1017459 Rev. A 8©2016 Spyker Spreaders/A Brinly-Hardy Co.

3. SPEED CONTROL LEVER:

The speed control lever limits the forward speed of

the unit by limiting the travel of the forward control

lever. “Application speed” sets the unit’s ground

speed to about 3 mph. Use a slower speed while

learning how to use and control the unit.

4. GROUND SPEED CONTROL LEVERS:

Located on the right side of the control panel is the

forward ground speed control lever. The left lever

is for reverse. These two levers control the

maximum output of the hydrostatic transaxle and

thus the ground speed of the spreader independent

of the engine speed. Pulling the right lever rearward

increases the forward speed and pulling the left

lever rearward Increases the reverse speed. Do

not move both levers in unison, only pull one at a

time. When the levers are moved in unison they

will place excessive pressure on the cables, which

could cause them to break. To start the engine,

ensure both levers are in their neutral position.

5. HOPPER SHUT-OFF LEVER:

Open and close the hopper gate by pushing the

lever forward to open the gate, and pulling the lever

rearward to close the gate.

6. ACCUWAY SPREAD CALIBRATION LEVER:

To adjust spread pattern for uniform distribution,

adjust the Accuway. See Accuway Spreader

Pattern Adjustment Section for instructions.

7. SIDE DEFLECTOR

Raise and lower the side deector by pushing the

lever forward to lower the deector, and pulling the

lever rearward to raise the deector.

8. FREEWHEEL ROD:

A rod is located in the platform area. When the rod

is pulled out, the spreader can be manually pushed

forward or pulled in reverse. Push rod in to engage

transmission.

9. PARKING BRAKE:

The brake is activated by the lever in the foot

platform area. Press down on the lever to engage

the park brake, and lift up the lever to release. (See

Figure 5).

Operating Instructions

A. CONTROLS

1. ENGINE ON/OFF SWITCH:

The ON/OFF switch is located on the far left side of

the control panel. To start the engine, set the switch

to the “ON” Position. To turn off, throttle down the

engine, then set the switch to the “OFF” Position.

2. FUEL SHUTOFF VALVE:

The fuel shutoff valve is located between the

carburetor and the fuel tank on the LH side of the

engine. The handle turns 90 degrees to open or

close. When the handle is in the horizontal position,

it will open the ow of fuel to the engine. When it is

turned to a vertical position, it will shut off the fuel

ow to the engine. Anytime the spreader is being

trailered, or if the machine will not be in use for 30

minutes or more, close the fuel shutoff valve to

prevent ooding the engine.

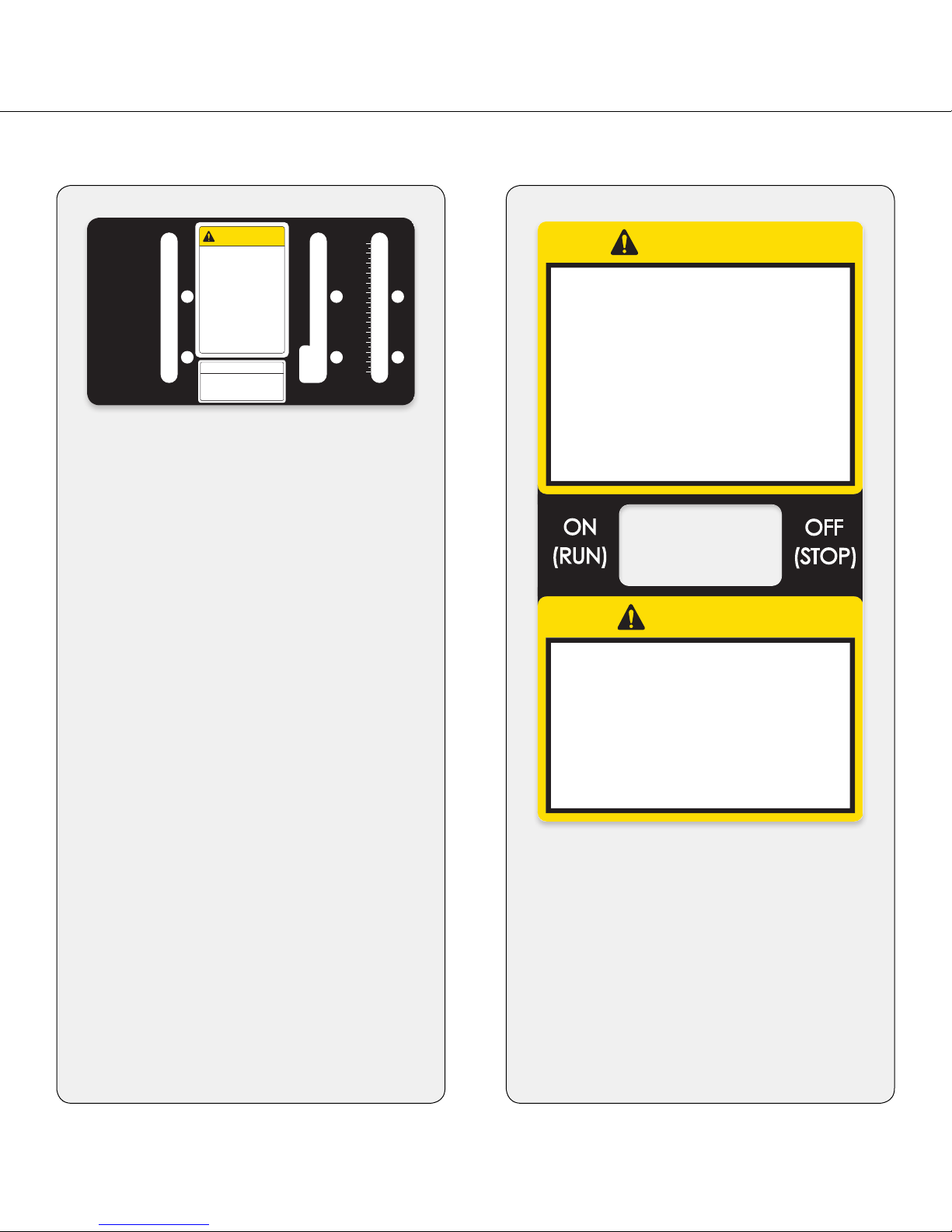

ACCUWAY

®

SPREAD CALIBRATION

OFF

ADJUSTMENT

OFF

SIDE

DEFLECTOR

DOWN

UP

HOPPER

SHUT-OFF

OPEN

CLOSED

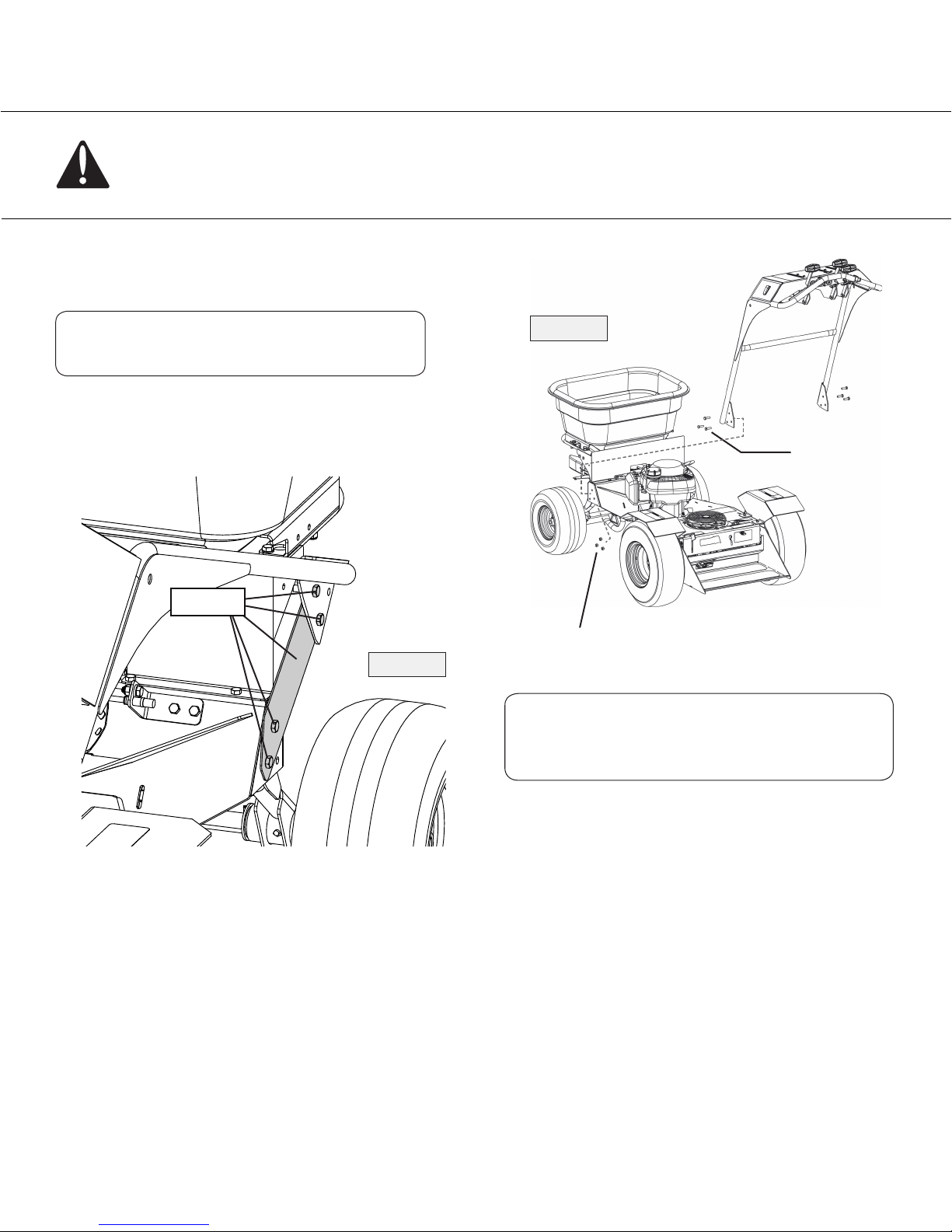

Serious bodily injury may

result from failure to follow

safe operator procedure.

•Read the operator’s manual before

operating this machine.

•Clear area of debris.

•Do not remove or disable shields, guards,

or safety devices.

•Always chock the wheel or engage the

parking brake when transporting the

machine or when parking on a grade.

•Stop engine, disconnect spark plug, set

parking brake before adjusting or servicing.

•Keep people and pets a safe distance away

from machine.

•Do not add fuel while engine is warm or

running.

•Use caution on slopes.

•Before leaving the operator’s position, wait

for all movement to stop.

•Do not allow operation of the machine by

untrained personel.

CAUTION

FOR FIRST-TIME OPERATORS

•START OFF IN A FLAT, OPEN AREA.

•KEEP BYSTANDERS AWAY

•SET THROTTLE AT A LOW SPEED.

•PRACTICE MANEUVERING,

(FORWARD, REVERSE, LEFT, RIGHT)

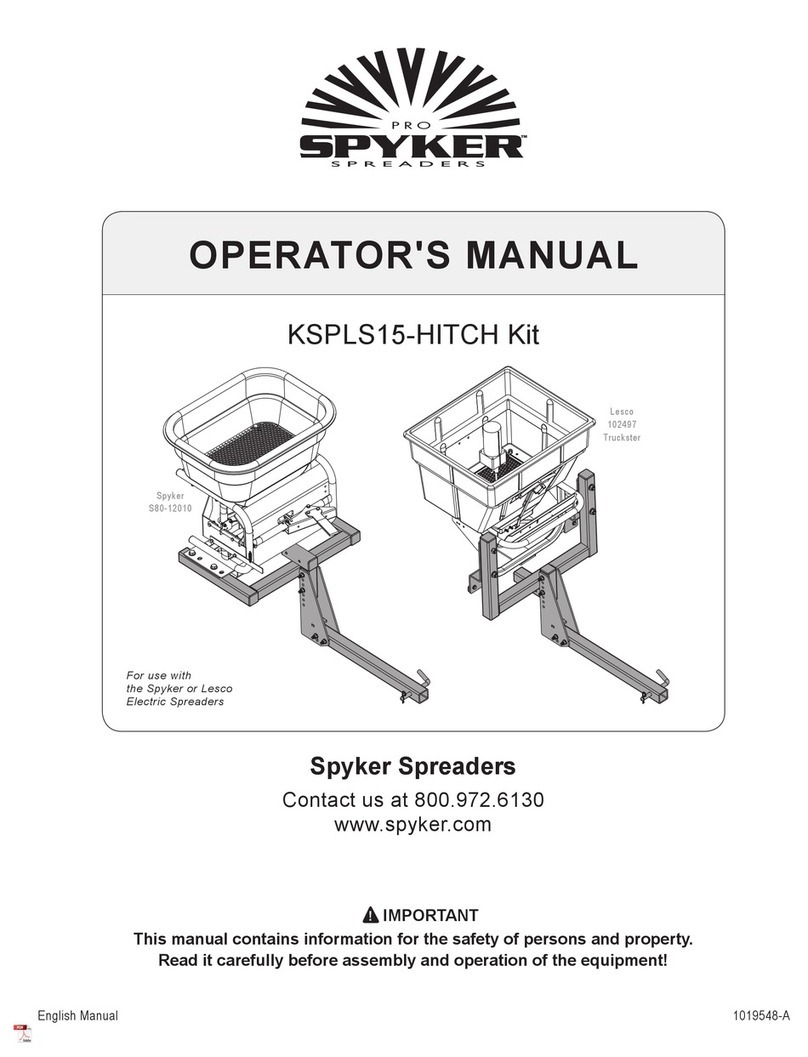

Reverse

Ground

Speed

Control

Speed

Control Lever

(Application

Transport)

Forward

Ground Speed

Control

Engine

ON/OFF

Switch

Hopper

Shut-Off

Side

Deector

Accuway

Spread

Calibration

Fig. 4