Advanced Ex-3001 User manual

Table of contents

Other Advanced Control Panel manuals

Advanced

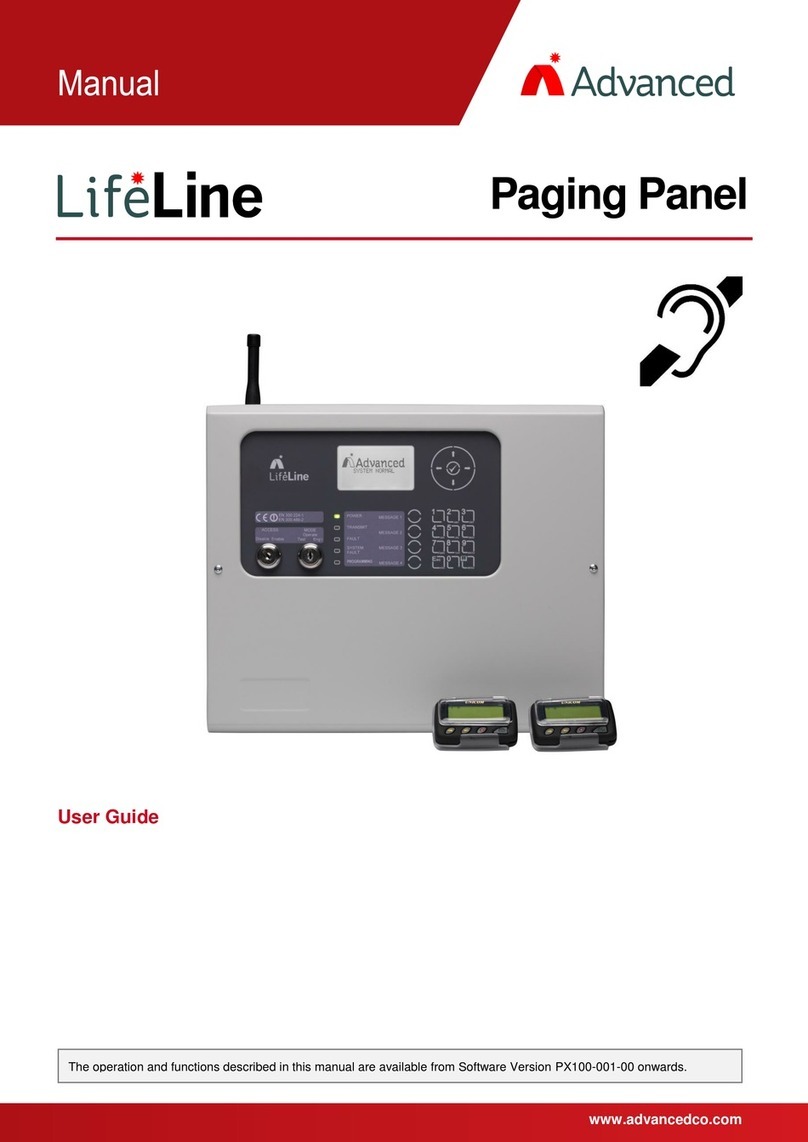

Advanced LIFELINE Px-100 User manual

Advanced

Advanced MxPro4 Series User manual

Advanced

Advanced Mx Pro 4 User manual

Advanced

Advanced MxPro 4 4100S User manual

Advanced

Advanced LIFELINE Px-100 User manual

Advanced

Advanced Lux Intelligent LX-9400 User manual

Advanced

Advanced ExGo Series User manual

Advanced

Advanced MxPro 5 Installation and operating instructions

Advanced

Advanced MxPro4 Series User manual

Advanced

Advanced MxPro4 Mx-4200 User manual

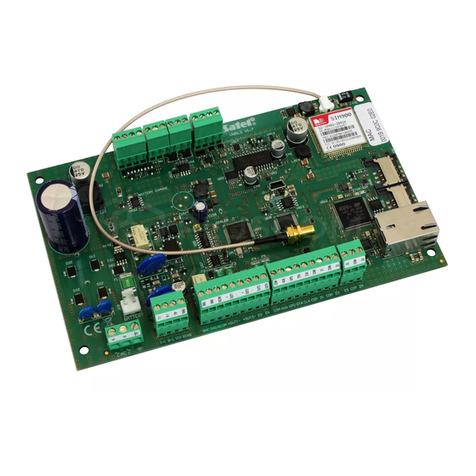

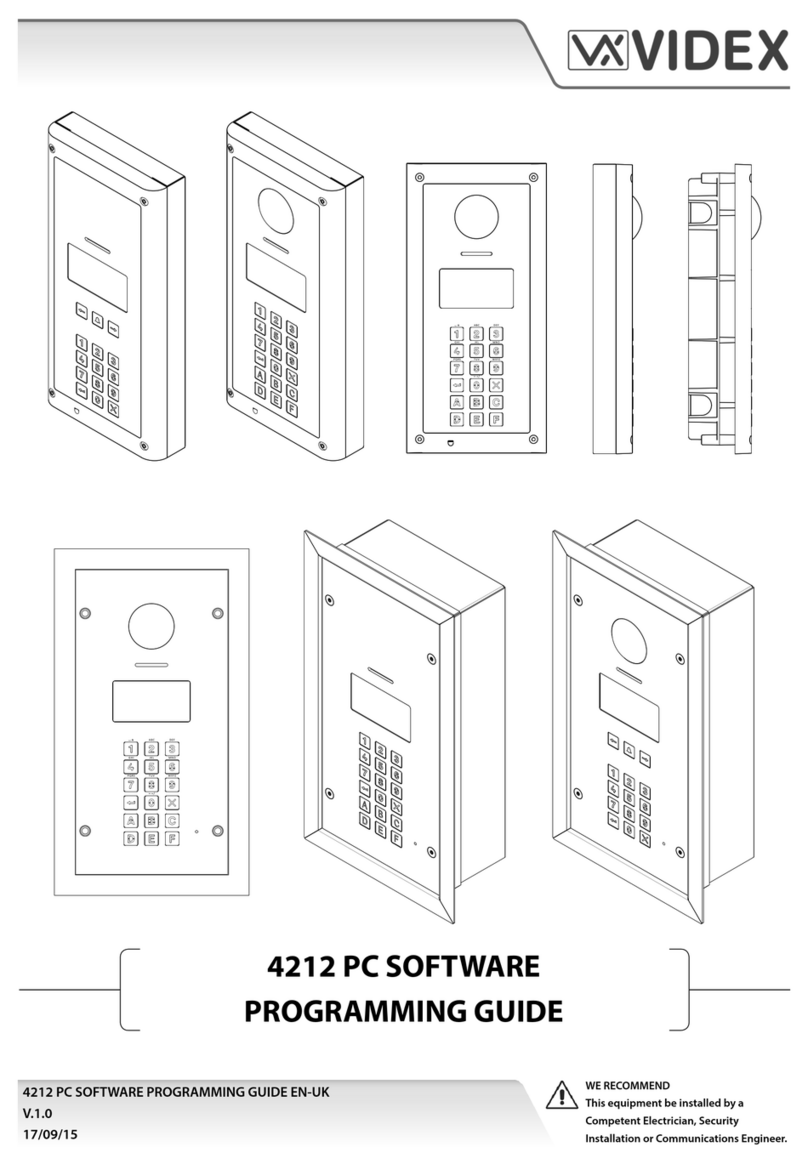

Popular Control Panel manuals by other brands

CAME

CAME ZL22N installation manual

Philips

Philips Pronto TSU9600/79 Specifications

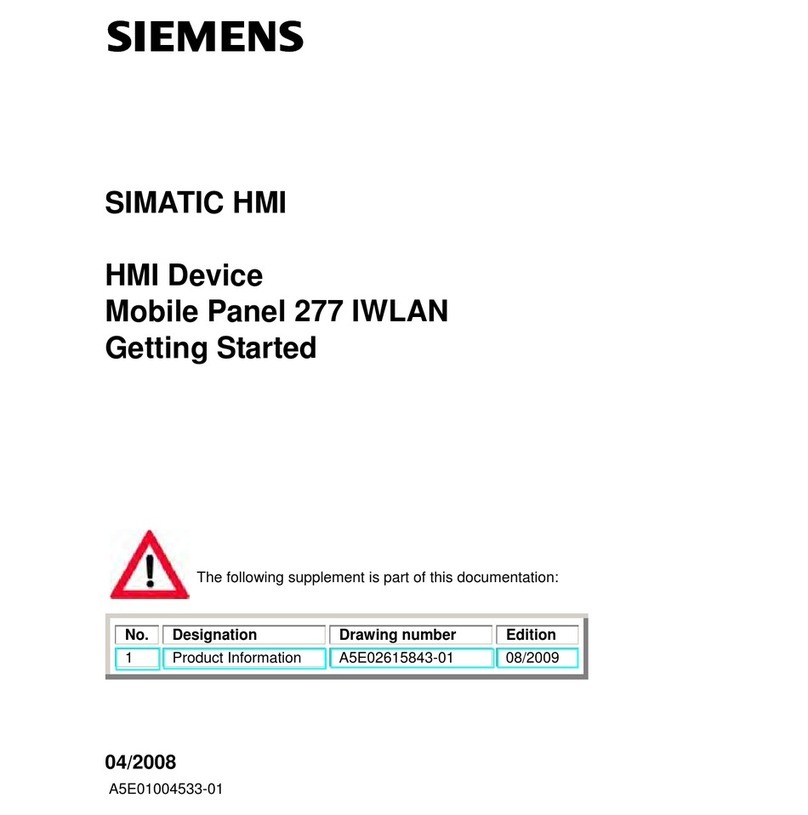

Siemens

Siemens SIMATIC 277 IWLAN Getting started

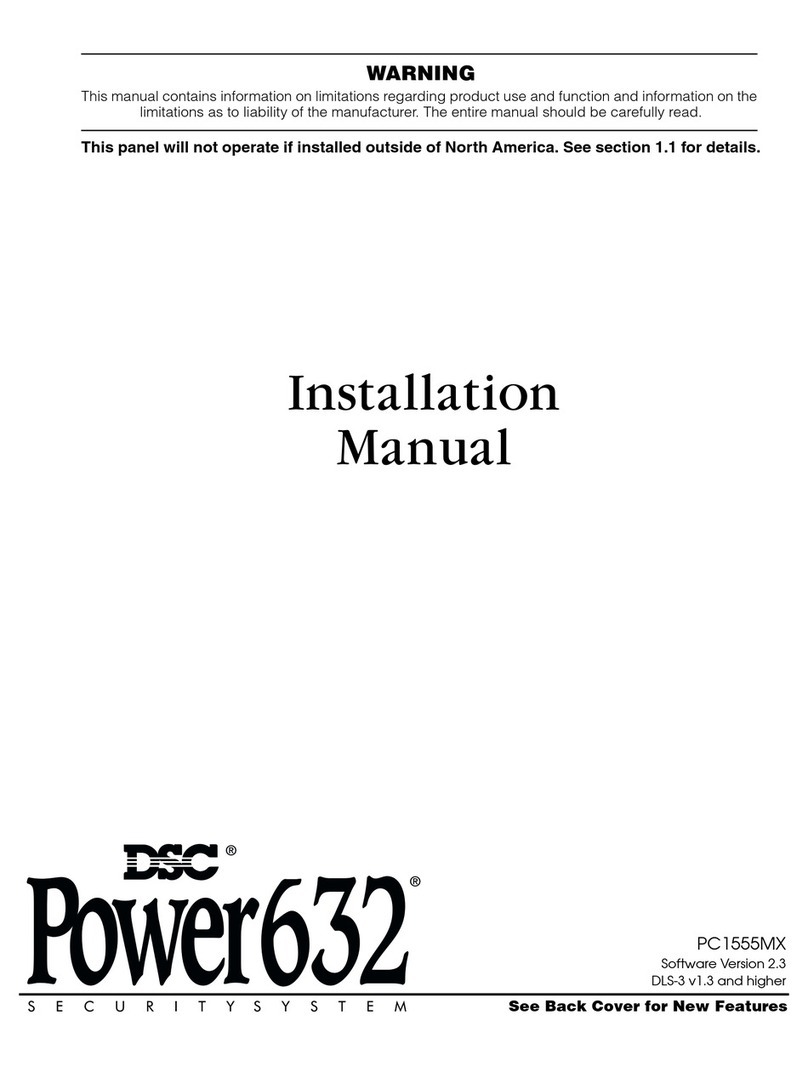

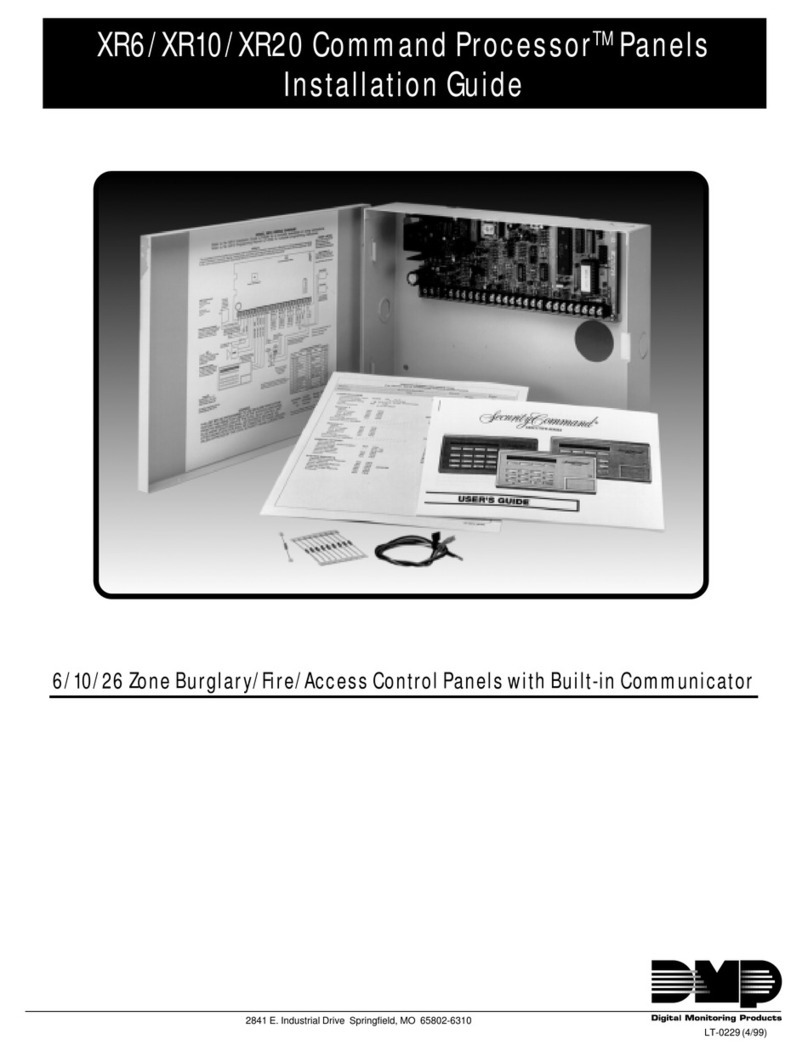

DMP Electronics

DMP Electronics SecurityCommand XR6 installation guide

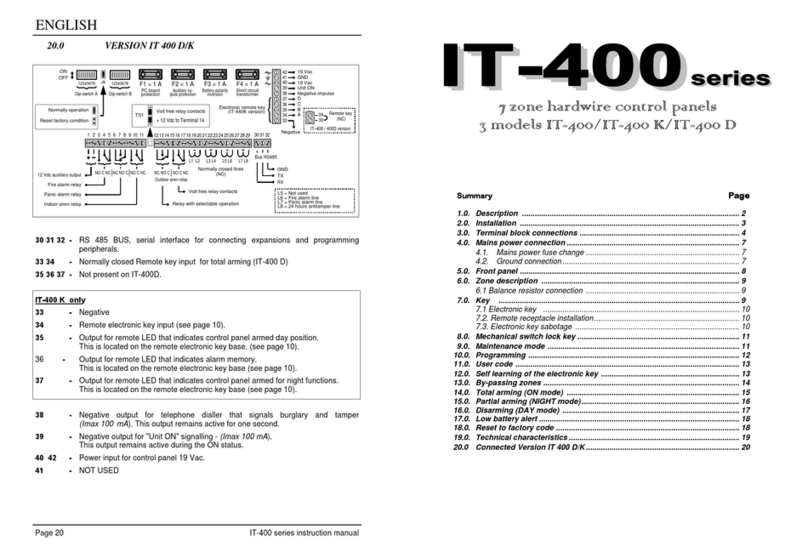

TRE i SYSTEMS

TRE i SYSTEMS IT-400 manual

HUBBELL LIGHTING

HUBBELL LIGHTING CX16 Quick Start, Installation & Programming Guide