i | VV – Manual | AntecControls.com

TABLE OF CONTENTS

INTRODUCTION ...............................................................................................................................................................................1

General ........................................................................................................................................................................................1

Safety Precautions.......................................................................................................................................................................1

Caution to Contractors.................................................................................................................................................................1

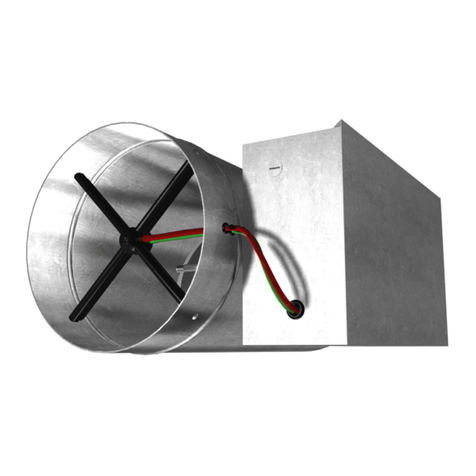

Product Overview........................................................................................................................................................................2

Technical Specifications ..............................................................................................................................................................2

Airflow Ranges ............................................................................................................................................................................2

GETTING STARTED WITH THE VV...................................................................................................................................................3

Receiving Inspection ...................................................................................................................................................................3

In the Box ....................................................................................................................................................................................3

Construction Options...................................................................................................................................................................5

INSTALLATION & MOUNTING INSTRUCTIONS............................................................................................................................10

Installing the Venturi Valve ........................................................................................................................................................10

Constant Volume Valve Reassembly.........................................................................................................................................12

VALVE ACCESSORIES ...................................................................................................................................................................13

Hot Water Coils (VVHWC) .........................................................................................................................................................13

Electric Coils (VVEC) ..................................................................................................................................................................15

Silencer (VVSIL) .........................................................................................................................................................................17

Valve Companion Connections (VCT) ........................................................................................................................................18

Valve Installation Tape (VIT).......................................................................................................................................................21

Valve Pressure Switch (VPS) .....................................................................................................................................................22

Valve Actuator ...........................................................................................................................................................................24

Valve Relay ................................................................................................................................................................................25

BALANCING ...................................................................................................................................................................................26

Variable Volume Venturi Valve...................................................................................................................................................26

Constant Volume Venturi Valve.................................................................................................................................................27

TROUBLESHOOTING.....................................................................................................................................................................28

Venturi Valve Troubleshooting...................................................................................................................................................28

Electric Coil Troubleshooting.....................................................................................................................................................28

Replacement Parts ....................................................................................................................................................................29

Technical Support......................................................................................................................................................................29