Princeton Instruments Activity Tracker User manual

4411-0039-CE

Version 6.B

January 24, 2005

*4411-0039-CE*

©Copyright 2003-2005 Princeton Instruments, a division of Roper Scientific, Inc.

3660 Quakerbridge Rd

Trenton, NJ 08619

TEL: 800-874-9789 / 609-587-9797

FAX: 609-587-1970

All rights reserved. No part of this publication may be reproduced by any means without the written

permission of Princeton Instruments, a division of Roper Scientific, Inc. ("Princeton Instruments").

Printed in the United States of America.

IPLab is a trademark of Scanalytics, Inc.

Macintosh is a registered trademark of Apple Computer, Inc.

Microsoft, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

Pentium is a registered trademark of Intel Corporation.

PVCAM is a registered trademark of Photometrics, Ltd.

Radio Shack is a registered trademark of TRS Quality, Inc.

TAXI is a registered trademark of AMD Corporation

The information in this publication is believed to be accurate as of the publication release date. However,

Princeton Instruments does not assume any responsibility for any consequences including any damages

resulting from the use thereof. The information contained herein is subject to change without notice.

Revision of this publication may be issued to incorporate such change.

iii

Table of Contents

Chapter 1 Introduction.........................................................................................9

Introduction......................................................................................................................... 9

MicroMAX System Components ....................................................................................... 9

About this Manual ............................................................................................................ 12

Environmental Conditions................................................................................................ 13

Grounding and Safety ....................................................................................................... 13

Precautions........................................................................................................................ 14

Repairs .............................................................................................................................. 14

Cleaning............................................................................................................................ 14

Princeton Instruments Customer Service.......................................................................... 15

Chapter 2 Installation Overview........................................................................17

Chapter 3 System Setup ....................................................................................19

Unpacking the System ...................................................................................................... 19

Checking the Equipment and Parts Inventory .................................................................. 19

System Requirements ....................................................................................................... 20

Verifying Controller Voltage Setting ............................................................................... 21

Installing the Application Software.................................................................................. 22

Setting up a PCI Interface................................................................................................. 22

Setting up a USB 2.0 Interface ......................................................................................... 24

Mounting the Camera ....................................................................................................... 27

Selecting the Shutter Setting............................................................................................. 32

Connecting the Interface (Controller-Computer) Cable................................................... 33

Connecting the Detector-Controller Cable ....................................................................... 34

Chapter 4 Operation...........................................................................................35

Introduction....................................................................................................................... 35

EMF and Xenon or Hg Arc Lamps................................................................................... 35

Vacuum............................................................................................................................. 35

Cooling ............................................................................................................................. 35

Baseline Signal .................................................................................................................36

Analog Gain Control......................................................................................................... 37

Imaging Field of View...................................................................................................... 38

RS-170 or CCIR Video..................................................................................................... 38

USB 2.0 and System On/Off Sequences........................................................................... 40

First Light (Imaging) ........................................................................................................ 40

First Light (Spectroscopy) ................................................................................................ 45

Chapter 5 Timing Modes....................................................................................51

Fast and Safe Speed Modes .............................................................................................. 51

Standard Timing Modes ................................................................................................... 52

Frame Transfer Operation ................................................................................................ 57

Interline Operation............................................................................................................ 59

iv MicroMAX System User Manual Version 6.B

Chapter 6 Exposure and Readout.....................................................................63

Exposure ........................................................................................................................... 63

Array Readout...................................................................................................................67

Digitization ....................................................................................................................... 76

Chapter 7 MicroMAX DIF Camera (Double Image Feature) ............................77

Introduction....................................................................................................................... 77

Timing Modes................................................................................................................... 78

Tips and Tricks .................................................................................................................84

Chapter 8 TTL Control........................................................................................87

Introduction....................................................................................................................... 87

TTL In............................................................................................................................... 87

Buffered vs. Latched Inputs.............................................................................................. 88

TTL Out ............................................................................................................................ 88

TTL Diagnostics Screen ................................................................................................... 89

Hardware Interface ........................................................................................................... 89

Chapter 9 System Component Descriptions ...................................................91

MicroMAX Camera.......................................................................................................... 91

ST-133 Controller ............................................................................................................. 94

Cables ............................................................................................................................... 99

Interface Card ................................................................................................................... 99

Application Software........................................................................................................ 99

User Manuals.................................................................................................................. 100

Chapter 10 Troubleshooting............................................................................101

Introduction..................................................................................................................... 101

Baseline Signal Suddenly Changes ................................................................................ 102

Changing the ST-133's Line Voltage and Fuses............................................................. 102

Controller Is Not Responding......................................................................................... 103

Cooling Troubleshooting................................................................................................ 103

Data Loss or Serial Violation ......................................................................................... 104

Data Overrun message.................................................................................................... 104

Demo is only Choice on Hardware Wizard:Interface dialog.......................................... 105

Demo, High Speed PCI, and PCI(Timer) are Choices on Hardware

Wizard:Interface dialog............................................................................................ 106

Detector Stops Working ................................................................................................. 108

Detector Temperature, Acquire, and Focus are Grayed Out .......................................... 108

Error Creating Controller message ................................................................................. 109

Error occurs at Computer Powerup ................................................................................ 110

No CCD Named in the Hardware Wizard:CCD dialog.................................................. 112

Removing/Installing a Plug-In Module........................................................................... 113

Shutter Malfunctions ...................................................................................................... 114

Appendix A Specifications ..............................................................................115

CCD Arrays .................................................................................................................... 115

Temperature Control....................................................................................................... 116

Cooling ........................................................................................................................... 116

Mounting......................................................................................................................... 116

Shutters ........................................................................................................................... 117

Table of Contents v

Inputs .............................................................................................................................. 117

Outputs............................................................................................................................ 117

Programmable Interface.................................................................................................. 118

A/D Converter ................................................................................................................ 118

Computer Requirements ................................................................................................. 118

Miscellaneous ................................................................................................................. 118

Appendix B Outline Drawings.........................................................................119

Detectors......................................................................................................................... 119

ST-133B Controller ........................................................................................................ 125

ST-133A Controller ........................................................................................................ 125

Appendix C Kinetics Mode ..............................................................................127

Introduction..................................................................................................................... 127

Kinetic Timing Modes.................................................................................................... 128

Appendix D Virtual Chip Mode........................................................................131

Introduction..................................................................................................................... 131

Virtual Chip Setup .......................................................................................................... 132

Experimental Timing...................................................................................................... 136

Virtual Chip dialog box .................................................................................................. 136

Tips ................................................................................................................................. 137

Appendix E Repumping the Vacuum..............................................................139

Introduction..................................................................................................................... 139

Requirements .................................................................................................................. 139

Vacuum Pumpdown Procedure ...................................................................................... 140

Appendix F Spectrometer Adapters ...............................................................143

Acton (NTE with or without shutter) ............................................................................. 144

Chromex 250 IS (NTE with or without shutter)............................................................. 145

ISA HR 320 (NTE with or without shutter) ................................................................... 146

ISA HR 640 (NTE with or without shutter) ................................................................... 147

JY TRIAX family (NTE without shutter)....................................................................... 148

SPEX 270M (NTE with or without shutter)................................................................... 149

SPEX 500M (NTE with or without shutter)................................................................... 150

SPEX TripleMate (NTE with or without shutter) .......................................................... 151

Appendix G USB 2.0 Limitations.....................................................................153

Declarations of Conformity .............................................................................155

Warranty & Service...........................................................................................159

Limited Warranty............................................................................................................ 159

Contact Information........................................................................................................ 162

Index ..................................................................................................................163

vi MicroMAX System User Manual Version 6.B

Figures

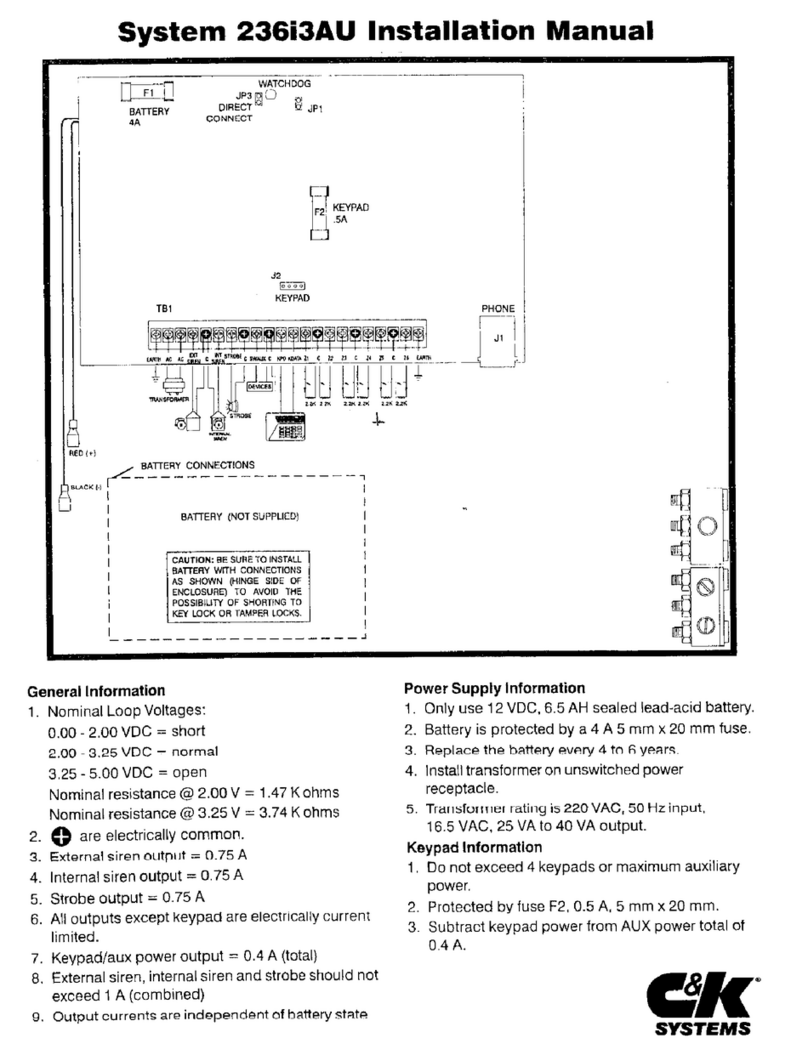

Figure 1. MicroMAX Cameras and Controller ................................................................. 9

Figure 2. Standard System Diagram................................................................................ 18

Figure 3. Controller Power Input Module ....................................................................... 21

Figure 4. WinView Installation: Interface Card Driver Selection................................... 22

Figure 5. RSConfig dialog box........................................................................................ 26

Figure 6. Hardware Wizard: PVCAM dialog box........................................................... 27

Figure 7. Bottom Clamps................................................................................................. 31

Figure 8. Bottom Clamp secured to Relay Lens.............................................................. 31

Figure 9. Shutter Setting for 25mm Internal Shutter ....................................................... 33

Figure 10. WinSpec/32 Detector Temperature dialog box.............................................. 36

Figure 11. Imaging Field of View ................................................................................... 38

Figure 12. Monitor Display of CCD Image Center Area ................................................ 39

Figure 13. Standard System Connection Diagram........................................................... 41

Figure 14. F-mount Focus Adjustment............................................................................ 45

Figure 15. Chart of Safe and Fast Mode Operation......................................................... 53

Figure 16. Free Run Timing Chart (part of the chart in Figure 15)................................. 54

Figure 17. Free Run Timing Diagram ............................................................................. 54

Figure 18. Showing Shutter "Preopen" & "Normal" Modes in External Sync Operation55

Figure 19. External Sync Timing Diagram (- edge trigger)............................................. 55

Figure 20. Continuous Cleans Flowchart ........................................................................ 56

Figure 21. Continuous Cleans Timing Diagram.............................................................. 57

Figure 22. Frame Transfer where tw1 + texp + tc< tR................................................... 58

Figure 23. Frame Transfer where tw1 + texp + tc> tR................................................... 59

Figure 24. Frame Transfer where Pulse arrives after Readout........................................ 59

Figure 25. Overlapped Mode where tw1 + texp + tc< tR............................................... 61

Figure 26. Overlapped Mode where tw1 + texp + tc> tR.................................................... 61

Figure 27. Overlapped Mode where Pulse arrives after Readout.................................... 61

Figure 28. Block Diagram of Light Path in System......................................................... 63

Figure 29. CCD Exposure with Shutter Compensation................................................... 64

Figure 30. Full Frame at Full Resolution ........................................................................ 67

Figure 31. Frame Transfer Readout................................................................................. 69

Figure 32. Overlapped Mode Exposure and Readout...................................................... 71

Figure 33. Non-Overlapped Mode Exposure and Readout.............................................. 72

Figure 34. 2 × 2 Binning for Full Frame CCD ................................................................ 74

Figure 35. 2 × 2 Binning for Interline CCD .................................................................... 75

Figure 36. Free Run Mode Timing Diagram ................................................................... 79

Figure 37. Setup using to Trigger an Event....................................................... 79

Figure 38. Timing for Experiment Setup shown in Figure 37......................................... 79

Figure 39. Timing Diagram for Typical IEC Measurement ............................................ 81

Figure 40. Setup for IEC Experiment with Two Lasers .................................................. 81

Figure 41. Timing Diagram for IEC Experiment with Two Lasers................................. 81

Figure 42. Another Hardware Setup for an IEC Measurement ....................................... 82

Figure 43. EEC Timing Example with Exposure Time in Software Set to texp............. 83

Figure 44. ESABI Timing Example: Image Exposure time = texp set in software......... 84

Figure 45. TTL In/Out Connector ................................................................................... 89

Figure 46. Controller Front Panel.................................................................................... 94

Figure 47. ST-133 Rear Panel ......................................................................................... 95

Table of Contents vii

Figure 48. Shutter Compensation Times ......................................................................... 98

Figure 49. Power Input Module..................................................................................... 102

Figure 50. Fuse Holder .................................................................................................. 102

Figure 51. Hardware Wizard: Interface dialog box....................................................... 105

Figure 52. RSConfig dialog box.................................................................................... 106

Figure 53. Hardware Wizard: PVCAM dialog box....................................................... 106

Figure 54. Hardware Wizard: Interface dialog box....................................................... 106

Figure 55. RSConfig dialog box: Two Camera Styles .................................................. 107

Figure 56. Hardware Wizard: PVCAM dialog box....................................................... 108

Figure 57. RSConfig dialog box: Two Camera Styles .................................................. 109

Figure 58. Error Creating Controller dialog box ........................................................... 109

Figure 59. Hardware Wizard: Detector/Camera/CCD dialog box................................. 112

Figure 60. Module Installation ...................................................................................... 113

Figure 61. Rectangular Camera Head: C-Mount........................................................... 119

Figure 62. Rectangular Camera Head: F-Mount ........................................................... 120

Figure 63. Rectangular Camera Head: Spectroscopy Mount with Shutter.................... 121

Figure 64. Rectangular Camera Head: Spectroscopy Mount without Shutter .............. 122

Figure 65. 1 MHz and 100kHz/1MHz Round Head Camera: C-Mount Adapter and

Shutter..................................................................................................................... 123

Figure 67. 1 MHz Round Head Camera: F-Mount Adapter.......................................... 124

Figure 68. ST-133B Controller Dimensions.................................................................. 125

Figure 69. ST-133A Controller Dimensions ................................................................. 125

Figure 70. Kinetics Readout .......................................................................................... 127

Figure 71. Hardware Setup dialog box .......................................................................... 128

Figure 72. Experiment Setup dialog box ....................................................................... 128

Figure 73. Free Run Timing Diagram ........................................................................... 129

Figure 74. Single Trigger Timing Diagram................................................................... 129

Figure 75. Multiple Trigger Timing Diagram ............................................................... 130

Figure 76. Virtual Chip Functional Diagram................................................................. 131

Figure 77. System Diagram ........................................................................................... 133

Figure 78. Virtual Chip dialog box................................................................................ 136

Figure 79. Vacuum Connector Required for Pumping.................................................. 140

Figure 80. Removing the Back Panel ............................................................................ 140

Figure 81. Attaching the Vacuum Connector................................................................ 141

Figure 82. Opening the Camera to the Vacuum System................................................ 141

Tables

Table 1. PCI Driver Files and Locations ......................................................................... 23

Table 2. USB Driver Files and Locations........................................................................ 26

Table 3. Bottom Clamps for Different Microscopes ....................................................... 30

Table 4. ST-133 Shutter Setting Selection ...................................................................... 32

Table 5. Camera Timing Modes ...................................................................................... 51

Table 6. Approximate Readout Time for the Full-Frame CCD Array ............................ 68

Table 7. Approximate Readout Time for the Frame-Transfer CCD Array ..................... 69

Table 8. Approximate Readout Time for the Interline CCD Arrays ............................... 73

Table 9. Readout Rates for PI 1300 × 1030 Array at 1 MHz.......................................... 73

Table 10. Well Capacity for some CCD Arrays.............................................................. 76

Table 11. Bit Values with Decimal Equivalents: 1 = High 0 = Low.............................. 88

viii MicroMAX System User Manual Version 6.B

Table 12. TTL In/Out Connector Pinout ......................................................................... 89

Table 13. ST-133 Shutter Drive Selection ...................................................................... 97

Table 14. I/O Address & Interrupt Assignments before Installing Serial Card............. 111

Table 15. I/O Address & Interrupt Assignments after Installing Serial Card ............... 111

Table 16. MicroMAX Model and CCD Types Cross Reference .................................. 115

Table 17. Shutter Compensation Times ........................................................................ 117

Table 18. MicroMAX:512BFT: Virtual Chip Size, Exposure Time, and Frames per

Second........................................................................................................... 132

Table 19. Features Not Supported under USB 2.0 ........................................................ 153

9

Chapter 1

Introduction

Introduction

The Princeton Instruments MicroMAX system is a high-speed, low-noise CCD camera

system designed for demanding imaging applications and is an optimal system for use in

fluorescence microscopy applications such as high-resolution immunofluorescence,

FISH or GFP imaging. The MicroMAX system incorporates a compact camera head,

cooled CCD, advanced exposure-control timing, video output, and sophisticated readout

capabilities.

Among the advantages of the MicroMAX concept are the range of CCD arrays available

and the built-in video output mode. The system can be configured with a variety of

interline CCDs to provide true 12-bit images at a readout rate of up to 5 million pixels

per second or with a variety of front or back-illuminated CCDs to provide true 16-bit

images. The built-in video output mode simplifies setup and focusing on the microscope.

The combination of the MicroMAX system with one of a variety of specialty software

packages results in a powerful digital imaging system that can meet most experimental

needs.

Note: "WinView/32" and "WinView" are used throughout this manual when referring to

the application software. Unless otherwise indicated, the information associated with

these terms also applies to Princeton Instruments' WinSpec/32 spectroscopy software.

MicroMAX System Components

Overview

The MicroMAX imaging system consists of

a camera (either a round head or a

rectangular head depending on application),

controller, digital interface card, a computer,

cables, manuals, and application software.

Together, these components allow you to

acquire quantitative digital data under very

low light imaging conditions. Each

component is optimized for its specific

function. In operation, data acquired by the

Figure 1. MicroMAX Cameras and

Controller

camera is routed to the controller and from there to the computer for processing and

display. A composite video output allows immediate viewing of the acquired images on a

separate monitor. The application software (for example, Princeton Instruments

WinView/32) allows the computer to control both the system configuration and data

acquisition.

10 MicroMAX System User Manual Version 6.B

Camera

Introduction: The function of the camera is to collect very low intensity light and

convert the energy into a quantitative, electronic signal (photo-electrons) over a two

dimensional space. To do this, light from the subject is focused onto a CCD array, which

accumulates photoelectrons for the exposure time. At the end of the exposure time, the

image thus formed is read out. The accumulated charge on each cell of the array is

transferred out of the CCD array, amplified, and sent to the controller as an analog

signal, where it is digitized prior to transfer to the computer.

The camera is highly integrated, containing the shutter (if applicable) and thermoelectric

cooler with optional forced-air supplemental cooling in a single, shielded housing.

Surface mount electronic technology is used wherever possible, giving a compact

package with uncompromising performance.

Depending on your application, the camera included in your MicroMAX system will be

either a compact round camera head or a high performance, cooled, rectangular camera

head. The round head features interline CCDs; its small size ensures that the camera can

be mounted on virtually any microscope port, including those found on inverted

microscopes. The rectangular head features back-illuminated CCDs with frame transfer

readout.

At the heart of the camera is the CCD array centered on the optic axis. Available formats

include the:

•

EEV CCD57-10, 512×512, 13×13µm pixels for the MicroMAX:512BFT

•

EEV CCD47-10, 1024×1024, 13×13µm pixels for the MicroMAX:1024B

•

Sony ICX075, 782×582, 8.3× 8.3µm pixels for the MicroMAX:782Yand the

MicroMAX:782YHS systems

•

Sony ICX061,1300×1030, 6.7× 6.7µm pixels for the MicroMAX:1300Y, the

MicroMAX:1300YHS, and MicroMAX:1300YHS-DIF systems

A special clocking mode to minimize background signal is supported. See the Princeton

Instruments brochures and data sheets for detailed specifications.

Cooling System: MicroMAX cameras have a multi-stage Peltier type cooler that is

thermally coupled to the CCD surface. Heat is sequentially transferred through the

Peltier stages and from there to the outer shell of the camera via a heat transfer block.

This cooling system allows the camera to maintain CCD temperature of typically -15°C

for round cameras head and -45°C for rectangular camera heads. Cameras equipped with

a fan assembly can reach lower CCD temperatures for reduced thermal noise and

extended exposure times.

Low Noise Readout: In order to achieve a low-noise readout of the CCD, several

design features have been implemented. These include cooling the preamplifier on the

CCD, isolating circuits to prevent electronic crosstalk and minimizing the path lengths of

critical electronic circuits. The net result of these design features is the lowest available

readout noise at the highest speed possible for these CCDs.

Chapter 1 Introduction 11

Controller

Data Conversion: The controller accepts the analog data and converts it to digital data

using specially designed, low-noise electronics supporting scientific grade 12- or 16-bit

Analog to Digital (A/D) converters.

The standard MicroMAX Controller enables both high-speed and high-precision readout

capabilities. It can collect 16-bit images at a readout rate of up to 1 million pixels per

second (1 MHz) in the high-speed mode or at 100 thousand pixels per second (100 kHz)

in the optional precision mode (16-bit). Switching between the two modes is under

software control for total experiment automation.

Modular Design: In addition to containing the power supplies, the controller contains

the analog and digital electronics, scan control and exposure timing hardware, and

system I/O connectors, all mounted on user-accessible plug-in modules. The design is

highly modularized for flexibility and convenient servicing.

Flexible Readout: There is provision for extremely flexible readout of the CCD.

Readout modes supported include full resolution, simultaneous multiple subimages, and

nonuniform binning. Single or multiple software-defined regions of interest can also be

tested without having to digitize all the pixels of the array

High Speed Data Transfer: Data is transferred directly to the host computer memory

via a high-speed serial link. A proprietary Interface card places the data from the

controller directly into the host computer RAM using Direct Memory Access (DMA).

The DMA transfer process ensures that the data arrives at sufficiently high speed to

prevent data loss from the controller. Since the data transfer rate is much higher than the

output rate from the A/D, the latter becomes the data acquisition rate-limiting factor.

Once the digital data is in RAM, the image acquisition program can transfer the image

into its own working RAM for viewing and further processing.

Note: A frame buffer with standard composite video, either RS-170 (EIA) or CCIR,

whichever was ordered, is also provided.

Applications

With its small size, fully integrated design, cooled CCD and temperature control,

advanced exposure control timing, and sophisticated readout capabilities, the

MicroMAX system is well suited to both general macro imaging and microscopy

applications.

12 MicroMAX System User Manual Version 6.B

About this Manual

Manual Organization

This manual provides the user with all the information needed to install a MicroMAX

camera and place it in operation. Topics covered include a detailed description of the

camera, installation, cleaning, specifications and more.

Note: The general identifier "ST-133" is used for both the ST-133A Controller and the

ST-133B Controller. Where there is a difference, the specific identifier is used.

Chapter 1

,

Introduction

briefly describes the MicroMAX family of cameras;

details the structure of this manual; and documents environmental, storage, and

cleaning requirements.

Chapter 2, Installation Overview

cross-references system setup actions with

relevant manuals and/or manual pages. It also contains system layout diagrams.

Chapter 3, System Setup

provides detailed directions for interconnecting the

system components.

Chapter 4, Operation

discusses number of topics, including temperature control,

vacuum degradation, and sensitivity to damage from EMF spikes generated by

Xenon or Hg arc lamps. Includes step-by-step directions for verifying system

operation.

Chapter 5, Timing Modes

discusses the basic Controller timing modes and

related topics, including Fast and Safe speed modes, Free Run, External Sync,

Continuous, Frame Transfer, and Interline operation.

Chapter 6, Exposure and Readout

discusses Exposure and Readout, together

with many peripheral topics, including: shuttered and unshuttered exposure;

saturation; dark charge; full frame, interline, and frame-transfer readout; and

binning.

Chapter 7, MicroMAX DIF Camera (Double Image Feature)

describes DIF

(Dual Image Feature) camera and its operation.

Chapter 8, TTL Control

provides information about how to use the TTL

connector on the rear of the controller.

Chapter 9, System Component Descriptions

provides descriptions of each

system component.

Chapter 10, Troubleshooting

provides courses of action to take if you should

have problems with your system.

Appendix A, Specifications

includes controller and camera specifications.

Appendix B, Outline Drawings

includes outline drawings of the MicroMAX

cameras and the ST-133A and ST-133B Controllers.

Appendix C, Kinetics Mode

describes how to set up and acquire data with the

Kinetics option, which allows frame transfer CCDs to take time-resolved

images/spectra.

Chapter 1 Introduction 13

Appendix D, Virtual Chip Mode

describes how to set up and use the Virtual

Chip option, a special fast-acquisition technique.

Appendix E, Repumping the Vacuum

explains how to restore the 1 MHz or

100kHz/1MHz round head camera's vacuum if that vacuum has deteriorated over

time.

Appendix F, Spectrometer Adapters

provides mounting instructions for the

spectrometer adapters available for MicroMAX rectangular head (NTE)

cameras.

Appendix G

,

USB 2.0 Limitations

covers the currently known limitations

associated with operating under the USB 2.0 interface.

Declarations of Conformity

contains the Declaration of Conformity for 1 MHz

(includes 100 kHz/1MHz) MicroMAX systems.

Warranty and Service

provides warranty and customer support contact

information.

Safety Related Symbols Used in This Manual

Caution! The use of this symbol on equipment indicates that one or more

nearby items should not be operated without first consulting the manual. The

same symbol appears in the manual adjacent to the text that discusses the

hardware item(s) in question.

Caution! Risk of electric shock! The use of this symbol on equipment

indicates that one or more nearby items pose an electric shock hazard and should

be regarded as potentially dangerous. This same symbol appears in the manual

adjacent to the text that discusses the hardware item(s) in question.

Environmental Conditions

•Storage temperature: < 55°C

•Operating environment: 0°C to 30°C

•Relative humidity: ≤50%, non-condensing.

Grounding and Safety

The apparatus described in this manual is of the Class I category as defined in IEC

Publication 348 (Safety Requirements for Electronic Measuring Apparatus). It is

designed for indoor operation only. Before turning on the controller, the ground prong of

the power cord plug must be properly connected to the ground connector of the wall

outlet. The wall outlet must have a third prong, or must be properly connected to an

adapter that complies with these safety requirements.

If the equipment is damaged, the protective grounding could be disconnected. Do not use

damaged equipment until its safety has been verified by authorized personnel.

Disconnecting the protective earth terminal, inside or outside the apparatus, or any

tampering with its operation is also prohibited.

WARNING

14 MicroMAX System User Manual Version 6.B

Inspect the supplied power cord. If it is not compatible with the power socket, replace the

cord with one that has suitable connectors on both ends.

Replacement power cords or power plugs must have the same polarity as that of the

original ones to avoid hazard due to electrical shock.

Precautions

To prevent permanently damaging the system, please observe the following precautions:

•

Always switch off and unplug the ST-133 Controller before changing your system

configuration in any way.

•

Never remove the camera’s front window, as it is necessary to maintain vacuum (or

to maintain a dry nitrogen environment).

•

The CCD array is very sensitive to static electricity. Touching the CCD can destroy

it. Operations requiring contact with the device can only be performed at the factory.

•

Never operate the camera cooled without proper evacuation or backfill. This could

damage the CCD!

•

Never connect or disconnect any cable while the MicroMAX system is powered on.

Reconnecting a charged cable may damage the CCD.

•

Never prevent the free flow of air through the equipment by blocking the air vents.

Repairs

Repairs must be done by Princeton Instruments. If your system hardware needs repair,

contact Princeton Instruments Customer Service. Please save the original packing

material so you can safely ship the system to another location or return it for repairs.

Cleaning

Turn off all power to the equipment and secure all covers before cleaning the units.

Otherwise, damage to the equipment or personal injury could occur.

Camera and Controller

Although there is no periodic maintenance that must be performed on the camera or the

ST-133 Controller, you may clean these components from time to time by wiping them

down with a clean damp cloth. This operation should only be done on the external

surfaces and with all covers secured. In dampening the cloth, use clean water only. No

soap, solvents or abrasives should be used. Not only are they not required, but they could

damage the finish of the surfaces on which they are used.

Optical Surfaces

Optical surfaces may need to be cleaned due to the accumulation of atmospheric dust.

We advise that the drag-wipe technique be used. This involves dragging a clean cellulose

WARNING

WARNING!

16 MicroMAX System User Manual Version 6.B

This page intentionally left blank.

17

Chapter 2

Installation Overview

The list and diagrams below briefly describe the sequence of actions required to

hookup your system and prepare to gather data. Refer to the indicated references

for more detailed information. This list assumes that the application software is

Princeton Instruments WinView/32.

Action Reference

1. If the system components have not already been unpacked, unpack

them and inspect their carton(s) and the system components for in-

transit damage. Store the packing materials.

Chapter 3 System Setup,

page 19

2. Verify that all system components have been received. Chapter 3 System Setup,

page 19

3. If the components show no signs of damage, verify that the

appropriate voltage settings have been selected for the Controller.

Chapter 3 System Setup,

page 21

4. If WinView/32 software is not already installed in the host

computer, install it. In addition to installing the WinView/32

software, this operation will load all of the interface card drivers.

Chapter 3 System Setup,

page 21

WinView/32 manual

5. If the appropriate interface card is not already installed in the host

computer, shut down the computer and install the interface card.

Chapter 3 System Setup,

page 22 or page 24

6. Depending on the application, attach a lens to the camera, mount the

camera to a microscope, or mount the camera to a spectrometer.

Chapter 3 System Setup,

page 28, 28, or 32

7. With the Controller and computer power turned OFF, connect the

interface cable (TAXI or USB) to the Controller and the interface

card in the host computer. Then tighten down the locking hardware.

Chapter 3 System Setup,

page 33

8. With the Controller power turned OFF, make the camera-to-

controller connections to the back of the Controller. Secure the

latch(es) to lock the cable connection(s).

Chapter 3 System Setup,

page 34

9. With the Controller power turned OFF, make the camera-to-

controller connections to the back of the Camera. Secure the

latch(es) to lock the cable connection(s).

Chapter 3 System Setup,

page 34

10. With the Controller power turned OFF, connect the Controller

power cable to the rear of the controller and to the power source.

11. If using a microscope Xenon or an Hg arc lamp, turn it on before

turning on the controller and host computer.

Chapter 4 Operation,

page 35

12. Turn the Controller ON.

18 MicroMAX System User Manual Version 6.B

Action Reference

13. Turn on the computer and begin running WinView/32. WinView/32 manual

14. Enter the hardware setup information or load the defaults from the

controller.

Chapter 4 Operation,

page 42 or page 46

15. Set the target array temperature. Chapter 4 Operation,

page 36, 42, or 46

16. When the system reaches temperature lock, begin acquiring data in

focus mode.

Chapter 4 Operation,

page 43 or page 48

17. Adjust the focus for the image. Chapter 4 Operation,

page 43 or page 48

Computer

110/220

Controller

Detector

EXPERIMENT

110/220

Camera

Detector-Controller

Microscope

Serial Com

or USB 2.0

Interface cable

(TAXI or USB 2.0)

Figure 2. Standard System Diagram

19

Chapter 3

System Setup

Unpacking the System

During the unpacking, check the system components for possible signs of shipping

damage. If there are any, notify Princeton Instruments and file a claim with the carrier. If

damage is not apparent but camera or controller specifications cannot be achieved,

internal damage may have occurred in shipment. Please save the original packing

materials so you can safely ship the camera system to another location or return it to

Princeton Instruments for repairs if necessary.

Checking the Equipment and Parts Inventory

Confirm that you have all of the equipment and parts required to set up the system. A

complete MicroMAX system consists of a camera, a controller, a computer and other

components as follows.

•Camera to Controller cable: DB25 to DB25, 10 ft (6050-0321). Two versions of

this cable are available, one having an external shield and the other not. The shielded

version offers superior noise performance and is required by regulation in some

countries.

•Computer Interface Dependent Components:

•Controller-Computer Interface cable:

•TAXI cable: 25 ft DB9 to DB9 cable (6050-0148-CE) is standard. Lengths

up to 165 ft (50 m) are available. Optional fiber-optic transducers can be

used to extend this distance to as much as 1000 m.or

•USB cable: Five (5) meter cable (6050-0494) is standard.

•Interface Card:

•TAXI: High Speed PCI Interface board or

•USB 2.0: Native on motherboard or user-provided USB 2.0 Interface Card

(Orange Micro 70USB90011 USB2.0 PCI is recommended for desktop

computers and the SIIG, Inc. USB 2.0 PC Card, Model US2246 is

recommended for laptop computers).

•Vacuum Pumpdown connector (2550-0181): This item is required if it becomes

necessary to refresh the vacuum for round camera heads. Contact the factory

Technical Support Dept. for information on refreshing the vacuum. See page 162 for

contact information.

•WinView/32 CD-ROM

•User Manual

20 MicroMAX System User Manual Version 6.B

System Requirements

Power

Detector: The MicroMAX detector receives its power from the controller, which in

turn plugs into a source of AC power.

ST-133: The ST-133 Controller can operate from any one of four different nominal line

voltages: 100, 120, 220, or 240 V AC. Refer to the Fuse/Voltage label on the

back of the ST-133 for fuse, voltage, and power consumption information.

Caution

The plug on the line cord supplied with the system should be compatible with the line-

voltage outlets in common use in the region to which the system is shipped. If the line

cord plug is incompatible, a compatible plug should be installed, taking care to maintain

the proper polarity to protect the equipment and assure user safety.

Host Computer

Note: Computers and operating systems all undergo frequent revision. The following

information is only intended to give an approximate indication of the computer

requirements. Please contact the factory to determine your specific needs.

Requirements for the host computer depend on the type of interface, TAXI or USB 2.0,

that will be used for communication between the ST-133 and the host computer. Those

requirements are a listed below according to protocol.

TAXI Protocol:

•AT-compatible computer with 200 MHz Pentium®II (or better).

•Windows®95, Windows®98SE, Windows®ME, Windows NT®, Windows®

2000, or Windows®XP operating system.

•High speed PCI serial card (or an unused PCI card slot). Computers purchased

from Princeton Instruments are shipped with the PCI card installed if High speed

PCI was ordered.

•Minimum of 32 Mbytes of RAM for CCDs up to 1.4 million pixels. Collecting

multiple spectra at full frame or high speed may require 128 Mbytes or more of

RAM.

•CD-ROM drive.

•Hard disk with a minimum of 80 Mbytes available. A complete installation of

the program files takes about 17 Mbytes and the remainder is required for data

storage, depending on the number and size of images or spectra collected. Disk

level compression programs are not recommended.

•Super VGA monitor and graphics card supporting at least 256 colors with at least

1 Mbyte of memory. Memory requirement is dependent on desired display

resolution.

•IEEE-488 GPIB port (required by DG535 Timing Generator, if present). May

also be required by Spectrograph.

•Two-button Microsoft compatible serial mouse or Logitech three-button

serial/bus mouse.

This manual suits for next models

1

Table of contents