PRICECNC AVHC10 User manual

1

CNC Plasma Torch Height Controller

Installation and Operation Manual

Model: AVHC10 Rev: 1.4

2

SAFETY NOTICE

WHEN THIS DEVICE IS IN OPERATION, VOLTAGES

HAZARDOUS TO HEALTH AND HUMAN LIFE ARE

PRESENT INSIDE THE ISOLATION MODULE.

This device should only be connected by a qualified and authorized person.

Improper connection can cause serious injury or death. Prior to installation and

operation, carefully read the entire manual and be absolutely sure that you fully

understand and are able to make the sole decision to determine if you are capable of

a safe and proper installation. Remember that inside the Isolation Module, voltages

hazardous to health and life may be present.

There must be no physical contact with any electrical connections while this device

or any connected device is powered. Do not operate this product with wet hands, wet

gloves, or any wet clothing. Before turning the unit on, secure the safety of others,

and read and understand all instructions. If you have any questions or concerns, do

not continue. Keep device away from water.

Warning: Provide adequate protection for all risks associated with plasma cutting.

For more detailed information of the risk associated with plasma cutting, refer to your

plasma cutter's owner manual.

This device must be earthed/grounded in accordance with this installation guide,

earthing of non-electrified conductive parts (including device housings) is an

essential part of electrical safety.

Touching non-insulated and non-grounded elements can be fatal. Provide a safe

place for your device. After installation, securely protect against any physical contact

between the terminals on the Isolation Module and any person(s).

It is strictly prohibited to perform any repairs or modifications to this product,

performing either one of these actions could lead to serious injury or death to

yourself and/or others.

Terms of Use: By proceeding with the installation and use of this product, you fully

understand and agree that PriceCNC and their distributors are not liable for any

incident or event resulting in direct loss, indirect loss, injury to self or others, damage

to property, or loss or damage of any kind and that the end user assumes all risks. If

you do not agree to these terms in their entirety, proceed no further, and return this

product for a full refund.

If you have any questions or are unsure about anything stated in this manual, please

contact a PriceCNC dealer or service centre for assistance.

3

Contents

Introduction ......................................................................................................................... 4

1. Things you should know before Installation .............................................................. 5

1.1 High Frequency Plasma Cutter Interference ................................................................ 5

1.2 Earthing ....................................................................................................................... 6

1.3 Floating Z-Axis (not included) ...................................................................................... 6

2. Installation ....................................................................................................................... 7

2.1.1 Raw Arc Measuring Point Connections ..................................................................... 7

2.1.2 (50:1) Measuring Point Connections ......................................................................... 7

2.2.1 Anti-Dive input signal on Mach3................................................................................ 7

2.2.2 Anti-Dive on UCCNC ................................................................................................ 8

2.3 Mounting Holes............................................................................................................ 8

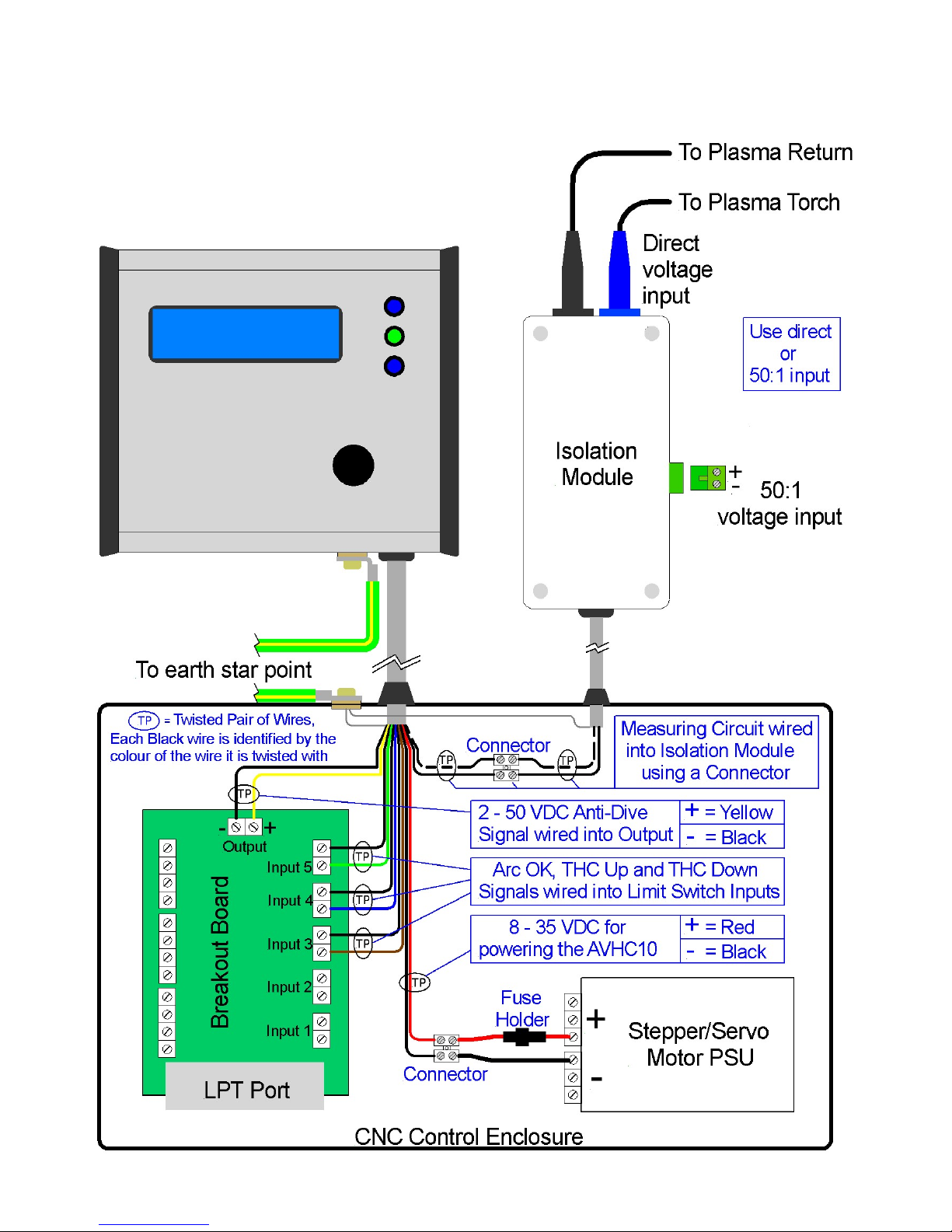

2.4 AVHC10 Installation Wiring Diagram ........................................................................... 9

2.5 Wiring Definitions ....................................................................................................... 10

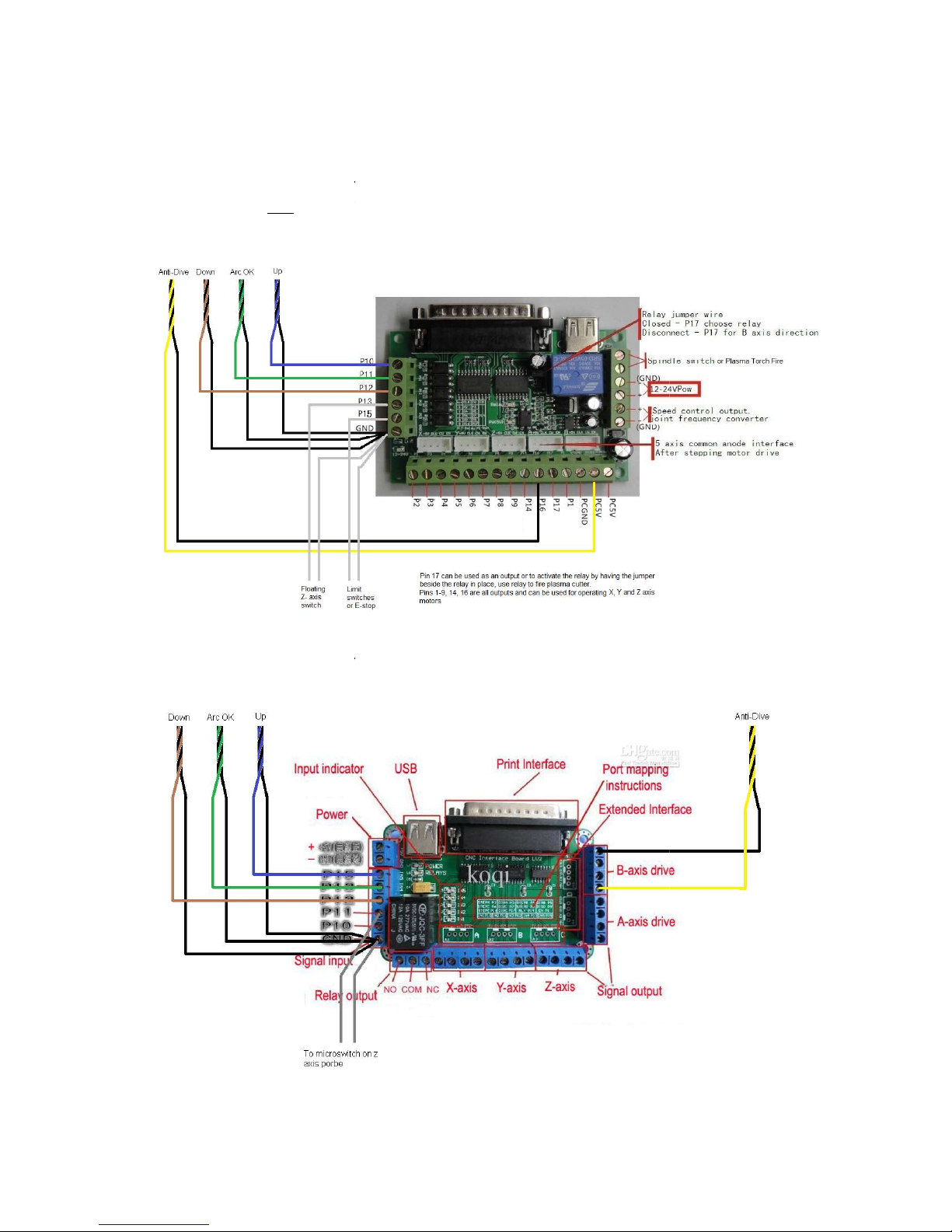

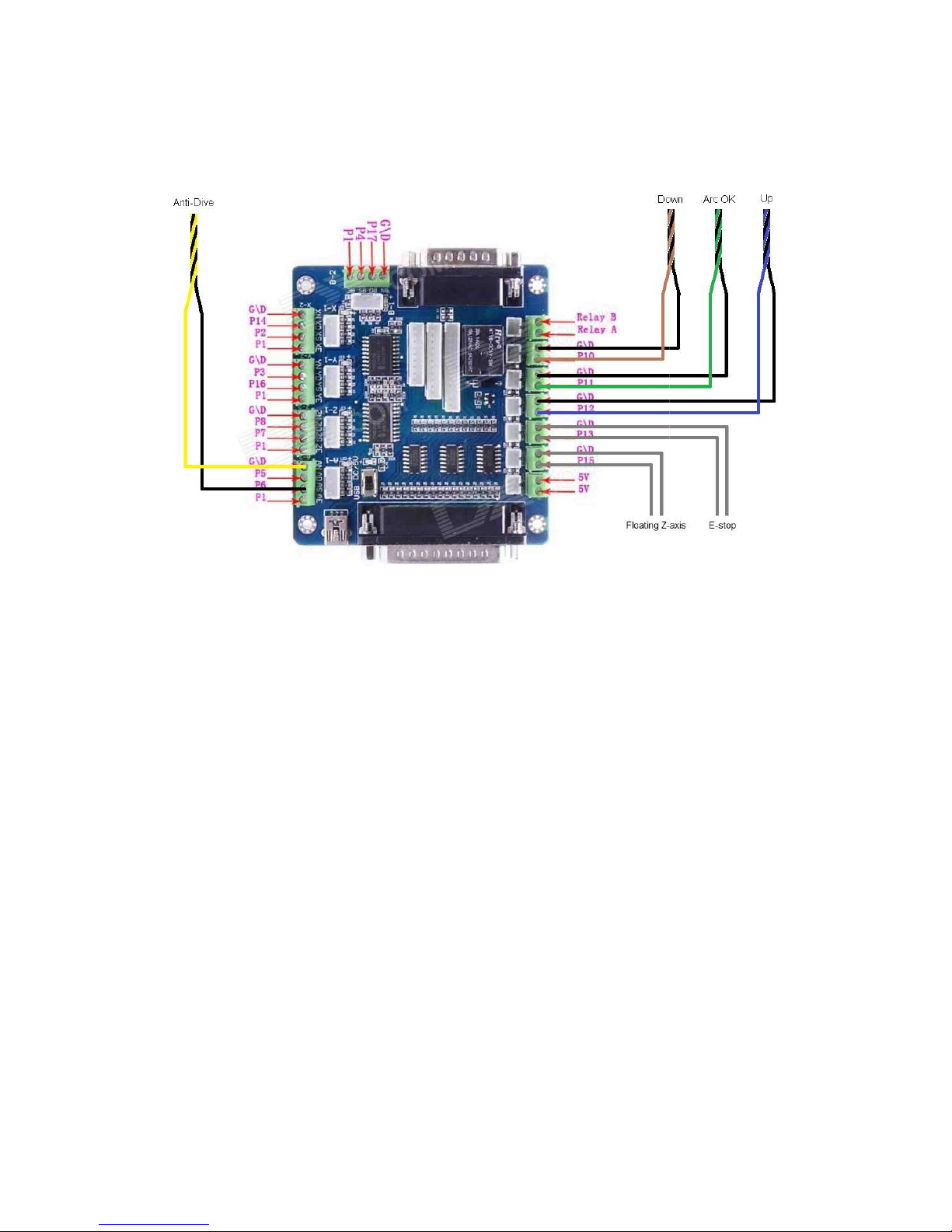

2.6 Popular Breakout Boards (BOB) Wiring Examples .................................................... 11

2.7.1 Setting up the AVHC10 in Mach3 ........................................................................... 13

2.7.2 Setting up the AVHC10 in UCCNC ......................................................................... 15

3. Things you should know before operating your Plasma CNC with THC ................... 16

3.1 Post Processors ........................................................................................................ 16

3.2 Basics ........................................................................................................................ 16

3.3 Air Pressure ............................................................................................................... 16

3.4 Plasma Current Considerations ................................................................................. 17

3.5 So what current do I choose? .................................................................................... 18

3.6 Feed Rate .................................................................................................................. 18

3.7 Torch Height Control ................................................................................................. 19

3.8 Finding the correct Arc Voltage .................................................................................. 19

3.9 Setting THC Sensitivity .............................................................................................. 19

3.10 Measure Period ....................................................................................................... 20

3.11 THC Z-Min and Z-Max ............................................................................................. 20

4. AVHC10 Operation ........................................................................................................ 21

4.1 Display List ................................................................................................................ 23

5. SheetCam Cut Rules ..................................................................................................... 25

4

Introduction

When using a CNC Plasma cutting table, good cut quality can only be achieved by

maintaining a consistent distance between the cutting torch and the material being cut. This

can be difficult to achieve as heat from the cutting process can warp the material being cut

or the material that is being cut may not be level or flat. To overcome these problems during

cutting, the cutting torch needs to be raised and lowered to compensate for changes in the

height of the sheet.

The PriceCNC Arc Voltage Height Controller measures the voltage between the plasma

torch and the material being cut, this is known as the ‘Arc Voltage’. As the distance between

the torch and the material changes during a cut, the voltage also changes. The greater the

distance, the higher the voltage whereas the smaller the distance the lower the voltage. By

measuring the changes in the Arc Voltage, the AVHC10 can continuously adjust the arc

length for optimum cutting performance.

Different materials types and thicknesses require different height controller settings. For

convenience, up to 30 different material or thickness settings can be saved on the AVCH10.

This is discussed further in Section 4: ‘AVHC10 Operation’.

CNC Plasma cutting is a complex process that can take some time to come to terms with

before satisfactory cut results are consistently achieved. Particularly if you are learning it all

as you build your own CNC table or through trial and error. I have included two unusual

sections in this manual to make it as useful as possible for those with little experience.

Section 1: ‘Things you should know before Installation’ and Section 3: ‘Things you should

know before operating your Plasma CNC with THC’ are based on my personal experience

from having designed and built my own CNC plasma Table and from the research taken to

develop this product.

5

1. Things you should know before Installation

The PriceCNC Arc Voltage Height Controller (AVHC10) has two main components. One is

called the ‘User Interface’ and the other is called the ‘Isolation Module’. Both of these units

need to be connected to each other. The Isolation Module also connects to the plasma

cutter. Additionally the user interface also connects to a power supply as well as the signal

inputs and outputs on the breakout board.

In this manual, we show how to install the PriceCNC AVHC10 on to a Plasma CNC table

with the following properties, other variations are possible:

Design Software SheetCam

Work Software MACH3 or UCCNC

Breakout Board 3-Axis with 3 spare inputs and 1 spare output

(spare output not required with UCCNC, an

unused axis can be used as 2 separate output

signals)

CNC Machine DIY or Professional 3-Axis CNC Table with

Floating Z axis and probe switch

Plasma Cutter Any commercially available model with cutting

arc voltages in 70-250V DC range

1.1 High Frequency Plasma Cutter Interference

Some value plasma cutters use a high frequency, high voltage starting arc to strike across

the air gap between the plasma cutter electrode and the work piece. This starting arc can

generate massive electromagnetic fields which can interfere with surrounding electronics

including CNC motors, drive units, breakout board and computers. This electromagnetic field

comes from the cables that connect the plasma cutter electrode to the plasma cutting

machine. Cables that are connected to this circuit can also spread interference. The

PriceCNC Arc Voltage Height Controller is designed to keep this interference away from the

CNC control circuitry by utilising a completely electrically isolated measuring circuit in the

Isolation Module. The Isolation Module is also supplied and fitted with a shielded cable that

provides the User Interface with a clean signal for accurate measurement.

6

1.2 Earthing

To prevent the previously mentioned High Frequency interference from becoming an issue

on your CNC plasma cutting equipment, proper earthing/grounding must be fitted using at

least 16mm2 (AWG 5) multi strand cable. In a typical 3-axis CNC plasma cutting setup, the

components should be earthed directly to the star point. The star point is a point where the

earth wires from all of these individual items meet; this is then connected to the earth

electrode. The components to be connected are as follows:

Arc Voltage Height Controller aluminium case.

Fixed portion of table.

Gantry

Buggy

Z axis travel plate

Stepper/Servo motor control box

Plasma Cutter case

The alternative to a star point earthing system is a daisy chain earthing system. This is not

recommended as it is not as effective at preventing interference. If your star point is not

sufficiently connected to the mass of earth, your earthing system may spread interference

instead of absorbing it into the ground.

1.3 Floating Z-Axis (not included)

A floating z-axis is a method of mounting the plasma torch to your CNC machine that allows

your CNC machine to measure the height of the material to be cut before each cut starts.

This feature is highly recommended as it sets the pierce height and initial cut height correctly

at the start of every cut regardless of sheet warping or slope.

To achieve this, the plasma torch must be mounted to the z-axis in such a way that it will

activate a micro-switch (or similar) when the tip of the torch touches the material to be cut.

Usually this is achieved my mounting the torch to the z-axis using a set of rails that permit it

to float up and down independent of the motorised z-axis.

This micro switch must be connected to an input on your Breakout Board (BOB) which

operates the Digitize/Probe inputs in Mach3 or UCCNC.

When this method is used with the correct G-code (G31), the Z-axis Digital Read Out (DRO)

will be reset to zero at the start of each cut. This compensates for uneven sheet height and

improves the cut quality.

In Mach3 and UCCNC, you can also set upper and lower z-axis limits of THC operation. This

is a very useful failsafe for THC and can prevent the torch raising too high or diving too low

during cutting. For the z-axis limits and the pierce and initial cut height settings to work

correctly, a floating z-axis or equivalent method of resetting the z-axis at the start of each cut

is essential for reliable and consistent plasma cutting.

The floating z-axis operation is managed by a Post Processor, see section 3.1 for more

details.

7

2. Installation

2.1.1 Raw Arc Measuring Point Connections

(We recommend you only use Raw/Direct Arc measurement when the 50:1 voltage divider is

not provided with your plasma cutter. Most good brands of plasma cutter sold for use on

CNC machines will have a 50:1 voltage divider.)

For Raw/Direct Arc measurement, a connection into the main plasma terminals on the

outside of the plasma cutter will usually be sufficient.

Sometimes rust or dirt on the work sheet can cause a poor clamp connection which can

create a voltage difference between the clamp and the work piece which can affect the

measured voltage used for controlling torch height. If you have problems measuring a stable

voltage during cutting, consider connecting the black connection on the Isolation Module to

the work piece by a separate small clamp (this option does not apply to the 50:1 input).

2.1.2 (50:1) Measuring Point Connections

The 50:1 measuring circuit is designed to work with the 50:1 voltage divider output on a

Hypertherm Powermax 45 plasma cutter and other plasma cutters that use the same resistor

network to create the 50:1 voltage. The Hypertherm Powermax 45 plasma cutter uses a

100,000 and a 2,000 ohm resistor in series to produce the 50:1 voltage across the 2,000

ohm resistor. The PriceCNC AVCH10 is calibrated for use with 50:1 voltage dividers with

these particular resistances. Other resistor values may work but the accuracy of the

measured voltage may be affected. Consult your plasma cutter manual to determine if your

plasma cutter has a built in voltage divider and to identify which pins on the connector on the

back of the plasma cutter you need to connect to. Many Hypertherm plasma cutters have

internal dip switches that select the ratio of the internal voltage divider. These may need to

be adjusted to select a 50:1 output voltage.

2.2.1 Anti-Dive input signal on Mach3

A reduced feed rate is often used when cutting small holes or tight angles, this reduced feed

rate will increase the arc voltage, which may cause the AVHC10 to lower the torch into the

work piece. To prevent the torch diving into the work piece when a reduced feed rate is

used, Torch Height Control (THC) should be deactivated during the reduced feed rate. To

temporarily deactivate THC you can use a selection of different methods. An option that is

available in Mach3 is the THC min speed setting which will make the software ignore the

up/down commands from the AVHC10 if the feed rate has dropped by the selected

percentage of the normal (G01) feed rate. This function is usually adequate for good plasma

cutters.

Cheap plasma cutters may need more specific anti-dive assistance by using Cut Rules in

SheetCam that tell the G-code to turn off and on THC as required. These rules are relatively

easy to setup as per section 5. Another way to deactivate Torch Height Control in Mach3 is

to use an anti-dive Macro. Unfortunately Mach3 pauses the operation of the CNC machine

momentarily while it executes the macro which may result in poor cut quality (dings/notches).

8

To overcome this, the PriceCNC AVHC10 can take in a signal that blocks outgoing Raise

and Lower commands. Using the correct cut rules in SheetCam, the Post Processor will

write G-code that includes a command to turn on and off a signal output on the breakout

board. This signal is received by the AVHC10 which tells it to block the raise and lower

commands. This method is simple to install on most breakout boards and prevents the CNC

machine from needing a Macro to turn Torch Height Control on and off from commands in

the G-code.

When anti-dive is activated in the AVHC10 using the anti-dive signal (yellow wire), both blue

LEDs will light up.

2.2.2 Anti-Dive on UCCNC

A reduced feed rate is often used when cutting small holes or tight angles, this reduced feed

rate will increase the arc voltage, which may cause the AVHC10 to lower the torch into the

work piece. To prevent the torch diving into the work piece when a reduced feed rate is

used, Torch Height Control (THC) should be deactivated during the reduced feed rate. To

temporarily deactivate THC you can use a selection of different methods. An option that is

available in UCCNC is the THC min speed setting which will make the software ignore the

up/down commands from the AVHC10 if the feed rate has dropped by the selected

percentage of the normal (G01) feed rate. This function is usually adequate for good plasma

cutters.

Cheap plasma cutters may need more specific anti-dive assistance by using Cut Rules in

SheetCam that tell the G-code to turn off and on THC as required. The M-codes M205 and

M206 can be inserted into your g-code file by using cut rules in SheetCam (M205 = THC on

and M206 = THC off). These rules are setup as per Section 5.

The Anti-dive (yellow wire) input signal on the AVHC10 is not required with UCCNC software

as UCCNC has special M-codes that turn on and off THC from within UCCNC.

2.3 Mounting Holes

There are two threaded holes on the rear of the AVHC10 that can be used to mount the unit

onto your CNC machine or control console. M4 screws are provided.

9

2.4 AVHC10 Installation Wiring Diagram

10

2.5 Wiring Definitions

AVHC10 (user interface)

Wire Pairs

Polarity

Function

Min.

Value

Max. Value

Unit

Red Positive Supplies power to the AVHC10 8 35 V

Black Negative

White Positive Measures the signal from the

Isolation Module

Black Negative

Yellow Positive Receives Anti-Dive Signal from

Mach3/UCCNC via Breakout Board 2 50 V

Black Negative

Green Either Sends Arc OK Signal to

Mach3/UCCNC via Breakout Board

50 V

Black Either 100 mA

Blue Either Sends Torch Up Signal to

Mach3/UCCNC via Breakout Board

50 V

Black Either 100 mA

Brown Either Sends Torch Down Signal to

Mach3/UCCNC via Breakout Board

50 V

Black Either 100 mA

Isolation Module

Wire Pairs

Polarity

Function

Max. Value

Unit

White Positive Sends Isolated and reduced

signal to the AVHC10

Black Negative

4mm Plug

Polarity

Function

Max. Value

Unit

Blue Negative* Connects to Plasma Electrode -300 continuous*

(HV starting Arc OK) V

Black Positive* Connect to Plasma Return clamp

50:1

Plug

Polarity

Function

Max. Value

Unit

Green See

Label Connects to 50:1 voltage divider 6 (HV starting through

100k Resistor OK) V

* Most Plasma Torch Electrodes operate at Negative Voltages

2.6

Popular Breakout Boards

Wiring Example 1:

This board has a common terminal for all of the input signals

via the USB port and 12-

24V via the Power Terminals

for anti-dive.

This BOB also has a

milling spindle on your CNC machine.

Wiring Example 2:

This board has a common terminal for all of the input signals and must be supplied with 5V

via the USB or 5V via the Power Terminals.

11

Popular Breakout Boards

(BOB) Wiring Examples

This board has a common terminal for all of the input signals

and must be supplied with 5V

24V via the Power Terminals

. Any unused axis output can be used

This BOB also has a

spindle speed control output, useful if you plan on using a

milling spindle on your CNC machine.

This board has a common terminal for all of the input signals and must be supplied with 5V

via the USB or 5V via the Power Terminals.

and must be supplied with 5V

. Any unused axis output can be used

spindle speed control output, useful if you plan on using a

This board has a common terminal for all of the input signals and must be supplied with 5V

Wiring Example 3:

This board has individual

terminal

via the mini

USB or 5V via the Power Terminals.

12

terminal

s

for all of the input signals and must be supplied with 5V

USB or 5V via the Power Terminals.

for all of the input signals and must be supplied with 5V

13

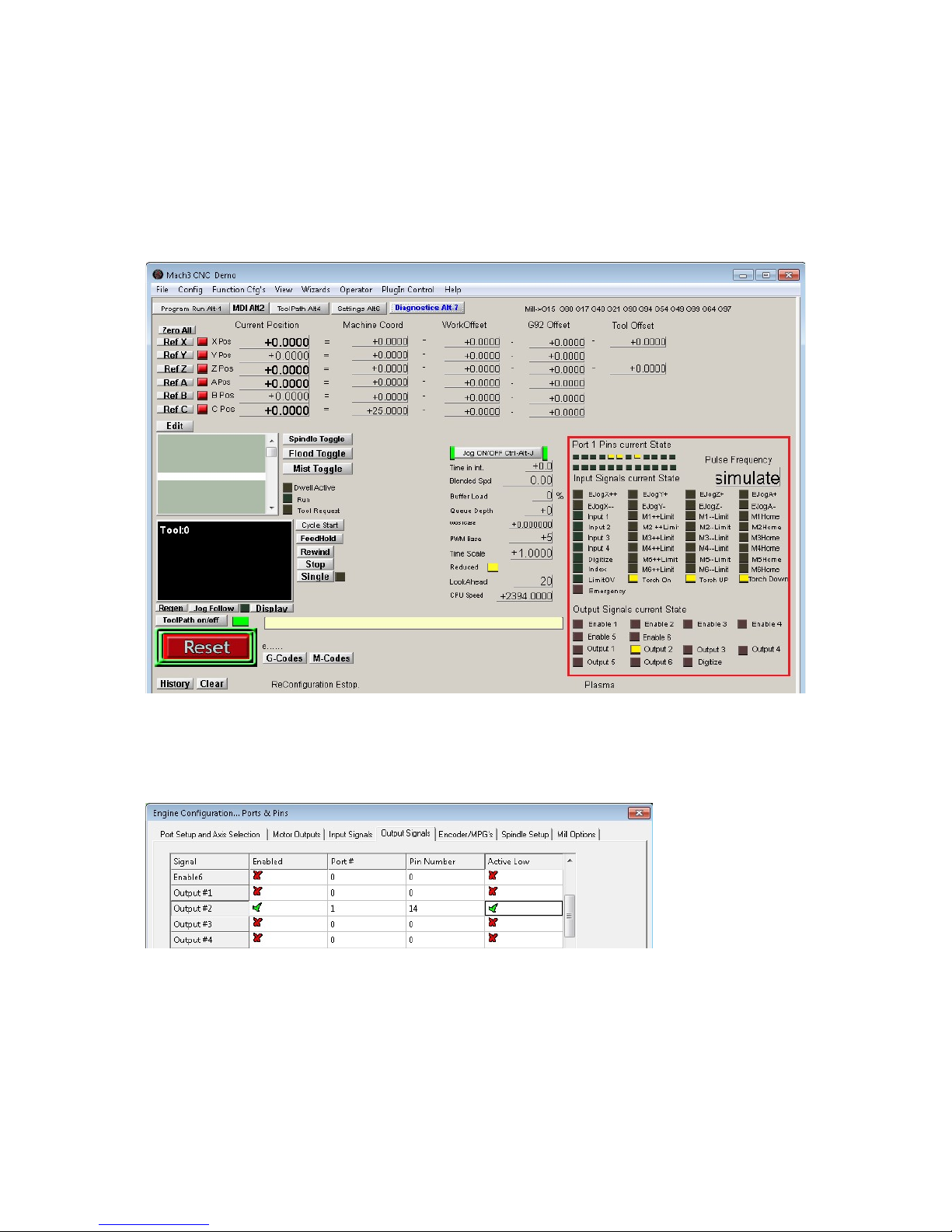

2.7.1 Setting up the AVHC10 in Mach3

1. From the Menu Bar in Mach3, click on ‘Config’ > ‘Ports and Pins’ > ‘Input Signals’.

2. Scroll down the Signals list and change the setting for ‘THC On’, ‘THC Up’ and ‘THC

Down’ to the correct Port and Pin Number.

Note: The ‘Probe’ signal is for the floating Z-axis and responds to G31 commands.

3. Click on the ‘Output Signals’ tab. Change the setting for ‘Output #2’ to the pin that will

operate the AVHC10 anti-dive.

Note: A different output number can be selected from the signal list. ‘Output #2’ is turned

on by the G-code command ‘M11P2’ and turned off by ‘M10P2’ If a different output

number is required, change the ‘2’ in the code snippet to the required number when

creating the rules in SheetCam. For details, see section 5.

14

To verify that Mach3 is communicating correctly with the AVHC10, view the diagnostics

screen in Mach3.

Using screen 6 on the AVHC10, you can manually operate the Arc OK, Torch UP and Torch

Down signals (see section 4.1 for details). If the AVHC10 is communicating correctly through

the Breakout Board, the corresponding signals should light up the respective pins signal

status indicators.

To verify the anti-dive signal is working, in Mach3 click on ‘Config’ > ‘Ports and Pins’ >

‘Output Signals’ , scroll down to ‘Output #2’ and click on ‘Active Low’ to change the state of

the signal. The two blue LEDs on the AVHC10 will light together to show the anti-dive signal

is activated and working. Click on ‘Active Low’ again to turn off the test signal.

15

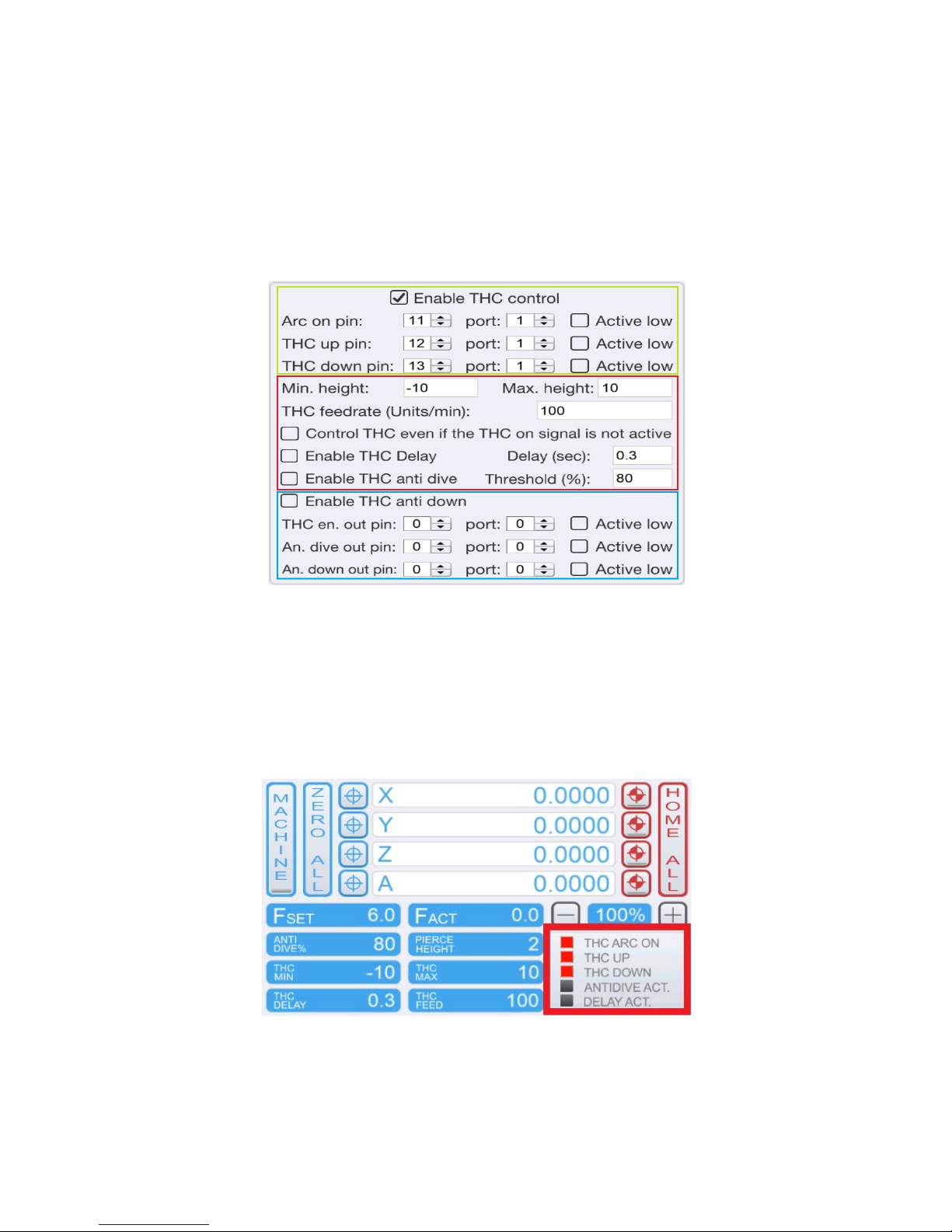

2.7.2 Setting up the AVHC10 in UCCNC

1. From the Menu Bar in UCCNC, click on ‘CONFIGURATION’ > ‘I/O SETUP’.

2. In the green area below, tick the ‘Enable THC control’ box and below that, set the Port

and Pin Numbers for the ‘THC On’, ‘THC Up’ and ‘THC Down’ signals. The values in the

red area can be set here or on the ‘Run’ screen (shown further below) and the values in

the blue area are not required.

3. Click on ‘Apply settings’ > ‘Save settings’

4. From the Menu Bar in UCCNC, click on ‘RUN’

5. Using screen 6 on the AVHC10, you can manually operate the Arc OK, Torch UP and

Torch Down signals (see section 4.1 for details). If the AVHC10 is communicating

correctly through the Breakout Board, the corresponding signals should light up on the

‘RUN’ screen in UCCNC.

The UCCNC signals should light with the LEDs on the AVHC10. If the signals are operating

in reverse to the LEDs on the AVHC10 (on is off and off is on), go back to Step 2 and tick the

‘Active low’ boxes beside the pins and Ports and save settings again.

16

3. Things you should know before operating

your Plasma CNC with THC

3.1 Post Processors

A post processor is a file that contains instructions that are used by SheetCam to permit

SheetCam to create G-code that will work with your particular CNC machine. Generally

features such as a Floating Z-axis, an Engraver or automatic Plasma Current Control will

require a special Post Processor that allows SheetCam to create G-code that can operate

these custom/optional features. There are many existing Post Processors that come with

SheetCam that contain these features.

If you are using the Floating Z-axis as described in section 1.3 you can download a Post

Processor that I have modified specifically for this purpose at www.pricecnc.com This Post

Processor will reset the Z-axis to zero each time, just before the torch fires. This Post

Processor also contains a switch offset value to correct for slack in the Probe switch when

zeroing the Z-axis. This is set to 0.7mm by default but you can edit the post processor in

SheetCam to change this number to compensate for any slack in your own Probe switch.

3.2 Basics

Your Torch Height Controller (THC) is designed to compensate for changes in the height of

the work piece only. It will not compensate for other bad setting that may lead to poor quality

cuts. If your feed rate, plasma current or air pressure are not set correctly or if there is a bad

electrical connection between the clamp and the work piece, you will likely produce poor

quality cuts with or without a THC. If any of these parameters are not correctly set, your THC

will not operate reliably. It is crucial to get all these other variables correct before you even

try to use Torch Height Control.

3.3 Air Pressure

The pressure that a particular plasma cutter operates at usually does not change with

material thickness or type. This value should be set as per your plasma cutter

manufacturer’s recommendations for the material being cut. Ensure that the pressure listed

is the pressure that your pressure gauge reads when the plasma cutter is firing. A pressure

value set when no air is flowing will usually drop lower when the air flows through your

plasma cutter. Some plasma cutters have a test switch that turns on the air without actually

firing the plasma cutter. Some form of compressed-air water catcher or drier is essential to

reduce changes to cutting properties brought about by water drops in the air flow.

17

3.4 Plasma Current Considerations

The correct Plasma Current on your plasma cutter may vary for different materials and

different thicknesses. Most plasma cutters come with a guide on this but that guide is at best

an indication of optimum values. The best current for your CNC table takes several factors

into consideration. These are:

Material Thickness – Thicker materials require Higher Current to cleanly pierce the

material. With a higher current, the feed rate can also be increased which saves time.

Material Type – Materials with a higher melting point and a higher material density

require more heat energy to melt, this means that steel will require more current or a

lower federate than a similar thickness piece of aluminium.

Max Feed Rate of CNC table – If the current is set to the max while cutting a

relatively thin piece of material, the CNC table may not be able to move fast enough

to achieve the feed rate required for a good cut.

Acceleration/Deceleration ability of CNC table – The top speed of your CNC

machine is not as important as how quickly it can turn a right angle corner.

Acceleration is all about how fast the machine can reach the required feed rate. If

you think about it, as your machine approaches a corner, one of your axes, let’s say

the X-axis, has to go from the cut feed rate to stopped and the other axis, the Y-axis

has to go from stopped to the cut feed rate. Depending on how fast your machine

can accelerate to a given feed rate will also determine how fast you can really cut.

Any amount of time that your CNC machine spends slowing down to, or speeding up

from a corner is time when it is not cutting at the ideal feed rate.

Duty Cycle of Plasma Cutter – Your Plasma Cutter might be rated at (for example)

50 Amps but that does not mean you can cut all day long at 50 Amps. Most plasma

cutters have a duty cycle, which if exceeded will overheat your plasma cutter and

cause it to shut down. Many Plasma Cutters can only run for 60% of every 15

minutes at full current or continuously at 60% of full current. If your cut job is going to

last just 5 minutes of torch on time, you may be able to achieve full current for the

whole job. But if the cut job requires 30 minutes of cutting on a large sheet of metal,

you may need to lower the current accordingly. The reduced current will require a

reduced feed rate. See your plasma cutters manual to determine the duty cycle.

18

3.5 So what current do I choose?

Initially you should choose the manufacturers recommended current for the given material

and material thickness and take all the above factors into consideration as your experience

of your machine grows. For a given material and thickness, higher currents will permit faster

feed rates when cutting. Faster is generally better as it saves time but cut quality can be

negatively affected if your CNC table is not able to maintain steady movement and fast

cornering at the higher speeds. If your table has poor acceleration, you may have to lower

the federate and current accordingly.

3.6 Feed Rate

I find manufacturer’s recommended feed rates are only a guide and the best feed rate to use

should be determined by testing.

Before you decide on a feed rate you need to decide on a Plasma Current, verify air

pressure is correct and ensure consumables (Plasma Electrode) are in good condition. Then

look up the manufacturer’s recommended feed rate for your plasma cutter and perform some

test cuts on a level piece of material.

To perform your test cuts, design a cut job that has 11 parallel test lines about 10mm (3/8”)

apart where each line is 100-150mm (4-6’) long. The cut feed rate for the centre line should

be set to the value that was recommended by the plasma cutter manufacturer and the

parallel lines on one side of that

line should each be cut 5-10%

faster and 5-10% slower to the

other side. This will produce 11

cut lines where you cut each line

at a different feed rate. The cut

job should also cut a rectangle

around the test lines so you can

lift up the test piece to easily

inspect the cut quality from both

sides.

When the test cut is finished, try

to determine which line has the

best cut quality. The best cut will

usually be the one with the least

dross and the most uniform cut.

The sides of the cut should have

minimal tapering.

19

3.7 Torch Height Control

Unless you have verified that you can cut reliably on level materials, Torch Height Control

will not improve your cut quality. THC is only able to compensate for a non-level work sheet

or for material warping caused by heat from cutting. It will not compensate for other faults or

bad settings.

3.8 Finding the correct Arc Voltage

To determine the correct arc voltage for a particular material type, material thickness, feed

rate and current; you should cut a 200mm (8”) long test line on a level sheet of material with

THC turned off in your software (Mach3/UCCNC). As the test cut proceeds, look at and

remember the measured Arc voltage on your THC (AVHC10).

Then set the Nominal Voltage on your THC to the value you witnessed on that cut and cut

another test line with the THC turned on in your software. You should lower the THC feed

rate in your software to about 5% of the cut feed rate until you get the other settings on your

THC correct. The arc voltage may still need to be fine-tuned so be prepared to adjust the arc

voltage during the first few cuts. If the torch is operating too close to the material, increase

the Nominal voltage by small amounts and if the torch is operating too high above the

material, lower the Nominal voltage. You may need to repeat this test cut several times until

it produces a good repeatable cut. If torch height control seems under or over responsive,

read the next section.

3.9 Setting THC Sensitivity

During cutting, your THC has to react to changes in the arc voltage. As there is always some

miniscule delay between the time the voltage is measured and the time the Z-axis motor

reacts to correct the arc voltage, it is possible that the corrective action can under or over

correct the height of the torch. If your Torch seems slow to react to the contours of the work

piece, it can be described as under responsive. To increase the sensitivity you can increase

the THC feed rate in your software and/or reduce the tolerance voltage on your THC.

Inversely, if your THC seems to over react and is continuously raising and lowering over

level parts of the work sheet (bobbing up and down). You can reduce the THC sensitivity by

lowering the THC feed rate in the software and/or increasing the tolerance voltage on the

THC.

I recommend you use a 5% THC feed rate until you are more confident with your THC. You

can increase this to 20% or 30% as your confidence in its operation grows.

I recommend you set the Tolerance voltage on your THC to 1.0 volts initially. Increase the

value to reduce Torch Bobbing (excessive up and down) or decrease the value to improve

responsiveness.

20

3.10 Measure Period

The PriceCNC AVHC10 has an adjustable measure period. The measure period is the

duration in milliseconds over which the THC repeatedly measures the arc voltage and

calculates an average value, which it compares to the nominal voltage when deciding on a

corrective action (raise or lower the torch). Cheap plasma cutters often have spikes or dips

in their current delivery which distorts the measured voltage and can cause undesirable

operation of a THC. If these spikes and dips are averaged over a slightly longer period of

time, the usefulness of the value in deciding whether to raise or lower the torch can be

greater than the any problem associated with the tiny additional delay caused by averaging

more measurements.

I recommend setting the measure period to 0.01 for users of high end Plasma Cutters and

between 0.05 and 0.1 for users of budget plasma cutters. This value should be set to the

lowest value that produces good Torch Height Control.

3.11 THC Z-Min and Z-Max

Torch Height Control can cause unexpected or undesirable results for a variety of

unforeseen reasons. A good way to limit the torch rising too high or diving too low during a

cut job is to narrow the range of operation by setting limits in Mach3/UCCNC that are set to

the practical limits the torch should operate in. I usually set the Z-min to 0 or -5mm and the

Z-Max to 10 or 20mm, depending on the warping that I expect to compensate for.

A practical Z-min, Z-Max and THC Feed Rate percentage can limit the actions of the torch to

practical limits which greatly reduces the chance of messing up the job. It can also give the

operator a chance to correct the Nominal Voltage on the Height Controller before the torch

does something that negatively affects the cut quality.

Other manuals for AVHC10

1

Table of contents

Other PRICECNC Controllers manuals