14

For each room that is to be heated, preliminary calcu ons of the heat losses will be performed

and on the basis of its dimension, the thermal output of the g body is to be selected.

The fuel is wood pellets mm/30mm class ʤ1. Quality of pellets is of par cular importance.

Despite the presence of a c te, some pellets show various defects upon combu on: releasing more

ash, forming slag (cinder) in the ash, low ĞĸĐŝĞncy and caloriĮc capacity. Use of other fuels and waste shall

not be allowed.

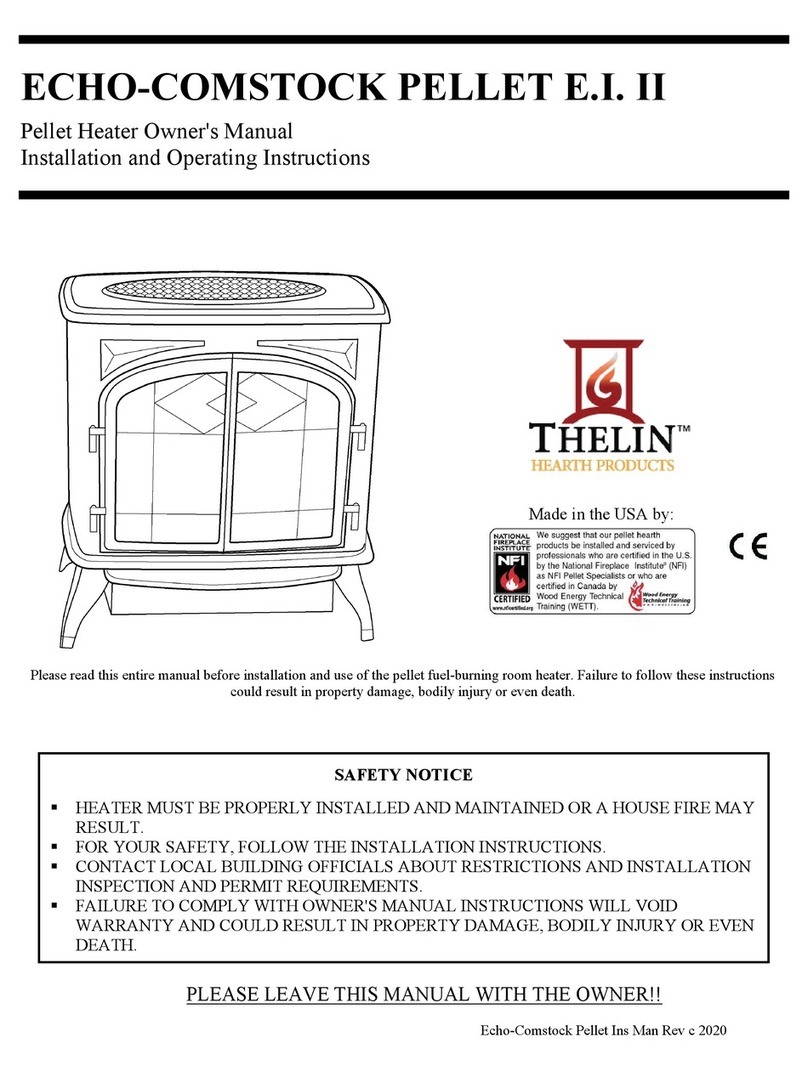

Pellets are loaded in the hopper and via auger dosing device are fed into the specially constructed steel

Įrepot (brazier) for burning, in accordance with the se ng selected at the controller.

Aer start-up, the pellets in lly loaded in the Įrepot (brazier) are automa ly ignited by the

electri ng cartridge - igniter, which erwards is switched oīďLJ the program.

Required amount of combu on air is fed through the Įrepot (brazier) grate in a controlled manner.

It is supplied over a Ø50 mm PVC pipe.

The quan ty of the incoming air is measured and controlled by the electronic Ňow/Ňow rate meter

for air.

The active fuel-air system compares the measured amount of incoming air with the necessary

amount of air to provide quality combus on process in the respec ve mode and brings it in conformity by

controlling the speed of the smoke fan.

This ensures quality combu on process completely independent on the parameters of the

chimney – length, height, resistance, pass-through capacity, d or on the parameters of the pipework,

providing the necessary air. In extreme situa ons – inadmissible or complete clogging, the stove will be

emergency shut down and A12 alarm will be triggered.

The ash remaining from the fuel combus on is collected in an ash box.

Flue gases are forcedly discharged into the chimney by means of an integrated smoke fan,

controlled in accordance with the se ngs and mode of opera on selected.

All processes are controlled in an intelligent manner by the integrated electronic unit – a dedicated

controller. It has the necessary opera on control sets - factory and user se ngs, programmed in it.

Aiming at preserva on of health, life and property of the user, there are safety fun ons provided,

which will stop the stove op on in cases of incorrect and foreseeably hazardous modes of opera on.

GENERAL SAFETY

Cau on:

Usage and handling this appliance require certain minimum of knowledge and skills acquired.

All instruc ons provided by the manufacturer must cons tute an important and essen al part of

these knowledge and skills, be always available to the user and abided by in order to minimise or

completely exclude all possible risks and dangerous consequences.

This appliance may not be used by children less than 12 years old and individuals with reduced

physical, sensory or mental cap s, or with insuĸĐient experience and knowledge, unless supervised or

instructed concerning the safe use of the appliance by the person in charge for their safety and are fully

aware of the hazards.

Children must not be allowed to play with the appliance.

No cleaning and servicing of the appliance may be done by children without supervision.

Always make sure that the stove is in a safe status, whether in opera on or during its down me.

During opera on, the Įrebox door must always be closed.

Do not allow opening of the Įrebox door during opera on and in presence of Įre for more than 10

seconds.

During opera on, some surfaces are heated to high temperatures, which if touched accidentally or

erroneously, severe heat-related injuries can occur.

ModiĮca ons of the appliance shall not be allowed.

When some part needs replacement, only original parts must be used.

STANDARDS AND LEGISLATION

dŚŝƐĮƌĞƉůĂĐĞŝƐŵĂĚĞŝŶĂĐĐŽƌĚĂŶĐĞĂŶĚĐŽŵƉůŝĞƐǁŝƚŚƚŚĞƵƌŽƉĞĂŶEŽƌŵƐ

Ø6

dŚŝƐĮƌĞƉŽƚŝƐŵĂĚĞŽĨĂůůŽLJĞĚƐƚĞĞůƌĞƐŝƐƚĂŶƚƚŽŚŝŐŚƚĞŵƉĞƌĂƚƵƌĞƐ