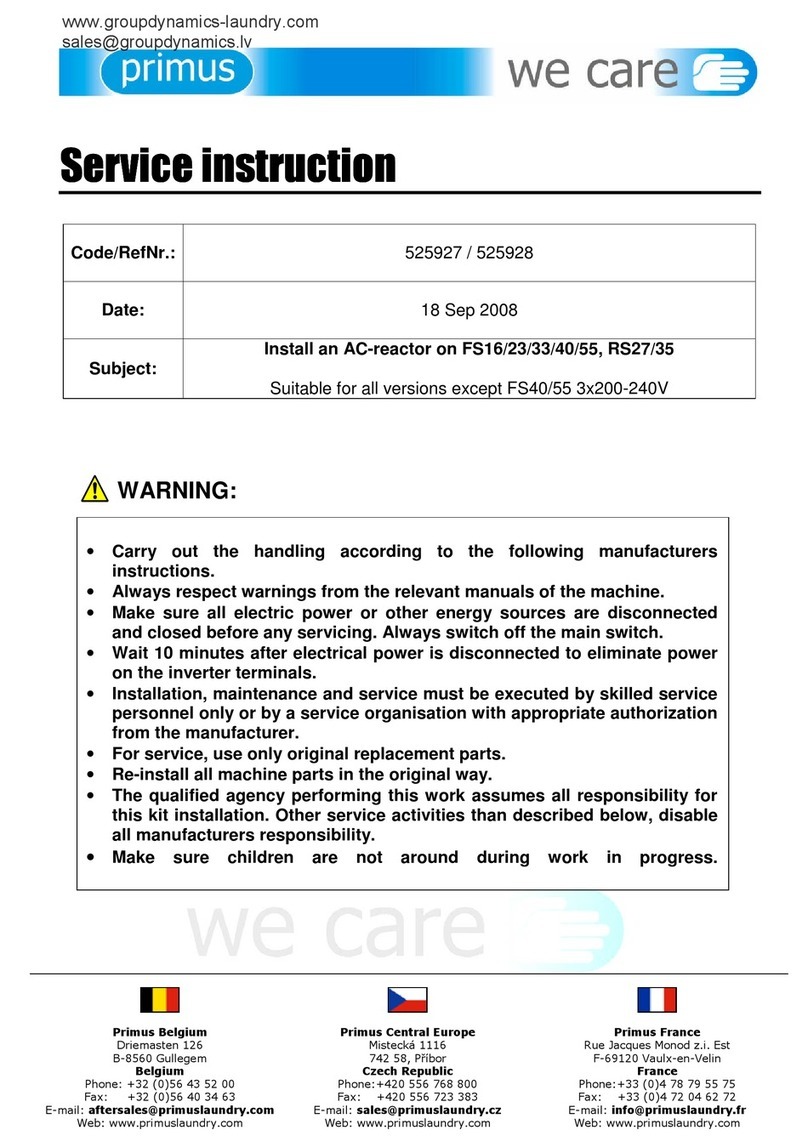

507 329 PUBLICATION DATE 05/05 USER´S MANUAL 7

CAUTION !

If the installed machine operates with coin,

token or similar operation, then the owner-

installer must provide a remote-located

emergency stop device. This device must be

placed in such a way that it is easy and safely

accessible for the users. The emergency stop

device ensures that at least the control circuit

of the washer extractors is interrupted.

USER’S MANUAL

1. ts

2. WARNINGS AND LABELS

READ THIS MANUAL CAREFULLY BEFORE OPERATINGTHE WASHER EXTRACTOR. IMPROPER USE OF

THE WASHER EXTRACTOR MAY CAUSE SERIOUS BODY INJURIES OR DEATH AS WELL AS SERIOUS

DAMAGE TO THE WASHER EXTRACTOR.

FAILURE TO COMPLY WITH THE INSTRUCTIONS IN THIS MANUAL MAY LEAD TO INCORRECT

USE OF THE WASHER EXTRACTOR, AND MAY RESULT IN BODILY INJURIES OR DEATH AND/OR

DAMAGE TO THE LAUNDRY AND/OR THE WASHER EXTRACTOR.

– This English version is the original version of this manual. Instructions for the washer extractor are only complete with the

programming and installation/maintenance manual.

– The washer extractor is designed for fabrics washing only, other objects can damage the machine and can cause damage or injuries.

– The manufacturer is not responsible for the damage to the fabrics that are washed by an inappropriate washing method.

– Always follow instructions and/or warnings that are stated on the fabrics, washing products or cleaning products mentioned by

the manufacturer.

– If the machine is used for special applications follow the instructions and warning to avoid person injury.

– Keep the washer extractor surface and surrounding clean and free of flammable materials.

– Do not put fabrics treated with flammable products in the washer extractor. Such fabrics must first be washed by hand and air dried.

– Store laundry aids, dry-cleaning solvents and disinfectants out of the reach of children, preferably in a locked cabinet.

– Do not tamper the washer-extractor controls and follow the safety instructions and the warnings.

– Do not remove warning signs placed on the machine. Follow instructions on signs and labels to avoid personal injuries.

– Do not put some part on the soap dispenser lid to held it open while filling or when the machine operates.

– We do not recommend to open the soap dispenser lid after the machine is started. The discharge or splashing of hazardous

liquid can cause serious scalding and burning.

– The use of hypochlorite will cause corrosion which may cause component failure under certain circumstances.

– Do not operate the washer extractor when parts are broken or missing or when covers are open. The machine shall not be

operated until the fixed guards are put correctly in place.

– The washer extractor is not designed for work which may create an explosive atmosphere inside the machine and will not be

used for this purpose.

– Do not expose the washer extractor to the weather, extreme low or high temperature and humidity.

– In case of steam escaping anywhere in the machine, shut off the main steam supply valve and call for maintenance.

– Under certain conditions, hydrogen gas may be created in the hot water system that has not been used for two or more weeks.

Hydrogen gas is explosive. If the hot water system has not been used for such period, open all hot water taps and let the water

run out for few minutes. This will release any accumulated gas. As this gas is flammable, do not smoke or use open flames

during this time.

– In case of danger turn off the main switch or other emergency disconnection devices.

– Check the functioning of the door lock mechanism on regular base.

– Turn off the main water supply at the end of each operating day.

– Only qualified service personnel can execute service on the washer extractor.

– Follow all valid and basic safety rules and laws.

– It is obvious that it is impossible to mention each possible risk in this manual. It is up to the user to proceed as

careful as possible.

– The manufacturer reserves the right to change the manuals without previous notice.

– If a problem should arise, contact your dealer for assistance.

– Norm IEC335 is applied for machines with a net usable drum capacity between 60 and 150 l. Norm EN60204-1 is used

for a net usable drum capacity above 150 l.

– The following table indicates the equivalent noise level values of given machines during extracting cycles:

SOFT-

MOUNT

22 KG

50 LB

33 KG

75 LB

40 KG

90 LB

55 KG

125 LB

RIGID-

MOUNT

22KG

50 LB

35KG

75 LB

43 KG

95 LB

dB (A) 70,6 77 77 77 dB (A) 76 76 76

ACOUSTIC OUTPUT

LP,A dB (P,A) 84,7 86,8 86,8