10

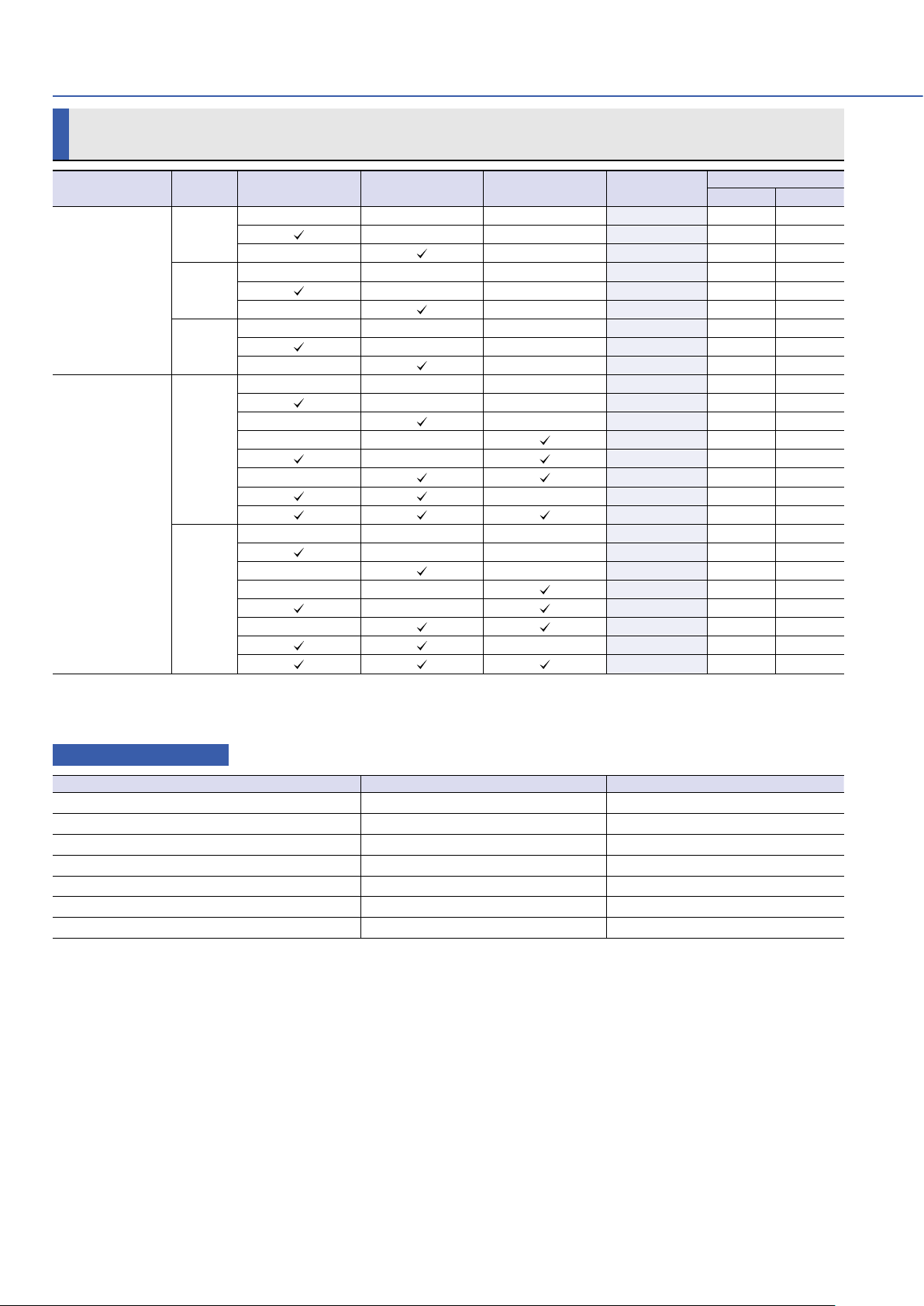

Specifications

Servo motor model no. Inside

《

》

indicates motor flange size

KB402

《42 mm sq.》

KB404

《42 mm sq.》

KB406

《42 mm sq.》

Condition

Symbol

Unit

Rated output ☆☆ PRW 23 40 60

Rated armature voltage ☆☆ VRV 20 24 24

Rated torque ☆☆ TRN

・

m 0.074 0.13 0.19

Rated armature current ☆☆ IRA 1.8 2.7 4.1

Rated speed ☆☆ NRmin-1 3000 3000 3000

Continuous stall torque ☆☆ TSN

・

m 0.08 0.14 0.20

Peak stall torque ☆☆ TP(N) N

・

m 0.42 0.76 1.2

Armature stall current ☆☆ ISA 1.8 2.7 4.1

Peak armature stall current

☆☆ IP(N) A 10 14 23

Maximum speed Nmax min-1 5000 5000 5000

Rated power rate ☆☆ QRkW/s 1.2 2.0 3.3

Torque constant ☆KTN

・

m/A 0.047 0.057 0.056

Voltage constant ☆KE×10-3V/min-1 4.9 6.0 5.9

Rotor inertia JM×10-4kg

・

m20.047 0.084 0.108

Armature winding resistance

☆Ra Ω 3.2 1.7 0.94

Armature inductance ☆La mH 0.9 0.7 0.5

Mechanical time constant ☆tm ms 6.9 4.4 3.2

Electrical time constant ☆te ms 0.28 0.41 0.53

Coefficient of voltage generated

☆KEG V/min-1 3×10-3±10%

Effective (rms) ripple ☆ε

s% 2

Peak-to-peak ripple ☆ε

s% 5

Linearity ☆δL% 1

Armature winding resistance

☆R1Ω 37

Armature inductance ☆L1mH 5

Minimum load resistance ☆RLkΩ 10

Rotor inertia JTG ×10-4kg

・

m20.011

Voltage ☆VBV––––

Current ☆IBA––––

Holding torque ☆☆ TBN

・

m––––

Inertia JB×10-4kg

・

m2––––

Resistance ☆RBΩ––––

Mass See the Dimensions section

Size of aluminum plates for heat dissipation during measurement

250 ×250 ×6 mm

Pulses per revolution for encoder

Line driver Standard: 2000 P/ROptional: 200,500,1000 P/R

Open collector Optional: 200,500,1000,2000 P/R

Oil seal ––––

■

Speed-Torque Characteristics

Servo motor model no. / Flange size / Rated output

KB402/42 mm/23 W KB404/42 mm/40 W KB406/42 mm/60 W

0

0.1

0.2

0.3

0.4

0.5

0

2000 3000 4000 500

1000

-1

Intermittent duty zone

V=20V

Continuous duty zone

0

0.2

0.4

0

2000 3000 4000 500

1000

0.6

-1

Intermittent duty zone

Continuous duty zone

V=24V

0

0.5

1

0

2000 3000 4000 50001000

-1

Intermittent duty zone

V=24V

Continuous duty zone

Input voltage

24 VDC class (Low-voltage model)

MotorTachogeneratorBrake

Encoders can not be installed to KB4 models with a tachogenerator.

The holding brake cannot be used for dynamic braking.

Holding brakes are also available in 24 and 48 V. (Optional)

Specifications are subject to change without notice.

24 VDC class models (low-voltage models) are outside the scope of CE

marking and UKCA marking.

The values in the row with "☆" are for when the ambient temperature and

armature winding temperature are 25°C.

The values in the row with "☆☆" are after thermal equilibrium is established.

The values in the table above are for when operated with a stable DC current

at ambient temperatures below 40°C.

The values for the tachogenerator are for when the test circuit shown below is

used.

10kΩ

10kΩ

0.1μF

TG