4.1.3 models 420 - 500 RP

FUNCTIONS AND USAGE OF THE FOOT PEDAL. The foot control device controls the rollers to move

depending on desired speed and keeping the machine on during the time needed.

This device is connected to the machine by plugging the foot pedal into the main machine.

USAGE FOR THE SHAPING OF THE DISKS. After turning on the machine with the toggle switch in position

1 or 2, and starting the movement of rollers with the foot pedal, you can start working.

Before introducing in opening of the highest cover the small ball of dough previously left to rise (at least 6 to

8 hours), squash the sides slightly so it can easily go through the highest rollers When the dough comes out,

you will see a reduction of thickness , with an oval sAt the end of the trial, support on exit the dough with

your hand letting it advance slowly till it comes out, at the end of this the rollers must be stopped. Turn the

dough to 90° placing it in the lowest rollers ready for the next trial. Out of these rollers it will have a disk

shape, this shape is not perfect so it needs the finishing touches by hand.

USAGE FOR THE SHAPING OF RECTANGLES. Position a baking pan under the machine clean and big

enough to fit underneath.

Turn on the machine ,start rollers, then introduce in the opening of the highest cover the small ball of dough

previously left to rise (at least 6 to 8 hours), squash sides slightly to facilitate entrance in the rollers through

which , on the first trial the dough becomes thinner.

At the end of trial, it is necessary for medium or big weights to proceed as follows: go forward step by step ,

for another constant manual widening of the dough , positioning for the next trial trough the rollers , from

here the shaped dough will fall down into the baking pan.

IMPORTANT TURN OFF THE MACHINE WHEN YOU HAVE FINISCHED WORKING.

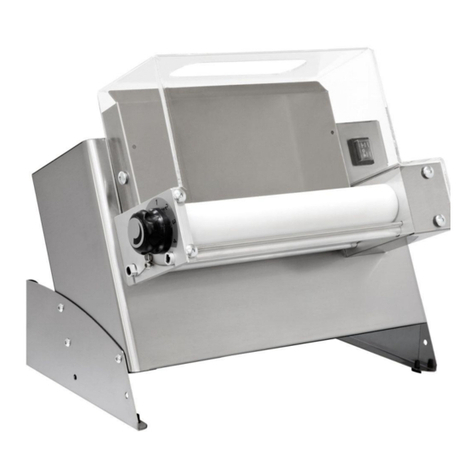

HOW TO REGULATE THE THICKNESS. Regulating the machine can only be recommended as there are

different characteristics of: the dough, the weight, the thickness, the size and the shape of the disk.

Therefore the correct regulating of the machine must be made by experimenting.

The machine is provided with a medium size regulation for the shapes of pizza.

IMPORTANT ALL REGULATION MUST BE MADE WHEN MACHINE IS ON HOLD.

With this machine you can have different thickness’ of dough to suit all requirements, just by turning and

turning the knob. Pull the black knob in order to release the levers.

To obtain the best results, we recommend to change the regulations.

The thickness can be modified turning the knob:

-MINIMUM THICKNESS (0) turning counter-clockwise

-MAXIMUM THICKNESS (4) turning clockwise.

NOTE TO AVOID THE DOUGH BRAKING, IT MUST PASS THROUGH THE ROLLERS ONLY ONCE.