Prismafood C/0 User manual

ENGLISH

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

VENTILATED AIR

TUNNEL OVEN

C/0

1

2

ATTENTION!

UPON INITIAL START UP OF THE OVEN, LEAVE

IT ON FOR ABOUT 20 MINUTES IN ORDER TO

VENT ANY SMOKE AND VAPOURS PRODUCED

BY THE SHEET METAL PROCESSING OILS

DO NOT USE THE BLADE DIRECTLY ON THE

BELT

HOT SURFACES ON THE HOODS. USE GLOVES

TO MAKE ADJUSTMENTS

DANGER HAND CRUSHING: TAPE IN

MOVEMENT

3

INDEX

Instructions for the installer

GENERAL WARNINGS..................................................................................................... 5

MODULE MOVEMENT AND POSITIONING .......................................................................... 5

STACKING .................................................................................................................... 6

MODULE POSITIONING .................................................................................................. 6

ELECTRICAL CONNECTION ............................................................................................. 7

SAFETY THERMOSTAT.................................................................................................... 8

Instructions for the user

SERIAL NUMBER ......................................................................................................... 9

SERIAL NUMBER LABEL.................................................................................................. 9

GENERAL INFORMATION ............................................................................................ 9

IMPORTANCE OF THE MANUAL ........................................................................................ 9

“OVEN OFF" STATUS...................................................................................................... 9

WARRANTY................................................................................................................... 9

TECHNICAL DATA ..................................................................................................... 10

TECHNICAL DATACARD .................................................................................................10

INTENDED USE ............................................................................................................11

USE LIMITS .................................................................................................................11

USE AND OPERATION ............................................................................................... 12

CONTROL PANEL ..........................................................................................................12

MAIN SCREEN..............................................................................................................13

SETTING PARAMETERS .................................................................................................14

PROGRAM SELECTION ON THE MAIN SCREEN ..................................................................14

MENU ITEMS................................................................................................................15

AUTO-OFF FUNCTION ...................................................................................................16

ERROR MANAGEMENT ...................................................................................................16

BELT SPEED.................................................................................................................16

PRODUCTIVITY ............................................................................................................17

MAINTENANCE ......................................................................................................... 18

CLEANING ...................................................................................................................18

MAINTENANCE FREQUENCY ...........................................................................................18

BELT DISMANTLING AND ASSEMBLY...............................................................................19

BELT ADJUSTMENT .......................................................................................................20

DEMOLITION ............................................................................................................ 21

GENERAL WARNINGS....................................................................................................21

TROUBLESHOOTING ................................................................................................. 21

SPARE PARTS ........................................................................................................... 22

4

EXPLOSION OVEN ........................................................................................................22

EXPLOSION DOOR........................................................................................................23

EXPLOSION SYSTEM .....................................................................................................24

SPARE PARTS LIST .......................................................................................................25

ELECTRICAL PART .................................................................................................... 26

WIRING DIAGRAM C/40 AND C/50 .................................................................................26

WIRING DIAGRAM C/65 AND C/80 .................................................................................27

5

Instructions for the installer

GENERAL WARNINGS

The place where the oven is installed must have the following environmental characteristics:

be dry, the temperature and relative humidity of the room in which it is to be installed must not

exceed the values indicated in technical data table;

adequately distant water sources;

ventilation and lighting suitable, compliant with the hygiene and safety standards required by

current laws.

THE OVEN MUST NOT BE INSTALLED NEAR FLAMMABLE MATERIALS (WOOD,

PLASTIC, FUELS, GAS, ETC.). ALWAYS AVOID THE CONTACT OF FLAMMABLE

OBJECTS WITH THE HOT SURFACES OF THE OVEN. ALWAYS ENSURE THE FIRE

SAFETY CONDITIONS. KEEP A FREE SPACE AROUND THE OVEN OF AT LEAST 30 CM.

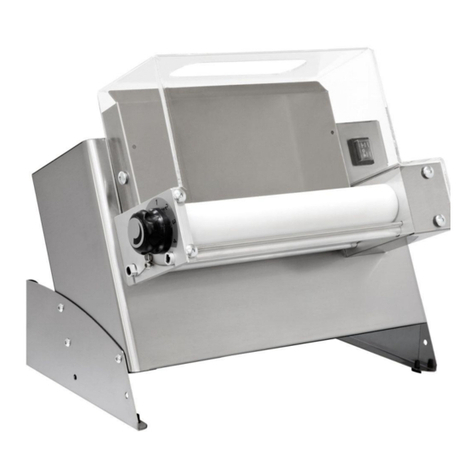

MODULE MOVEMENT AND POSITIONING

Remove the conveyor belt.

Use a forklift truck or a pallet truck with adequate capacity.

Raise the hoods and insert the forks, suitably covered with

soft material to prevent damage, into the cooking

chamber, through the tunnel inlet or outlet (Fig.1).

Position the oven at the corners of the base (Fig.2).

1

2

6

STACKING

MAXIMUM NUMBER OF OVENS THAT CAN BE STACKED: 3

MODULE POSITIONING

The gas appliance is type A₂/B₂₂ for which no connection to a chimney or device is installed that

discharges the fumes outside.

It is necessary to place the oven under an extractor hood.

EXTRACTOR HOOD

EXTERNAL EXHAUST

7

ELECTRICAL CONNECTION

Check that the power supply voltage, the frequency and the power of the system are compatible with the

values indicated both in the technical features and on the plate affixed to the back of the oven.The

characteristics of the power supply socket must be compatible with the plug installed on the cable.

THE ELECTRICAL CONNECTION OF THE OVEN TO THE POWER SUPPLY NETWORK

MUST ONLY BE PERFORMED BY AN AUTHORISED TECHNICIAN (ELECTRICIAN) IN

POSSESSION OF THE TECHNICAL-PROFESSIONAL REQUIREMENTS IMPOSED BY

THE APPLICABLE RULES IN THE COUNTRY OF USE OF THE OVEN. REQUEST

ISSUING OF A DECLARATION OF CONFORMITY OF THE INTERVENTION

PERFORMED.

FOR DIRECT CONNECTION TO THE NETWORK, IT IS NECESSARY TO USE A DEVICE

WITH AN OPENING BETWEEN THE CONTACTS THAT ENSURES COMPLETE

DISCONNECTION IN THE CONDITIONS OF THE OVERVOLTAGE CATEGORY III, IN

ACCORDANCE WITH THE INSTALLATION RULES.

To connect the machine to the electrical network, proceed as follows:

fit a normalised and polarised plug at the other end of the cable (the distinction between phase and

neutral must be unequivocal).

WITH ELECTRICAL CONNECTION COMPLETED, THE AUTHORISED TECHNICIAN

(ELECTRICIAN) MUST ISSUE A DECLARATION THAT CERTIFIES THE CONTINUITY

MEASUREMENT OF THE EQUIPOTENTIAL PROTECTION CIRCUIT.

THE APPLIANCE IS TO BE SUPPLIED THROUGH A RESIBASIC CURRENT DEVICE

(RCD) HAVING A RATED RESIBASIC OPERATING CURRENT NOT EXCEEDING 30 MA.

8

SAFETY THERMOSTAT

The safety thermostat is located inside the ventilation chamber immediately adjacent to the burners. This

is calibrated at 427°C and is manual reset. If a temperature equal to or greater is detected, the power

supply to the whole oven is removed and the gas is closed accordingly.

To restart the oven, a qualified technician must intervene who will check the reason for this anomaly and

can then reset it manually only by opening the panel in the technical compartment (system door). See the

figure below where the safety thermostat is highlighted.

The position of the red reset button is indicated by the arrow.

Reset is not possible until the chamber temperature has dropped below 427°C.

Since the safety thermostat only intervenes where there are serious malfunctions,

carefully check the oven’s working and repair if necessary before starting up the

oven again.

SAFETHY THERMOSTAT

RESET BUTTON

9

Instructions for the user

SERIAL NUMBER

SERIAL NUMBER LABEL

The serial number consists of a grey silk-screened adhesive label applied to the back of the oven.

The following data is clearly and indelibly marked on the plate:

Name of the manufacturer;

Serial number

Electrical power (kW/A)

Voltage and electrical

frequency (Volt/Hz)

Model

Year of construction

"Made in Italy" wording;

Weight of the oven

GENERAL INFORMATION

IMPORTANCE OF THE MANUAL

Before using the oven in question, it is mandatory to read and understand this manual in all its parts.

This manual must always be available to "authorised operators" and be near the oven, carefully kept and

stored.

The manufacturer declines all responsibility for any damage to persons, animals and property caused by

non-observance of the rules described in this manual.

This manual is an integral part of the oven and must be kept until its final disposal.

The "authorised operators" must only perform the interventions relating to their specific competence on

the oven.

“OVEN OFF" STATUS

Before carrying out any type of maintenance and/or adjustment on the oven it is compulsory to cut off the

electric power source by removing the power plug from the wall socket, making sure that the oven is

actually switched off and has cooled.

WARRANTY

The warranty duration period is valid for twelve months from the date of the original purchase receipt.

Within this period, parts that are objectively ascertainable as defective due to manufacturing defects,

excluding electrical components and parts subject to normal wear and tear, will be replaced or repaired

free of charge at our factory premises.

All shipping and labour costs are expressly excluded from the warranty.

The warranty is void in all cases in which it can be ascertained that the damage has been caused by:

transportation, inadequate maintenance, operator inexperience, tampering, repairs carried out by

unauthorized personnel, or failure to comply with manual instructions.

The manufacturer declines all liability for any direct or indirect damages resulting from the time for which

the machine is inoperative, including for the following reasons:

faults in the equipment, time spent waiting for repairs, or, in any case, absence of the equipment.

THE TAMPERING WITH AND/OR REPLACEMENT OF PARTS WITH NON-ORIGINAL

SPARE PARTS WILL VOID THE WARRANTY AND EXONERATE THE MANUFACTURER

FROM ALL LIABILITY.

10

TECHNICAL DATA

TECHNICAL DATACARD

Measurement

unit

C/40

C/50

C/65

C/80

Temperature control

°C

0-350

External dimensions

without support

cm

L 142,5

P 98,5

H 45,0

L 186,0

P 121,0

H 50,0

L 207,0

P 132,0

H 56,0

L 225,0

P 156,0

H 60,0

Belt width

cm

40,0

50,0

65,0

80,0

Belt length

cm

105,0

160,0

185,0

200,0

Chamber length

cm

54,0

75,0

100,0

110,0

Electrical power supply

--

Three-phase

Voltage

Vac

400/230

Frequency

Hz

50/60

Current

A (400V)

A (230V)

11

34

21

62

27

80

35

106

Total electrical power

kW

7,8

14,2

18,4

24,4

Electrical connection

--

five-pole cable without socket

Cable length

m

2

Conductors section

mm²

4

6

Working temperature limits

°C

0-40

Working humidity limit

--

95% without condensation

11

INTENDED USE

The intended use for which the oven has been designed and built is as follows:

INTENDED USE: COOKING OF PIZZA, BREAD, FOCACCE, GRATIN BAKING OF FOOD

PRODUCTS AND THE HEATING OF FOOD ON A BAKING TRAY.

THE OVEN CAN BE USED EXCLUSIVELY BY A DESIGNATED OPERATOR (USER).

THIS APPLIANCE IS NOT INTENDED TO BE USED BY PERSONS (CHILDREN

INCLUDED) WITH REDUCED PHYSICAL, SENSORIAL OR MENTAL CAPABILITIES OR

WITH INSUFFICIENT EXPERIENCE AND KNOWLEDGE, UNLESS THEY HAVE

RECEIVED ASSISTANCE OR INSTRUCTIONS FOR USE OF THE APPLIANCE FROM A

PERSON RESPONSIBLE FOR THEIR SAFETY.

CHILDREN MUST BE MONITORED TO AVOID THEM PLAYING WITH THE APPLIANCE.

USE LIMITS

The oven in question has been designed and produced exclusively for the intended use described

therefore any other type of use is absolutely forbidden in order to guarantee, at all times, the safety of

authorised operators and the efficiency of the oven itself.

IT IS FORBIDDEN TO MANIPOLATE THE DEVICES INSTALLED IN THE APPLIANCE.

WARNING: PAY ATTENTION WHEN OPENING THE DOOR, BURN HAZARD AND HAND

CRUSHING

WARNING: DO NOT TOUCH THE TAPE WITH THE OVEN WORKING, BURN HAZARD

AND HAND CRUSHING

12

USE AND OPERATION

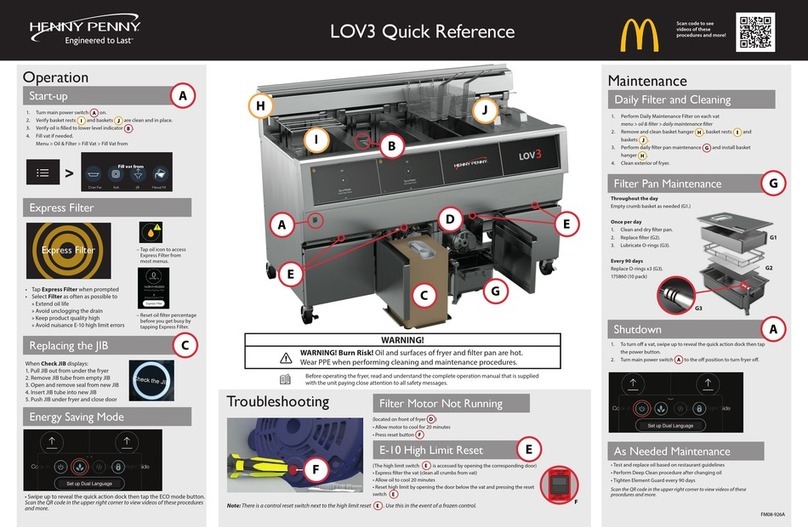

CONTROL PANEL

1

Display

5

Increase function when setting values or

navigation to the right if on the main screen.

2

Parameters setting:

- UPPER TEMPERATURE

- LOWER TEMPERATURE

- BELT SPEED

6

Decrease function when setting values or

navigation to the left if on the main screen.

3

Access to the menu with items:

- PROGRAMS

- PROGRAMMED SWITCH ON/SWITCH OFF

- DATE/TIME

- BELT DIRECTION

- LANGUAGE

- MAINTENANCE MENU

- EXIT

7

Switching the pcb on/off.

4

Confirmation of the values set or

starting/stopping of the belt if on the main

screen.

13

MAIN SCREEN

1

UPPER TEMPERATURE

the temperature detected by the probe located higher up;

2

LOWER TEMPERATURE

the temperature detected by the probe located lower down;

3

OPERATING SYMBOLS UPPER

HEATING ELEMENTS

it is activated when the upper heating elements are on to bring

the measured temperature to the top set point set;

4

OPERATING SYMBOLS

LOWER HEATING ELEMENTS

it is activated when the lower heating elements are on to bring

the measured temperature to the base set point set;

5

BELT SPEED

Displayed in minutes and seconds, corresponds to the cooking

time in chamber. See dedicated paragraph.

6

BELT ROTATION DIRECTION

If the arrow is to the left the food is cooked from right to left, if

the arrow is to the right the food is cooked from left to right.

7

BELT OPERATION SYMBOL

It is in motion when the belt is operational.

It is only indicative and does not vary with respect to the speed

set.

8

DATE AND TIME

Displays current date and time.

9

PROGRAM SELECTION LINE

Starting from the manual (M), 6 programs selectable via the right

and left direction keys, operating when the ENTER key is pressed.

The program in use is highlighted.

14

SETTING PARAMETERS

TEMP KEY (2)

When pressed, the parameter to be set starts to flash in the order:

- UPPER TEMPERATURE

- LOWER TEMPERATURE

- BELT SPEED

Upon the third press, the setting is exited and the parameters set are confirmed. Alternatively, it is

possible to exit and confirm without passing all the parameters by pressing the ENTER key or instead to

wait a few seconds.

The settings are therefore always saved automatically.

MENU KEY (3)

Pressing results in access to the menu with the list of items:

- PROGRAMS

- SCHEDULER

- DATE/TIME

- BELT DIRECTION

- LANGUAGE

- MAINTENANCE MENU

- EXIT

Navigation takes place through the arrows (KEYS 4 and 5); to access the corresponding item press the

ENTER key; to exit the menu go to the exit item and press ENTER.

ENTER KEY (4)

If pressed in the main screen it has the function of starting or stopping the belt.

If within the parameters configuration or the menu, the parameter is saved.

LEFT ARROW KEY (5)

Navigation to the left by scrolling through the programs in the row of the main screen, starting with START

button. If within the parameter configuration it decreases the value or selects the previous item.

RIGHT ARROW KEY (6)

Navigation to the right by scrolling through the programs in the row of the main screen, starting with START

button. If within the parameter configuration it increases the value or selects the next item.

ON/OFF KEY (7)

It turns on the pcb or the door in standby when on.

PROGRAM SELECTION ON THE MAIN SCREEN

On the main screen the programs are visible as follows:

The empty box indicates that the

program in use is the manual

one.

The program in use is 3.

Instead, when selecting the

program using the navigation

arrows (4 and 5), the box

becomes full.

After 5 seconds, the program is

automatically activated.

It can also be saved by pressing

ENTER.

Note on the navigation keys: when pressed on the main screen, the first press fills the box of the program

in use, the second press moves the box to be able to select another program.

15

MENU ITEMS

PROGRAMS

Screen with the possibility to set 6 programs, each of which contains the parameters

- UPPER TEMPERATURE

- LOWER TEMPERATURE

- BELT SPEED

The MANUAL program is not present, it only remains on the main screen. It keeps the set values

memorised that will be recalled whenever returning from a program 1-6 to manual.

PROGRAMMED SWITCH ON/SWITCH OFF

Possibility to set a switch-on time and a switch-off time for each day of the week.

The checked box indicates that the programmed ignition is active for that particular day.

When only one day has the function activated, there is a symbol on the main screen that indicates its

programming; the symbol also remains on the pcb in standby.

Once the oven is switched on automatically, this is brought to a fixed and non-variable temperature of

140°C and at 100% belt speed, for reasons of safety and electrical consumption.

DATE/TIME

Date and time setting

BELT DIRECTION

Setting the belt direction.

Select the right arrow to move the belt clockwise, loading the food on the left and unloading it on the

right;

select the left arrow to move the belt anti-clockwise, loading the food on the right and unloading it on the

left;

LANGUAGE

Select from the languages:

ENGLISH

ITALIANO

FRANÇAIS

DEUTSCH

ESPAÑOL

MAINTENANCE MENU

Menu protected by password and reserved for the producer/maintenance technician.

EXIT

Menu item to exit and return to the main screen

16

AUTO-OFF FUNCTION

When switched off, the oven will keep the ventilation switched on until it has cooled down.

An alert will appear on the screen with the current and shut down temperature.

The oven will continue to cool down to a temperature of 140°C, after which it will automatically shut down

when this temperature is reached.

During this phase DO NOT disconnect the power supply cable as

this could damage the electronic components.

ERROR MANAGEMENT

The probe is not connected or it is broken, check it then press

ENTER to reset.

BELT SPEED

The net speed is indicated on the main screen and it’s expressed in minutes and seconds.

The indicated time is the cooking time in the chamber, see the drawing below.

Time selection take place at intervals set in this way:

From 1:00 to 5:00 steps of 10 seconds

From 5:00 to 10:00 steps of 20 seconds

From 10:00 to 20:00 steps of 30 seconds

Below are the minimum and maximum cooking times that can be selected according to the model:

C/40 from 1:00 to 13:00

C/50 from 1:00 to 15:30

C/65 from 1:20 to 20:00

C/80 from 1:10 to 17:30

COOKING TIME

17

PRODUCTIVITY

Depending on the model of the oven, the number of pizzas / hour is calculated using the table:

C/40

C/50

C/65

C/80

NR° PIZZAS Ø25 IN CHAMBER

2,5

5

8

12

NR° PIZZAS Ø32 IN CHAMBER

1,5

2,5

6

7

NR° PIZZAS Ø40 IN CHAMBER

1,33

1,67

3

5

NR° PIZZAS Ø45 IN CHAMBER

0

1,5

2,33

3,33

COOKING TIME (sec)

210

210

210

210

CHAMBER PASSAGES IN ONE

HOUR

17

17

17

17

Ø25 PIZZAS/HOUR

43

86

137

206

Ø32 PIZZAS/HOUR

26

43

103

120

Ø40 PIZZAS/HOUR

23

29

51

86

Ø45 PIZZAS/HOUR

0

26

40

57

Note:

The amount of pizzas is calculated with a cooking time of 3:30, at the temperature of 320°C and a

preparation from scratch, not with frozen products.

18

MAINTENANCE

BEFORE PERFORMING ANY KIND OF MAINTENANCE INTERVENTION IT IS

MANDATORY TO DISCONNECT THE OVEN PLUG FROM THE POWER SUPPLY OUTLET.

CLEANING

Cleaning must be carried out at the end of each use in observance of the rules on hygiene and to protect

the functionality of the oven.

Cleaning the chamber:

De-energise the oven by turning the power switch.

Remove the conveyor belt joint guard.

Release the belt from the hook by moving it upwards.

Slide the joint itself towards the control panel releasing it from the conveyor belt drive shaft.

Raise the inlet and outlet sliding hoods into the maximum opening position.

Lift the conveyor belt on both sides and pull it out from the side of the controls.

Open the side door and, using a pair of gloves, remove the diffusers that are secured with screws.

Clean the metal surfaces with a sponge soaked in water and non-abrasive and/or corrosive detergent, then

rinse the surfaces with a sponge soaked in pure water.

External cleaning of the oven: (stainless steel surfaces, inspection glass and control panel): this

operation must be carried out with the oven cold.

THE OPERATOR IS ADVISED TO USE SUITABLE GLOVES AND CLOTHING TO AVOID

BURNS.

FOR CLEANING IT IS FORBIDDEN TO USE: WATER JETS, ABRASIVE POWDERS,

CORROSIVE SUBSTANCES OR ANYTHING ELSE THAT COULD DAMAGE THE

COMPONENTS AND COMPROMISE SAFETY IN GENERAL, AND IN PARTICULAR FROM

A HYGIENE POINT OF VIEW.

MAINTENANCE FREQUENCY

For any extraordinary maintenance, repair and/or replacement, contact an authorized operator who meets

the technical-professional requirements required by current regulations.

Maintenance, checks, inspections and cleaning

Regularity

Mechanical protection devices

Check condition, and for any deformation, loosening or removed parts.

Monthly

Control

Check mechanical part, for any breakage or deformation, tightening of screws. Check

readability and condition of words, stickers and symbols and restore if necessary.

Yearly

Machine structure

Tightening of main bolts (screws, fixing systems, etc.) of machine.

Yearly

Safety signals

Check readability and condition of safety signals.

Yearly

Electrical control panel

Check the electrical components installed inside the Electric Control Panel. Check wiring

between the Electrical Panel and machine parts.

Yearly

Electrical connection cable and plug

Check connection cable (replace it if necessary) and plug.

Yearly

General machine overhaul

Check all components, electrical equipment, corrosion, pipes,…

Every 10

years

19

BELT DISMANTLING AND ASSEMBLY

Belt removal instructions. To refit it, proceed in reverse order.

1

2

3

4

5

6

7

8

9

Table of contents

Other Prismafood Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Sengun Makina

Sengun Makina SM-30 Single User & maintenance manual

Inoksan

Inoksan PMP100 instruction manual

Mychef

Mychef iCOOK product manual

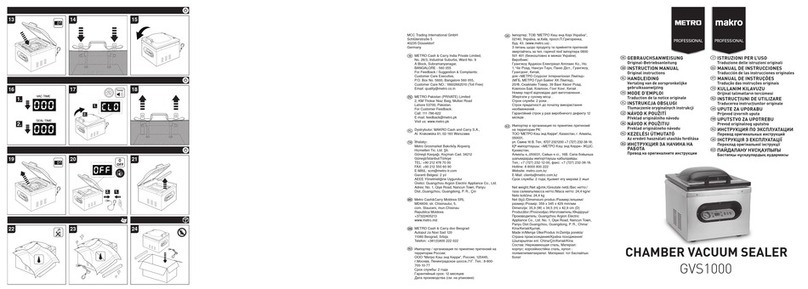

METRO PROFESSIONAL

METRO PROFESSIONAL makro professional GVS1000 instruction manual

Roller Grill

Roller Grill FM2 Use and installation manual

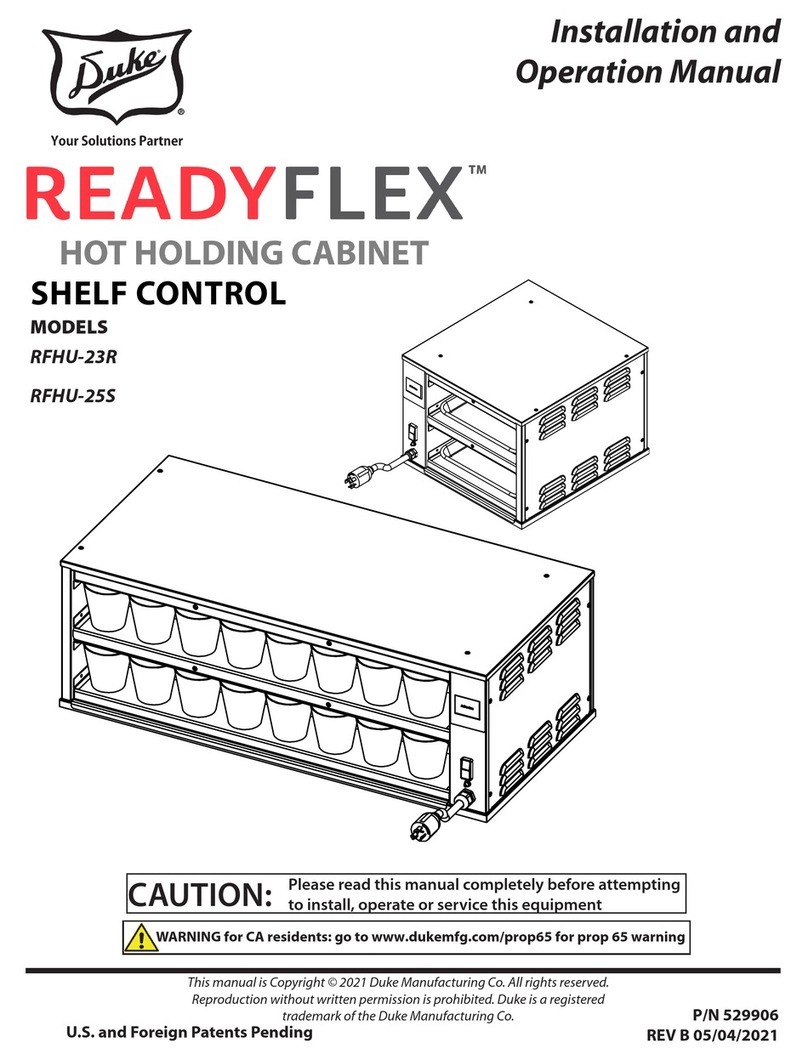

Duke

Duke ReadyFlex RFHU-23R Installation and operation manual