Keep the machine as clean as possible.

Clean the inside of the machine by compressed air ,at least 2 times per year.

(Depen- ds on the quality of the water).

Periodically clean the electrode No 16 from deposited salts ,and pay attention on

its replacement. (See the correct position on the enclosed wiring diagram).

Periodically check if the links of the water and steam pipes have leaks.

When the heating element No 23 has to be replaced, take the chance to clean the

salts of the inside of the steam boiler No 22 , by a pointed instrument.

When you keep the machine out of operation for a long period of time, leave the

steam boiler Nr 22 filled with water to avoid boiler’s inside oxidation .

The pump does not run:

- Check the responding fuse for pump on the electronic PC board typ.ECO 903No33

- Check if the voltage of the power supplied to the pump No 21 is 230V.

- Check if the pump is stuck off due to salts –this usually happens when the pump is

out of work for a long period time - Shooting :Turn the Pivot of the pump by

putting a scre- wdriver through the hole at the back side of the machine which

leads to the pump.

- Check if the pump is clogged.

The water is not heated while the steam lamp lights on.

- Check the fuse(1Amber) which is used for the heating on the electronic circuit

card

- Check the relay which is used for the heating on the Electronic circuit card.

- Check the Pressure switch No 15 (symbol PS on the wiring diagram)

- Check the relay K1(symbol on the wiring diagram)

The steam iron is not heated while the iron lamp lights on:

- Check the fuse (25Amber) according to the wiring diagramm.

- Check the iron itself, the cabel, the thermostat etc.

If the iron is heated normally but it does not blow steam check the coil 12W/230V of

the solenoid steam valves No 38 (EV1, EV2 on the wiring diagram) as well as the

steam microswitch of the iron.

If the boiler is overfilled and the iron blows steam & water

- Check electrode E1 No16:clean or replace it.

- Check solenoid water valve No30: clean or replace it.

- Check if the water control system on the Electronic circuit card No32 is running

normally. If not, replace it.

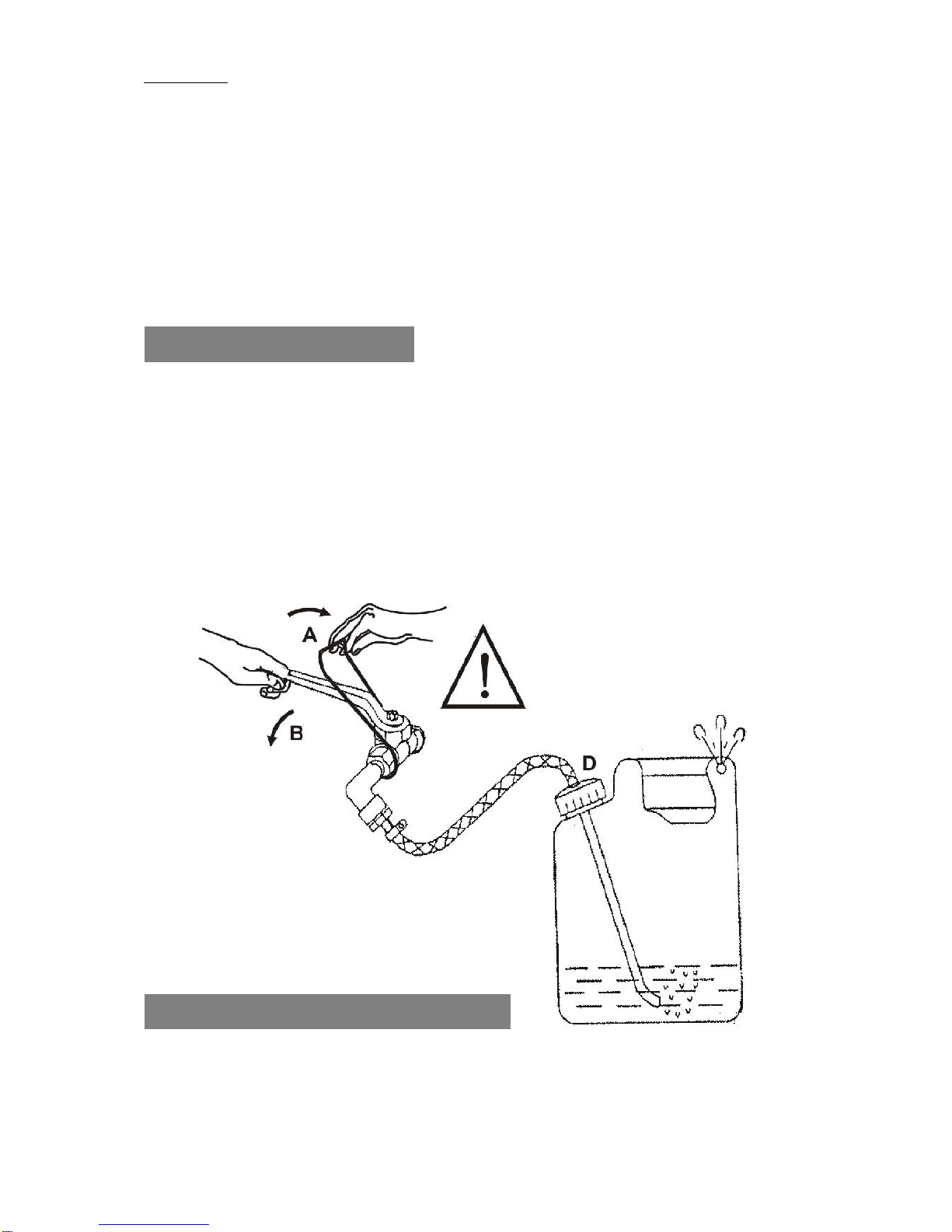

If the pump is ordered to feed water in very short periods & steam draining is

appeared in the feed-water tank No 1, check the one way valve No29:Clean or

replace it , by paying attention on putting it back in the correct direction.