praher SUPERSTAR E-3000/F2 User manual

2

3 G

/

4 C

5

6

7 - 8

9

10

Page

Safety references

eneral regulations / Intended use

Assembly

ycle sequence/rinsing times

Digital clock/Prog. Back rinsing trigger time

Function film keyboard

Settings for back and clear rinsing duration

Setting for deceleration time

Electr. Connection

Board for E-3000/F2 - 24V

Exploded view

G

F

ED

A

C

H

B

L

K

I

M

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

Table of contents:

Ensuing damage due to neglect of the operating instructions or due to damaging sealed parts lead to a lapse

of the warranty. We do not take on liability for thus resulting damages! Please read the operating instructions

carefully before starting.

PRECISION - POWER - PROGRESS - PRODUCTION

Page 2

1. Safety Instructions:

•

•

•

•

•T

•

•

•

•

•

•

•

•

This equipment has been built and examined according to the safety precautions for electronic

devices and has left the plant in a perfect safety-related condition.

To keep this status and to guarantee a safe operation, the user must

observe the safety instructions, which are included in these operating instructions.

The installation work may only be undertaken by an authorized and licensed installer or

electrical business.

The electrical installations must be carried out according to the respective local and regional

regulations (e.g. OEVE, VDE...) and possible official regulations.

he electrical connection must have separating device built into the permanently installed

electrical installation, which enables the disconnection of all electrical contacts with a

contact space of minimum 3 mm from the mains.

Pay attention that the supply voltage is correctly protected and an

earth-leakage circuit breaker 30 mA is installed.

Only use the equipment in dry rooms, in which no combustible gases and

vapors are present.

Do not operate the equipment immediately if it has been taken from a cold into a warm area

The thereby developing condensation water could destroy your equipment

If the equipment has visible damages doesn't work anymore or has been stored for longer

periods under adverse conditions then it is to be expected that a safe operation is not possible

anymore.

In this case the equipment is to be secured against unintentional start-up and if necessary to be

decommissioned.

Live parts can be uncovered when opening the cover or removing parts.

Before an alignment, maintenance, a repair or a change of parts or devices, the equipment must

be separated from all voltage supplies, if opening the equipment is necessary. If after that an

alignment, maintenance or a repair on the opened equipment under voltage is inevitable, it may

only be done by experienced skilled personnel, who have knowledge of the associated dangers

and/or the relevant regulations.

Capacitors in the equipment can be still charged, even if the equipment

is separated from all voltage supplies.

Assembly and/or disassembly of the armature only in a pressure-free status (i.e. empty piping

beforehand).

Armature flow and/or direction of flow must be considered!

<

PRECISION - POWER - PROGRESS - PRODUCTION

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

2. General:

PRAHER superstar controls are significant technical products, which are manufactured with high accuracy and according

to the most modern technical production methods. Entitled complaints will naturally be rectified as fast as possible if they

occur.

Warranty: According to “EU”-law. The warranty begins on the delivery day. The date is in the serial number on the rate

plate.

3. Intended use:

It is a control unit for a 6-way valve, with which a filter is fully automatically flushed by pressure application. A filter pump

connector is available, which when reaching the respective valve positions switches on delayed for approx.. 20 seconds.

Parallel there is also a potential-free signal. The dry operation protection ensures a safe operation of the plant.

Additional electrical connections are possible:

To position flush, to position back and clear rinse, for the serial connection of various valves, for the interruption of a heating

or heat exchanger before cycle start, for ball valve during the cycle

4. Assembly:

Equipment installation - installation of the valve

Integrate the valve into the piping according to the inscription and the following sketch. Use transition screw connections.

Seal threaded connections only with teflon band. The equipment is functional in any position, however if possible should

not be installed with the actuator downwards.

Pump

Basin

Drain

To the Filter

From the Filter

PUMP from the pump

to the filter

BOTTOM from the Filter

Return to the basin

Waste to the Drain

TOP

IFILTER

Pump

Basin

Drain

To the Filter

From the filter

I: Filtration of medium (e.g. water):

pool

II : D

pool

III : Cleaning up filter medium (e.g. Sand) in upstream (reserved flow in filter):

pool

V :

pool

- pump - valve (to the filter) - valve (from the filter) - pool

rainlage of pool with pump:

- pump - valve - drain

- pump - valve (from the filter) - filters - valve (to the filter) - waste

Cleaning of filter medium (e.g. Sand) after backwash:

- pump - valve (to the filter) - filters - valve (from the filter) - waste

II EMPTY

Pump

Basin

Drain

To the Filter

From the filter

III BACK RINSE

Pump

Basin

Drain

To the Filter

From the filter

VRINSE

Pump

Basin

Drain

To the Filter

From the filter

Page 3

6 - way valve-type 1 1/2”, 2”, 3”

Connections: Thread or stick (all connectors open)

max. Operating pressure: ABS 1 1/2", 2": 3,5 bar ; GFK 1 1/2", 2": 6 bar; GFK 3": 5 bar

PRECISION - POWER - PROGRESS - PRODUCTION

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

Page 4

5. Cycle sequence: Starting position "filter" - equipment ON

- Start of the back rinsing cycle

- Control light "test key" for back rinsing cycle running, lights up

- Output heating COM-NO switches to Com-NC control.

- Adjusted time of potentiometer (deceleration time) runs off (cooling time for heat exchanger).

- Output pump COM-NO switches off

- Output serial connection switches from COM-NC to Com-NO

- Output ball valve switches from COM-NO to COM-NC

- Valve on back rinse

- Output back rinse/clear rinse COM-NC switches to COM-NO

- Pump deceleration time of approx. 20 seconds runs

- Output pump COM-NO closes

- Output back rinse COM-NC switches to COM-NO

- Adjusted time of potentiometer runs (back rinsing time)

- Output pump COM-NO switches off

- Output back rinses switches from COM-NO to COM-NC

- Output back rinse, clear rinse switches from COM-NO to COM-NC

- Valve on clear rinse

- Output back rinse/clear rinse switches from COM-NC to COM-NO

- pump deceleration time of approx. 20 seconds runs

- Output pump COM-NO closes

- Adjusted time of potentiometer runs (clear rinse)

- Output pump COM-NO switches off

- Output back rinse/clear rinse switches from COM-NO to COM-NC

- Valve on filter

- Output serial connection COM-NO switches to COM-NC

- Output ball valve switches from COM-NC to COM NC

- Pump deceleration time of approx. 20 seconds runs

- Output pump COM-NO closes

- Output heating switches from COM-NC to COM-NO

7

5

6

Transpose

Filter - back rinse

Back rinse

Transpose

Back rinse - clear rinse

Clear rinse

Transpose

Clear rinse - filters

Cycle period

approx. 45 sec.

25 sec. - 11 min.

approx. 35 sec.

20 sec. - 3 min.

approx. 25 sec.

Rinsing times and changing over time:

Deceleration time 25 sec. - 23 min.

approx. 3 - 40 min.

PRECISION - POWER - PROGRESS - PRODUCTION

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

Page 5

9. Function:

Operating this key switches off the equipment, regardless of the position

of the valve.

Operating this key switches on the equipment, the valve takes on

basic position - position "Filter" - (yellow control light shines)

TEST KEY

Operating this key triggers the back rinsing cycle for the length of a back rinse procedure (green

control light shines)

EMPTY

Operating this key sets the valve to position "Empty" (red control light shines)

OFF

ON

1

2

3

4

This product corresponds to the following EEC - Guidelines:

l Electromagnetic compatibility 89/336/EEC

l Low voltage directive 73/23/ EEC

214

3

7. Adjusting the digital clock:

- attach equipment to line voltage

- with pointed article [ Res. ] - press key

- clock - keep key pressed and with Day - key select desired day

- clock - keep key pressed and with h+ - key select desired hour

- clock - keep key pressed and with m+ - key select desired minute

8. Program back rinsing time:

- Prog. - press key

- Manual - key ¤press ‘ON’ - on display appears “ON-Time programmming”

- with Day - key select day (E)

- with h+ - key select hour

- with m+ - key select minute

(- with Manual - key programming time can be switched between ON and OFF)

- Prog. - press key

- Manual - key ¡ press ‘OFF’ - on display appears “OFF-Time programming”

- with Day - key select day (E)

- with h+ - key select hour

- with m+ - key select minute

- Prog. - --> press key program

Terminated

NOTE:

Trigger back rinsing program for max. 1 minute!

e.g.: ON ¤8:00

OFF ¡8:01

Programmable 20 times/week!

When programming several back rinsing times

--> repeat aforementioned steps.

PRECISION - POWER - PROGRESS - PRODUCTION

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

Page 6

10. Adjust duration of back rinsing

The back rinsing time is adjusted with the potentiometer (rotary button) .

- turn potentiometer

clockwise direction for a lengthy period

against clockwise direction short period

- triggering a back rinsing procedure

with the test key

- checking the back rinsing time

- repeat the sequence, until the

desired time is set.

10.1 Adjusting the clear rinsing duration

The clear rinsing time is adjusted with the potentiometer (rotary button) .

- turn potentiometer

clockwise direction for a lengthy period

against clockwise direction short period

- trigging a back rinsing procedure with the test key

- checking the clear rinsing time

- repeat the sequence, until the desired time is adjusted.

10.2 Adjusting the deceleration time

The deceleration time can be stopped with the potentiometer (rotary button) .

- turn the potentiometer

clockwisedirection clockwisedirection

against clockwise direction short period

- trigger a back rinsing procedure with the test key.

check the deceleration time

- repeat the sequence, until the desired time is adjusted.

6

5

7

PRECISION - POWER - PROGRESS - PRODUCTION

8

5

6

7

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

Page 7

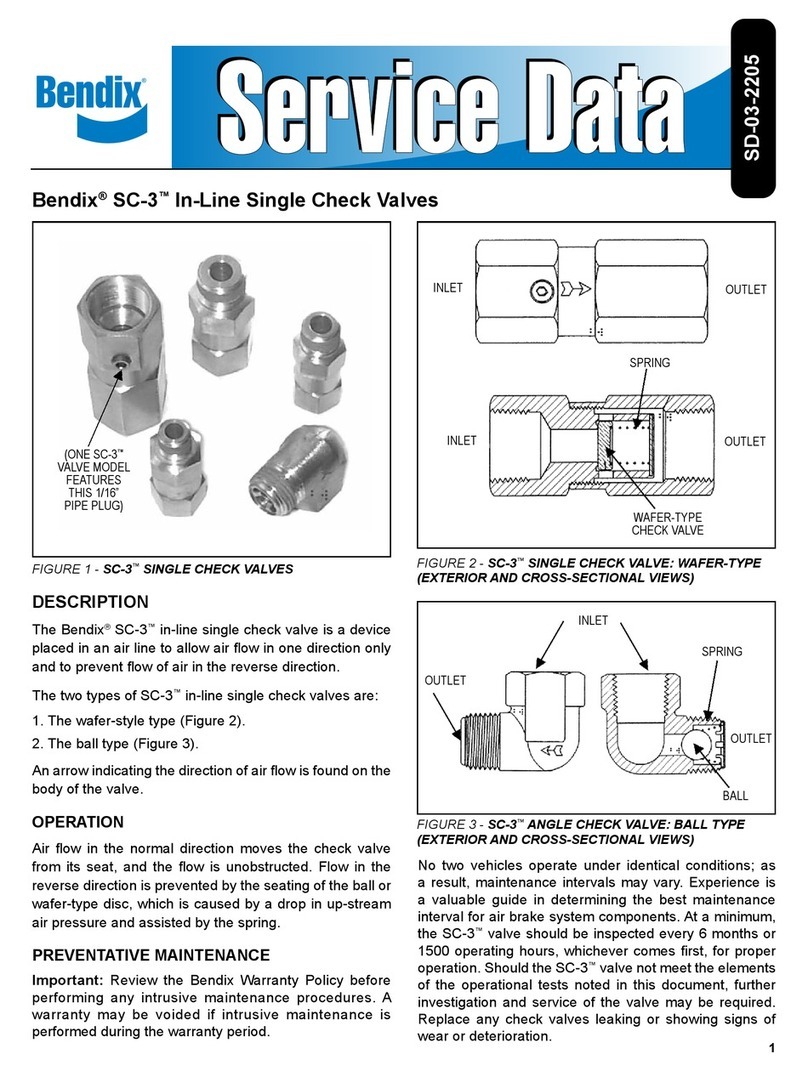

11. Electrical connections

a) Supply voltage connection:

b) Connector for dry operation protection (float switch):

The clamps [ 9 ] and [ 10 ] are connected. If this

connection is interrupted, the pump is switched off.

c) Pump connection:

Zero potential: I max. 8 A

Switches to the positions filter, back rinse, clear rinse

and empty approx. 30 sec. later.

d) Connection for ball valve:

Zero potential: I max. 8 A

In position filter G --> 6 is connected through .

G --> 2 connected through, during entire

back rinsing cycle and position emptying.

e) Connection for 2. Back rinsing pump:

Zero potential: I max 4 A

In position back rinse 28 --> 27 is connected through.

Switches only if pump is [ 13, 14 ] switched on.

f) Connection for signal on position back rinse and clear rinse:

Zero potential: I max 4 A

25 --> 24 connected through in position back rinse and clear

rinse.

Switches independently of the pump to position back rinse

and clear rinse.

24 VAC, 50/60 Hz.

L1 N

910

13 14

NO COM

6G2

NO COM NC

NO COM NC

NO COM NC

27 28 29

24 25 26

PRECISION - POWER - PROGRESS - PRODUCTION

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

Page 8

g) connection for signal for heating/heat exchanger:

Zero potential: I max. 4 A

After triggering a back rinsing cycle 22 becomes --> 23

durchgeschaltet.

Filter pump remains for the duration of the adjusted deceleration time

(rotary button ) switched on. Afterwards the pump switches off

(Heat exchanger cools down).

h) connection for signal for serial connection:

Zero potential: I max. 4 A.

During the entire cycle 19 is connected through -->18.

Connecting several valves:

i) Push button switch input:

Trigger cycle EXTERNAL: Floating

Connection possibilities (SPS, push button switch...)

push button switch cycle strarts about 40 - 50 seconds later

(to compensate pressure peaks).

j) Trigger cycle EXTERNAL:

Zero potential: Note: trigger only short pulse.

(SPS, ...)

(Pressure switch)

NO COM NC

NO COM NC

21 22 23

18 19 20

-

G

18

20

+

CH2

CH1

19

20

1918

Valve 3

+

GCH2

CH1

-

Valve 2

20

1918

Valve 1

Serial connection for several valves

Technical data:

Voltage: Protective system:

Frequency: clock: approx. 1 month accu backup

max. Power consumption: approx. 4 Watts/12 Watts 1 1/2 “, 2"- approx. 4 Watts/20 Watts 3 "

24 VAC IP 54

50/60 Hz

II

+Ch1

7

PRECISION - POWER - PROGRESS - PRODUCTION

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

Page 9

PRECISION - POWER - PROGRESS - PRODUCTION

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

schaltung

Circuit diagram for

1,5" / 2" / 3"

1,5" / 2" = 500mA T

Control-Fuse

Steuersicherung

Motor2 nur

Motor 2

24V~50-60Hz

supply

Electricity

spannung

Digi-Uhr 2Kanal

Kanal1= Backwash

Kanal1=Rückspülzyklus

Kanal2=Filterpumpe

Kanal2=Filterpumpe

CH2=

CH2=

CH1=

CH1=

Pump

max.8A

Serien-

bei Ventil 3"

max.8A

Relais-

24V~

S

G

™

SS-5GLD1

S

G

™

SS-5GLD1

12VDC Clock

Clock

Ventil-

24V~ 3VA

Parkstellung

™

MotorKondensator

Anschlußplan für

MIL 72E Analog-12VCD

4

CH1

weiß

AKKUAKKU

+1h

H1

h+

CH2

OFF

Res.

H2

m+

E-6000/F E-3000/F

MIL 72E Analog

S14K35

14:28

OFF

Day

CH2

CH1CH1

MO

CH1

Clock

Uhr

pot.frei

Output

Kugelhahn

Ausgang-

Kugelhahn

Ballvalve

Relais-

Pump

Output

pot.frei

Pumpe

Ausgang-

13 14

Pumpe

Switch

Level

Schalter

Niveau-

9

10

Digital Uhr/

E-Prom

™

SS-5GLD1

Versorgungs-

S

G

S

G

SS-5GLD1

MotorKondensator

3" = 1,6A T

E-Type - 24VAC

-

2

grau

+

1

braun

3

grün

G

C3

C2

27

RÜCKSPÜLEN

28

BACKWASH

RÜCKSPÜL

ZEIT

ZEIT

KLARSPÜL

R.4

29

VERZÖG.-ZEIT

DELAY TIME

-

switch

pump

RINSE

BACKWASH

+

TIME

pressure

switch

TIME

3min.

25sec-

-

Backwash

Rückspülen

+

Entleeren

G

CH2

Drain

CH1

DELAY

VERZÖGERUNG

Rinse

Klarspülen

24 25 26

RINSE

BACKWASH

KLARSPÜLEN

RÜCKSPÜLEN

R.3

21

Filtern

Filter

22 23

R.5

Serie

SEQUENCING

R.6

RINSE

L1

N

- +

23min

25sec-

- +

11min.

25sec-

Praher

R

Motor1

sw

gr

gn

6

G

2

18 19

20

LEDLED

5

4

2

sw

gr

gn

NETZ

LP004.0370.01.A

DELAY

3

BACKWASH

BACKWASH

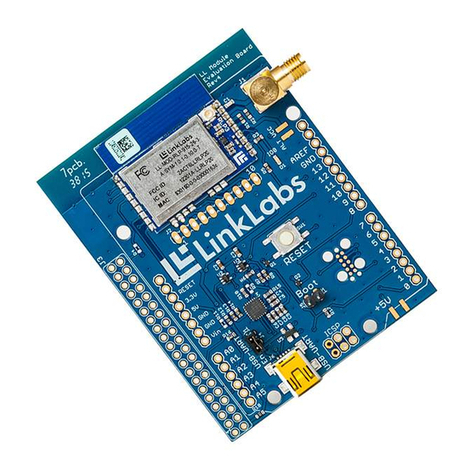

Page 10

© by PRAHER, Austria

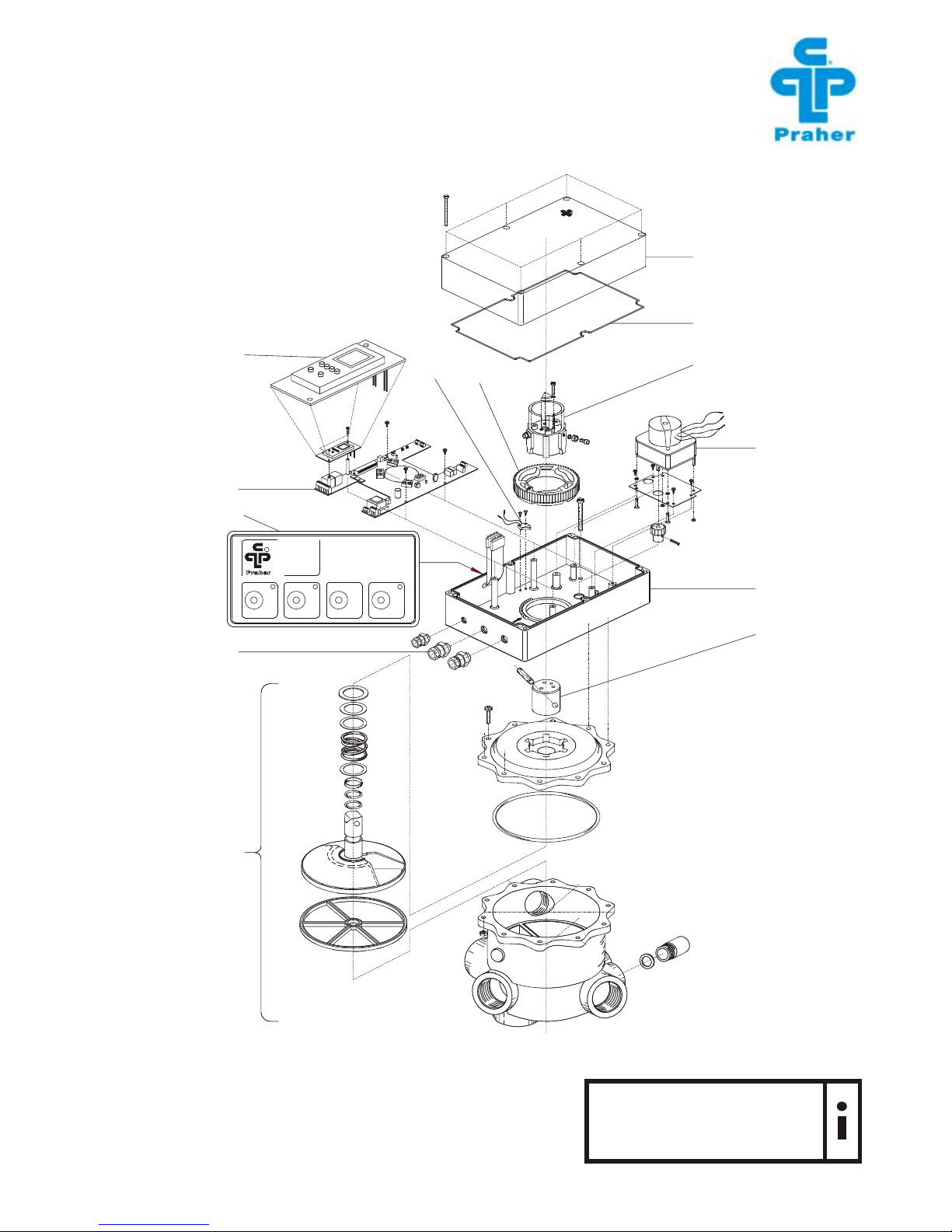

13

12

1

2

3

5

8

10

4

6

7

9

11

1. Deckel

2. Dichtung (Moosgummi)

3. Steuerkopf

4. Kurvenzahnrad

5. Motor

6. Steuerplatine

7. Pumpenendschalter

8. Automatikunterteil

9. Anbauverschraubung

10. Kupplung

11. Ventil

12. Rückspüluhr

13. Folientastatur

QUALITY

INNOVATION

ENTLEEREN

DRAIN

AUS

OFF

EIN

ON

PRÜFTASTE

TESTBUTTON

SERVICE

RR

R

SUPERSTAR

1 Cover

2 Seal (foam rubber)

3 Control switch

4 Curve gear wheel

5 Motor

6 Control board

7 Pump limit switch

8 Automatic lower part

9 Mounted screw connection

10 Clutch

11 Valve

12 Back rinsing clock

13 Film keyboard

Operating instructions

SUPERSTAR E-3000 / F2

for 1 1/2", 2"and 3" 24 VAC

PRAHER VALVES

Tel.: ++ 43 / ( 0 ) 72 62 / 61 178 - 0*

Fax: ++ 43 / ( 0 ) 72 62 / 61 203

austria@praher.com ; www.praher.com

Table of contents

Other praher Control Unit manuals

Popular Control Unit manuals by other brands

LOVATO ELECTRIC

LOVATO ELECTRIC EXP10 00 quick start guide

syscomtec

syscomtec SCT-IPKVM-CX user manual

Emerson

Emerson SAPAG 7700 Installation, Maintenance and Adjustment Instruction

TECO

TECO JN5-CM-PDP user manual

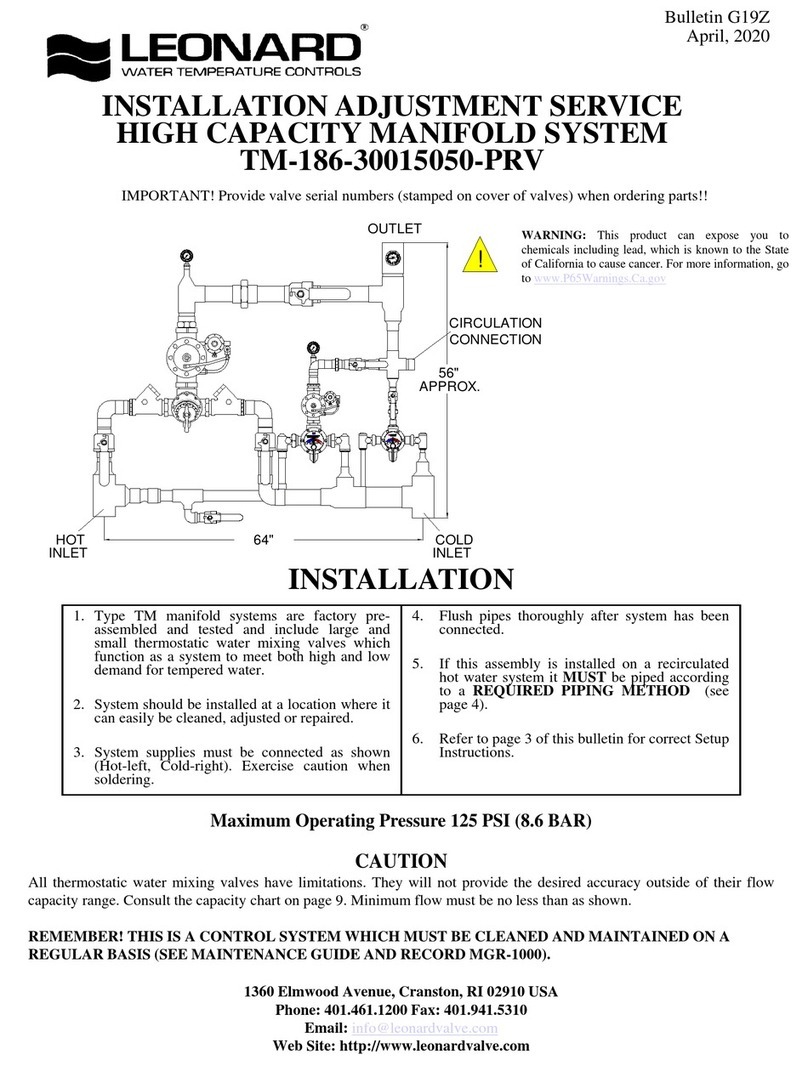

Leonard

Leonard TM-186-30015050-PRV INSTALLATION ADJUSTMENT SERVICE

Klafs

Klafs 16028 operating instructions