Prizelawn PS 200 II User manual

OWNER’S MANUAL

Prizelawn

PrizelawnPrizelawn

Prizelawn

®

® ®

®

PS

PSPS

PS

200

200200

200

II

IIII

II

Power Spreader

TM

Shown with optional Side

Deflector installed

TABLE OF CONTENTS

Assembly Instructions…………………………...Section 1

Safety Precautions………………………………..Section 2

Training……………………………………………..Section 3

Preparation…………………………………………Section 4

Operation…………………………………………...Section 5

Operating Instructions…………………………...Section 6

Spreader Operation Instructions……………….Section 7

How to Determine Settings & Swath Width….. Section 8

Spreader Rate Setting Conversions……………Section 9

Maintenance, Adjustments, & Storage...………Section 10

Parts List…………………………………………….Section 11

Warranty……………………………………………..Section 12

Technical Specifications………………………….Section 13

Notes…………………………………………………Section 14

2.

1.1

Parking brake is engaged for shipping.

Disengage brake before removing unit from carton.

Install Upper Handle Assembly to Main Frame using (4)

5/16-18 x 1 1/2” SS. Hex Bolts washers and Lock Nuts

as shown. Install the one washer on the outside of

the Frame and on the outside of the Upper Handle

with each bolt.

1.2

Slide the hole in the bottom of

Hopper over the impeller shaft and

attach hopper to Frame using the front

two (2) holes in Hopper with two (2) 1/4-

20 x 5/8 Hex Bolts, Washers, and Lock

Nuts, but do not tighten. NOTE: the two

(2) Screen Retaining Clips are installed in

the back two (2) holes with two (2) 1/4-20

x 5/8 Hex Bolts, Washers, and Lock Nuts

as shown but do not tighten. Center the

Impeller Shaft in the hole in the Hopper.

Tighten all the bolts. From inside the

Hopper, install the 3/8” ID. Flat Washer

over the Impeller Shaft. Insert Agitator

Wire into hole in the Impeller Shaft as

shown. Install Hopper Screen under

Screen Retaining clips previously

installed.

1. Assembly:

3.

5/16-18 x 1 1/2”

Hex Bolts &

Lock Nuts

Impeller Shaft

Front Holes

Inside Hopper

Back Holes

Inside Hopper

Screen

Retaining Clip (2)

3/8” ID. Flat

Washer

Agitator Wire

Upper

Handle

Parking Brake

Control

Panel

#10-24 x 5/8”

Screw (4)

1.3

Install Control Panel with the

Spreader On/Off Assembly and the

Throttle Cable attached to the engine

onto the Upper Handle using four (4)

#10-24 x 5/8” Pan Hd. Screws. Tighten

securely.

Install a washer on the

outside of frame and the han-

dle brace w/ each bolt

1.5

Slide Transmission Cable into Bracket on

Upper Handle as shown. Center the threads

above and below the Bracket and tighten Nuts

securely.

1. Assembly-Continued:

Transmission

Cable

Transmission

Cable Nuts

Handle Bracket

4.

1.6

Thread the Yoke and Locking Nut onto the

end of the Transmission Cable. Attach to the

Forward/Reverse Lever Bracket in the hole

shown using a 3/16” dia. Clevis Pin. (the second

hole shown is an optional attachment point).

Adjust Yoke so the Forward/Reverse Lever

is straight up in relation to the upper handle

in the neutral position. Check operation of

Forward/Reverse Lever. It should operate

smoothly. When complete, secure the Clevis

Pin with 3/16” Dia. Cotter Pin.

1.4

Place bent end of the Main Shutoff

Connecting Rod through the hole in the Pivot Lever

on the Hopper. Secure Rod with a Hitch Pin Cotter

as shown.

Thread a 5/16-18 Hex nut onto thread on

opposite end of Rod until it stops. Insert rod through

the pivot arm on the lever as shown. Thread

second nut up to the pivot arm: do not tighten. Pull

the shutoff lever to the closed position and look

inside hopper to see if the port holes are closed.

Adjust top nut in small increments until the holes

are just closed. CAUTION-DO NOT ADJUST THE

NUT TOO FAR DOWN AS DAMAGE CAN

OCCUR. When ports are completely closed, thread

bottom nut up and tighten both nuts.

Clevis &

Cotter Pin

Yoke &

Locking Nut

Forward/Reverse

Lever Bracket

Main Shutoff

Connecting

Rod

Hitch Pin Cotter

Pivot Lever

Main Shutoff

Connecting

Rod

Pivot Arm

5/16-18 Hex

Nuts

Equal Threads

on each side of

nuts

2. Safety Decals

Specific safety warning decals are located on the equipment near the immediate areas of potential

hazards. These decals should not be removed or obliterated. Replace them if they become non-readable.

5

This is the operator’s manual for your Prizelawn

®

PS 200

ll

TM

. The owner’s manual for the engine of the

spreader is separately enclosed. Keep the engine owner’s manual with this manual for future reference. Requests

for replacement engine manuals and questions regarding your engine should be directed to the engine

manufacturer.

2.1 SAFETY:

This Safety Alert Symbol is used both in this manual and on the machine to identify important safety messages

which must be followed to avoid accidents.

The safety alert symbol appears above information which alerts you to unsafe actions or situations and will be

followed by the word DANGER, WARNING, or CAUTION.

DANGER—Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING—Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION—indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Read the Operator’s Manual and other training material. If the operator(s) or mechanic(s) cannot read English it is

the owner’s responsibility to explain this material to them.

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

All operators and mechanics should be trained. The owner is responsible for training the users.

Never let children or untrained people operate or service the equipment. Local regulations may restrict the age of

the operator.

The owner/user can prevent and is responsible for accidents or injuries occurring to themselves, other people or

property.

Never leave a running machine unattended.

Evaluate the terrain to determine any potential risks to stability prior to operating.

Inspect the area where the equipment is to be used and remove all objects such as rocks, toys, and wire which can

destabilize the machine.

Wear appropriate clothing including hard hat, safety glasses and hearing protection. Long hair, loose clothing or

jewelry may get tangled in moving parts.

Do not exceed weight capacity of hopper.

Use extra care when handling gasoline and other fuels. They are flammable and vapors are explosive.

Use only an approved container

Never remove gas cap or add fuel when engine is running. Do not smoke.

Never refuel or drain the machine indoors.

Check that operator’s presence controls, safety switches and shields are attached and functioning properly. Do

not operate unless they are functioning properly. 6.

3.Training:

4. Preparation:

Engine parts, especially muffler, become

Extremely hot.

Severe burns can occur.

Allow parts to cool before touching.

6. Operating Instructions:

FAMILIARIZE YOURSELF WITH ALL CONTROLS PRIOR TO OPERATING. REFER TO THE FOLLOWING ILLUSTRATIONS:

Forward Ground Speed: Located on right hand lever. Pull lever towards operator to increase speed. SLOWLY

release lever to decrease ground speed. Release lever completely to stop movement.

Reverse Ground Speed: Located on Left hand lever. Pull lever towards the handle bar to increase speed. SLOWLY

release lever to decrease ground speed. Release lever completely to stop movement.

Throttle Control: The cable is linked to engine throttle for controlling engine speed. Move lever forward to increase

engine rpm, move lever rearward to decrease engine rpm. Move lever all the way rearward to shut off engine.

Choke Control: The throttle control is linked to the engine choke. Move the lever all the way forward to engage.

Ground Speed Control: Located on the right hand side of the control panel. Loosen knob and move plate to

limit the movement of the forward ground speed lever to achieve desired ground speed.

5. Operation:

This machine shall not be operated without all guard(s), shield(s), and cover(s) in place.

Never run an engine in an enclosed area.

Only operate in good light, keeping away from holes and hidden hazards.

Be sure all drives are in neutral before starting engine.

Only start engine from the operator’s position.

Be sure of your footing and wear proper footwear while using.

Be aware of potential for reduced footing in wet or muddy conditions.

Slow down and use extra care on hillsides. Take care in changing directions on slopes. Tip-overs can occur with

sudden stops when operating straight down hill-sides.

Turf conditions can affect the machine’s stability.

Use caution while operating near drop-offs

Slow down and use caution when making turns and when changing directions on slopes.

Never operate with shields or guards not securely in place.

Do not change the engine governor setting or over speed the engine.

Stop on level ground, shut off engine before leaving the operator’s position for any reason including reloading the

hopper or unclogging or cleaning the spreader mechanism.

Stop equipment and inspect after striking objects or if an abnormal vibration occurs. Make necessary repairs before

resuming operations.

Keep hands and feet away from the spreader mechanism and other moving parts.

Look behind and down before backing up to be sure of a clear path.

Never carry passengers and keep pets and bystanders away.

Slow down and use caution when making turns and crossing roads and sidewalks.

Do not operate the machine on slopes greater than 15 degrees.

Be aware of the spreader discharge direction and do not intentionally point it at anyone.

Do not operate under the influence of alcohol or drugs.

Use care when loading or unloading the machine into a trailer or truck.

Use care when approaching blind corners, shrubs, trees, or other objects that may obscure vision.

Performance and response of machine may vary as weight of hopper contents changes.

7.

Directional Controls: Handle bars are moved to pivot the unit and steer the in the desired direction.

Spreader On/Off Control: Located in the LH. side of the control panel. Push lever to open spreader, pull back to

close.

Spreader-Rate Control: Located on the upper portion of the back of the spreader hopper. See rate setting section.

Spread Pattern Control: Located on the front of the hopper above the impeller. See pattern control section.

Drive Wheel Release: Located on the L.H. side of the machine near the front L.H. wheel. Release is used to release

drive system to allow machine to be pushed without engine running. Pull rod out and hook latch to allow machine to be

pushed without engine running.

Parking Brake Engagement: Located on the back of main frame. Push rod in and hook latch to engage parking

brake.

8.

Broadcast

Spreader

Rate Control

Parking Brake-

Push in & Lock

to Engage

Drive Wheel

Release -Pull Out &

Lock to Engage

Spread Pattern

Control

Forward Ground

Speed Control

Directional

Control

Throttle/Choke

Control

Spreader On/

Off Control

Directional

Control

Reverse Ground

Speed Control

When transporting spreader from location to location,

make sure the spreader on/off control lever is in the

“OFF” position.

Use Swath Width

on Package or Adjust

per Operator’s

Ground Speed

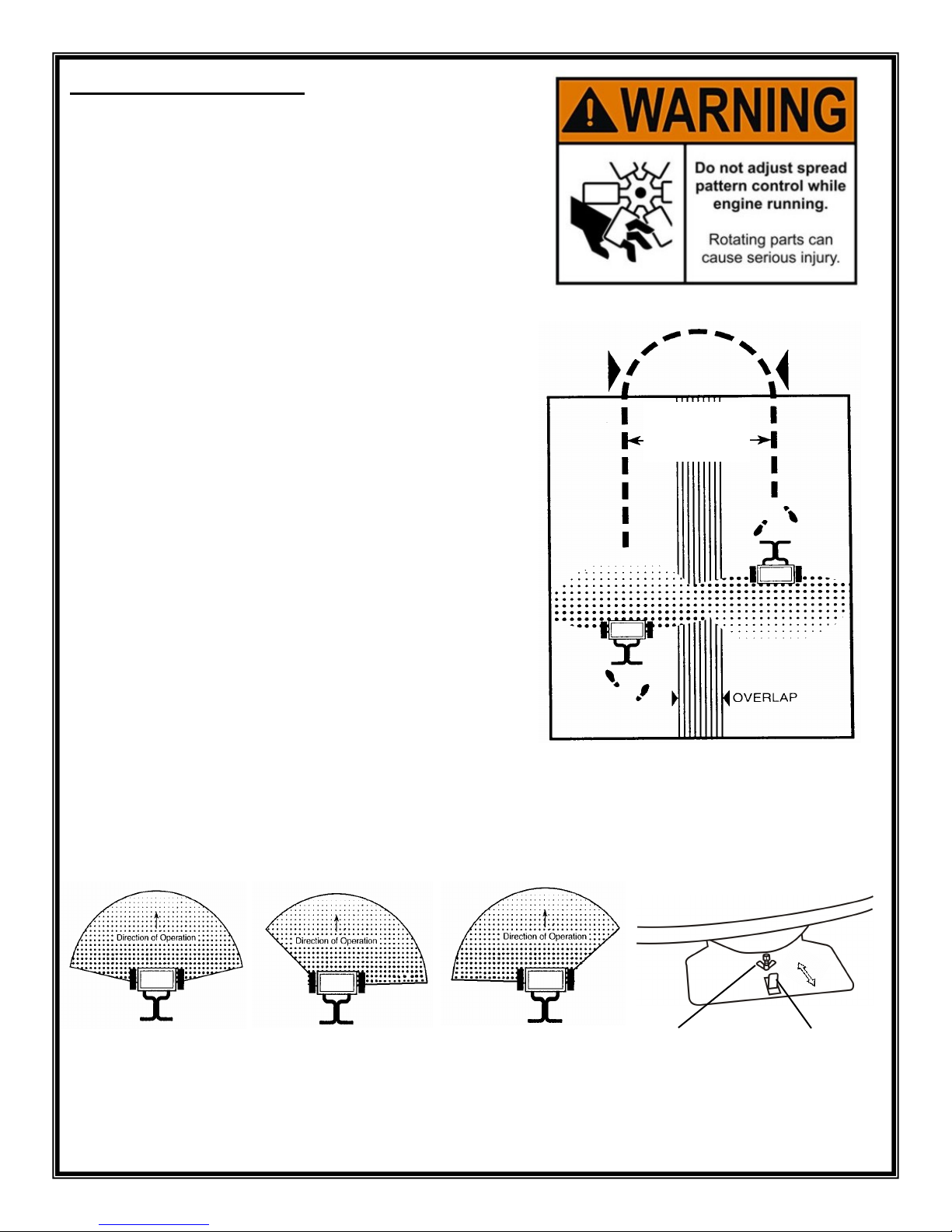

Normal spreading of material requires no adjustment unless otherwise stated on the package. In those cases where

the spread pattern has shifted, the pattern can be adjusted. If the pattern is heavier to the right (as viewed from the

operating position), loosen the wing nut and move the control plate in toward the hopper. If it is heavy to the left, move

the control plate out away from the hopper. Tighten wing nut after each adjustment is made.

7. Spreader Operation:

Check the product package for the rate setting (letter), pattern

setting (number), and recommended swath width. Loosen the

rate control knob and slide the rate plate to the proper rate

setting. See “Pattern Adjustment” for further details.

Before filling hopper, make sure the spreader on/off control lever

is in the “OFF” position. Make sure screen is in the hopper. Fill

hopper.

Start spreader moving before opening ports, close ports before

stopping spreader. Always push spreader, DO NOT PULL.

The setting and swath width on the product label are

recommended starting points. Always check the delivery rate and

pattern on a small area before treating a large area. Actual deliv-

ery rates can vary due to weather conditions, operating variables,

and condition of the products being applied. See “How to Deter-

mine Spreader Settings and Swath Width” for details.

Spreader should be operated at 3 m.p.h. (66 feet in 15 seconds).

If faster application speed is desired, the rate setting will need to

be adjusted. Apply header strip at each end of area to be treated

then space trips across the area as shown.

Empty the spreader after each use and clean thoroughly.

Do not leave unused material in hopper. Return

leftover material to its original container.

Normal Pattern Pattern Heavy

Left

Pattern Heavy

Right

Wing

Nut Control Plate

9.

Effective Pattern Width

A simple visual pattern test can be made by

operating spreader over a non-turf area and

evaluating the pattern. A more accurate

method is to place a row of common,

disposable, aluminum cake pans

approximately 1 foot on centers. Set the rate

plate at a middle setting and make 3 or 4

passes in the same direction as shown. Pour

the material collected from each pan into

individual bottles of the same size. Set them

side by side in order, and visually inspect their

volume. If the pattern is not centered

(example: volume in bottle #2 left not equal

tobottle #2 right) adjust the pattern control as

described in the “PATTERN ADJUSTMENT”

section. Once the pattern is uniform, the

effective pattern width can be determined. the

effective pattern width is the distance out

from the spreader to a point where the amount of

material is 1/2 the average amount in the center

pans. This distance is multiplied by 2 to achieve

the total effective pattern width.

8. How to Determine Settings & Swath Width:

Two major factors should be considered when determining correct spreader settings of

any product:

1. The product application rate, or the amount of material applied per 1,000 square feet.

2. The effective pattern width, or the actual width in which the material is applied. Label

settings are a guide and can be effected by numerous factors.

Application Rate

Knowing the effective pattern width (for example,

10 feet), measure a distance equal to 100 square

feet (10’ length x 10’ swath width). Determine the

product coverage in pounds-/100 sq. ft. by taking

the weight of product and dividing it by the recom-

mended square foot coverage (add two zeros to

the weight of the bag).

EXAMPLE: Product Weight: 25 lbs.

Sq. ft. Coverage: 5,000 sq. ft.

2,500 lbs. divided by 5,000 sq. ft.

= .5 lbs. / 100 sq. ft.

Weigh out between 15 to 20 lbs. of material and

spread over the 100 sq. ft. area. Weigh

remaining material left in hopper and adjust rate

setting as required. Repeat test until application

rate is correct.

10.

FERTILIZER

PARTICLE SIZE

BAG RATE

Pounds of fertilizer used

per 1,000 sq. ft. of

coverage

APPROX.

SETTING

SPREAD

WIDTH

(IN FEET)

Large, heavy

particles

5

10

15

J

K

L

12

12

12

Medium- mixed

particles

5

10

15

G

H

I

10

10

10

Small particles

(nitrogen)

1

2

3

D

F

J

10

10

10

Mixed size particles

-some fines

5

10

15

I

J

K

8

8

8

Light weight

particles

5

10

15

F

G

H

6

To

8

The following provides approximate Prizelawn

PrizelawnPrizelawn

Prizelawn

®

PS 200

PS 200PS 200

PS 200

ll

ll ll

ll

TM

settings when only the product weight,

square foot coverage, and visual inspection of material is available. Settings are based on an application

speed of 3 mph. Settings will require adjustment if ground speed is faster.

The conversions should be used as guidelines for establishing proper rate settings for the particular product

being applied. Steps for obtaining the most accurate settings are outlined in the “How to Determine Spreader

Settings and Spread Width” section of this manual.

These settings are approximate and may vary due to physical characteristics of the product. Walking speed.

wear, condition of the turf and humidity, may cause actual rate setting to deviate. No expressed nor implied

warranty or guarantee is provided as to coverage or uniformity indicated by these rate settings.

PS 200

PS 200PS 200

PS 200

Setting

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

Lesco

#029600

Setting

A

—

B

C

D

—

E

F

—

G

H

I

—

J

K

L

—

M

N

O

—

P

Q

R

—

S

Scotts

AP/SR2000

Setting

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

—

V

W

—

X

Y

Z

Earthway

2200/2400

Setting

5

—

—

—

—

10

—

—

—

—

15

—

—

—

—

20

—

—

—

—

25

—

—

—

—

30

Spyker

76/78-2

Setting

—

—

3

—

—

—

4

—

—

5

—

—

6

—

—

7

—

—

8

—

—

—

9

—

—

10

9. Spreader Rate Setting Conversions:

The following provides approximate Prizelawn

PrizelawnPrizelawn

Prizelawn

®

PS 200

PS 200PS 200

PS 200

ll

llll

ll

TM

settings for those units listed. Settings

are based on an application speed of 3 mph. Settings will require adjustment if ground speed is faster.

11.

10. MAINTENANCE, ADJUSTMENTS & STORAGE:

•

Park machine on level ground.

•

Never allow untrained personnel to service machine.

•

Disengage drives, set parking brake, stop engine, and disconnect spark plug wire. Wait for all movement to

stop before adjusting, cleaning or repairing.

•

Clean debris from hopper and spreader units, drives, mufflers, and engine to help prevent damage or fires.

Clean up oil or fuel spillage.

•

Let engine cool before storing and do not store near open flame.

•

Shut off fuel while storing or transporting. Do not store fuel near open flames or drain indoors.

•

Use jack stands to support components when required.

•

Remove spark plug wire before making any repairs.

•

Use care when checking belts and moving parts. Only replace such belts or parts. Attempts to straighten, re-

connect or otherwise repair such parts could lead to injury.

•

Keep hands and feet away from moving parts. Do not make adjustments with the engine running.

•

Keep all parts in good working condition and all hardware tightened. Replace all worn or damaged decals.

•

Follow engine manufacturer’s recommendations as provided in engine manual.

•

Never leave material in spreader hopper. Return unused product to its original container.

•

Wash unit thoroughly after each use and dry completely. Avoid spraying water directly on engine.

•

Impeller surface should be cleaned periodically to remove build-up of product. Build-up can cause the spread

pattern to change.

•

Tire pressure should be 12 to 15 PSI. for best traction. Do not over inflate.

•

Oil the pivot points on the shut-off linkage and spring in the housing under the rate plate.

•

Apply grease to fittings on the sulky wheels, and sulky pivot points.

•

Several times during the season, remove the hood and grease the impeller pulley bearings-do not overfill.

Apply a few drops of oil to the bearings in each of the back side idler pulleys as shown.

The

PS 200ll

spreader was factory calibrated, however,

calibration should be checked occasionally to assure

optimum performance.

Pull the on/off control lever to the closed position. Set the

rate control plate at setting “A” .

Push the on/off control forward to the “ON” position. Check

the center port. It should be just open as shown. If adjustment

is necessary continue to step #3.

Remove cotter pin from adjusting swivel and slide of control

tube. Slide adjusting swivel out of hole in pivot bracket (NOTE

SIDE OF PIVOT BRACKET FROM WHICH IT WAS

REMOVED). Thread swivel up or down on lower rod as

required. Install swivel back onto pivot bracket facing the

same way it was removed. Check calibration. Repeat

procedure until calibration is correct. Reinstall cotter pin.

ADJUSTING SWIVEL

PIVOT BRACKET

SHUT-OFF

PLATE

PORT JUST

OPEN

12.

Grease Impeller

Pulley Bearings

Apply a few drops of

oil to each of the

bearings in the back

side Idler pulleys on

the transmission and

impeller belts

13.

11. Parts List: PS200

PS200PS200

PS200

ll

llll

ll

1

2

3

4

5

7

8

9

13

10

11

12

79

18

19

20

25

22

23 21

26

27

24

14

28

29

33

34

37

38

39

35

30

32

39

40

41

42

45

44

53

47

48

50

51

52

24

56

57

58

59

60 61 62 63

64

65

15

16

17

31

36

67

77

43

68

71

70

66

69

72

73

74

75

54

76

46

49

6

78

55

3

80

81

#16322 Optional Side

Deflector Kit-Not Shown

No.

Description

Part # No. Description

Part #

1 Main Body-Weld Assembly 16185 41 Retainer-Agitator 16299

2 Access Panel 16188 42 Felt Seal-Agitator 780900

3 Nut-Push-In 90617 43 Hood 16183

4 Engine Pulley 4Lw/ Key-Transmission 16228 44 Bearing Spacer Washer 90084

5 Engine Pulley 3L w/ Key-Impeller 16381 45 Impeller Pulley-Plate 16343

6 Engine-Honda GXV160 16220 46 Impeller Pulley/Hub Assembly 16349

7 Throttle Control-Engine 16488 47 Impeller Pulley-Assembly 16202

8 Connecting Rod-Main Shutoff 16486 48 Impeller Shaft/Hub Assembly 16348

9 Handle-Weld Assembly 16494 49 3L Belt-Impeller Pulley 16382

10 Control Lever-Pivot Bracket (2) 16209 50 Idler Arm-Impeller Pulley 16265

11 Handle-Grip (2) 16294 51 Backside Idler Pulley 16341

12 Lever-Grip (2) 16295 52 Spring-Impeller Pulley 16274

13 Lever Assembly-Forward/Reverse 16493 53 Heavy Duty Snap Ring (2) 90089

14 Control Panel 16480 54 18” Tire/Rim Assembly W/Spacer 16416

15 Spreader On/Off Lever Assembly 16481 55 Tire/Rim-Spacer 16417

16 Bracket-Spreader On/Off Lever (2) 16485 56 Hydrostatic Transaxle 16221

17 Shut Off Plate Link 14846 57 Rod-Neutral Lockout 16267

18 Hopper-Shut Off Plate 16309 58 Frame-Weld Assembly 16176

19 Lower Control Rod 14917 59 Bottom Plate-Frame 16187

20 Pivot Lever Assembly & Plate 16491 60 Pivot Rod/Coupling Assembly 16196

21 Rate Control Plate 14915 61 Sulky-Base/Frame Weld Ass’y. 16199

22 Spring Housing 12702 62 Axle Collar W/Set Screw (2) 780200

23 Pointer 790342 63 Sulky-Axle 16198

24 Adjusting Swivel 14913 64 13” Tire/Rim Assembly 16229

25 Hopper-Screen 14863 65 Sulky-Safety Tread 16201

26 Hopper-Cover 16319 66 Arm-Brake Lever 790292

27 Screen-Clips (2) 14864 67 Adjusting Swivel-Threaded 16335

28 Hopper 16347 68 Rod-Brake Engagement 16268

29 Hopper-Bottom Plate 16307 69 4L Belt-Transmission 16226

30 Shut Off Plate-Guide 14836-1 70 Warning & No Step Labels 16311

31 Hopper-Deflector Plate 16308 71 Danger, Warning, Caution Labels 16310

32 Grommet-Push/Pull Cable 90062 72 Clevis Assembly w/ Nut 16215

33 Retainer Bracket-Drive Belt 16342 73 Push/Pull Cable 16214

34 Idler Arm– Drive Pulley 16271 74 Bracket-Transmission Cable 16304

35 Spring-Drive Pulley-4 1/8” Long 16334 75 Key Stock-Drive Wheel (2) 90072

36 Impeller 15752 76 Dampener w/ Threaded Balls 16379

37 Agitator 15940 77 Tinnerman Nut-1/4-20 (10) 90068-1

38 Collar W/Set Screw 16204 78 Brake Label 16336

39 Ball Bearing (2) 790170 79 Rate Control Knob w/Washer 12704

40 Cross Member/Bearing Tube 16262 80 Rate Control Spring 13354

81 Hood Gasket 16550

1.

SPREADER MODEL NUMBER

2.

SPREADER NAME

3.

PART NUMBER

4.

NAME OF PART AS SHOWN

PART OF OUR SERVICE IS

PROVIDING REPLACEMENT PARTS.

Parts may be obtained through your

local distributor. Be sure to give:

PSB Company

555 West Goodale Street P.O. Box 1089

Columbus, Ohio 43216-1089

Phone: (614) 559-2655

Fax: (614) 221-9398

IF YOUR LOCAL

DISTRIBUTOR CANNOT

SUPPLY PARTS,

CONTACT: 14.

11. Parts List Cont: PS200

PS200PS200

PS200

ll

llll

ll

13. Technical Specifications:

Engine: Honda GVX 160

Drive System: Hydrostatic transaxle

Ground Speed: Infinitely variable up to 6+ mph.

Turning Radius:3” from C/L of unit.

Brake: Hydrostatic dynamic braking

Parking Brake: Manually operated

Neutral engagement: Manually operated

Front Tires: 18 x 8.50-8

Sulky Tires: 13 x 5.00-6

Unit weight: 245 lbs. empty.

Hopper Capacity: 3.8 cubic foot or 200 lbs.

Controls: Hand operated forward & reverse, throttle/choke, speed control, and spreader controls.

Steering: Handle bars rotated to pivot sulky for directional control.

Construction: Main frame-Welded 11 ga. #300 SS, Sulky-Welded 11 ga. steel, powder coated finish,

Handle-Welded 14 ga. tubing, powder coated finish.

Specifications subject to change without notice

15.

12. Warranty:

The Warranty Registration form must be completed to validate your warranty protection.

The Product’s engine is covered by a three (3) year limited warranty from the engine manufacturer to the original owner.

The Product’s hydrostatic transaxle is covered by a one (1) year limited warranty from the transmission manufacturer to

the original owner. PSB recommends that you record the engine, transmission, and unit serial numbers for future refer-

ence:

ENGINE SERIAL # __________________________________ UNIT SERIAL # ______________________________

TRANSMISSION SERIAL # (Located on the Warranty Registration Card)

_____________________________________

PSB warrants to Purchaser the following:

1. The equipment and parts of the Product manufactured entirely by PSB will be free of defects in materials and workmanship for a period of one year

from date of purchase.

2. PSB will decide in its reasonable discretion if the Product’s part(s)/equipment is defective.

3. The Product or part(s) will be shipped to PSB at the customer’s expense with a written description of defect to the attention of PSB WARRANTY

DEPARTMENT.

4. If the Product is used for commercial rental, the Limited Warranty shall be limited to a period of 90 days.

5. All Product and part replacement will be performed at the reasonable discretion of PSB.

6. Labor charges are not covered and the Product need not be returned to the dealer for warranty service.

7. Proof of purchase must be supplied to PSB.

PSB's sole obligation under this warranty is limited to repairing or replacing the defective part which was entirely manufactured by PSB. Upon re-

placement of any Product or Product part, the replaced item shall become the property of PSB. If PSB determines that the Product covered by this

warranty requires service, PSB shall prepay return shipping charges from PSB. In all other instances, such charges shall be paid by Purchaser. Ex-

cept for loss or damage caused by PSB's negligence, Purchaser relieves PSB of responsibility for all risks of loss or damage to the Product and its

parts during the period the Product is in transit to and from PSB.

This warranty does not extend to any Product or parts thereof that have not been manufactured entirely by PSB, or that have been allowed to cor-

rode, or subjected to misuse, neglect, accident, or modification by anyone other than PSB or that have been affixed to any nonstandard accessory

attachment or that have been used, stored, installed, maintained or operated in violation of PSB’s instructions or standard industry practice. No

agent, employee or representative of PSB has any authority to bind PSB to any affirmation, representation or warranty concerning the Product and

any affirmation, representation or warranty made by any agent, employee or representative shall not be enforceable by Purchaser.

THIS WARRANTY EXTENDS ONLY TO THE ORIGINAL PURCHASER AND IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED

WARRANTIES, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS OR INTENDED USE

FOR A PARTICULAR PURPOSE AND OF ANY OTHER OBLIGATION ON THE PART OF PSB.

PSB SHALL NOT BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL LOSS, DAMAGE OR EXPENSE DIRECTLY OR INDI-

RECTLY ARISING FROM THE USE OF ANY OF THE PRODUCT INCLUDING, BUT NOT LIMITED TO, DAMAGE OR LOSS OF OTHER PROP-

ERTY OR EQUIPMENT, LOSS OF PROFITS OR

Pat.#D662,522

16.

.

14. Notes:

Printed 1-13

Table of contents

Other Prizelawn Spreader manuals