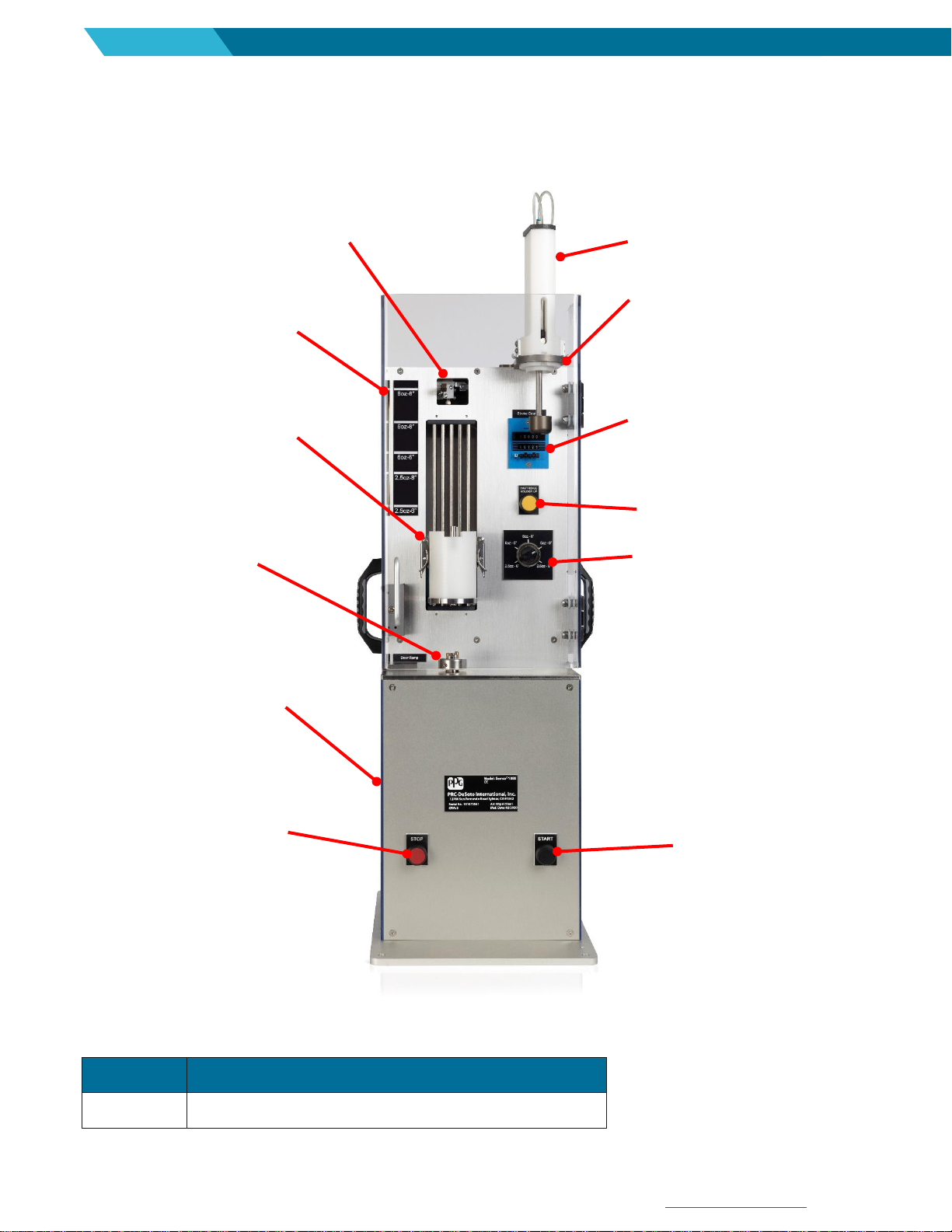

7. Operation

7.1 Open safety guard door.

7.2 If machine is holding a Semkit cartridge from

earlier cycle. Open the latches on both sides

of the cartridge pusher assembly clockwise to

release and place into the cartridge pusher

holder on the top of the machine. Release the

dasher rod from the spindle drive pins and

move the cartridge upwards, lift and remove

Semkit from the cartridge holder.

7.3 New cartridge - Adjust to size. Use the Semkit

package ruler to determine cartridge size and

rod length. Semco sizes: 2.5 oz.-6" rod, 6 oz.-

6" rod, 2.5 oz.-8" rod,6 oz.-8" rod & 8 oz.-8"

rod are supported. Fully extend the dasher rod

on the Semkit package all the way to the top

of the cartridge and measure the length

against the Semkit package ruler. Use Semkit

configuration switch to select the configuration

of dasher rod and cartridge. The machine will

automatically adjust to the selected con

figuration. See Appendix 1 for Semkit package

diagram (barrier and injection style).

7.4 For barrier style Semkit packages,

remove tape surrounding cartridge and break

the dasher free (loosen barrier) before loading

into mixer.

7.5 Load the Semkit into the cartridge holder and

take the cartridge pusher assembly and place

into the open end of the Semkit cartridge.

Press the cartridge holder up button while

pushing down on the cartridge pusher

assembly. Close the latches on both sides of

the holder to keep the cartridge firmly in place.

(For mixers with twist style cartridge pushers,

firmly turn the pusher assembly

counterclockwise to lock the pins in place. The

red or black indicator lines should be aligned

to verify correct orientation.)

7.6 Check the toggle switch (roller valve) at the

top of the machine to make sure it’s not

depressed or jammed in any way by the two

flags on the rear of the cartridge pusher

assembly.