PRICECNC AVHC10 User manual

1

CNC Plasma Torch Height Controller

Installation and Operation Manual

Model: AVHC10 Revision: 1.2

2

3

SAFETY NOTICE

WHEN THIS DEVICE IS IN OPERATION, VOLTAGES

HAZARDOUS TO HEALTH AND HUMAN LIFE ARE

PRESENT INSIDE THE ISOLATION MODULE.

This device should only be connected by a qualified and authorized person.

Improper connection can cause serious injury or death. Prior to installation and

operation, carefully read the entire manual and be absolutely sure that you fully

understand and are able to make the sole decision to determine if you are capable of

a safe and proper installation. Remember that inside the Isolation Module, voltages

hazardous to health and life may be present.

There must be no physical contact with any electrical connections while this device

or any connected device is powered. Do not operate this product with wet hands, wet

gloves, or any wet clothing. Before turning the unit on, secure the safety of others,

and read and understand all instructions. If you have any questions or concerns, do

not continue.

Warning: Provide adequate protection for all risks associated with plasma cutting.

For more detailed information of the risk associated with plasma cutting, refer to your

plasma cutter's owner manual.

This device must be earthed/grounded in accordance with this installation guide,

earthing of non-electrified conductive parts (including device housings) is an

essential part of electrical safety.

Touching non-insulated and non-grounded elements can be fatal. Provide a safe

place for your device. After installation, securely protect against any physical contact

between the terminals on the Isolation Module and any person(s).

It is strictly prohibited to perform any repairs or modifications to this product,

performing either one of these actions could lead to serious injury or death to

yourself and/or others.

Terms of Use: By proceeding with the installation and use of this product, you fully

understand and agree that PRICECNC and their distributors are not liable for any

incident or event resulting in direct loss, indirect loss, injury to self or others, damage

to property, or loss or damage of any kind and that the end user assumes all risks. If

you do not agree to these terms in their entirety, proceed no further, and return this

product for a full refund.

If you have any questions or are unsure about anything stated in this manual, please

contact a PRICECNC dealer or service centre for assistance.

4

Contents

Introduction......................................................................................................................... 4

1 Installation........................................................................................................................ 5

1.1 High Frequency Plasma Cutter Interference ................................................................ 5

1.2 Earthing....................................................................................................................... 6

1.3 Raw Arc Measuring Point Connections........................................................................ 6

1.4 50:1 Measuring Point Connections .............................................................................. 6

1.5 Floating Z Axis (not included) ...................................................................................... 7

1.6 Anti-Dive...................................................................................................................... 7

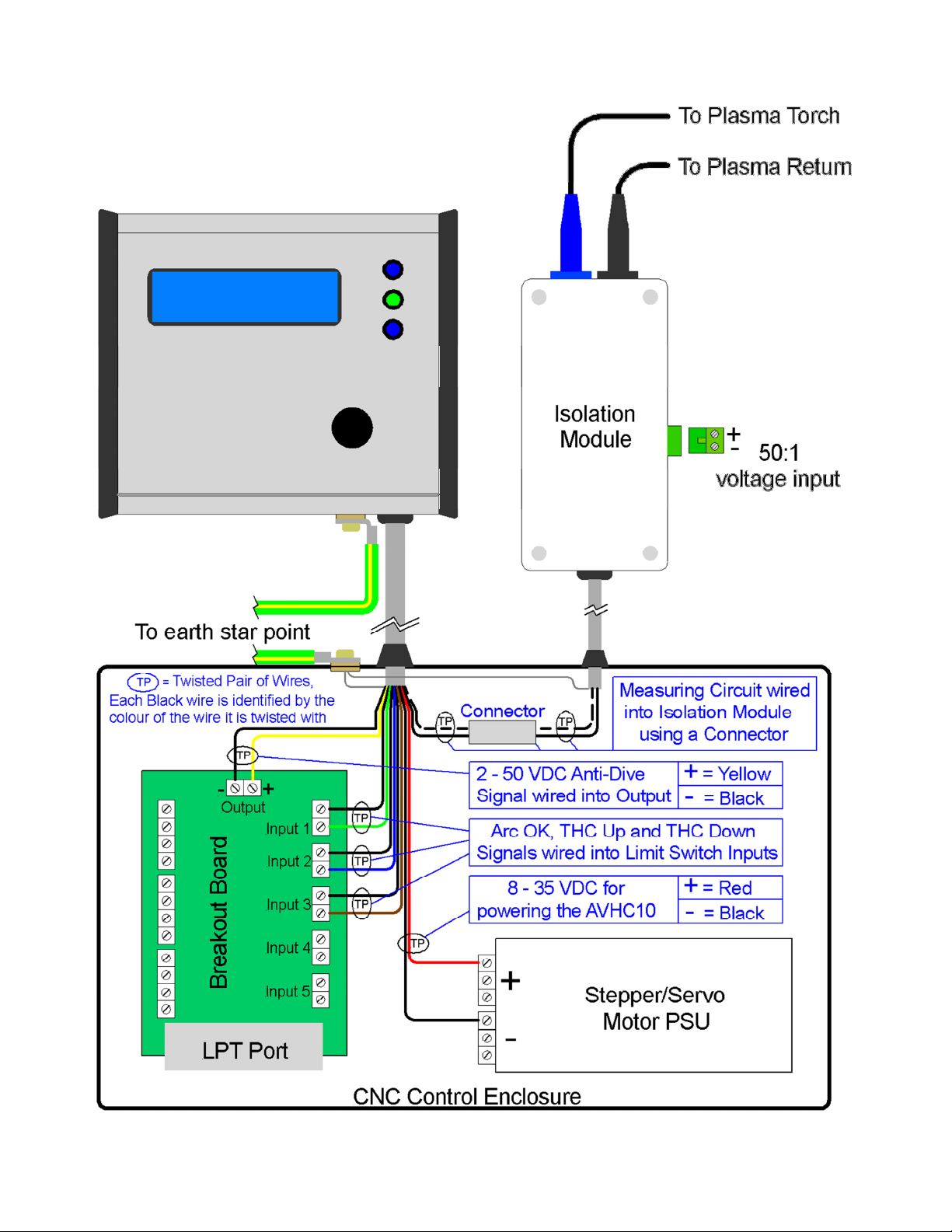

1.7 AVHC10 Installation Wiring Diagram ........................................................................... 8

1.8 Wiring Definitions......................................................................................................... 9

2 AVHC10 Operation ......................................................................................................... 10

2.1 Display List ................................................................................................................ 11

3 Appendix ........................................................................................................................ 14

3.1 Setting up the AVHC10 in Mach 3......................................................................... 14

3.2 Setting up the AVHC10 in SheetCAM........................................................................ 16

Introduction

When using a CNC Plasma cutting table, good cut quality can only be achieved by

maintaining a consistent distance between the cutting torch and the material being cut. This

can be difficult to achieve as heat from the cutting process can warp the material being cut

or the material that is being cut may not be level or flat. To overcome these problems during

cutting, the cutting torch needs to be raised and lowered to compensate for changes in the

height of the sheet.

The PRICECNC Arc Voltage Height Controller measures the voltage between the plasma

torch and the material being cut, this is known as the ‘Arc Voltage’. As the distance between

the torch and the material changes during a cut, the voltage also changes. The greater the

distance, the higher the voltage and the smaller the distance the lower the voltage. By

measuring the changes in the Arc Voltage, the AVHC10 can continuously adjust the arc

length for optimum cutting performance.

Different materials types and thicknesses require different height controller setting. For

convenience, up to 30 different material or thickness settings can be saved on the AVCH10.

5

1 Installation

The PRICECNC Arc Voltage Height Controller has two main components. One is called the

‘User Interface’ and the other is called the ‘Isolation Module’. Both of these units need to be

connected to each other. The Isolation Module also connects to the plasma cutter and the

user interface also connects to a power supply and the signal inputs and outputs on the

breakout board.

In this installation example, we show how to install the PRICECNC AVHC10 on to a Plasma

CNC table with the following properties:

Design Software SheetCam

Work Software

MACH 3

Breakout Board 5-axis with 1 relay output and 5 inputs

PC to Breakout Board Interface

LPT

Parallel Printer Port

CNC Machine Custom/Homemade/DIY 3 Axis CNC Table with

Floating Z axis

Mechanical Drive Stepper Motors

Plasma Cutter R-Tech Plasma50CNC

1.1 High Frequency Plasma Cutter Interference

Some value plasma cutters use a high frequency, high voltage striking arc to strike across

the air gap between the plasma cutter electrode and the work piece. This striking arc can

generate massive electromagnetic fields which can interfere with surrounding electronics

including CNC motors, drive units, breakout board and Computers. This electromagnetic

field comes from the cables that connect the plasma cutter electrode to the plasma cutting

machine. Cables that are connected to this circuit can also spread interference. The

PRICECNC Arc Voltage Height Controller is designed to keep this interference away from

the CNC control circuitry by utilising a completely electrically isolated measuring circuit in the

Isolation Module. The Isolation Module is also supplied and fitted with a shielded cable that

provides the User interface with a clean signal for accurate measurement.

6

1.2 Earthing

To prevent the above mentioned High Frequency interference from becoming an issue on

your CNC plasma cutting equipment, proper earthing/grounding must be fitted using at least

16mm

2

(AWG 5) multi strand cable. In a typical 3 axis CNC plasma cutting setup, the

following components should be earthed direct to the star point:

•Arc Voltage Height Controller aluminium case.

•Fixed portion of table.

•Gantry

•Buggy

•Z axis travel plate

•Stepper/Servo motor control box

•Plasma Cutter case

The star point is a point where the earth wires from all of these individual items meet, this is

then connected to the earth electrode. The alternative to a star point earthing system is a

daisy chain earth system. This is not recommended as it is not as effective at preventing

interference.

1.3 Raw Arc Measuring Point Connections

For best results, the cables that connect the Isolation Module to the plasma cutter should be

protected from the effects of a bad connection on the circuit that carries the plasma current.

Sometimes rust or dirt on the work sheet can cause a poor clamp connection which can

create a voltage difference between the clamp and the work piece which would affect the

measured voltage used for controlling torch height. For best results, the black connection on

the Isolation Module should be connected to the work piece by a separate small clamp.

A poor connection on the torch cable can cause the same issue, for best results, the

connection from the Blue plug on the Isolation Module should be connected to the plasma

torch as close to the tip as safely possible. Preferably, where the flexible air/current hose

connects to the torch.

1.4 50:1 Measuring Point Connections

The 50:1 measuring circuit is designed to work with the 50:1 voltage divider output on a

Hypertherm Powermax 45 Plasma Cutter and other Plasma cutters that use the same

resistor network to create the 50:1 voltage. The Hypertherm Powermax 45 plasma cutter

uses 100,000 and 2,000 ohm resistors in series to produce the a 50:1 voltage across the

2,000 ohm resistor. The PRICECNC AVCH10 is calibrated for use with 50:1 voltage dividers

with these particular resistances. Other resistor values will work but the accuracy of the

measured voltage may be affected. The overall circuit resistance of the voltage divider

should not exceed 120,000 ohms.

7

1.5 Floating Z Axis (not included)

For best plasma cutting results, the height at which each cut in a job starts should be

measured by a floating Z axis. The floating Z axis operates a switch which activates the

Digitize/Probe input in Mach3 when the torch descends into the work piece. When this

method is used with the correct G-code (G31), the Z axis Digital Read Out (DRO) will be

reset to zero at the start of each cut. This compensates for uneven sheet height and

improves the cut quality.

1.6 Anti-Dive

A reduced feed rate is often used when cutting small holes or tight angles, this reduced feed

rate increases the arc voltage which will cause the AVHC10 to lower the torch into the work

piece. To prevent the torch diving into the work piece when a reduced feed rate is used,

Torch Height Control should be deactivated during the reduced feed rate. One way to

deactivate Torch Height Control is to use an anti-dive Macro in Mach 3. Unfortunately Mach

3 pauses the operation of the CNC machine momentarily while it executes the macro which

may result in poor cut quality (dings/notches).

To overcome this, the PRICECNC AVHC10 can take in a signal that blocks outgoing Raise

and Lower commands. Using the correct cut rules in SheetCAM, the Post Processor will

write G-code that includes a command to turn on and off a signal output on the breakout

board. This signal is received by the AVHC10, blocking the raise and lower commands. This

method is simple to install on most Breakout boards and prevents the CNC machine from

needing a Macro to turn Torch Height Control on and off.

When anti-dive is activated, both blue LEDs will light up.

1.7 Mounting Holes

There are two threaded holes on the rear of the

AVHC10 that can be used to mount the unit

onto your CNC machine or control console.

8

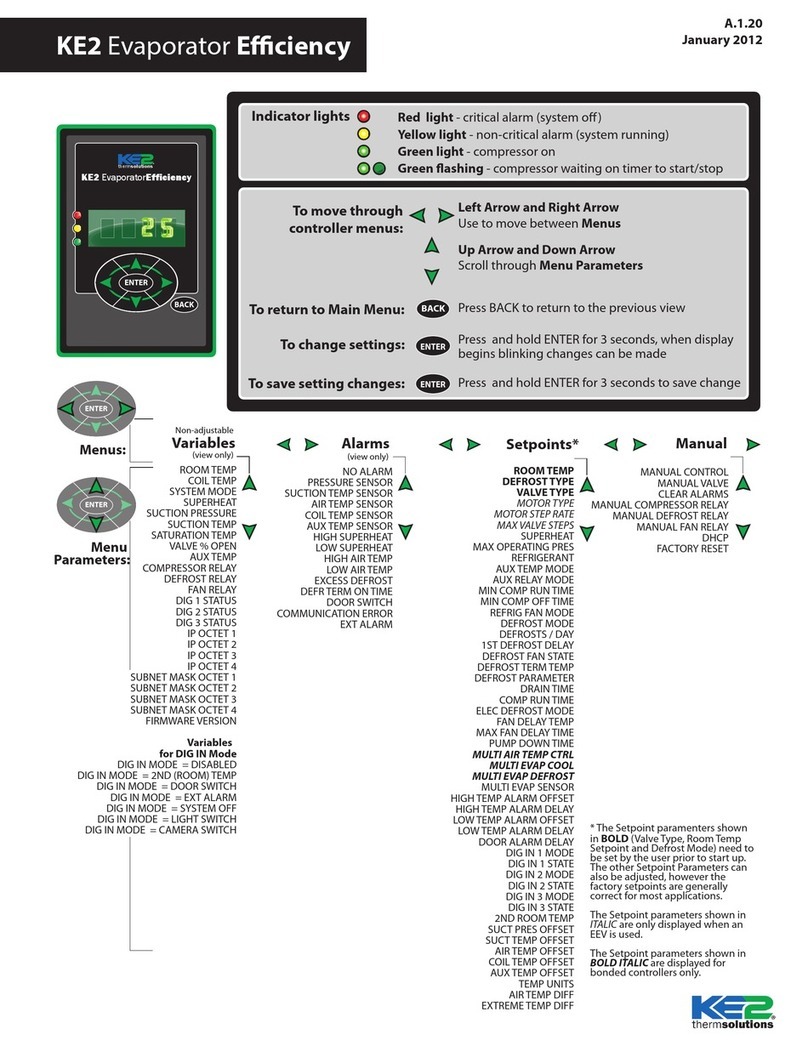

1.8 AVHC10 Installation Wiring Diagram

9

1.9 Wiring Definitions

AVHC10

Wire Pairs Polarity Function Min. Value Max. Value Unit

Red Positive Supplies power to the AVHC10 8 35 V

Black Negative

White Positive Measures the signal from the

Isolation Module

Black Negative

Yellow Positive Receives Anti-Dive Signal from

Mach 3 via Breakout Board 2 50 V

Black Negative

Green Either Sends Arc OK Signal to

Mach 3 via Breakout Board

50 V

Black Either 100 mA

Blue Either Sends Torch Up Signal to

Mach 3 via Breakout Board

50 V

Black Either 100 mA

Brown

Either

Sends Torch Down Signal to

Mach 3 via Breakout Board

50

V

Black Either 100 mA

Isolation Module

Wire Pairs Polarity Function Max. Value Unit

White Positive Sends Isolated and reduced

signal to the AVHC10 5 V

Black Negative

4mm Plug Polarity Function Max. Value Unit

Blue Negative* Connects to Plasma Electrode -300 continuous*

(HV starting Arc OK) V

Black Positive* Connect to Plasma Return clamp

50:1 Plug Polarity Function Max. Value Unit

Green See

Label Connects to 50:1 voltage divider 6 (HV starting through

100k Resistor OK) V

* Most Plasma Torch Electrodes operate at Negative Voltages

10

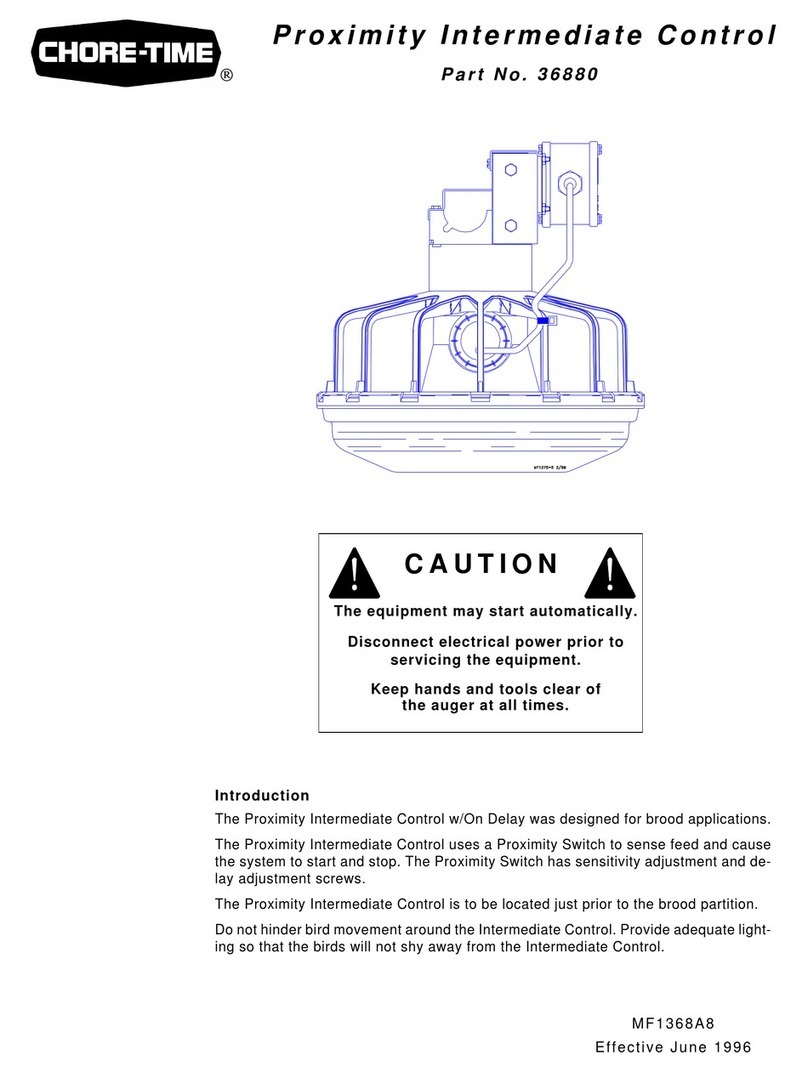

2 AVHC10 Operation

The AVHC10 is always ready to work when powered on, minimising the need to interact with

the device. The way the AVHC10 operates can be set by the user by using the Jog Wheel to

navigate through the simple menu structure.

The recommended sequence of events for Plasma Cutting using the AVHC10 is:

1. Prepare G-code that uses a floating Z axis to find a new Z axis zero at the start of

each cut and also activates Anti-Dive on certain types of cut operations like tight

radius cuts and corners.

2. Run the cut job.

3. The Torch moves over the first pierce point.

4. The Torch lowers until the floating Z axis switch is triggered by the torch touching the

material to be cut. (G31).

5. The Z axis position is reset to Zero minus the switch offset (G92).

6. The Torch is raised to the pierce height and Plasma is turned on.

7. After the (G-code) pierce delay, the torch is lowered to the cut height.

8. The torch moves along the cut while the AVHC10 monitors the Arc Voltage and

issues raise and lower commands to Mach 3 via the Breakout Board.

9. The torch comes to a tight radius bend during the cut which contains an M11P2 (Turn

off THC) command which turns on the output signal that activates the AVHC10 Anti-

LCD Display

Display Number

Jog Wheel

Earthing Screw

2 Mounting

Screws on

Rear

Signal

Indicator

LEDs

11

Dive. Both the Up and Down LEDs on the AVHC10 turn on to signify Anti-Dive is

operating.

10. The torch comes from the end of the tight radius bend to a straight section of the cut

which contains an M10P2 (Turn on THC) command which turns off the output signal

that activated the AVHC10 Anti-Dive. Both the Up and Down LEDs on the AVHC10

turn off and the AVHC10 resumes torch Height Control.

11. The torch moves along the cut while the AVHC10 monitors the Arc Voltage and

issues raise and lower commands to Mach 3.

12. The cut finishes and Mach 3 turns off the torch.

13. The AVHC10 recognises the voltage is now outside the Arc OK range and stops

issuing any commands.

If the Arc OK signal is utilised and the Plasma Arc fails during a cut for longer than the

Arc Fail duration that is set on the AVHC10, the Arc OK LED will go out and the Arc OK

signal to Mach 3 will change. This will make Mach 3 pause the job until the Arc OK signal

resumes, which may happen if your plasma cutter automatically tries to re-fire an arc.

2.1 Display List

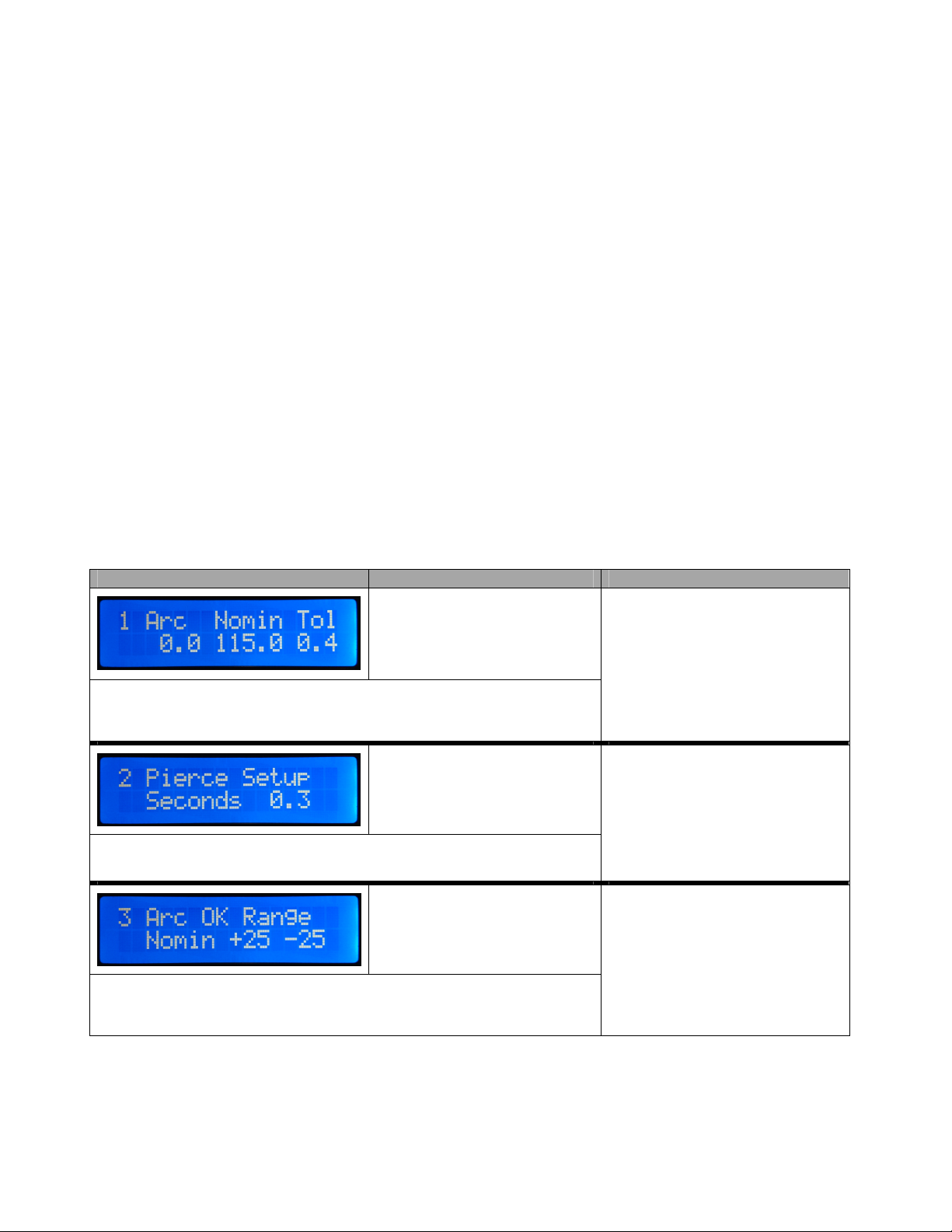

AVHC10 Display Use Operation

Displays the measured Arc Voltage.

Displays and edits the Nominal and

Tolerance Voltages.

1. Press Select (Nomin flashes)

2. Use Jog Wheel to edit Nominal

Voltage

3. Press Select (Tol flashes)

4. Use Jog Wheel to edit Tolerance

Voltage

5. Press Select

The Nominal Voltage is the Voltage the Plasma cutter operates at when cutting at the

correct height. The Tolerance Voltage is amount that the Arc Voltage is permitted to

differ from the Nominal Voltage before the AVHC10 will issue Raise or Lower

Commands.

Displays and edits the Pierce Delay 1. Press Select (Seconds Flashes)

2. Use Jog Wheel to edit the Pierce

Delay

3. Press Select

The Pierce Setup is the delay that is used to give the Plasma Torch time to pierce

and achieve a stable voltage, before the AVHC10 starts issuing Raise and Lower

Torch Commands.

Displays and edits the Arc OK

Range.

1. Press Select (+flashes)

2. Use Jog Wheel to edit Upper

Range Voltage

3. Press Select (-flashes)

4. Use Jog Wheel to edit Lower

Range Voltage

5. Press Select

The Arc OK Range is the Voltage above and below the Nominal Voltage that decides

if the measured Arc Voltage is acceptable. If the measured Arc Voltage is within this

range, the Arc OK Signal will be issued and the AVHC10 will issue Raise and Lower

commands as needed. Outside this range, no signals are sent.

12

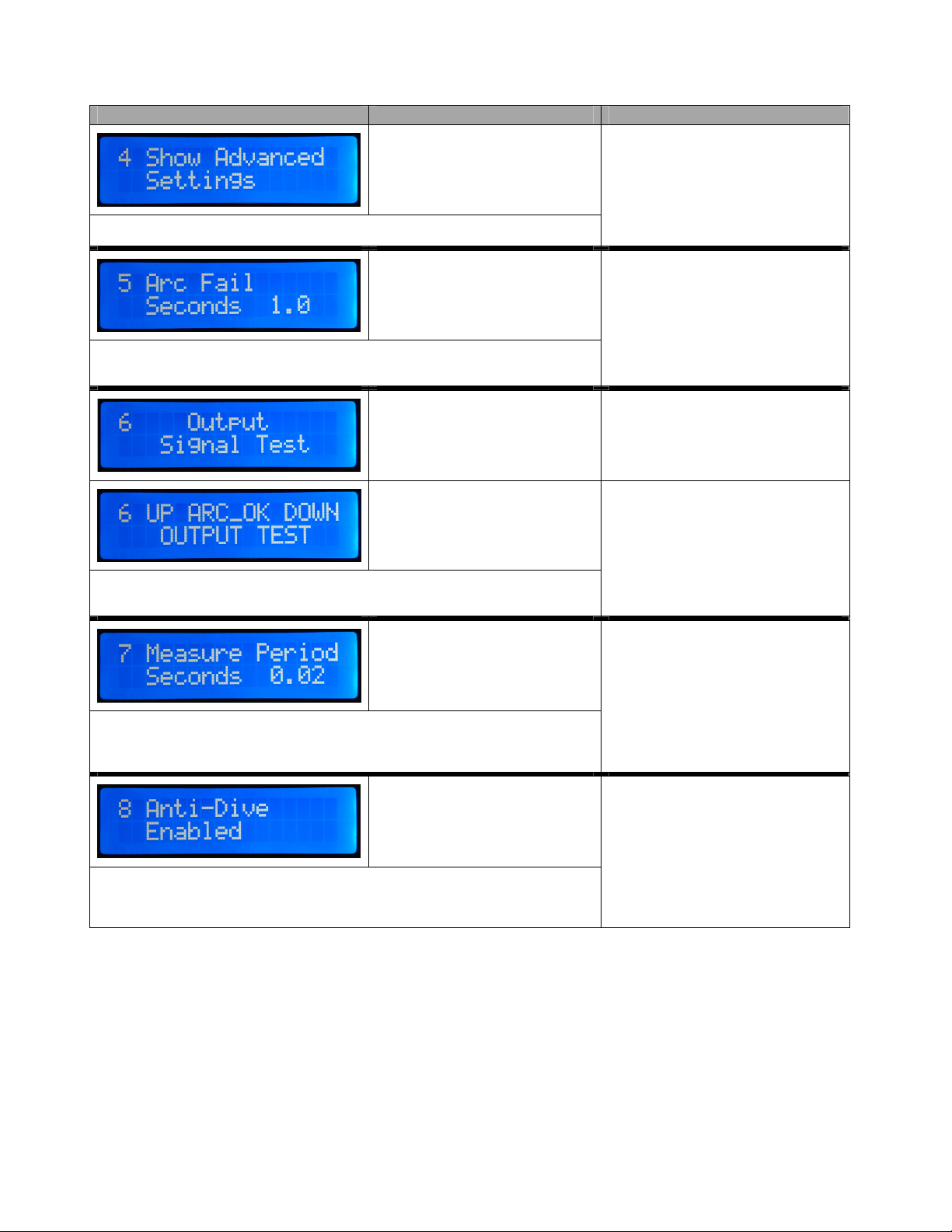

AVHC10 Display Use Operation

Hides or Shows the Advanced

Settings Displays

1. Press Select to change Show to

Hide

2. Press Select again to change back.

For normal operation, the Advanced displays are not usually necessary and can be

hidden using this Display.

Displays and edits the Arc fail

Duration

1. Press Select (Seconds Flashes)

2. Use Jog Wheel to edit the Arc fail

Duration

3. Press Select

The Arc Fail Duration is the length of time that the Measured Arc Voltage is permitted

to be outside the Arc OK range before the Arc OK signal is stopped. This is to

prevent short duration Arc Voltage spikes or dips from causing problems.

Tests the output signals 1. Press Select (Screen Changes)

Selects the Signal to Test 2. (Up Flashes)

3. Use Jog Wheel to select other

outputs

4. Press Select (Screen Changes

Back)

This display is used to Test the Output signals of the AVHC10 and is useful for

verifying that Mach 3 is receiving the signals. The Diagnostics Screen in Mach 3

displays all active inputs and the signals they represent. See section 3.1 for details.

Displays and edits the Period of

measurement. (How quickly the unit

responds to Measured Voltage

Changes)

1. Press Select (Seconds Flashes)

2. Use Jog Wheel to edit the Measure

Period Duration

3. Press Select

The Measure Period selects how long the AVHC10 output signals take to react to

changes in the Measured Voltage. This is used to tune the AVHC10 response time to

best suit your system. (0.1 recommended for beginners, but this value should be

raised and lower to find the response time that bests suits your equipment.)

Enables or Disables the response of

the AVHC10 to an Anti-Dive

command

1. Press Select to change Enable to

Disable

2. Press Select again to change back.

If the AVHC10 Anti-Dive is enabled but the G-code that is running the cut job does

not use Anti-Dive commands, Mach 3 may leave the Anti-Dive signal in the on (high)

state which would stop the AVCH10 from sending Raise and Lower commands. To

prevent this problem, Anti-Dive can be Disabled on this Display.

13

AVHC10 Display Use Operation

Selects weather to save present

settings or load saved settings.

1. Press Select (SAVE, LOAD or

CANCEL) flashes.

2. Use Jog wheel to highlight the

required option.

3. Press Select

Settings can be saved in any of the 30 memory slots on the AVHC10. The memory

slot that contains the setting for cutting a particular material or thickness should be

referenced in the name of the SheetCAM tool that is used for that material or

thickness.

Selects the Memory slot to save to or

load from.

1. Use the jog wheel to scroll to the

required memory slot.

2. Press Select to confirm the

memory slot. (Settings will be

saved or loaded)

The number that is initially displayed is the number of the last saved or loaded

memory slot.

14

3 Appendix

3.1 Setting up the AVHC10 in Mach 3

1. From the Menu Bar in Mach 3, click on ‘Config’ > ‘Ports and Pins’ > ‘Input Signals’.

2. Scroll down the Signals list and change the setting for ‘THC On’, ‘THC Up’ and ‘THC

Down’ to the correct Port and Pin Number.

Note: The ‘Probe’ signal is for the floating Z axis and responds to G31 commands.

3. Click on the ‘Output Signals’ tab. Change the setting for ‘Output #2’ to the pin that will

operate the AVHC10 anti-dive.

Note: A different output number can be selected from the signal list. ‘Output #2’ is

turned on by the G-code command ‘M11P2’ and turned off by ‘M10P2’ If a different

output number is required, change the ‘2’ in the code snippet to the required number

when creating the rules in SheetCAM. For details, see section 3.2.

15

To verify that Mach 3 is communicating correctly with the AVHC10, view the diagnostics

screen in Mach 3.

Using screen 6 on the AVHC10, you can manually operate the Arc OK, Torch UP and Torch

Down signals. If the AVHC10 is communicating correctly through the Breakout Board, the

corresponding signals should light up the respective pins signal status indicators.

To verify the anti-dive signal, go to the output signals configuration screen and click on

‘Active Low’ to change the state of the signal. If anti-dive is enabled on the AVHC10, this will

make the two blue LEDs on the AVHC10 light together to show anti-dive is activated.

16

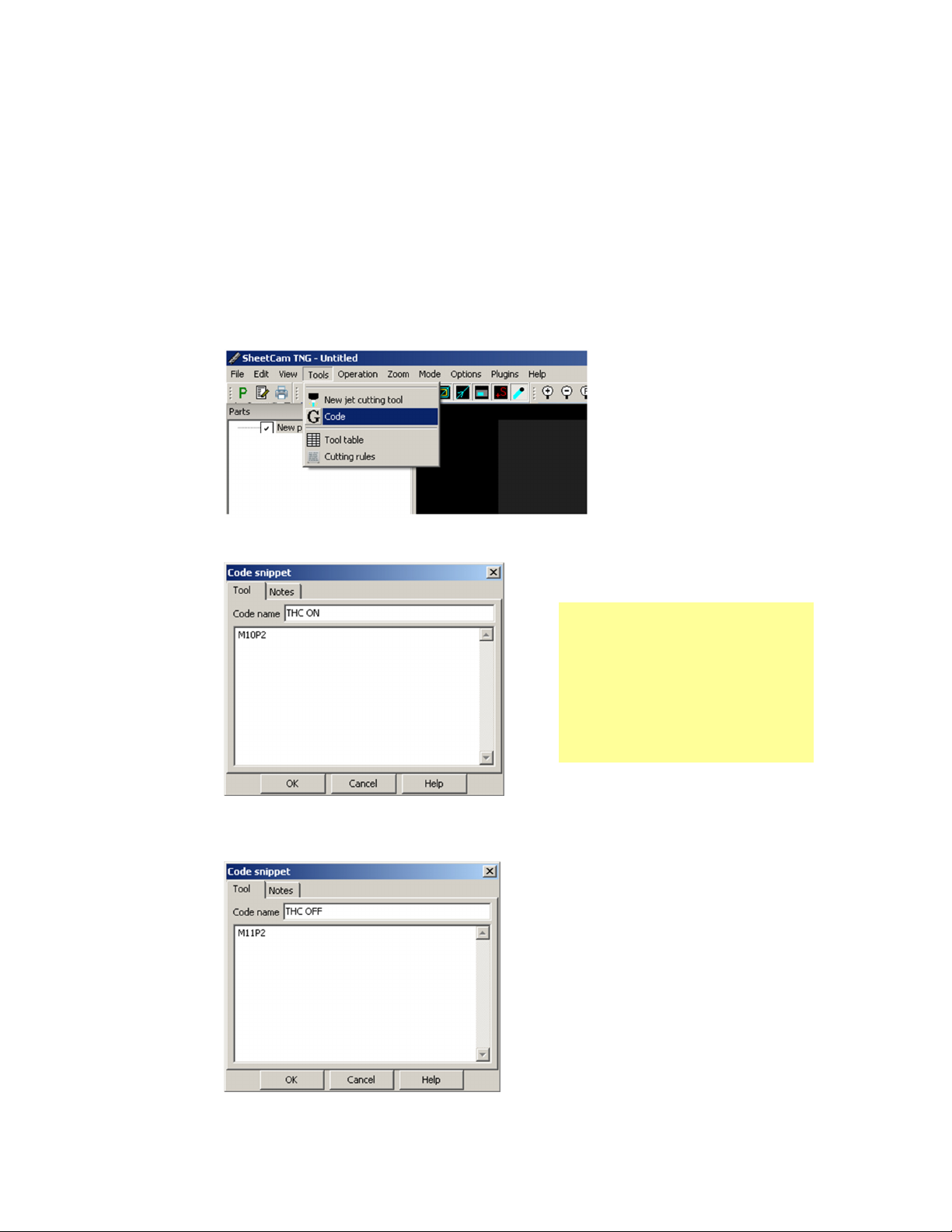

3.2 Setting up the AVHC10 in SheetCAM

SheetCAM has a useful feature where you can set rules for cutting different types of shapes.

This is a great aid to improving cut quality and can also be used to activate and deactivate

torch height control during different parts of a cut.

To set a rule in SheetCAM that will turn off torch height control during part of a cut, open

SheetCAM and follow these steps:

1. From the menu bar, click on ‘Tools’ and then click on ‘G Code.

2. Type ‘THC ON’ and ‘M10P2’ as show here, then click OK.

3. Repeat step 1 and make another Code snippet called ‘THC OFF’ using the code

M11P2 as shown here, then click OK.

TIP

M10/M11 are on/off commands for

external outputs. P2 refers to which

output channel is selected. In Mach 3,

P2 will be allocated to a specific pin in

the LPT port which will operate a digital

out on the Breakout Board.

17

4. From the menu bar, click on ‘Tools’ and then click on ‘Cutting rules’.

5. From the dropdown beside ‘Rule set’, select ‘Add new rule set’

6. Create a new name for the rule and click ‘OK’

7. Click ‘Add rule’

18

8. Click on the first dropdown to see what part or type of cut you want to apply the

rule to. Here, I have selected to make a rule that affects small circles.

9. Click on the drop-down beside ‘Start code’ and select ‘THC OFF’, then click on

the drop-down beside ‘End code’ and select ‘THC ON’. Click OK.

10. Repeat steps 7 to 9 to make more rules. Additional rules like the ones show here

may further improve cut quality.

11. The new Path rules should be displayed, click OK to close this window.

19

12. When creating a Jet cutting operation in SheetCAM, select the required rule from

the ‘Path rules’ drop-down. This will use improved cut techniques and turn the

height control on and off when required. If the rules are working correctly, the

M10P2 and M11P2 commands should appear in the G-code file.

20

Other manuals for AVHC10

1

Table of contents

Other PRICECNC Controllers manuals