Pro-face AGP3300-U1-D24 User manual

1

AGP3300-U1-D24

Installation Guide

Package Contents

(1) GP Unit (1)

(2) English and Japanese installation

Guides (1 of each) <This Guide>

(3) Warning/Caution Information (1)

(4) Installation Gasket (1, attachedto the

GP unit)

(5) Installation Fasteners (Set of 4)

(6) Power Connector (1)

(Attached to the GP unit)

(7) USB Cable Clamp (1 port) (1)

This unit has been carefully packed, with

special attention to quality. However,

should you find anything damaged or

missing, please contact your local GP

distributor immediately.

About the Manual

For detailed information on the GP3000

series, refer to the following manuals:

• GP3000 Series Hardware Manual

• Maintenance/Troubleshooting

• Device/PLC Connection Manual

The manuals can be selected from the

help menu of GP-Pro EX or downloaded

from Pro-face Home Page.

URL

http://www.pro-face.com/otasuke/

Caution

Be sure to read the “Warning/Caution

Information” on the attached sheet

before using the product.

2

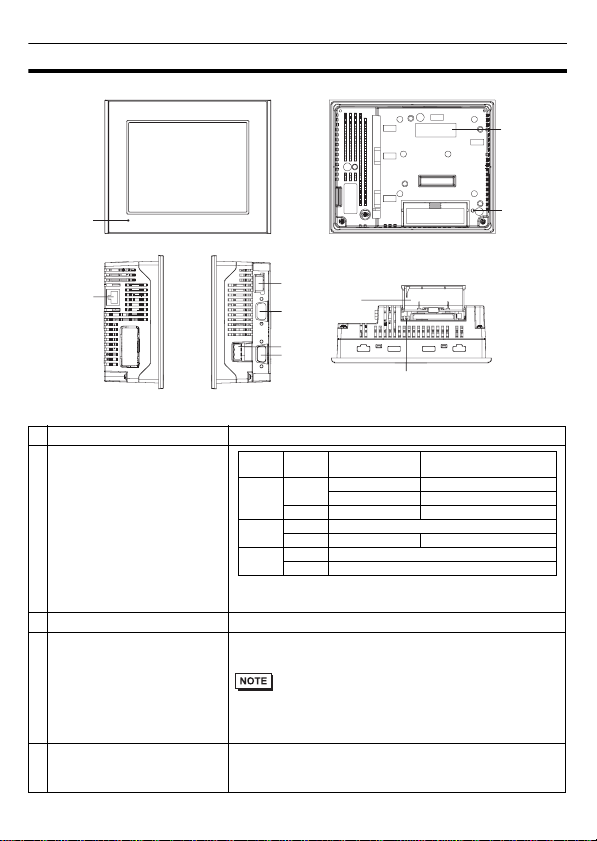

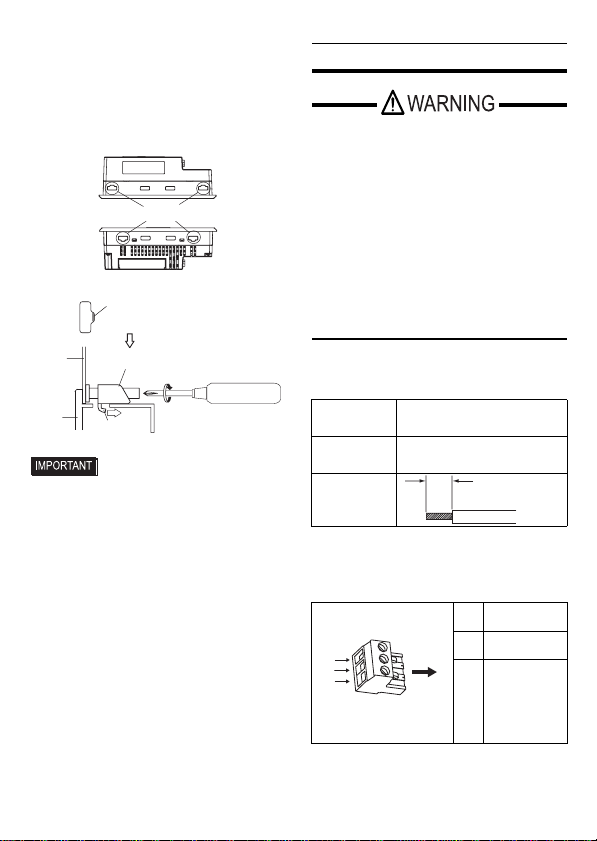

Part Names and Functions

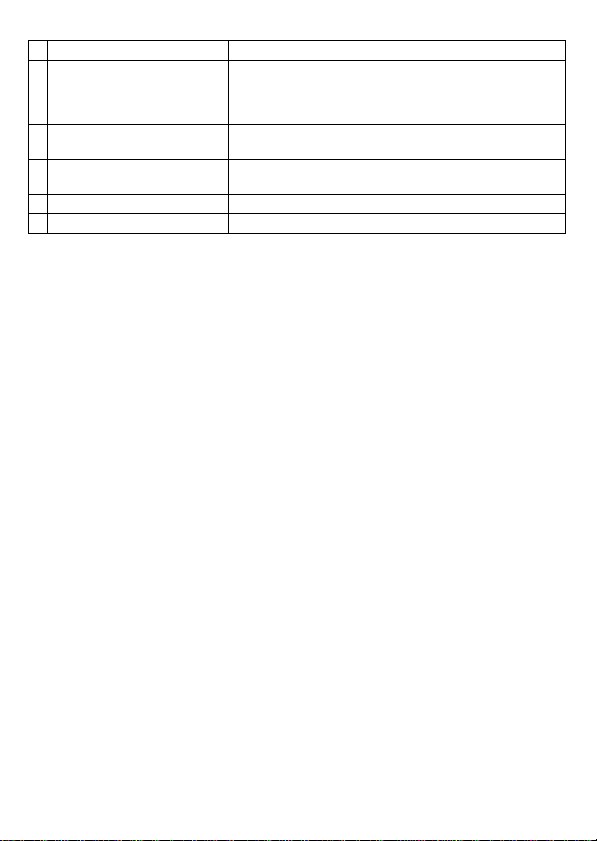

Name Description

AStatusLED

B Expansion UnitInterface(EXT) Used to connect an expansion unit that can transmit data.

C CF Card Access LED

Lit in green when the CF Card is inserted and the cover

is closed, or when the CF Card is being accessed.

• Do not remove or insert the CF Card when the LED

lamp is on. Doing so may damage data on the CF

Card.

D Ethernet Interface (LAN) 10BASE-T/100BASE-TX

This interface uses an RJ-45 type modular jack

connector (8 pins).

A

Front

DF

G

E

H

B

C

I

J

Rear

Right sideLeft side Bottom

Color Indicator

Operation Mode

(Drawing) Logic execution mode

(when logic is enabled)

Green ON OFFLINE

-

In operation RUN

Flashing

In operation STOP

Red ON When power is turned on.

Flashing

In operation Major Error

Orange ON Backlight burnout or GP malfuction *1

*1 When backlight replacement or repair of the GP is

required, please contact your local GP distributor.

Flashing

During software startup

3

E Power Connector (Socket)

-

F USB Host Interface (USB) Complies with USB 1.1. Uses a “TYPE-A” connector.

Power supply voltage:DC5V ±5%,

Output current:500mA (max.)

The maximum communication distance: 5m

G Serial Interface (COM1) D-sub 9-pin plug type. RS232C, RS422, and RS485

are switched by software.

H Serial Interface (COM2) D-sub 9-pin socket type. RS422 and RS485 are

supported.

ICFCardCover

J DIP Switches

Located inside the CF Card Cover.

4

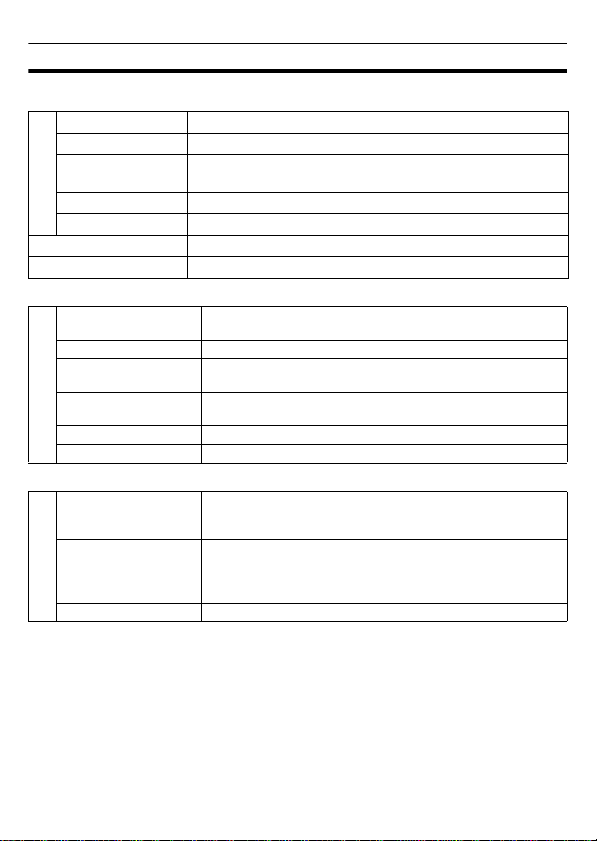

General Specifications

Electrical Specifications

Environmental Specifications

Structural Specifications

Power Supply

Input Voltage DC24V

Rated Voltage DC19.2 to 28.8V

Allowable Voltage

Drop 5ms (max.)

Power Consumption 26W (max.)

In-Rush Current 30A (max.)

Voltage Endurance

AC1000V 20mA for 1 minute (between charging and FG terminals)

Insulation Resistance DC500V 10MΩ(min.) (between charging and FG terminals)

Physical

Surrounding Air

Temperature 0 to 50°C

Storage Temperature -20 to +60°C

Ambient Humidity 10 to 90% RH (Wet bulb temperature: 39°C max. - no

condensation.)

Storage Humidity 10 to 90% RH (Wet bulb temperature: 39°C max. - no

condensation.)

Dust 0.1mg/m3and below (non-conductive levels)

Pollution Degree For use in Pollution Degree 2 environment.

Installation

Grounding Grounding resistance of 100Ω, 2mm2or thicker wire, or your

country’s applicable standard.

(Same for FG and SG terminals)

Structure*1

*1 The front face of the GP unit, installed in a solid panel, has been tested using conditions equivalent to

the standards shown in the specification. Even though the GP unit’s level of resistance is equivalent to

these standards, oils that should have no effect on the GP can possibly harm the unit. This can occur in

areas where either vaporized oils are present, or where low viscosity cutting oils are allowed to adhere

to the unit for long periods of time. If the GP’s front face protection sheet becomes peeled off, these

conditions can lead to the ingress of oil into the GP and separate protection measures are suggested.

Also, if non-approved oils are present, it may cause deformation or corrosion of the front panel’s plastic

cover. Therefore, prior to installing the GP be sure to confirm the type of conditions that will be present

in the GP’s operating environment.

If the installation gasket is used for a long period of time, or if the unit and its gasket are removed from

the panel, the original level of the protection cannot be guaranteed. To maintain the original protection

level, be sure to replace the installation gasket regularly.

Rating: IP65f NEMA #250 TYPE 1

(Front surface at panel embedding)

Feature size: All-in-one

Installation configuration: Panel embedding

Cooling Method Natural air circulation

5

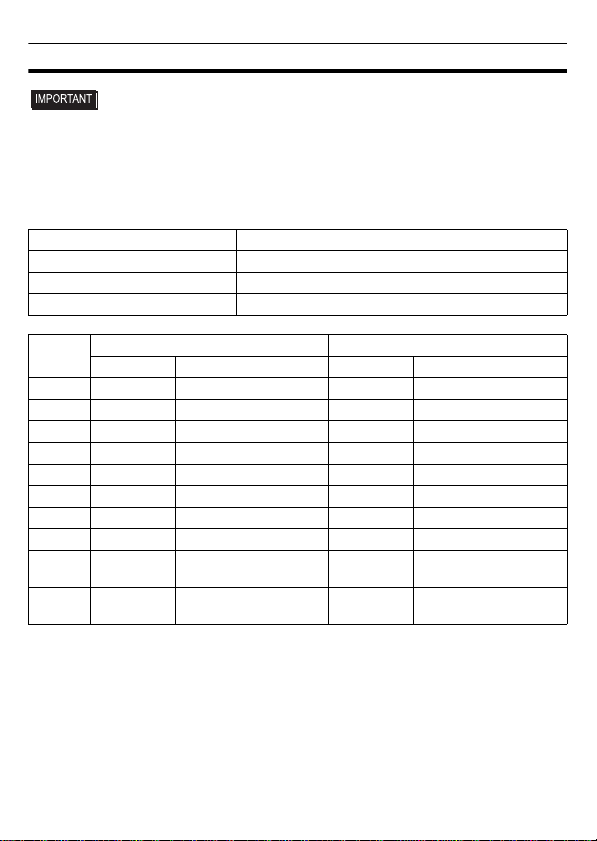

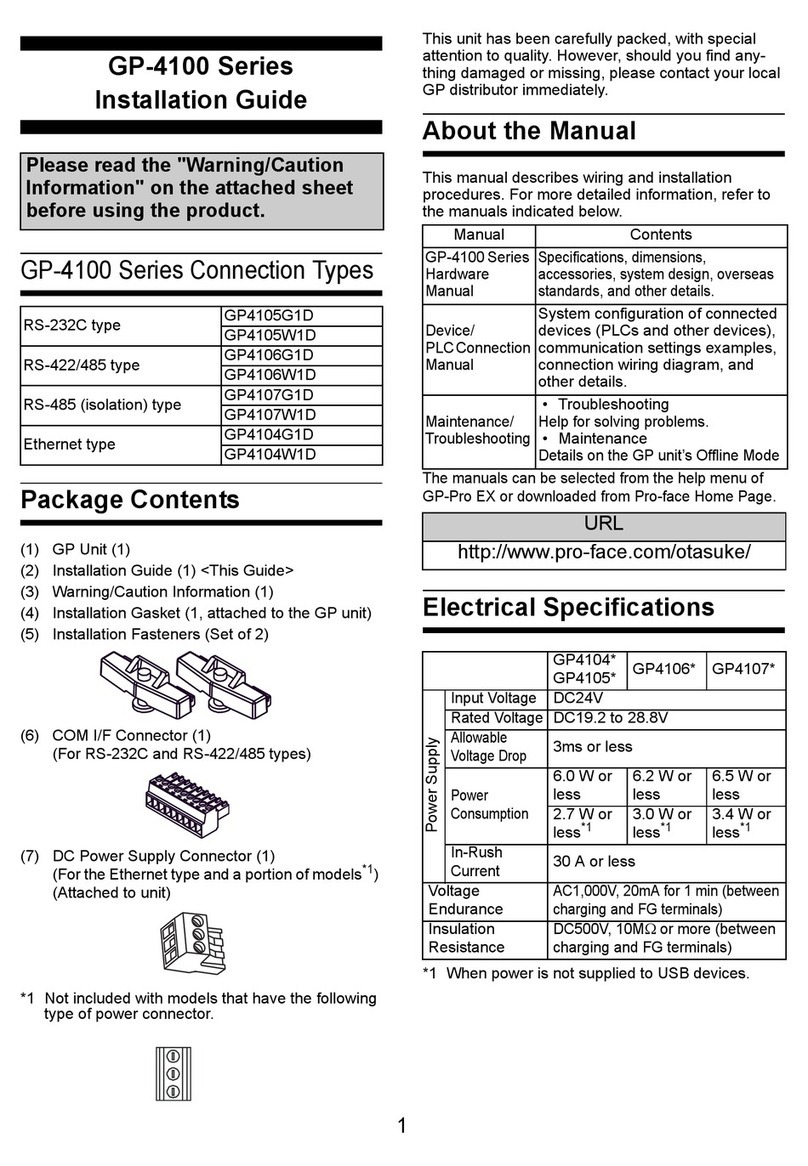

External Interfaces

• For instructions on how to connect to other devices, always refer to the “GP-Pro EX

Device/PLC Connection Manual”.

• Always connect the #5 SG (Signal Ground) of the GP unit to the connected device,

especially if the connected device is also not isolated. Failure to do so may damage

the RS232C/RS422/RS485 circuit.

COM1

Recommended Cable Connector XM2D-0901 <made by OMRON Corp.>

Recommended Jack Screw XM2Z-0073 <made by OMRON Corp.>

Recommended Cable Cover XM2S-0913 <made by OMRON Corp.>

Fitting fastener #4-40 (UNC)

Pin # RS232C RS422/RS485

Signal Name Meaning Signal Name Meaning

1 CD Carrier Detect RDA Receive Data A(+)

2 RD(RXD) Receive Data RDB Receive Data B(-)

3 SD(TXD) Send Data SDA Send Data A(+)

4 ER(DTR) Data Terminal Ready ERA Data Terminal Ready A(+)

5 SG Signal Ground SG Signal Ground

6 DR(DSR) Data Set Ready CSB Clear to Send B(-)

7 RS(RTS) Request to Send SDB Send Data B(-)

8 CS(CTS) Clear to Send CSA Clear to Send A(+)

9CI(RI)/VCC

Called status display/

+5V ±5% Output 0.25A

*1

*1 The RI/VCC selection for Pin #9 is switched via software. The VCC output is not protected against

overcurrent. To prevent damage or unit malfunctions, use only the rated current.

ERB Data Terminal Ready B(-)

Shell FG Frame Ground

(Common with SG) FG Frame Ground

(Common with SG)

6

COM2

• Always connect close to the GP unit's COM port when terminating with the

termination pins (TRMRX/TRMTX).

Recommended Cable

Connector XM2A-0901 <made by OMRON Corp.>

Recommended Jack Screw XM2Z-0073 <made by OMRON Corp.>

Recommended Cable Cover XM2S-0913 <made by OMRON Corp.>

Fitting fastener #4-40 (UNC)

Pin # RS422/RS485

Signal Name Meaning

1 TRMRX Termination (Receiver side: 100Ω)

2 RDA Receive Data A(+)

3 SDA Send Data A(+)

4 RS(RTS) Request for Send

5 SG Signal Ground

6VCC

+5V ±5% Output 0.25A

*1

*1 The VCC output for Pin #6 is not protected against overcurrent. To prevent damage or unit

malfunctions, use only the rated current.

7 RDB Receive Data B(-)

8 SDB Send Data B(-)

9 TRMTX Termination (Receiver side: 100Ω)

Shell FG Frame Ground (Common with SG)

7

Installations

1. Installation Requirements

• For easier maintenance, operation, and

improved ventilation, be sure to install the

GP at least 100mm [3.94in.] away from

adjacent structures and other equipment.

• Be sure that the surrounding air

temperature and the ambient humidity

are within their designated ranges.

(Surrounding air temperature: 0 to

50°C, Ambient humidity: 10 to 90%RH,

Wet bulb temperature: 39°C max.)

When installing the GP on the panel of

a cabinet or enclosure, “Surrounding

air temperature” indicates both the

panel face and cabinet or enclosure’s

internal temperature.

• Be sure that heat from surrounding

equipment does not cause the GP to

exceed its standard operating

temperature.

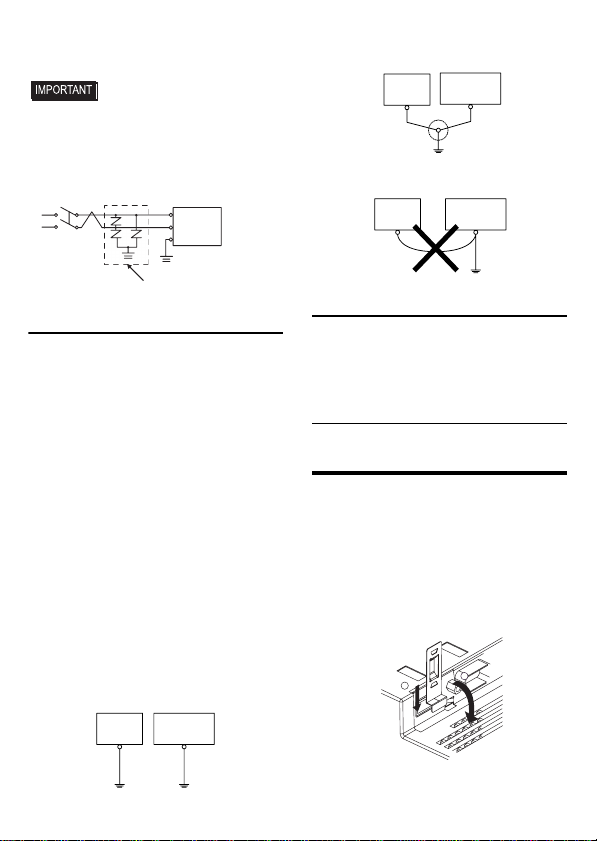

2. GP Installation

(1) Create a Panel Cut and insert the GP

into the panel from the front. Deter-

mine the panel thickness according to

the panel thickness range with due

consideration of panel strength.

(2) Confirm that the installation gasket is

attached to the GP unit and then

place the GP unit into the Panel from

the front.

• It is strongly recommended that you

use the installation gasket, since it

absorbs vibration in addition to

repelling water.

For the procedure for replacing the

installation gasket, refer to “GP3000

Series Hardware Manual”.

100

[3.94]

100

[3.94]

100

[3.94] 100

[3.94]

Unit:mm[in.]

100

[3.94]

100

[3.94]

100

[3.94]

Panel Face Inside Cabinet

GP X Y Panel

thickness

AGP-3300 U

156.0

[6.14 ]

123.5

[4.86 ]

1.6 [0.06]

to

5.0 [0.20]

Unit: mm [in.] Xr ≤ 3 [0.12]

Panel

thickness

GP

Y

+1

-0

+0.04

-0

+1

-0

+0.04

-0

8

(3) The following figures show the four

(4) fastener insertion slot locations.

Insert each fastener’s hook into the

slot and tighten it with a screwdriver.

Insert the installation fasteners

securely into the insertion slot

recess.

• Tightening the screws with too much force

can damage the GP unit’s plastic case.

• The necessary torque is 0.5N•m.

Wiring

• To avoid an electric shock, prior to con-

necting the GP unit’s power cord termi-

nals to the power terminal block,

confirm thatthe GP unit’s power supply

is completely turned OFF, via a

breaker, or similar unit.

• Any other power level can damage

both the GP and the power supply.

• When the FG terminal is connected, be

sure the wire is grounded.

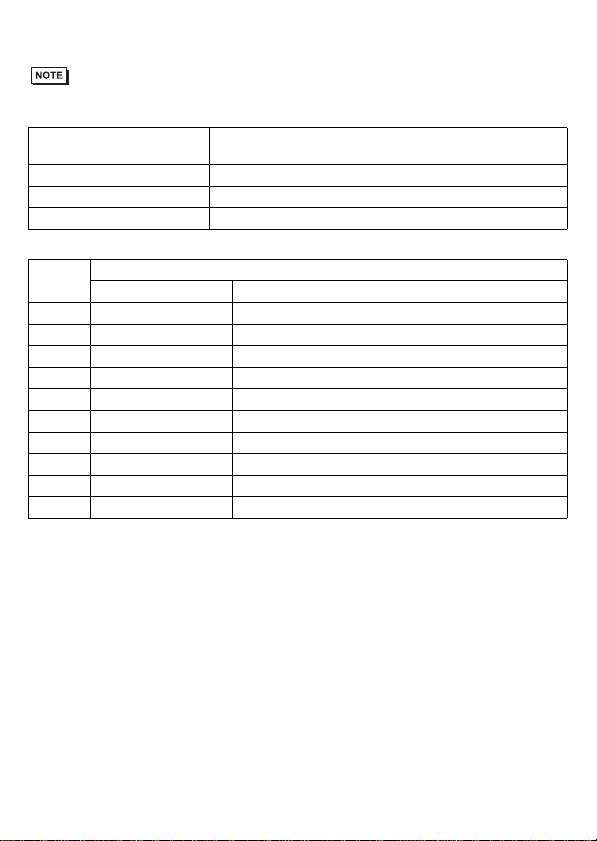

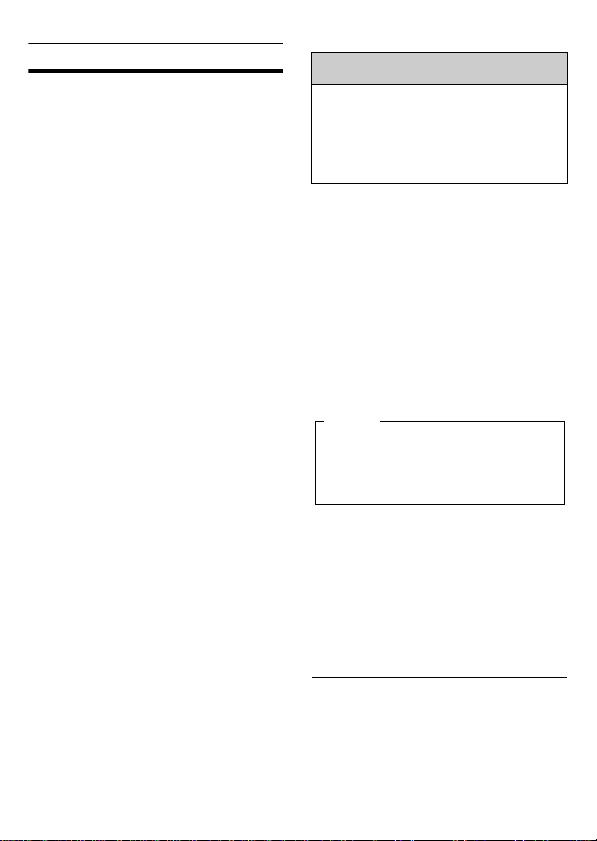

1. Wiring the DC Type Power Cord

Power Cord Specifications

Use copper conductors only.

Power Connector (Plug) Specifications

Top

Insertion Slots

Bottom

Insertion Slot Recess

Hook the fastener on the

Recess,

Panel Installation Fastener

GP Hook

and secure the fastener

on the panel with a

screwdriver.

Power Cord

Diameter 0.75 to 2.5mm2

(18 - 12AWG)

Conductor

Type Simple or Stranded Wire*1

*1 If the Conductor’s end (individual) wires are not

twisted correctly, the end wires may either short

against each other, or against an electrode.

Conductor

Length

+ 24V

-

0V

FG

Grounding

Terminal

connected

to the GP

chassis

7mm

[0.28in]

Insertion

Direction

+

-

FG

9

• The power connector (plug) is CA5-

DCCNM-01 made by Pro-face or

MSTB2,5/3-ST-5,08 made by Phoenix

Contact.

When connecting the Power Cord, use the

following items when performing wiring:

(Items are made by Phoenix Contact.)

Connecting the GP Power Cord

(1) Confirm that the GP unit’s Power

Cord is unplugged from the power

supply.

(2) Remove the power connector (plug)

from the right side of the main unit.

(3) Strip the power cord, twist the

conductor’s wire ends, insert them

into the pin terminal and crimp the

terminal. Attach the terminal to the

power connector.

• Use a flat-blade screwdriver (Size 0.6

X 3.5) to tighten the terminal screws.

The torque required to tighten these

screws is 0.5 to 0.6N•m [5-7Lb•In.].

• Do not solder the cable connection.

Doing so may damage the unit due to

abnormal heat or cause a fire.

(4) Attach the Power connector (Plug) to

the GP.

2. Power Supply Cautions

• Input and Output signal lines must be

separated from the power control

cables for operational circuits.

• To improve noise resistance, be sure to

twist the ends of the power cord wires

before connecting them to the Power

connector (Plug).

• The GP unit’s power supply cord should

not be bundled with or kept close to main

circuit lines (high voltage, high current),

or input/output signal lines.

• To reduce noise, make the power cord

as short as possible.

• If the supplied voltage exceeds the GP

unit’s range, connect a voltage trans-

former.

• Be sure to use a low noise power

supply between the line and the

ground. If there is an excess amount of

noise, connect a noise reducing

transformer.

• The temperature rating of field installed

conductors: 75oC only.

• Use voltage and noise reducing

transformers with capacities exceeding

Power Consumption value.

• Must be used with a Class 2 Power

Supply. (24VDC)

Recomended

Driver SZF 1-0.6x3.5

(1204517)

Recomended

Pin Terminals

AI 0.75-8GY (3200519)

AI 1-8RD (3200030)

AI 1.5-8BK (3200043)

AI 2.5-8BU (3200522)

Recomended

Pin Terminal

Crimp Tool

CRIMPFOX ZA 3

(1201882)

Power Connector (Socket)

Power connector (Plug)

FG

+

-

10

• Connect a surge absorber to handle

power surges.

• Be sure to ground the surge absorber

(E1) separately from the GP unit (E2).

Select a surge absorber that has a

maximum circuit voltage greater then

that of the peak voltage of the power

supply.

3. Grounding Cautions

• Be sure to create an exclusive ground

for the Power Cord’s FG terminal. Use

a grounding resistance of 100Ω, a wire

of 2mm2or thicker, or your country’s

applicable standard.

• The SG (signal ground) and FG (frame

ground) terminals are connected

internally in the GP unit.

When connecting the SG line to

another device, be sure that the design

of the system/connection does not

produce a shorting loop.

• The grounding wire should have a

cross sectional area greater then

2mm2. Create the connection point as

close to the GP unit as possible, and

make the wire as short as possible.

When using a long grounding wire,

replace the thin wire with a thicker

wire, and place it in a duct.

4. Input/Output Signal Line Cautions

• All GP Input and Output signal lines

must be separated from all operating

circuit (power) cables.

• If this is not possible, use a shielded

cable and ground the shield.

Securing the USB cable

connection

When using a USB device, attaching the

USB holder to the USB Interface located

on the side of the GP unit prevents the

USB cable Interface from becoming

disconnected.

Attaching the USB Cable Clamp

(1) Insert the USB holder into the slot in

front of the GP unit’s USB port and

pull it down and forward.

Lightening Surge Absorber

E1 E2

FG GP

GP unit Other

Equipment

Exclusive Grounding

(BEST)

GP unit Other

Equipment

Common Grounding (OK)

GP unit Other

Equipment

Common Grounding

(Not OK)

12

11

(2)

Pass the band of the USB cable clamp

through the bridge of the USB holder.

(3) Insert the USB cable into the port.

Fasten the band around the plug and

secure it with the clamp.

Removing the USB Cable Clamp

(1) Lower the tab and lift the clamp to

release the plug.

UL/c-UL Approval

The AGP3300-U1-D24 unit is a UL/c-UL

listed product.

(UL File No.E220851)

These products conform to the following

standards:

• UL508

Industrial Control Equipment

•

CSA-C22.2 No.142-M1987 (c-UL Approval)

Process Control Equipment

<Cautions>

Be aware of the following items when

building the GP into an end-use product:

•

The GP unit’s rear face is not approved as

an enclosure. When building the GP unit

into an end-use product, be sure to use an

enclosure that satisfies standards as the

end-use product’s overall enclosure.

• The GP unit must be used indoors only.

• Install and operate the GP with its front

panel facing outwards.

• If the GP is mounted so as to cool itself

naturally, be sure to install it in a

vertical panel. Also, it’s recommended

that the GP should be mounted at least

100mm away from any other adjacent

structures or machine parts. The

temperature must be checked on the

final product in which the GP is

installed.

• For use on a flat surface of a Type 1

Enclosure.

USB Holder

Bridge

USB Holder

Clamp

USB Cable

Tab

Clamp

Product Model No.

UL/c-UL Registration

Model No.

AGP3300-U1-D24 3710015-01

12

CE Marking

• The AGP3300-U1-D24 unit is a CE

marked, EMC compliant product.

This unit also conforms to EN55011

Class A, EN61000-6-2 directives.

Digital Electronics Corporation

8-2-52 Nanko-higashi

Suminoe-ku, Osaka 559-0031

JAPAN

TEL: +81-(0)6-6613-3116

FAX: +81-(0)6-6613-5888

http://www.pro-face.com

The information in this document is

subject to change without notice.

© Copyright 2009 Digital Electronics

Corporation. All rights reserved.

PFX119872F

.AGP3300-U1-MT02E-BTH

2010.6 SS/B

Inquiry

Do you have any questions about

difficulties with your GP?

Please access our site anytime that

you need help with a solution.

http://www.pro-face.com/otasuke/

Please be aware that Digital Electronics

Corporation shall not be held liable by the

user for any damages, losses, or third

party claims arising from the uses of this

product.

Note

Table of contents

Other Pro-face Control Panel manuals

Pro-face

Pro-face Pro-face ST Series User manual

Pro-face

Pro-face GLC2500-TC41-200V User manual

Pro-face

Pro-face GP-3500 Series User manual

Pro-face

Pro-face GP3000U Series User manual

Pro-face

Pro-face GLC2500-TC41-24V User manual

Pro-face

Pro-face GC4000 Series User manual

Pro-face

Pro-face GP-4100 series User manual

Pro-face

Pro-face GP-2300 Series User manual

Popular Control Panel manuals by other brands

Airmax

Airmax 651730 installation instructions

mr. steam

mr. steam iSteam Controls Installation, operation & maintenance manual

Securakey

Securakey SK-ACP Connecting guide

SIGMA TEK

SIGMA TEK ETV 0853-3 manual

DM TECH

DM TECH FP9000E Installation and operation manual

BENSON HEATING

BENSON HEATING CP2 User handbook