We, the sole importer into the UK, declare that the product listed here is in conformity with the following standards and directives. The

construction file for this product is held by the Manufacturer and may be inspected, by a national authority, upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Professional Tools.

HYDRAULIC COIL SPRING COMPRESSOR

Model: VS7011.V3

98/37/EC Machinery Directive

93/68/EEC Marking Directive

11th January 2006

Declaration of Conformity

Signed by

Tim Thompson

INSTRUCTIONS FOR:

HYDRAULIC COIL SPRING COMPRESSOR

MODEL NO: VS7011.V3

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions and properly maintained, give you years

of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

2. INTRODUCTION & SPECIFICATION

2.1. Introduction. The VS7011.V3 is supplied with a 1 ton hydraulic hand pump unit that

powers the ram and yoke assembly. Up to 50% quicker than using other ratchet driven spring

compressors. Equipped with 2 pairs of spring yokes with plasticised covers to prevent slippage

and damage to springs.

VS7011.V3 - 1 - 110106 VS7011.V3 - 1 - 110106

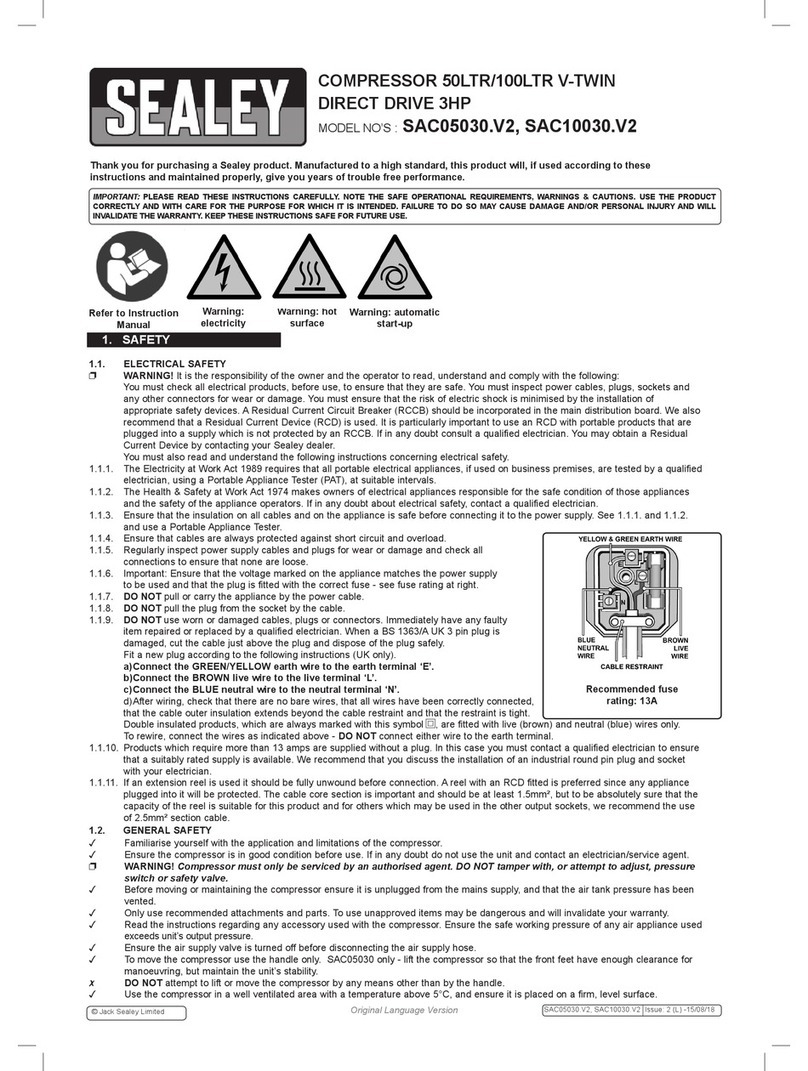

!WARNING! Measure the outer diameter of the spring to be

compressed and select the correct set of jaws.

"

DANGER! Do not compress the spring to an extent

where the coil windings touch. (See fig.2-A)

#Ensure that the centre line of the spring remains

parallel to the compressor body at all times. This

applies to both straight springs and conical springs. The

spring should not be touching the piston or body of the

compressor. (See fig.2-B)

#Secure the strut with a clamp, vice or other adequate

holding device.

#Before use check compressor assembly for signs of

damage and particularly ensure jaws are in good

condition and securely mounted.

4.1. To Compress a Strut Removed From a Vehicle.

4.1.1. Screw the selected jaws onto the ram body and the

piston respectively. Ensure that the recessed sides of

the jaws are facing each other.

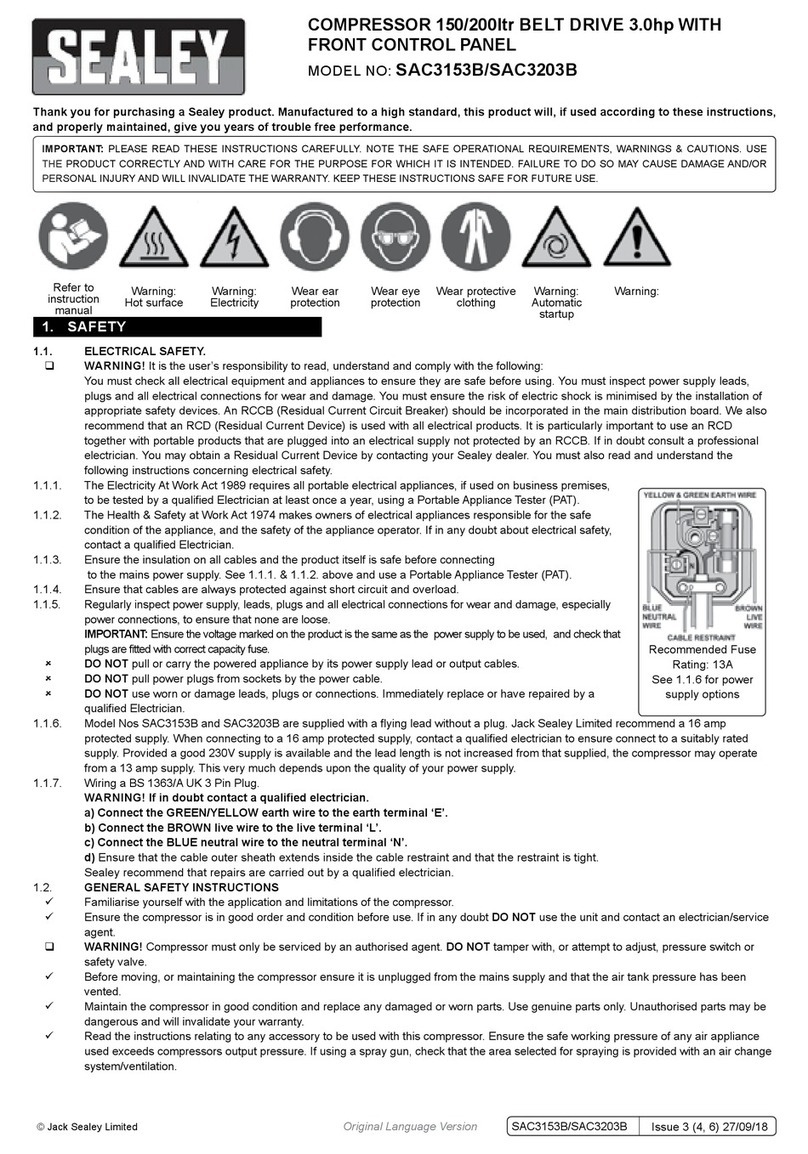

4.1.2. Operate the pump handle (see fig.1) to drive the jaws

together to the approximate length of the spring and to

allow compression of as many windings as possible.

4.1.3. Place the spring strut compressor onto the spring,

ensuring the spring seats correctly into both the upper

and the lower jaws and cannot slide out during

compression. (See fig.2-D & E)

4.1.4. Ensure that the centre lines of the spring and

compressor body are parallel. (See fig.2).

4.1.5. Operate the pump handle (see fig.1) and compress the

spring until the upper support bearing is free and the

spring will rotate.

4.2. To Decompress a Strut Removed From a Vehicle.

4.2.1. To decompress the spring, reverse the compressing

procedure.

5.1. Before each use check the compressor to ensure it is

not damaged or worn. If suspect do not use the unit, but contact your local Sealey

Dealer who will be able to advise you.

5.2. After use, release the hydraulic pressure and grease the piston rod using LM grease.

5.3. Keep the compressor clean, and when not in use store in a safe, dry, childproof location.

5. MAINTENANCE

4. OPERATION Fig.2.

3. ASSEMBLY

3.1. Assembly. Connect the hose to the ram unit as shown in fig.1. Ensure the hose

connectors are fully done up but do not over tighten. See fig.1 for valve operation.

3.2. Ensure the jaws are fully screwed down.

3.3. Screw locking ring against bottom jaw to prevent jaw rotating.

2.2. Specification

Capacity ................................................1000kg

Maximum working length ...................... 240mm

Ram travel ............................................240mm

Weight ....................................................19.5kg

Small jaw capacity ........Max spring OD 122mm

Small jaw capacity ............Min spring ID 80mm

Big jaw capacity ............Max spring OD 165mm

Big jaw capacity ..............Min spring ID 110mm

!WARNING! Wear approved safety eye protection (standard spectacles are not adequate).

!WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations

are adhered to when using this equipment.

$DO NOT allow untrained persons to use the spring compressor.

$DO NOT operate the spring compressor when you are tired or under the influence of

alcohol, drugs or intoxicating medication.

$DO NOT use the spring compressor for a task it is not designed to perform.

$DO NOT operate spring compressor if parts are damaged or missing as this may cause

failure and/or personal injury.

#Maintain the spring compressor in good condition. Replace or repair damaged parts. Use genuine

parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

#Remove ill fitting clothes. Remove ties, watches, rings, other loose jewellery. Contain and/or tie

back long hair.

#Familiarise yourself with the applications, limitations and potential

hazards of the spring compressor.

#Keep the work area clean, uncluttered and ensure there is

adequate lighting.

#Keep hands and body clear of the spring when operating

the spring compressor.

#Maintain correct balance and footing. Ensure the floor is not

slippery and wear non-slip shoes.

#Keep the spring compressor clean for best and safest

performance.

#When not in use release pressure from the spring compressor.

#Wear appropriate protective clothing.

#When not in use clean and store the spring compressor in a

safe, dry, childproof location.

#Ensure that the locking ring is installed and is firmly secured

against the lower

Fig.1.

01284 757500

01284 703534

E-mail:

sales@sealey.co.uk

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

Web address: www.sealey.co.uk

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our catalogue and latest promotions call us on 01284 757525 and leave your full name, address and postcode.