12

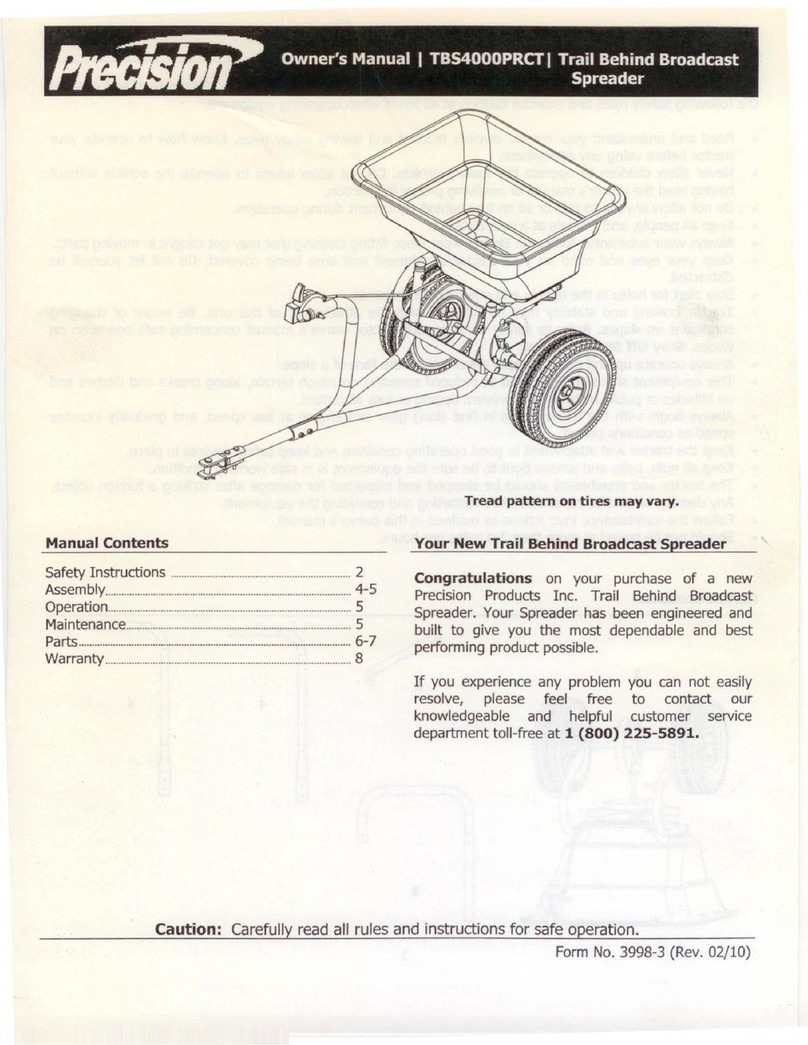

Manufacture’s Limited Warranty for Pull Behind Accessories

The limited warranty set forth below is given by Precision

Products Incorporated with respect to new merchandise

purchased and used in the United States, its possessions

and territories.

Precision Products Incorporated warranties the product(s)

listed against defects in material and workmanship, and

will at our option, repair or replace, free of charge, any

part found to be defective in materials or

workmanship. This limited warranty shall only apply if

this product has been assembled, operated, and

maintained in accordance with the owner’s manual

furnished with the product, and has not been subject to

misuse, abuse, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water, or damage

because of other peril or natural disaster.

Normal wear parts or components thereof are subject to

separate terms as follows: All normal wear parts or

component failures will be covered on the product for a

period of one year. Parts found to be defective within the

warranty period will be replaced at our expense. Our

obligation under this warranty is expressly limited to the

replacement or repair, at our option, of parts found to be

defective in material and workmanship.

Contacting Service

Warranty parts replacements are available, ONLY WITH

PROOF OF PURCHASE, through our Customer Service

Department.

Call 1 (800) 225-5891

This limited warranty does not provide coverage in the

following cases:

1. Routine maintenance items such as lubricants and

filters.

2. Normal deterioration of the exterior finish due to use

or exposure.

3. Transportation and/or labor charges.

No implied warranty, including any implied warrant of

Merchantability of fitness for a particular purpose, applies

after the applicable period of express written warranty

above as to the part as identified below. No other

expressed warranty, whether written or oral, except as

mention above, given by any person or entity, including a

dealer or retailer, with respect to any product, shall bind

Precision Products, Inc. during the period of the

warranty, the exclusive remedy is repair of replacement

of the product as set forth above. The provisions as set

forth in this warranty provide the sole and exclusive

remedy arising from the purchase.

Precision Products, Inc. will not be liable for incidental or

consequential loss or damage including, without

limitation, expenses incurred for substitute or

replacement lawn care services, or for rental expenses to

temporarily replace a warranted product.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, or limitation on how

long an implied warranty lasts, so the above exclusions or

limitations may not apply to you.

During the warranty period, the exclusive remedy is

replacement of the part. In no event shall recovery of

any kind be greater that the amount of the purchase

price of the product sold. Alteration of safety features of

the product shall void this warranty. You assume the risk

and liability for loss, damage, or injury to you and your

property and/or to others and their property arising out

of the misuse or inability to use this product.

This limited warranty shall not extend to anyone other

than the original purchaser or to the person for whom it

was purchased as a gift.

Local Law to this Warranty

This limited warranty gives you specific legal rights, and

you may also have other rights which vary from state to

state.

Warranty Period

The warranty period stated below begins with the Proof

of Purchase. Without the proof of purchase, the

warranty period begins from the date of manufacture,

determined by the serial number’s manufacturing date.

Product Warranty Period

The warranty period for this product is as follows: All

parts are covered for 1 year.