Note: The

limit

tne

rmostat(s) can

on

lvbe reset

once the unit has cooled down. Unless the

cause of t

he

f

au

lt

co

n

di

t

ion

is

readilyobvious,

for example a power

(ut

whitst

the heater was

operati

ng

.aservice

en

g

in

eer

shou

ldbecontacted.

E)

Maintenance

To

maintain efficient, reliableand safe operation

of

the

heater

It

must

serviced annually

bV

a qualified person,

F)

IMPORTANT

Free access must

be

maintained to and around the heater

for servicing purposes and the air supply

to

the heater

must not

be

restricted

in

any

way

.Combustible materials

must not

be

stored adjacent to the heater.

If at any time a gas l

eak

is

suspected, turn

OFF

the

gas

supply at the meter and contact the

local

gas undertaking

Immediately.

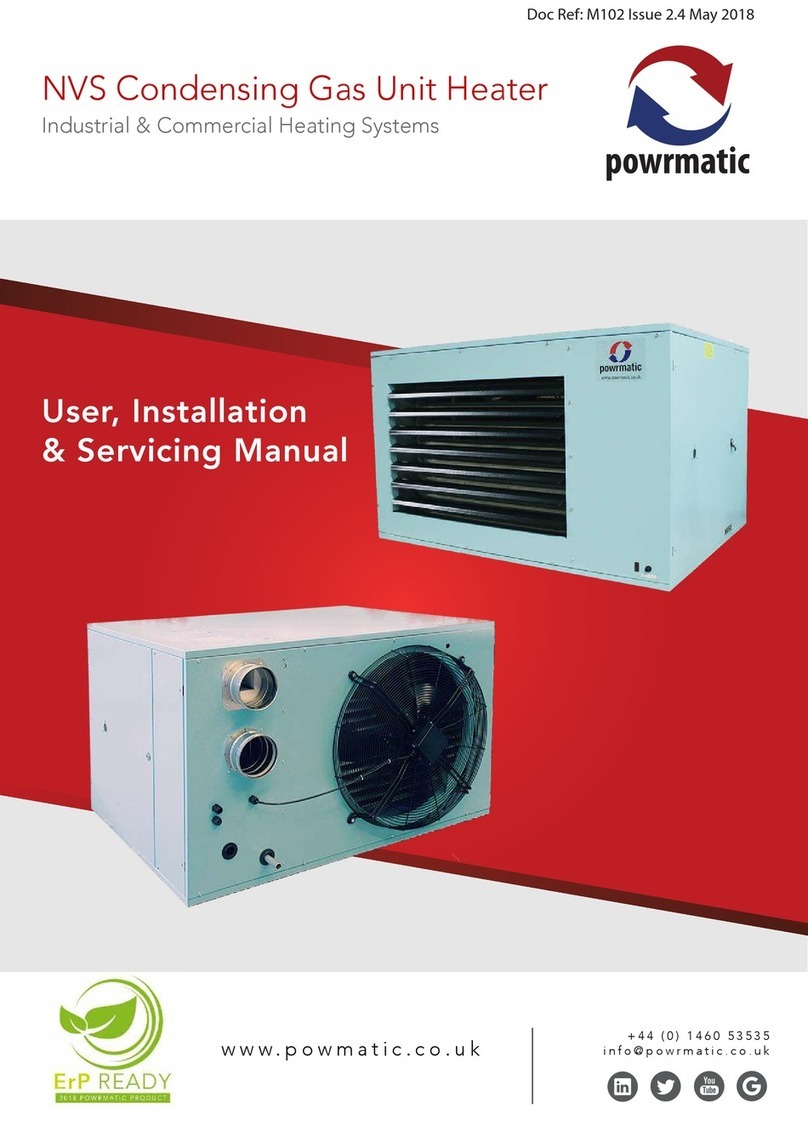

The

lNVl(

range are

high

lyefficient, gas

fi

r

ed,

fanned

ctrC\Jlatlon

air heaters thatcover heat outputs

of

15kW

to

140kW,

have a closed combustion

circuit

and are supplied

complete with a nue system.

lNVl(

heatersare certified

for

use

on

Natural

Gas,

Group

H-

G20

·.

Appliance

Categories are

Cat

112H

1GB,

IE).

All

lNV)(

heaters are

CE

certified and conform to

all

the

EUropean

directives stated

In

section

1.3.1

l

NVl(

heaters are designed to

be

suspended

fr

om suitable

roof points or a1ternativelvto

be

mounted

on

pur

pose

designed brackets and are intended

primarily

for heattng

commercial or

IndustriaJ

premtses.

All

variants are for

internal use

on

ly.

lNVl(

Maters feature a closed

combustJOrt

cIrcuit

and

have an internal eKhaust

fan,

mounted downstream

of

the heilt

el(changer,

to evacuilte t

ile

products

of

combustion and draw

in

air for combustion.

The

air

heater

must

be

connected to a flue system that

is

approved

by

Powrmatlc Ltd.

lNVl(

heaters

may

be used where the atmosphere inside

the premises

could

be

contaminated

e.g.

Dust,

oil

mist

etc. butthe heaters are not

ai

rtight and therefore

may

not

be

used

in

areas cl

aSSIfied

as

hazardous

as

defined

in

as

5345: Part 2 or areas subjectedto significant negative

pressures due to el(tract systems,

Use

r Instructions

All

Powrmat

lc

heaters use gas and electricity to

power

them, they

may

also contain

movmg

parts such as

pulley

s

and belts. It

wou

ld

be

hazardous to tamper with or

attempt to service

un

less

you

are a competent pluson

in

the

field

of

Gas

and Electri

cal

work

.

If

you

have any safety questions reference the servicing

and installation

of

any

of

our heaters please

do

not

hesitate to contact

our

head office

for

el(pert

advice

.

Your

safety

Is

paramountto us.

Gas

Safety (Installation.

Un'

(Amendment)

Aeculations

2018

It

Is

~w that

all

cas appliances arelnst;aJled,

adJustltd and, If n.cessary,

conv.rt.d

by

quallflltd p.rson

s'"

In

accordance wtth the

curr.nt 'SIU. of the above reculatlons.

Fallur. to Inltall appil

anc.I

corr.ctly can lead

to

prosKution.

It

II

In

your own I

nt.r

.sts

a

nd

that of safety

to

.nlur.

that thalaw Is compllltd w

fth

.

•

Gas

Safe Register@dEnglneer

1.1

Introduction

lNVl(

F,

lNVl(

Duo

and

lNVl(

Vheaters

have

an

axial

fan

assemblyfitted to circulate the

aJr

being heated through

the formed tube heat exchanger.

lNVl(

cn

units are

supplied with a centrifugal fan and

lNVl(

0 units

for

use

with ducted systems where the air

moving

fan

is

by

others

or

a centrifugalfan section

Is

used adjacent to or

remote

from

the heater.lNVl(

OH

units are for use

in

air

handling units.

Heaters are fitted

as

standard with

Ins

hot burners, a

fully

automatic control

for

igniti

on,

fl

2lme

sen

sing.

gas supp

ly

control and

sa

fety functions,

an

internal e)(haust r

an,

main air fan

IF

and

CCF

models!,

and fan/limit thermostat.

Options

include

High/low or Modutating burner controls,

inlet duct connection, outlet duct connection. 30-, 45-

head,

90

-outlet bend, vertIcal/horizontal outlet louvre

assembly and a full range

of

modular duct components.

IMPOATANT

SaNk'

and

Ma

l

nt.n

.

nce

[nc

l

nurs

shan

ensure that replacemant

It.ms

are fitted,

adjusted and sat

In

accordance wtth tha

data and d.tall

set

out

In

thasa Inltructlons.

If

In doubt

conlult Powrmatk

Techn

ical Dapartment.

•

LPG

conllefSion

/tits

available.