Premier Tech Aqua 5/20 Ecoflo®Polyethylene –Installation Guide Ontario

Edition: 2020-06-23

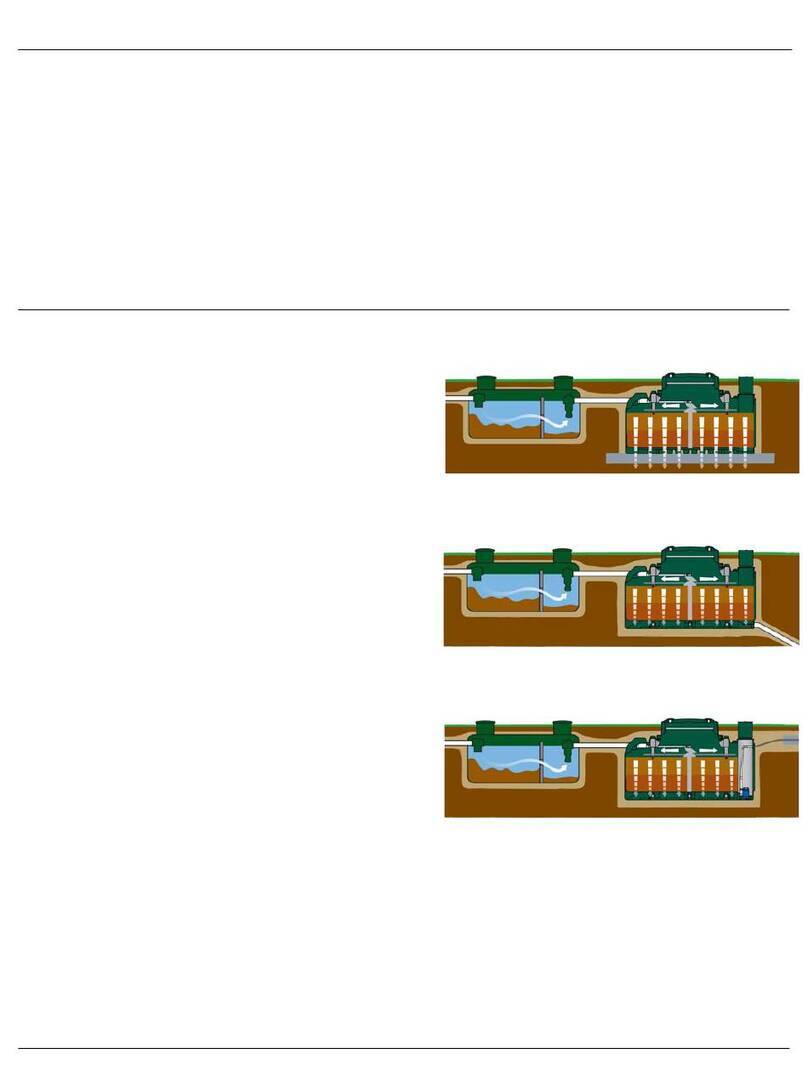

3.3 Installation conditions

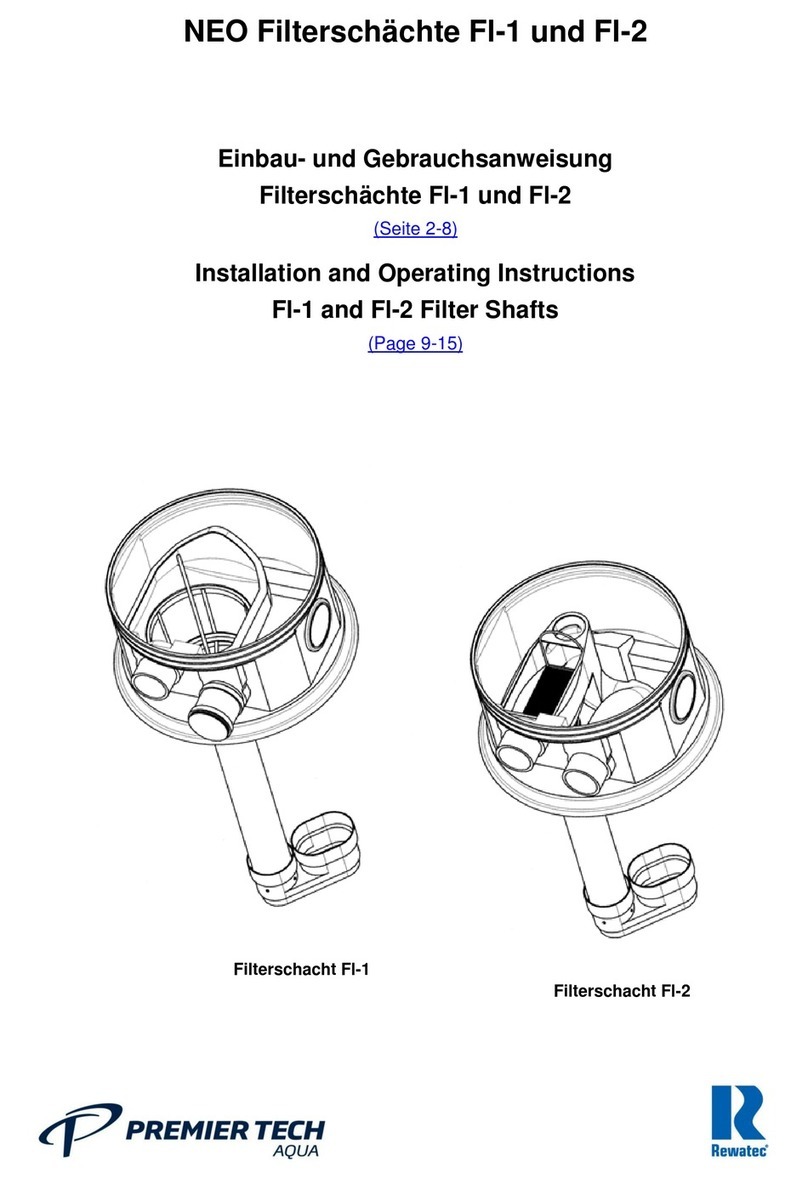

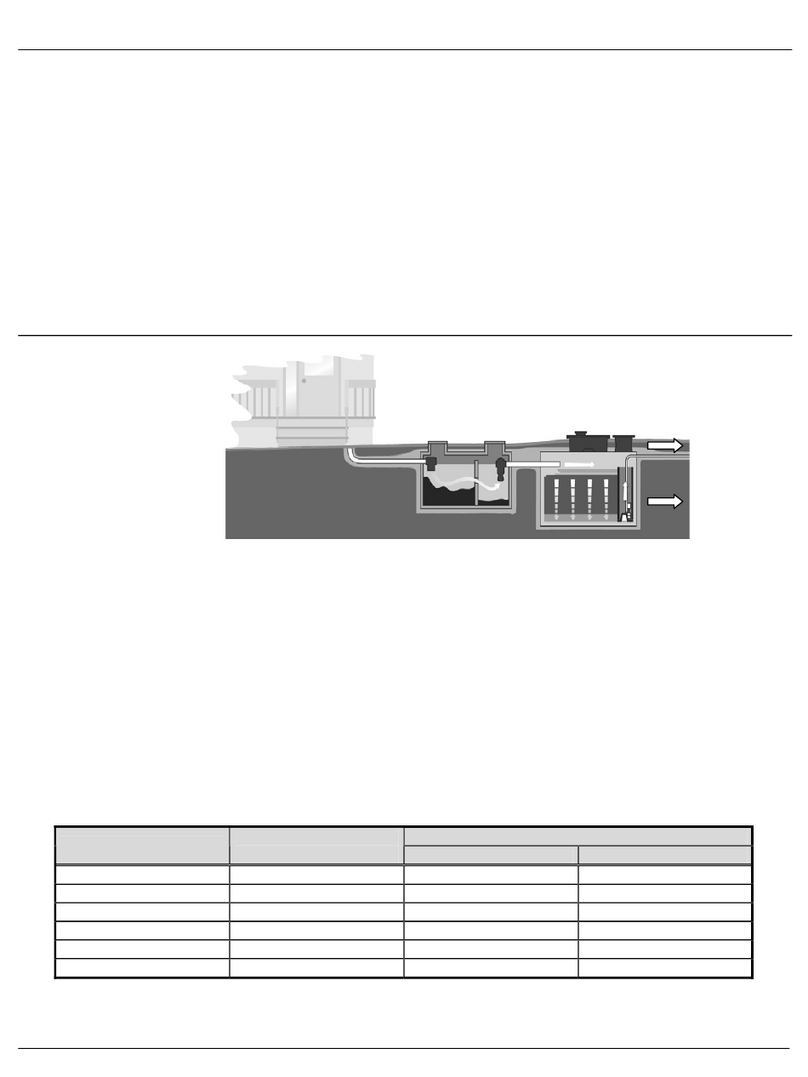

3.3.1 Primary reactor

The primary reactor must be installed in compliance with the following instructions:

•Both openings must be extended to the soil surface through watertight and insulated chimneys and equipped

with watertight covers;

•The depth of the backfill piled over the tank must not exceed 90 cm (36 in.);

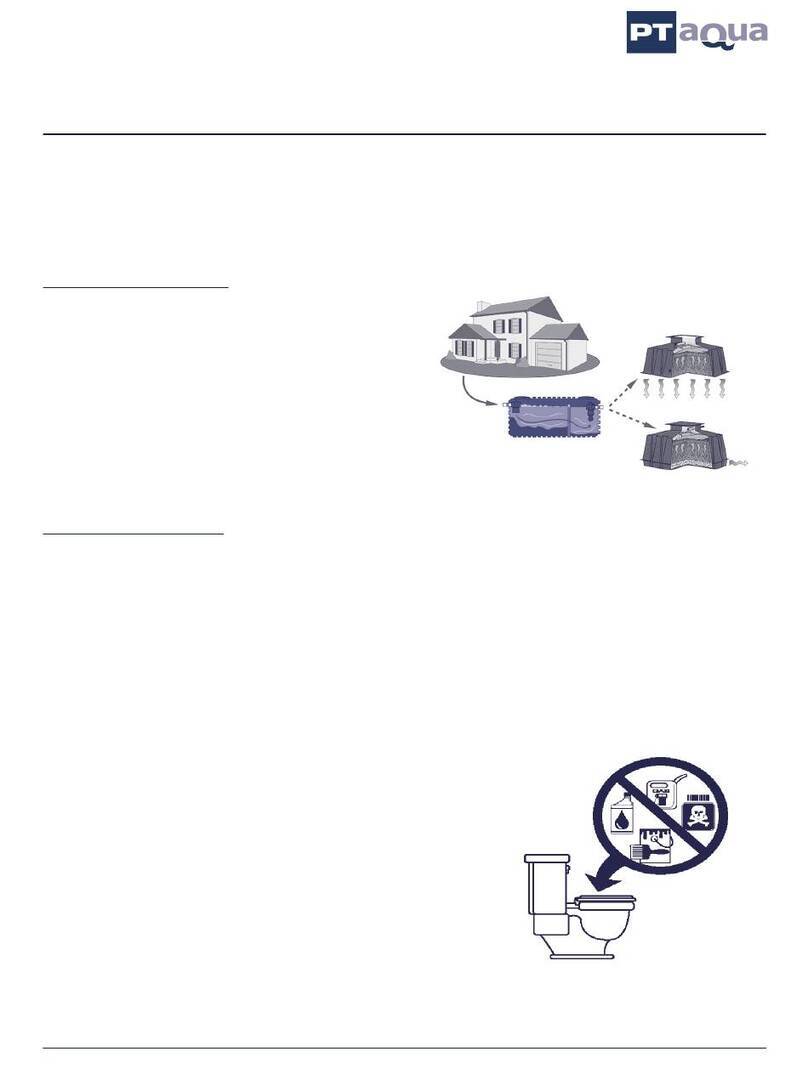

•The installation must be 100% watertight and only receive the residence’s domestic wastewater (no

foundation, land or roof drainage);

•The primary reactor must be placed where it is not at risk of being flooded or submerged (depending on the

situation, it may be necessary to provide for drainage around the primary reactor to prevent groundwater from

reaching a level that would pose a flooding risk);

•The manufacturer’s specifications.

3.3.2 Polyethylene Ecoflo®Biofilter

The Ecoflo®Biofilter must be installed in compliance with the following recommendations and it is important to

notify all stakeholders (installer, landscaper, owner, snow removal company, etc.) of them to prevent damage to

the wastewater processing system components.

•Ensure access to the covers of your septic installation at all times. NEVER cover them with mulch, soil or a

fixed structure.

•Once your septic installation has been completed, the covers must be 50 mm (2 in.) higher than the surface of

the landscaped terrain.

•NEVER install extensions over the access of the polyethylene Ecoflo®Biofilter.

•NEVER plant trees within 2 m (6.5 ft.) of the infiltration zone.

•NEVER connect a land or foundation drainage line, gutter spout, sump or bilge pump or air conditioner drain

to your septic installation.

•NEVER pile up more than 300 mm (12 in.) of backfill on the shell.

•NEVER drive a vehicle or place objects weighing more than 225 kg (500 lbs.) within a radius of 4 m (13’ 1’’.)

from the covers of the Ecoflo® Biofilter.

•Ensure a rapid regrowth of the vegetation to prevent soil erosion.

•Ensure that the maximum seasonal groundwater level never exceeds the base of the shell.

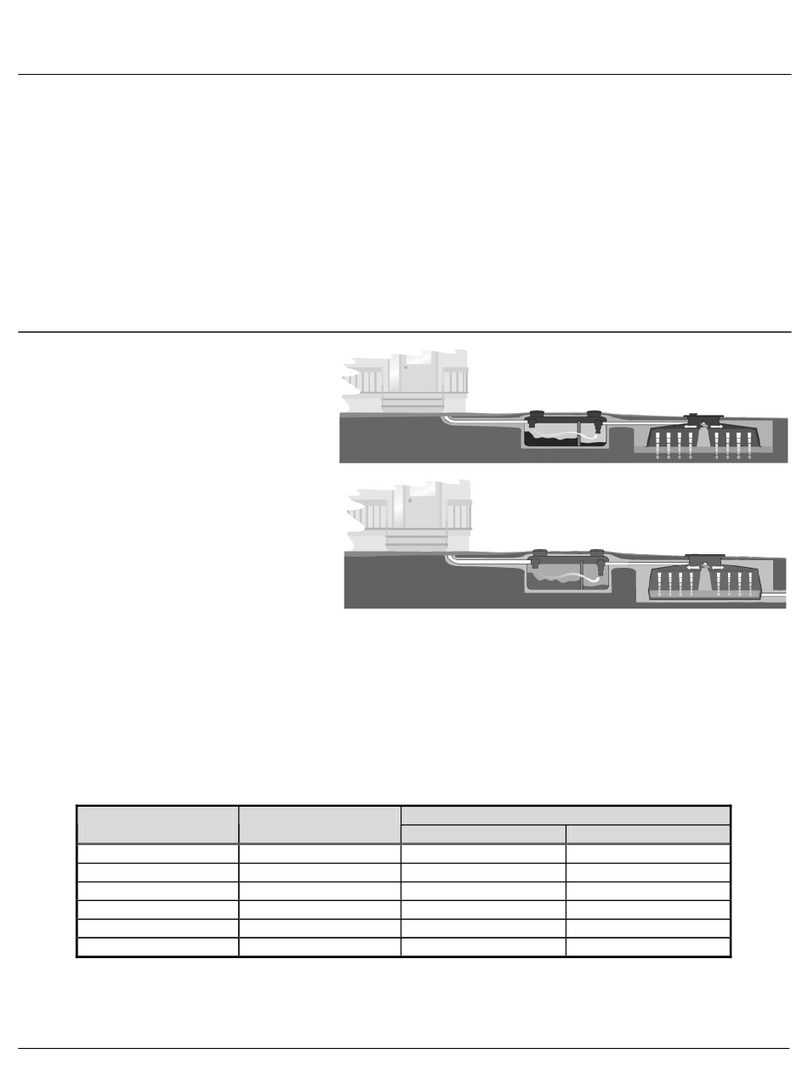

•When dual biofilters are installed with pumped discharge, it is possible to combine a watertight-bottom

biofilter with gravity discharge and a watertight-bottom biofilter with an integrated. The base of a biofilter with

a gravity discharge must be from 25 mm (1 in.) to 75 mm (3 in.) higher than the base of a biofilter with pumped

discharge.

Also, the Ecoflo®Biofilter with a perforated bottom must be installed in a location:

•Where the soil is permeable or very permeable;

•That is never susceptible of being flooded or submerged by ground water. If that is the case, an Ecoflo

Biofilter with a watertight bottom should be used. Please contact our customer service department for further

information.

By respecting these guidelines, you contribute to the proper operation of your wastewater treatment system.

Failure to abide by these guidelines may void the warranty, at Premier Tech’s discretion

3.4 Dosing tank and control unit (Time dosed biofilter only)

The dosing tank and the control panel must be installed in compliance with the manufacturer’s specifications.