8

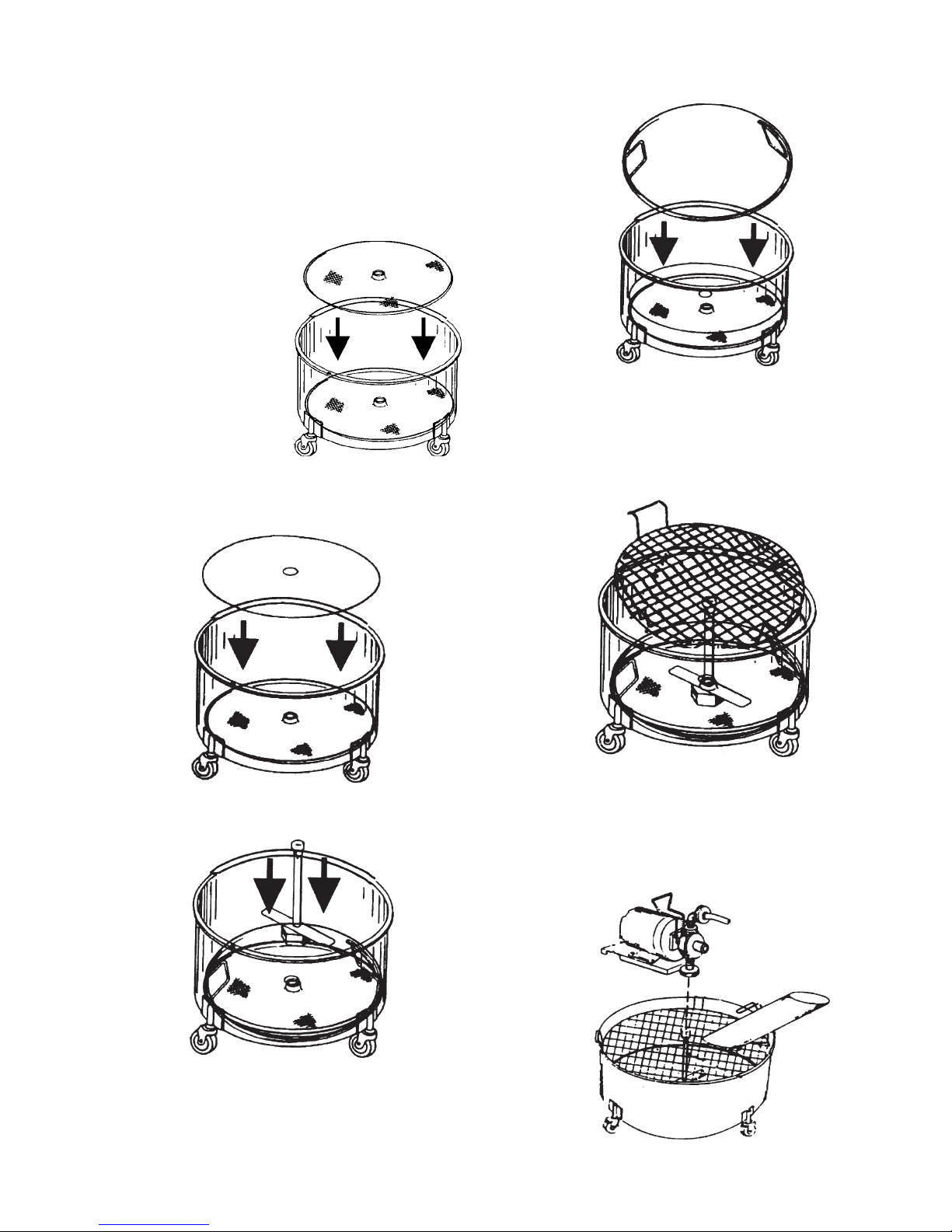

7. Place the anti-splash tube on filter bowl by doing the

following:

A. Grasp tube by handle.

B. Hook prongs under lip of bowl.

C. Rotate downward until tube rest is against the

shortening filter bowl.

The anti-splash tube has 2 ends. One end has a

diffuser plate attached inside the tube, and the

opposite end is open. Hook the tube over the filtering

bowl rim so that the end with the diffuser is closest to

the safety grid.

8. Attach hose to pump. Make sure the connection is

hand tight. Put the nozzle in its holder.

CAUTION: This hose is made to bend up to a

radius of six inches (15.2 cm). If the hose is

bent under six inches (15.2 cm) or if the hose

is crimped, it could crack, causing it to leak

hot oil which may cause burns. If the hose is

cracked and/or leaking, do not use until it

has been replaced or repaired.

When finished filtering each vat, roll the unit to the next

vat by using the handle attached to the motor and pump

assembly.

CAUTION: Do not pull the unit by the power

cord or the hose.

OPERATING INSTRUCTIONS

Refer to your McDonald’s Operations and

Training Manual for the proper procedures to

filter your Fry Vats. If your manual does not

contain this procedure, contact your Regional

Training Department.

Close

After the filtering, the filter must be cleaned and stored

so that it will be ready for next use. Follow these

cleaning procedures:

CAUTION: Parts are hot. Handle with care,

and use filter shortening gloves.

1. Unplug the power cord. Return the filtering machine

to the back sink to disassemble.

2. IMMEDIATELY disconnect the hose from the pump

and drain the shortening from the hose into the bowl.

3. Unscrew the pump from the standpipe and lift the

motor assembly from the bowl.

4. Remove the safety grid, ring weight, anti-splash tube,

and place them in the back sink. Unscrew the

standpipe assembly from the screen assembly and

place in the back sink.

5. Remove and discard filter paper.

7. Discard any shortening left in the bowl into the

shortening disposal cart/shortening drum.

8. Wash the ring weight, standpipe, screen and bowl

with the hottest water possible and fryer cleanser to

prevent carbon buildup. (Do not use APC.)

9. Wipe dry with a clean towel.

10. Wipe the motor assembly and filter hose using a

clean towel.

11. Reassemble bowl, filter screen and ring weight.

Place the standpipe assembly, and filter hose inside

the bowl.

12. Roll filtering equipment into storage location.

CAUTION: Do not store motor and pump

assembly on the screen assembly. This

could cause the screen to warp, tear away

from the welds or cause grease to damage

the power cord and motor.

CAUTION: Do not pump water through the

motor and pump assembly. This will cause

the pump gears to rust and void the war-

ranty.