PowerShield 8 User manual

Other PowerShield UPS manuals

PowerShield

PowerShield DC Pilot 50 User manual

PowerShield

PowerShield GLADIATOR User manual

PowerShield

PowerShield Centurion PSCE1000 User manual

PowerShield

PowerShield PSCM1100 User manual

PowerShield

PowerShield Centurion PSCER6000 User manual

PowerShield

PowerShield Pilot DC 50 User manual

PowerShield

PowerShield Centurion RT Series User manual

PowerShield

PowerShield Centurion RT 6000VA User manual

PowerShield

PowerShield Defender 1200 User manual

PowerShield

PowerShield Ninja Slimline PSLN600 User manual

PowerShield

PowerShield Centurion 10000 VA User manual

PowerShield

PowerShield Centurion Series User manual

PowerShield

PowerShield 1100 VA User manual

PowerShield

PowerShield Centurion Pro Series User manual

PowerShield

PowerShield SAFEGUARD PSG750 User manual

PowerShield

PowerShield AS400 User manual

PowerShield

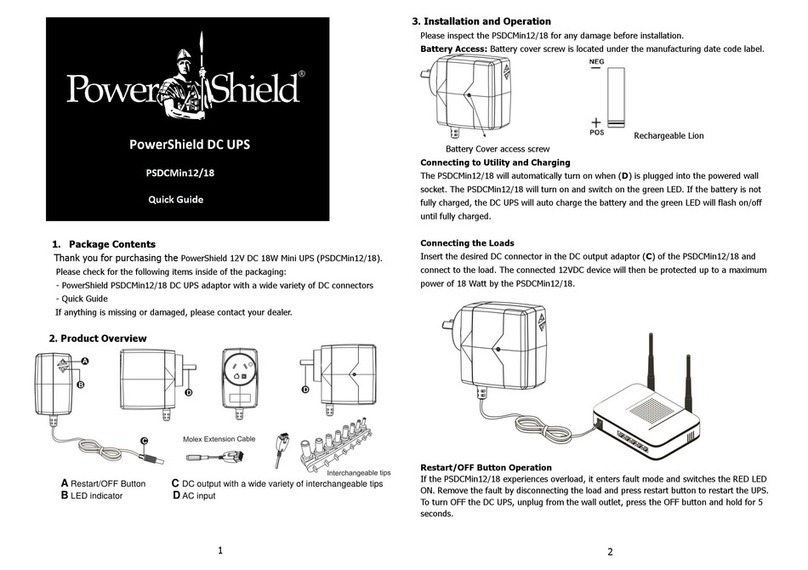

PowerShield PSDCMin12 User manual

PowerShield

PowerShield Defender Series User manual

PowerShield

PowerShield defender PSD 650 User manual