5

priceindustries.com |PCM - INTERIOR AND PERIMETER ZONES COOLING AND HEATING - Manual

PCM - INTERIOR AND PERIMETER ZONES COOLING AND HEATING

INSTALLATION & MOUNTING INSTRUCTIONS

4PCM - INTERIOR AND PERIMETER ZONES COOLING AND HEATING - Manual |priceindustries.com

PCM - INTERIOR AND PERIMETER ZONES COOLING AND HEATING

Product overview

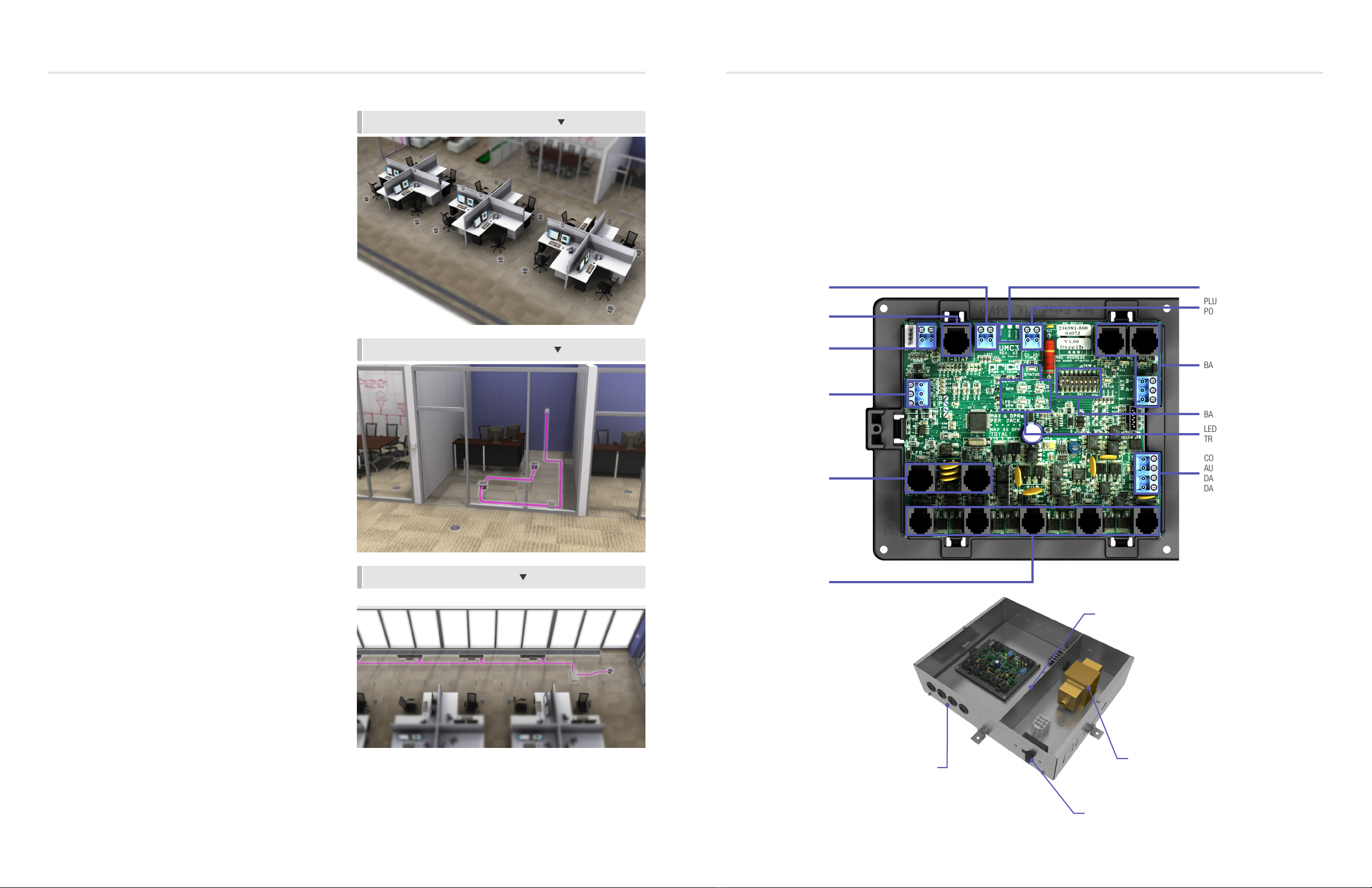

Features of the PCM

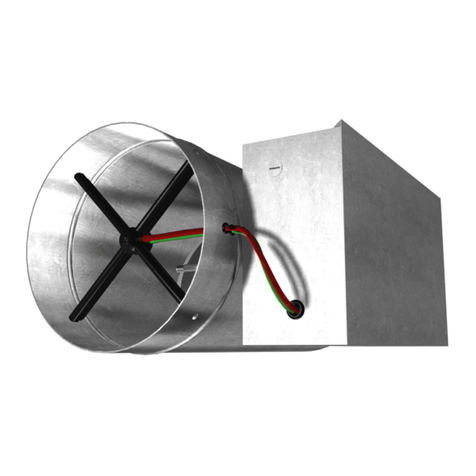

• Control up to 30 underfloor dampers.

• Modular connections to dampers – Use RJ-12 cables

included with dampers to connect underfloor dampers to

PCM. LFGH dampers use RJ-45 connections.

• Outputs protected by self-resetting thermal fuses – Prevents

damage to circuit board in the event of a damaged cable.

Fault LED lights when dampers are trying to drive on an

output with damaged cable.

• Auxiliary 24VAC Binary Output – Use for reheat, room lights,

signal to other equipment, etc. Rated for a maximum output

of 0.5A (12VA).

• Auxilary Analog Outputs (2) – Use to connect to other

equipment, BAS, etc. Output range fully configurable (2-

10VDC, 0-10VDC, 10-2VDC, etc.). Rated at a maximum

output of 10mA each.

• Analog Inputs (2) – Configurable to allow control of the

PCM from a source other than a Price Thermostat (BAS,

third party thermostat, etc.). Accepts the standard dual

0-10VDC signal for cooling/heating. (if not using LFGH

or other heaters connected to PCM, only the 0-10V cooling

signal is needed).

• Input (1) 10K type J thermistor – Can be used to monitor a

temperature over the network. Can also be used for heat/

cool changeover.

• Thermostat port - For RJ-45 connection to thermostat from

the PCM controller.

• Native BACnet MS/TP communication – Connect using RJ-

45 cable, or use discrete twisted-pair wire to terminal block.

Available speeds: 9600, 19200, 38400, 76800 (default).

• LED Indication – For ease of troubleshooting – displays

status, damper directions, BACnet status, and output fault.

• Pluggable terminal blocks – For easy installation.

• High-Voltage disconnect switch.

• Max 100VA multi-tap transformer with circuit breaker.

• Metal safety guard separating high and low voltage areas.

• 4 grommeted openings for modular cable connections.

• Temperature sensor input (for monitoring).

• Disconnect switch.

• Pluggable 24VAC power terminal.

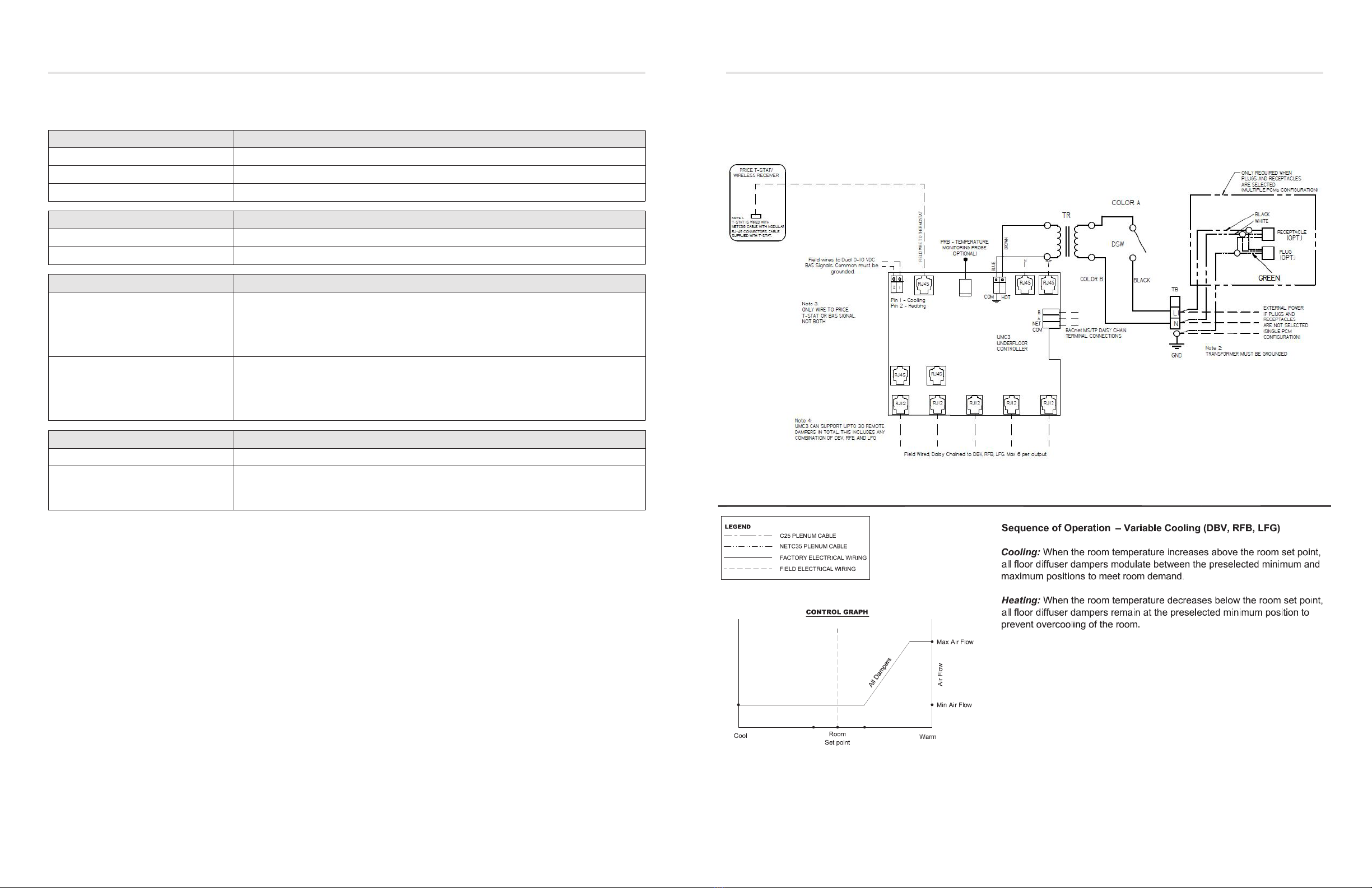

Operation

The PCM controller is an advanced and fully configurable

underfloor ModuFlex cooling controller. It is typically interfaced

with one of four Price Thermostats to determine room load and

allow for setup functions. With a variety of output configurations,

the PCM can control up to 30 underfloor dampers, as well as

auxiliary equipment using its auxiliary 24VAC binary outputs, and

analog 0-10V outputs.

Upon an increase in space temperature the controller regulates the

dampers open to increase the flow of cool air. On an increase

of space temperature greater than the proportional band,

the dampers’ positions are maintained at their pre-selected

maximum setting.

On a decrease in space temperature the controller regulates the

dampers closed to decrease the flow of cool air. If connected to

LFGH floor grills with integrated damper and reheat, the PCM

will energize or modulate the heat proportionally to the room

demand. If the space temperature decreases to less than the

proportional band, the dampers’ positions are maintained at

their pre-selected minimum setting.

The PCM can also be configured to accept 0-10V input signals

from a BAS system or third party thermostat for room load

calculations, instead of data from the thermostat.

The PCM can be used as a stand alone unit, or can be

interfaced into a BAS with the MS/TP BACnet network.

The PCM offers five thermostat options that provide a range of

control from room temperature sensing, all the way to motion

sensing. With the use of the LCD Thermostat, balancing and

system setup can be achieved. Further, with the use of the LCD

Thermostat with Motion, the PCM can be used as a motion-

occupied zone and lighting controller. The LCD Thermostat with

Motion offers different levels of sensitivity and still performs all

the functions of the regular LCD Thermostat.

Installation

1. Before installation, make sure that Building installation

should have maximum of 20 A Circuit Breaker.

NOTE: PCM doesn’t contain any primary Protection and

entirely relies on protection from Building Installation.

2. Place the PCM in the underfloor plenum in the center of

the controlled zone.

3. Supply power and ground to terminal per wiring diagram.

NOTE: This task must be completed by a certified and

licensed electrician.

4. Connect underfloor dampers using CFLEX cables supplied

with dampers. Follow these general rules:

A. Connect no more than 30 dampers total

B. Daisy chain up to 6 dampers per output – no more

C. Do not connect standard dampers (with RJ-12 plug) to

LFGH outputs (which use RJ-45 plug)

D. LFGH dampers (up to 12) count towards the maximum

of 30 dampers per controller

5. Run CFLEX thermostat cable to thermostat, and plug into

“T-Stat” port on the PCM. (For thermostat installation

reference the Installation & Mounting Instructions

Thermostat Installation section.)

6. Connect BACnet network (if used). For more detailed

information on networking with PCM reference the Display

Navigation Address Menu section.

7. Flip the PCM’s power switch to the ON position.

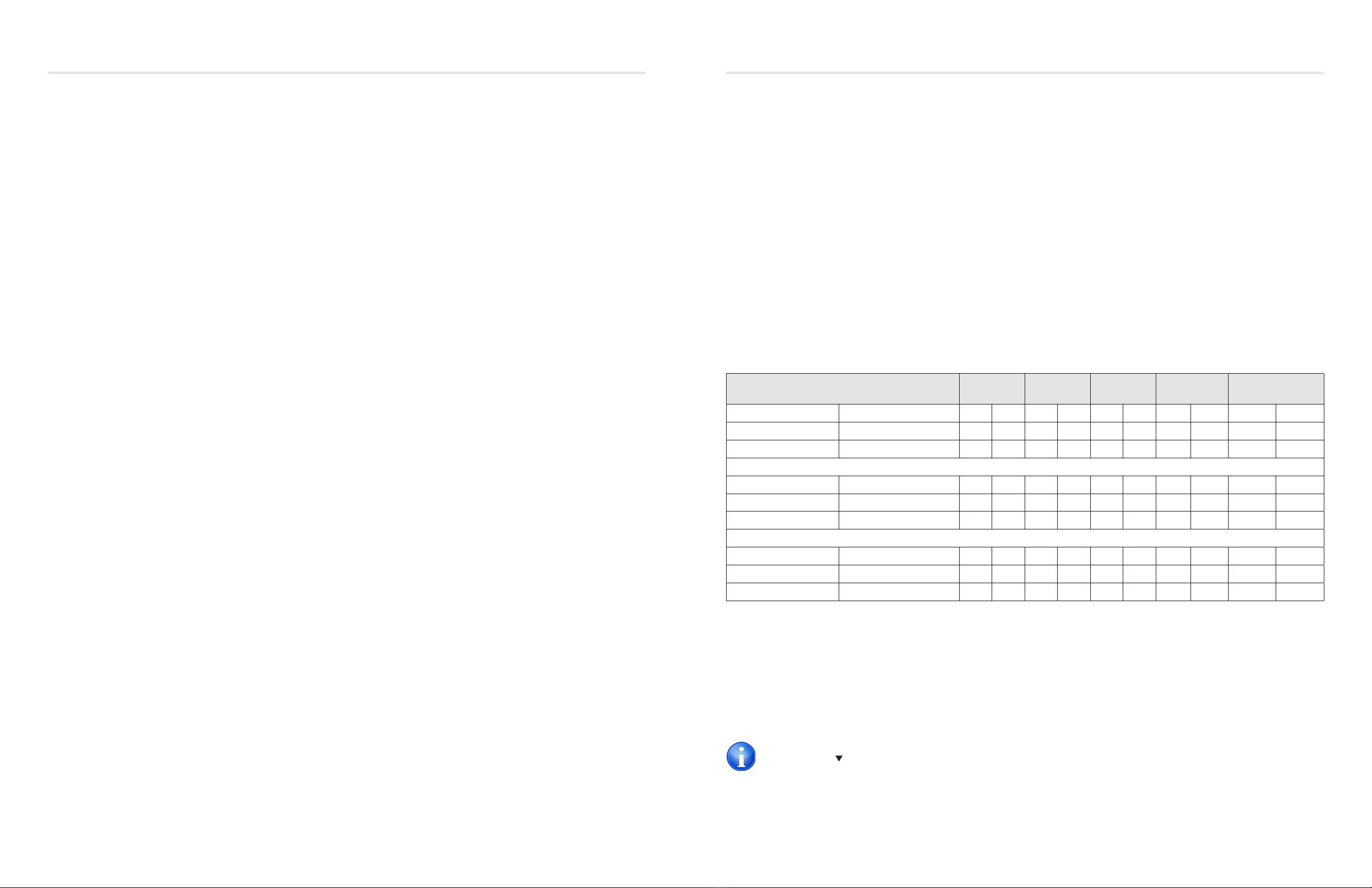

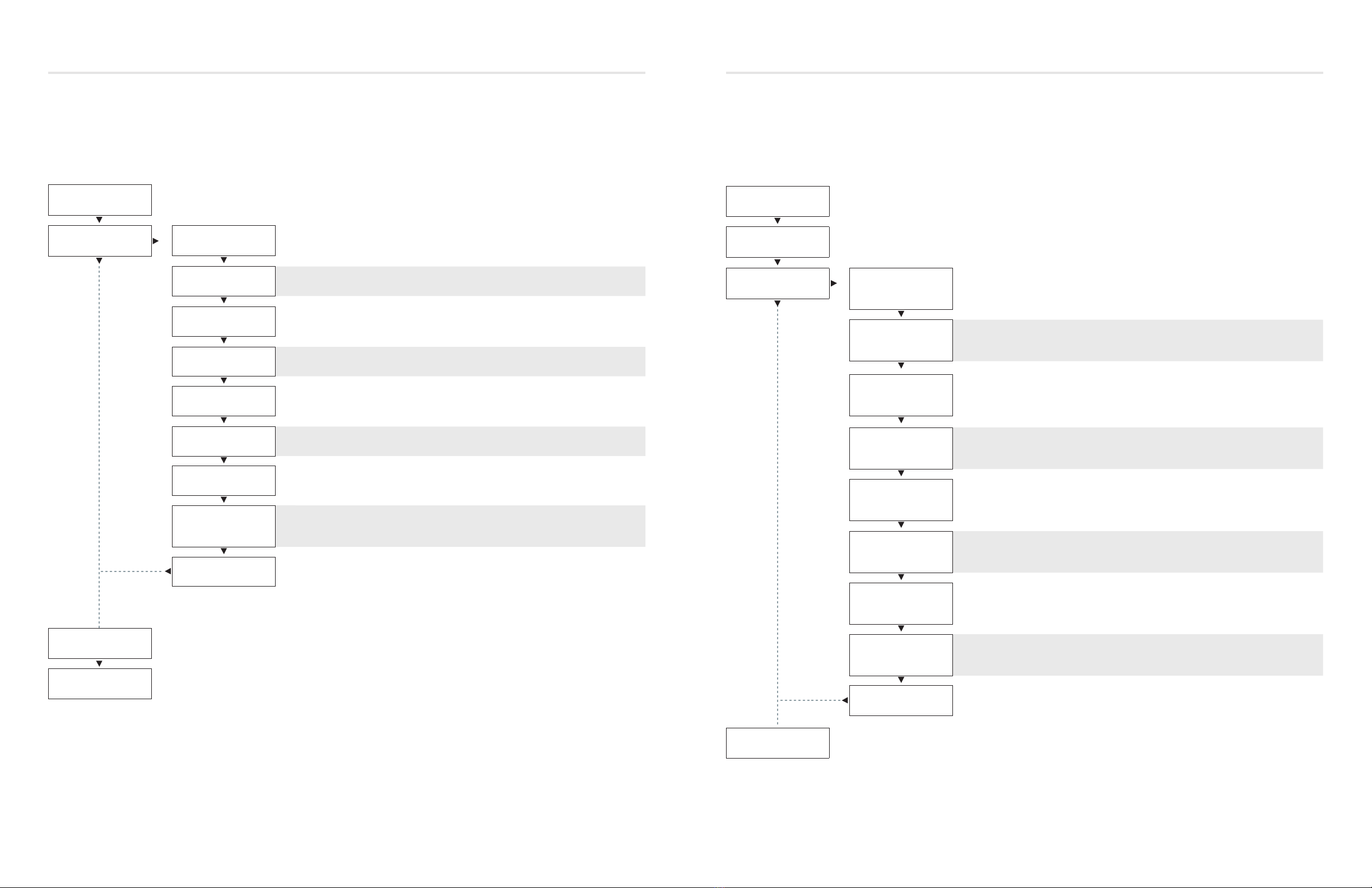

Price Flow Response Chart

HCCO Response Cooling

Min

Cooling

Flows

Heating

Min

Heating

Flows

Neutral Supply

Air Flow

PI = Cooling Supply air = Cold D L

PI = Heating Supply air = Cold D L

PI = Neutral Supply air = Cold D L

PI = Cooling Supply air = Hot D L

PI = Heating Supply air = Hot D L

PI = Neutral Supply air = Hot D L

PI = Cooling Supply air = Neutral D L

PI = Heating Supply air = Neutral D L

PI = Neutral Supply air = Neutral D L

“D” indicates the target of the regular dampers and “L” represents the target of the LFGH dampers (with integrated reheat)

NOTE 1: By default the PCM is shipped configured for cold supply air only. This can be changed to enable HCCO with thermistor

probe (however this will almost never be the case).

NOTE 2 : PI = Proportional Integral = room load (either cooling/neutral/heating)

Above is a flow response chart for the PCM, showing the demand, duct air condition, and the controller’s output.

E.g.: PI = Cooling, Supply Air = Cold, Output = Cooling Flows. This indicates that the room demand is in cooling, the supply air is cold,

and the controller would modulate both the regular dampers and the LFGH dampers between the Cool Min and Cool Max values.

Use the above table to determine what airflows are being chased in certain modes. Example: If PCM is trying to heat the room (PI = Heating)

and cool air is being supplied (Duct Air = Cold) it will chase its heating min flow.

TECH TIP