Table of contents

Preface..............................................................................................2

Table of contents.............................................................................3

Layout characteristics ....................................................................5

General layout characteristics......................................................5

Safety instruction attributes..........................................................6

Basic safety instructions ......................................................7

Proper, intended use....................................................................7

Avoid the risk of fatal injuries........................................................8

Avoid explosion hazards ..............................................................8

Avoid risk of injury ........................................................................8

Avoid damage to the pressure equipment ...................................8

Description.......................................................................................9

Equipment overview and scope of supply....................................9

Function......................................................................................11

Product features.........................................................................11

Side and direction specifications................................................11

Accessories................................................................................12

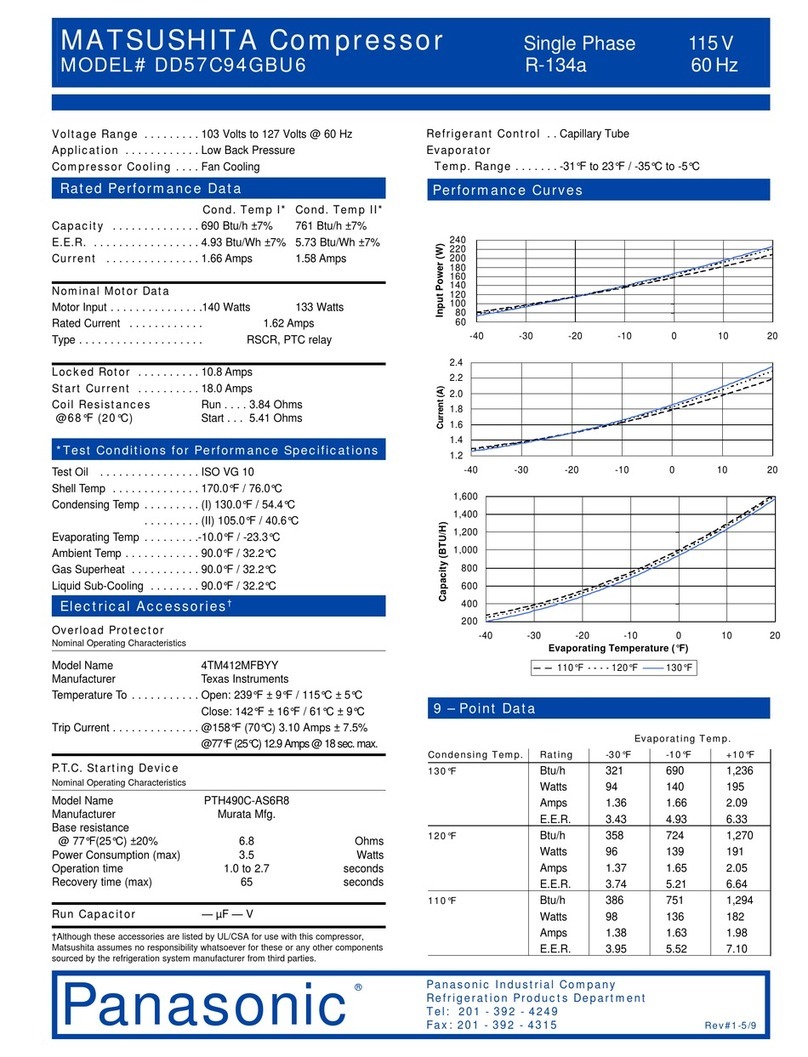

Information on the rating plate....................................................12

Preparing the pressure equipment..............................................13

Unpacking the pressure equipment............................................13

Check condition..........................................................................14

Connecting pressure equipment to the compressed air supply.15

Using the pressure equipment.....................................................19

After operation...............................................................................23

Disconnect the compressed air supply ......................................23

Transporting and storing the pressure equipment....................25

Packing.......................................................................................25

Storage.......................................................................................26