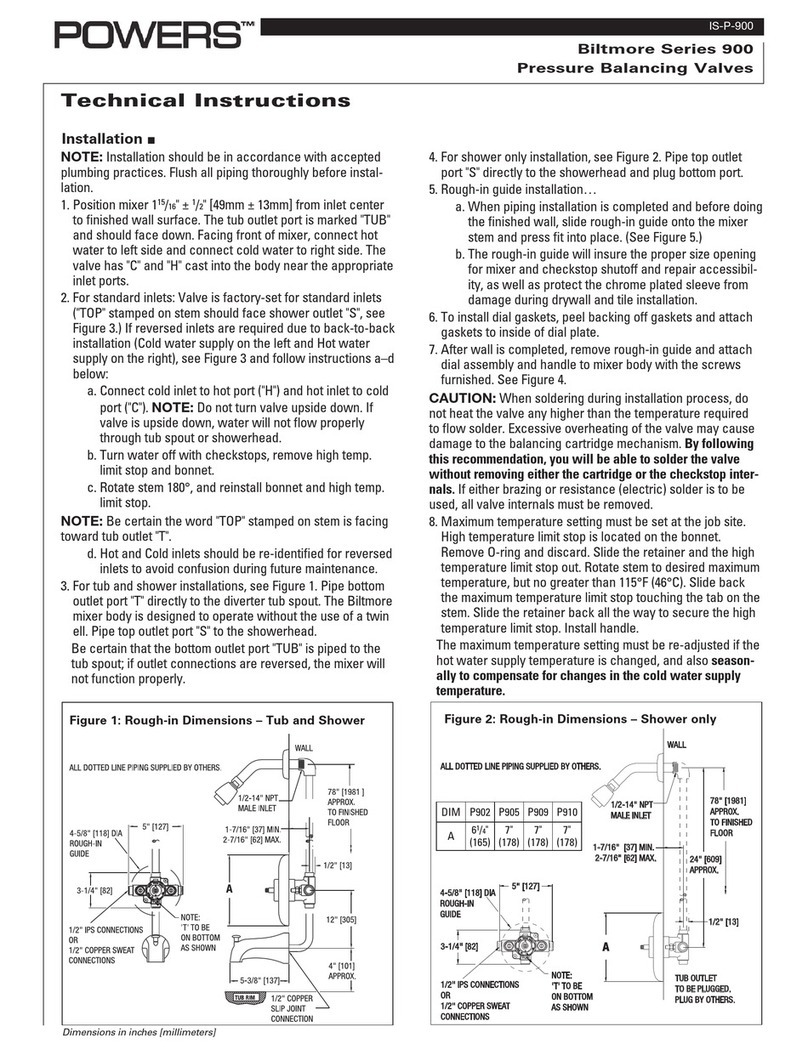

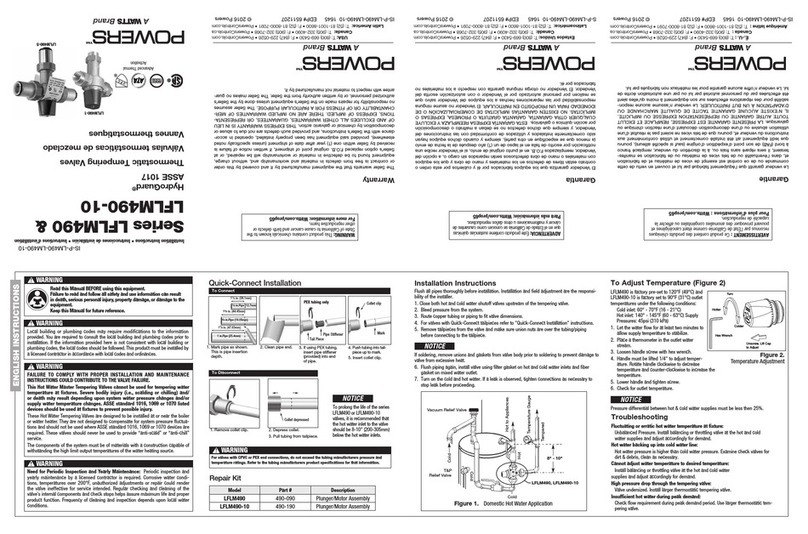

3. Loosen locknut (see Fig. 1)

4. Turn temperature adjusting screw counterclockwise to increase or

clockwise to decrease the outlet temperature. (see Fig. 1)

Please allow valve temperature to settle in before making your next

adjustment.

IS-P-SH1430 1336 EDP# 6512307 © 2013 Powers

Warranty n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

THIS EXPRESS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, GUARANTEES, OR REPRESENTATIONS, EXPRESS OF IMPLIED.THERE ARE

NO IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE.The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller.The Seller makes no guarantee with respect to material

not manufactured by it.

A Watts Water Technologies Company

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

For more information: www.watts.com/prop65

WARNING

!

Any changes in supply condition could effect the out-

let water temperature. Check and adjust the valves

accordingly to prevent injury to the users. After com-

pleting repairs, check discharge temperature, (105°F

[41°C]). Reset if necessary. Failure to perform this

operation could result in unsafe discharge tempera-

ture, which may cause injury or death.

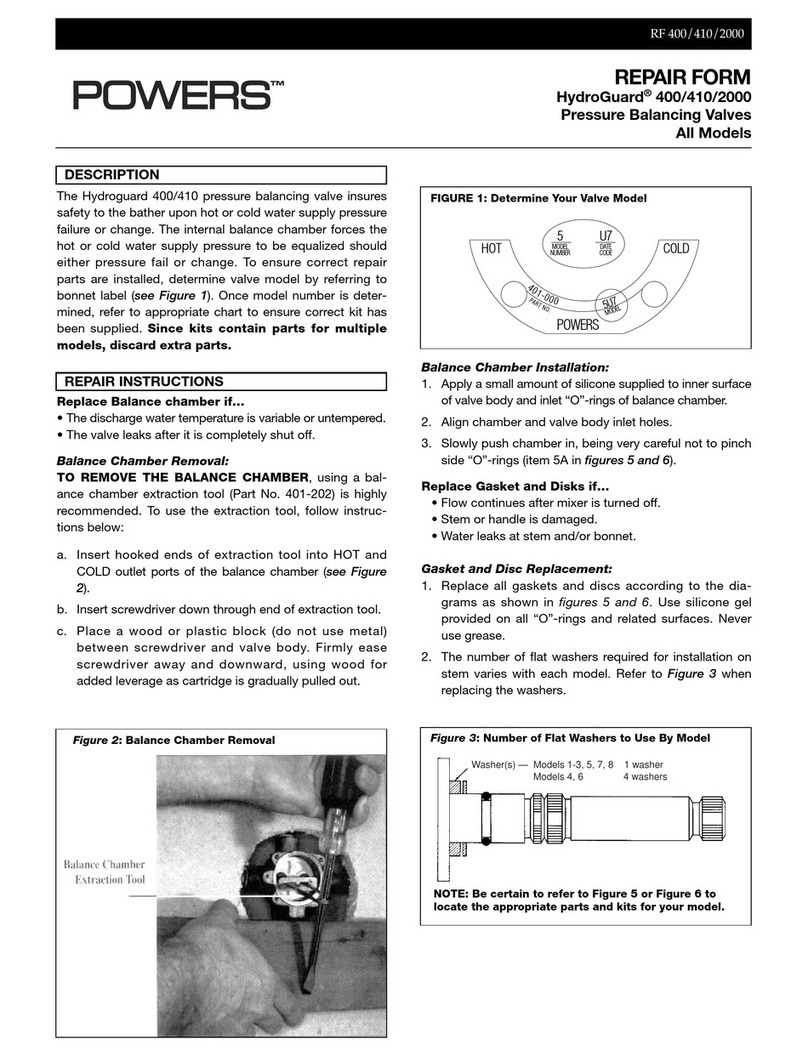

What to look for if:

• The ow of water is less than desired...

a. Stop valves or supply to HydroGuard not fully open.

b. Clogged checkstop strainer screens.

c. Accumulation of lime deposits around valve seats.

d. Low supply pressures.

• The ow of water is completely shut off...

a. Stop valves or supply valves are completely closed.

b. Valves downstream from HydroGuard fully closed.

c. Loss of either hot or cold water supply pressure.

• Discharge temperature varies...

a. Very large restriction in outlet flow.

b. Very large drop in inlet pressure.

c. Very large fluctuation of hot water supply temperature.

d. Worn valve seats.

e. Minimum flow requirement not achieved.

f. Lime deposits around motor, poppets and/or seat.

Maintenance and Troubleshooting n

5. Temperature setting must be checked by an installer before

use. See temperature adjustment below.

To Remove The Plunger Assembly Or Funnel from Bottom

1. Remove the bottom cap.

Spring is under tension.

2. Pull out spring.

3. Pull out plunger using a pair of pliers.

4. To remove Funnel, you will need a deep socket wrench and funnel

removal tool.

5. Reassemble in reverse order.

6. Temperature setting must be checked by an installer before

use. See temperature adjustment below.

After reassembling go back to thermal actuator section and make sure

it is sitting in its holder properly.

NOTICE

CAUTION

!

NOTICE

Distributed By: M&M Control Service, Inc.

www.mmcontrol.com/powershome.php

800-876-0036 847-356-0566