General

1. These guidance notes refer only to the installation of

Concrete surround CNSB Bypass Separators.

2. Manufactured to BS EN 858 Class 1 and Class 2.

3. These guidance notes cannot provide specic, site-

related installation instructions.

4. If in any doubt whatsoever about any aspect of the

installation please contact Conder Aqua Solutions on

0870 264 0004.

Pre-Installation Inspection

1. The lter pod in these tanks is held in place during

transportation by means of a Transit Brace. This is to

hold the lter pod in place during transportation and

ensure the separator is delivered to site in the same

A1 condition as it left our manufacturing facility. THIS

MUST BE REMOVED PRIOR TO INSTALLATION. Failure

to remove the brace may prevent access to the pod for

maintenance and WILL RENDER THE WARRANTY ON

THE TANK INVALID.

2. The timber transit brace consists of a vertical brace

holding the lter pod in place and a horizontal restraining

bar. To remove the brace, unscrew the horizontal

restraining bar and remove both pieces of timber.

3. Tanks should be subject to a visual inspection prior to

installation

4. Check the tank is the correct size and duty, see label on

tank

5. Any damage should be notied to the delivery driver and

to Conder Aqua Solutions on 0870 264 0004.

6. Do not attempt to carry out any unauthorised repairs, as

this will invalidate the warranty on the tank.

7. Check for:

- Fractures to the shell or ribs

- Delaminations

- Scratches or abrasions deeper than 1.5mm

- Stress cracks or star crazing

8. Check invert depth is correct and inlet and outlet pipe

orientations are correct

9. REMOVE TANK FROM PALLET

Service Specication

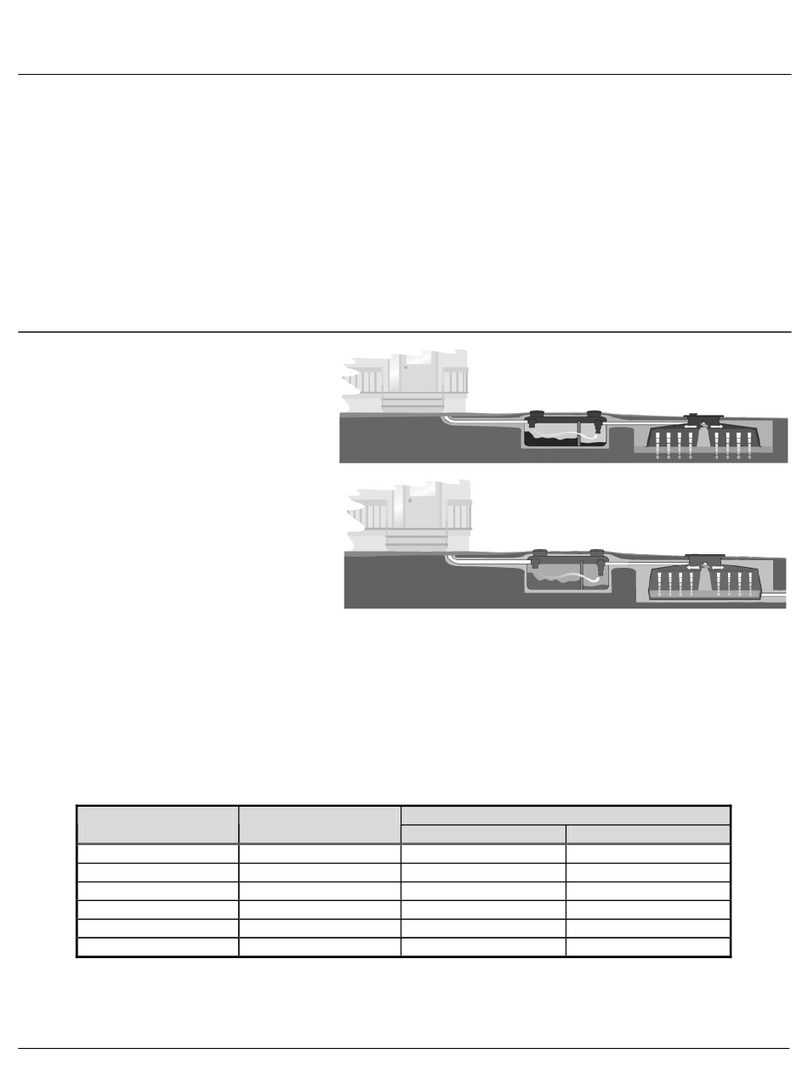

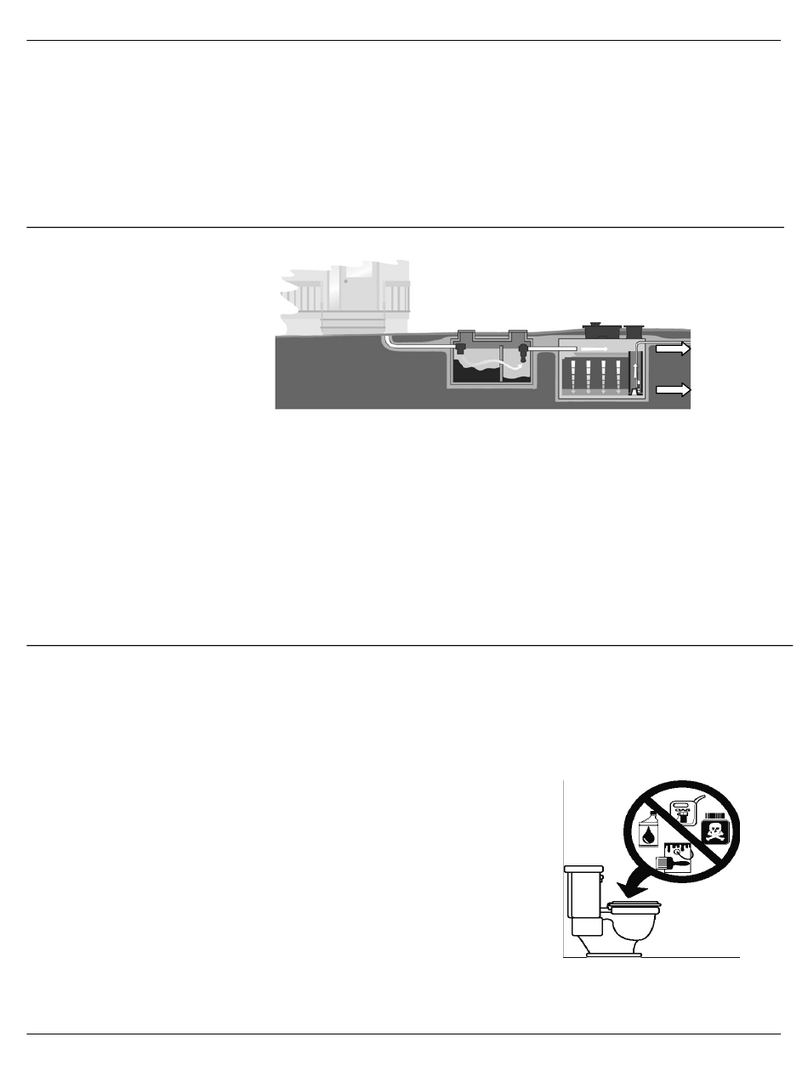

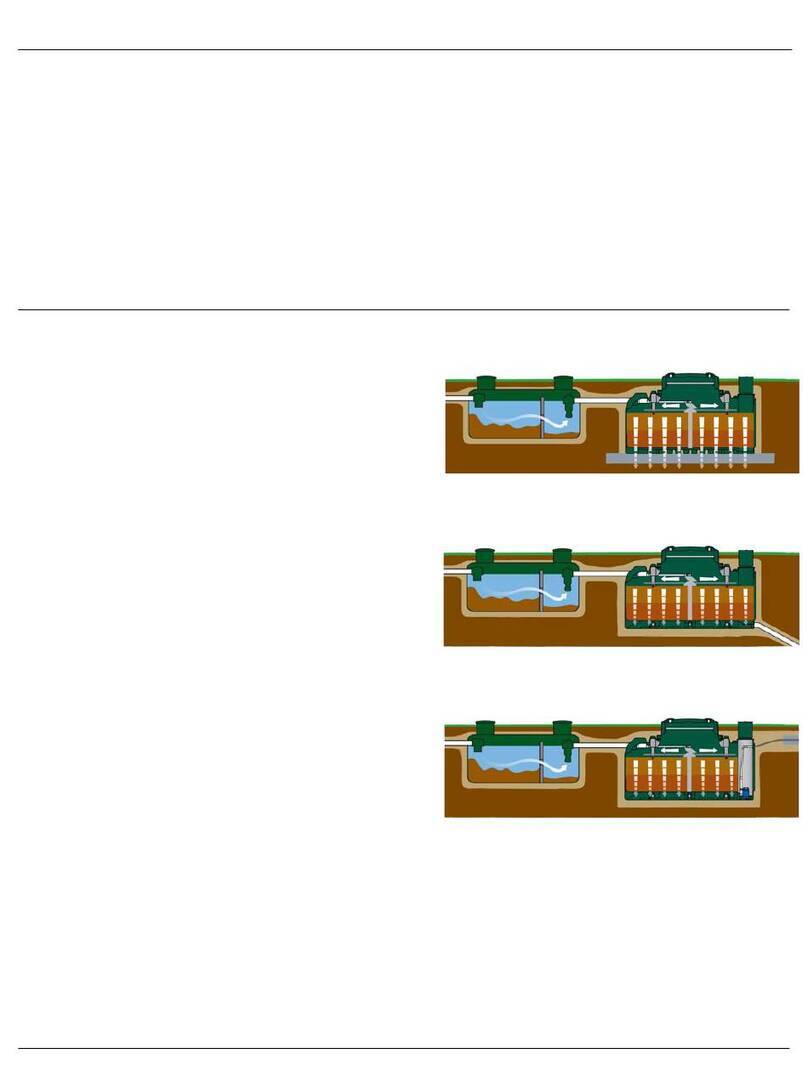

1. These tanks are designed to be installed below ground

and completely surrounded with concrete.

2. Generally, the depth from nished ground level to the

top crown of the main shell should be no more than 2

metres, this may vary dependent upon ground water

conditions. Deeper inverts may be accommodated on a

standard shell providing the water table level does not

exceed 2 metres above the top crown of the main shell.

For deeper burial with high water table conditions heavy

duty shells are available. Should you be in any doubt

regarding suitable shell application please call our sales

number 0870 2640004. If the tank is installed outside

these parameters it may suffer irreparable damage.

Concrete Specication

1. The specication for the concrete mix to surround the

tank may be taken from BS 5328: Part 1: 1991 (including

amendments), taking into account the site conditions and

application requirements.

2. For a typical non-structural application in non-

aggressive soils a Standard Mix ST4 with a 50mm slump

is generally suitable, but also permits the equivalent

Designated Mix GEN3 to be specied as an alternative.

If for non-typical applications, structural or other reasons

a higher than normal designation is required, the

purchaser of the fresh concrete can use table 6 in BS

5328: Part 2: 1991 (amendment 8759/October 1995) for

guidance.

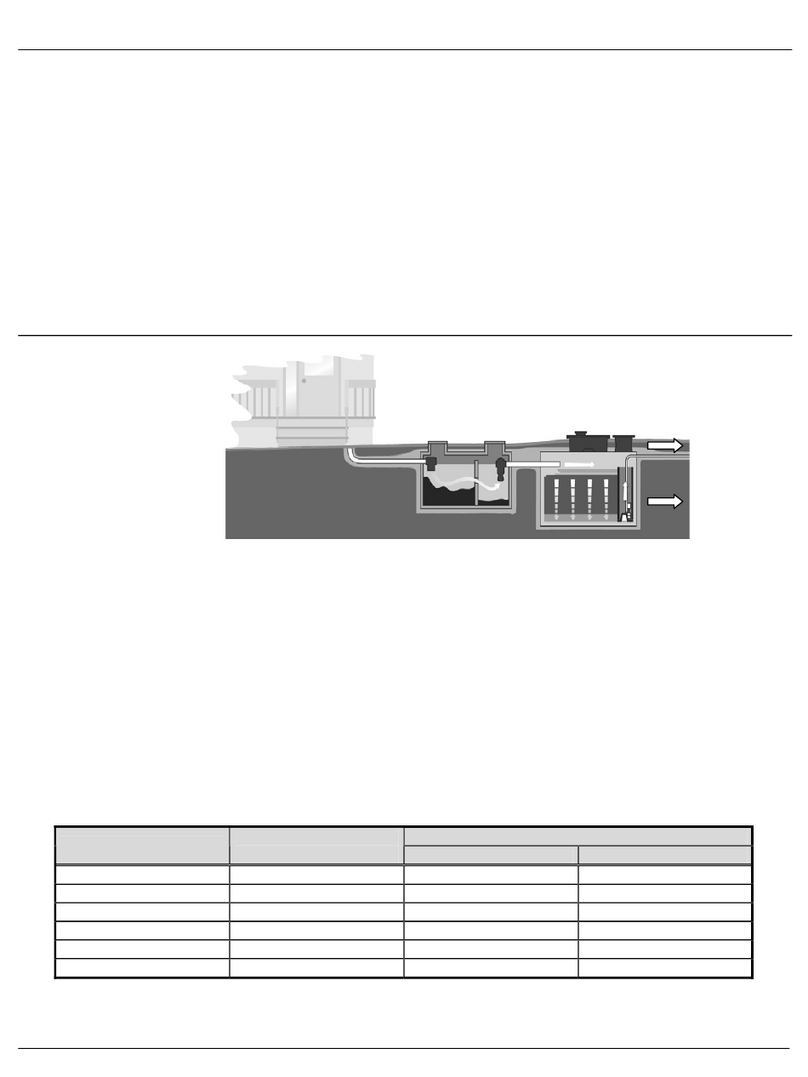

Lift height (Rate of Rise)

1. Determine the lift height (m), or rate of rise (m/h) for

the specic concrete type used, to ensure that a

design pressure (P max) of 15kN/m on the tank is not

exceeded.

Vibration

1. The design of the tank assumes minimal compaction of

the surrounding concrete. Where necessary, this may

be extended to include light internal vibration. Never

use deep revibration which will substantially increase the

pressure on the tank, possibly causing failure.

Conder CNSB Bypass Separator: Concrete Surround

Conder Installation Guidelines Ref: UTG9503

2 Whitehouse Way, South West Industrial Estate, Peterlee, Co Durham, SR8 2RA UNITED KINGDOM.

+44 (0) 8702 640004 Email: sales@conderproducts.com www.conderproducts.com

THE PARTNER OF CHOICE

Page 1

Revision No. 4