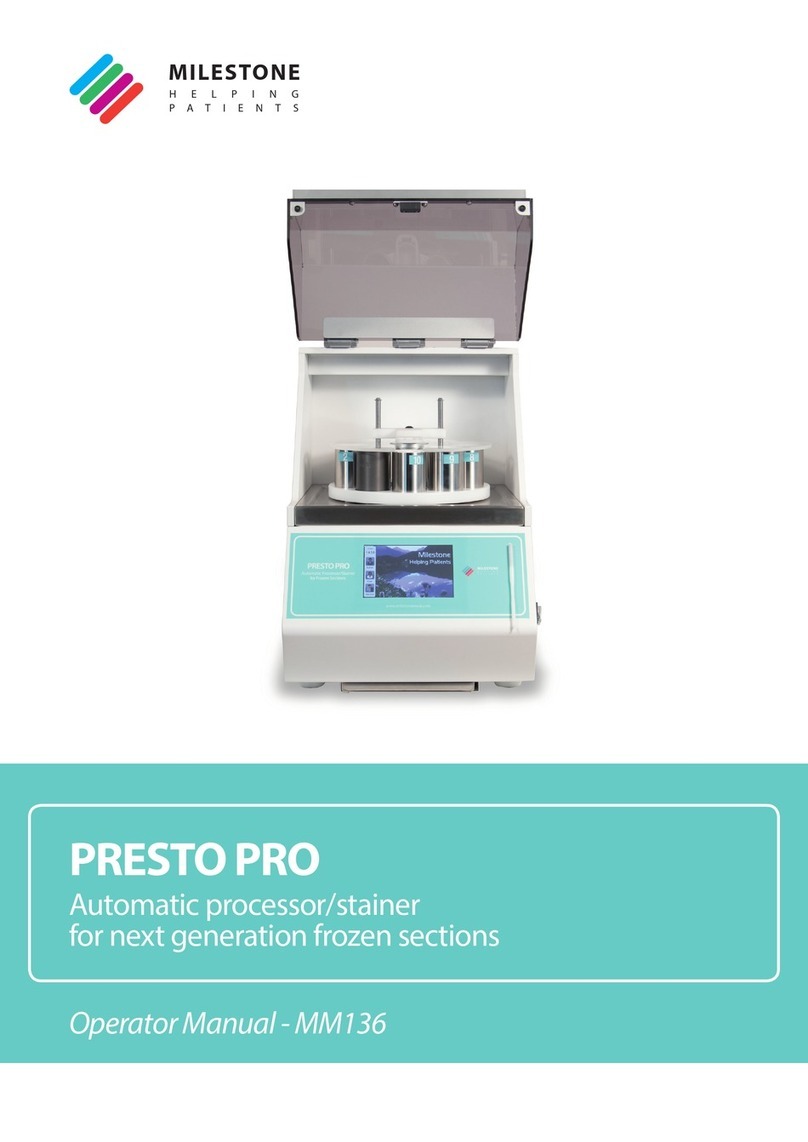

DecalMATE MM112-003 - Operator Manual

4

SUMMARY

SUMMARY ........................................................................................................................................................ 4

1.

INTRODUCTION........................................................................................................................................ 6

1.1.

Symbol used...................................................................................................................................... 6

1.2.

Designated uses................................................................................................................................ 7

1.3.

Technical specifications..................................................................................................................... 7

1.3.1.

Touch control terminal............................................................................................................... 8

1.4.

Transportation and storage conditions .............................................................................................. 8

1.5.

Warning information........................................................................................................................... 9

1.6.

Labelling explanation....................................................................................................................... 10

1.7.

Compatible reagents........................................................................................................................ 10

1.8.

Waste disposal of the equipment .................................................................................................... 11

1.9.

Waste disposal of reagents ............................................................................................................. 11

2.

INSTALLATION........................................................................................................................................ 12

2.1.

Space requirements......................................................................................................................... 13

2.2.

Unpacking and checking list............................................................................................................ 14

2.3.

Placement........................................................................................................................................ 16

2.3.1.

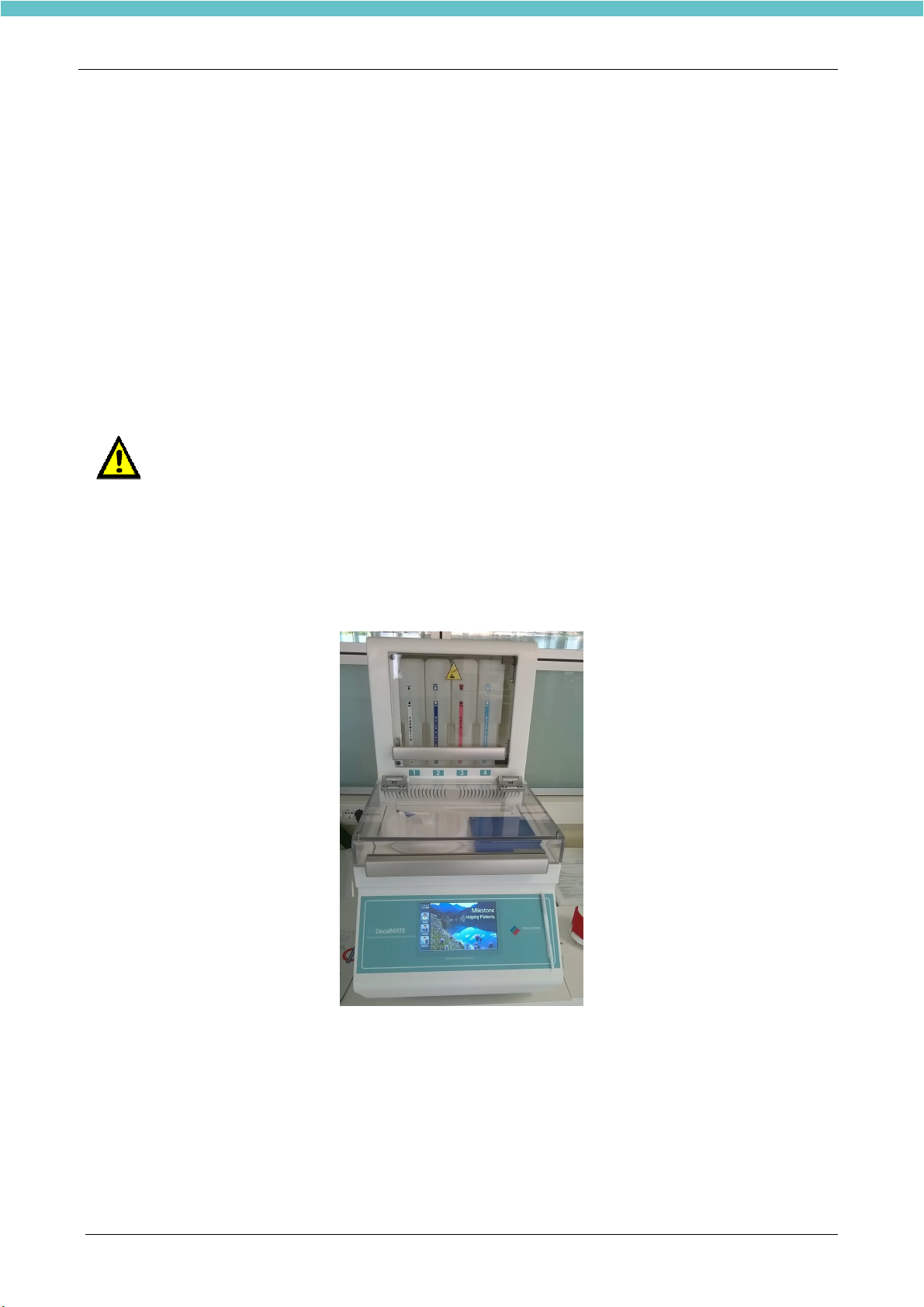

Unit overview ........................................................................................................................... 16

2.4.

Fume extraction system................................................................................................................... 17

2.5.

Power supply ................................................................................................................................... 18

2.6.

Electrical installation........................................................................................................................ 18

2.6.1.

Back side connection plate...................................................................................................... 18

2.6.2.

Main power supply connection ................................................................................................ 19

2.6.3.

Power supply connection (NO UPS mode) ............................................................................. 19

2.6.4.

Power supply connection (Local UPS mode).......................................................................... 20

2.7.

Remote alarm connection................................................................................................................ 21

2.8.

Reagents.......................................................................................................................................... 22

2.9.

Log in and log out............................................................................................................................ 22

2.9.1.

Create a new user ................................................................................................................... 23

2.10.

Set system date and time................................................................................................................ 24

2.11.

Tanks............................................................................................................................................... 25

2.11.1.

Labels ...................................................................................................................................... 25

2.12.

Load DecalMATE with reagents...................................................................................................... 26

2.12.1.

Load DecalMATE with reagents.............................................................................................. 26

2.13.

Most used programs........................................................................................................................ 29

2.14.

Owner settings................................................................................................................................. 31

3.

OPERATE WITH DecalMATE.................................................................................................................. 33

3.1.

Loading cassettes into the rack....................................................................................................... 33

3.2.

Run a program................................................................................................................................. 33

3.2.1.

Run a favourite program.......................................................................................................... 34

3.2.2.

Run a standard decalcification program.................................................................................. 38

3.2.3.

Checking Status of DECAL Rate............................................................................................. 43

3.2.4.

Interval check status................................................................................................................ 45

3.2.5.

Run a program using the STEP START function.................................................................... 45

3.2.6.

Run a DELAYED PROGRAM.................................................................................................. 45

3.3.

Retrieving saved processes............................................................................................................. 46

3.3.1.

How to delete a saved process................................................................................................ 48

3.4.

Modify a program............................................................................................................................. 49

4.

REAGENTS MANAGEMENT................................................................................................................... 51

4.1.

Reagents reuse life.......................................................................................................................... 51

4.1.1.

Reagents settings.................................................................................................................... 52

4.1.2.

Recommendations for reuse life.............................................................................................. 53

4.2.

Reagents replacement procedure ................................................................................................... 54

5.

SAFETY MODE PROCEDURE................................................................................................................ 57

5.1.

Power failure.................................................................................................................................... 57

5.2.

Loading time out management........................................................................................................ 59

6.

REPORTING ............................................................................................................................................ 60

6.1.

Export processing from the terminal to the USB key....................................................................... 60

6.2.

Install and operate with the LogViewer............................................................................................ 61