L4388 .3

1.0 INTRODUCTION

Overview

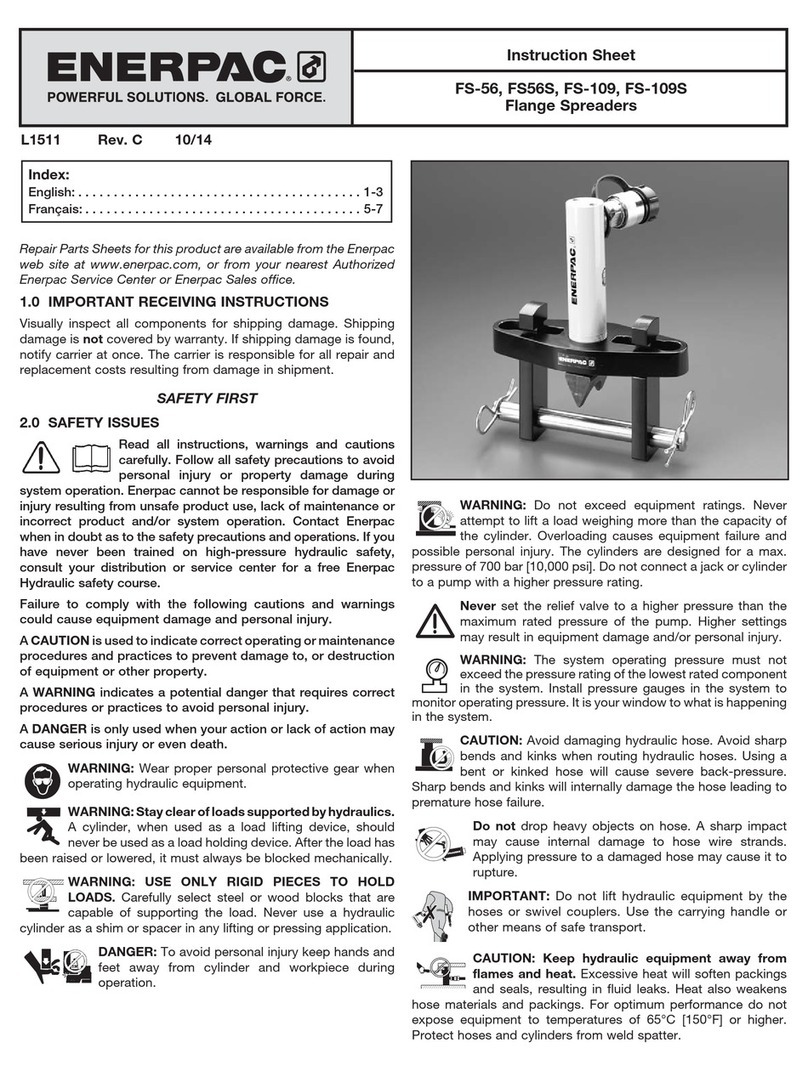

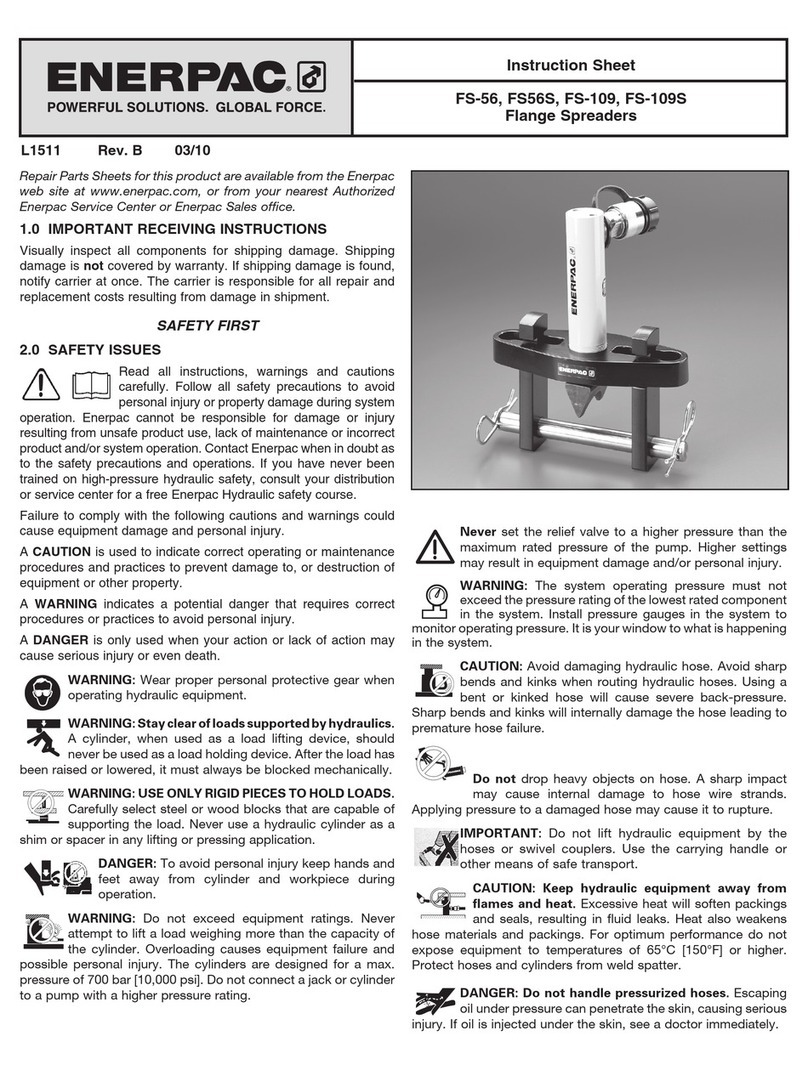

Enerpac Wedge Spreaders use the integrated wedge

concept. They are used to spread flanges in order to

create space for cleaning and repairing flange surfaces

and gasket replacement.

The Enerpac wedge spreader FSM8 is a manual operated

tool, and is actuated by a 22mm (0.87in) ratchet spanner

The Enerpac FSH14 is a hydraulic operated tool, that is

actuated by an Enerpac RC102 single acting cylinder.

The FSH14 must be powered by an Enerpac hand pump.

The FSC14 is actuated by an integral pump.

Application

Wedge spreaders can be used for: pipe and flange repair,

removing of elbows, couplers, gasket and metal seals

replacement, maintenance/ replacement of valve and

control equipment.

Delivery Instructions

Upon delivery all components must be inspected for

damage incurred during shipping. If damage is found the

carrier should be notified at once. Shipping damage is

not covered by the Enerpac warranty.

Warranty

• Enerpac guarantees the product only for the purpose

for which is intended.

• Refer to the Enerpac Global Warranty document for

terms and conditions of the product warranty.

Any misuse or alteration invalidates the warranty.

• Observe all instructions as communicated in this

manual.

• When replacement parts are needed, use only genuine

Enerpac replacement parts.

Modification to any part of the equipment outlined in this

manual should not be attempted, nor any component

part be replaced without first consulting Enerpac.

Modifications may render the equipment dangerous.

Component parts are each rated to suit the demands

of the overall equipment design and replacement with

similar items without provenance may lead to unexpected

and dangerous accidental features.

If any equipment abuse is evident, the warranty will be

invalidated and Enerpac will not be made responsible

for an injury due to misuse or failure to comply with the

above safety notes.

Part Replacement

Check the Repair Parts Sheets (RPS), available at

www.enerpac.com, to order replacement parts when

required.

Conformance to National and International Standards

Enerpac declares that the product(s) have been tested

and conforms to applicable standards and the product(s)

are compatible to all EU and UK Requirements.

Copies of the EU Declaration as well as the UK Self-

Declaration are enclosed with each shipment.

2.0 SAFETY

Read all instructions carefully. Follow all recommended

safety precautions to avoid personal injury as well as

damage to the product and / or damage to other property.

Enerpac cannot be responsible for any damage or injury

from unsafe use, lack of maintenance, or incorrect

operation. Do not remove warning labels, tags, or decals.

In the event of any questions or concerns arising, contact

Enerpac or a local Enerpac distributor for clarification.

If you have never been trained on high-pressure hydraulic

safety, consult your distributor or service center for

information about Enerpac Hydraulic Safety Courses.

This manual follows a system of safety alert symbols,

signals, words, and safety messages to warn the user of

specific hazards. Failure to comply with these warnings

could result in death or serious personal injury, as well as

damage to the equipment or other property.

The Safety Alert Symbol appears

throughout this manual. It is used to alert

you to potential physical injury hazards.

Pay close attention to Safety Alert Symbols

and obey all safety messages that follow this symbol

to avoid the possibility of death or serious injury.

Safety Alert Symbols are used in conjunction with certain

Signal Words that call attention to safety messages or

property damage messages and designate a degree or

level of hazard seriousness. The Signal Words used in

this manual are DANGER, WARNING, CAUTION, and

NOTICE.

Indicates a hazardous situation that, if not

avoided, will result in death or serious personal injury.

Indicates a hazardous situation that, if not

avoided, could result in death or serious personal injury.

Indicates a hazardous situation that, if not

avoided, could result in minor or moderate personal

injury.

Indicates information considered important,

but not hazard related (e.g. messages related to property

damage). Please note that the Safety Alert Symbol will

not be used with the signal word.

These tools conform with

the requirements for

CE and UKCA.

•FSM8 •FSH14 •FSC14

WARNING

CAUTION