Pro-Line System CS300FU User manual

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

~

·".

Contents

Key

to

symbols

General

safety

instructions

Overview

of

products

Frequency

Converter

lnitial

Operation

Programming

with

the

LCD

monitor

Navigator

(LCD

monitor

only)

Overview

of

functions

Error

messages

and

rectification

Technical

data

EU

Declaration

of

Conformity

Appendix

Danger

of

personal

injury!

The

safety

instructions

must

be

observed!

Warning!

Danger

to

property!

The

safety

instructions

must

be

observed!

Information

Special

information

OR

Reference

to

other

sources

of

information

2

2

2

3

5

8

13

14

16

24

26

26

27

Guarantee

The

function

and

safety

of

the

equipment

is

only

guaranteed

if

the

warning

and

safety

instructions

included

in

these

opera-

ting

instructions

are

adhered

to.

The

produ

cer

is

not

liable

for

any

personal

injury

or

damage

to

property

that

occurs

as

a

result

of

the

warning

and

safety

instructions

being

disregarded

.

Using

the

equipment

for

its

intended

purpose

The

es

300

FU

controls

are

designed

only

for

controlling

gates

and

doors

with

digital

end

position

systems

and

integrated

frequency

converters.

It

is

only

permitted

to

operate

the

equipment

in

dry

rooms

.

Target

group

Only

qualified

and

trained

electricians

may

connect,

program

me

and

service

the

controls.

Qualified

and

trained

electricians

meet

the

following

requirements

:

-

knowledge

of

the

general

and

specific

safety

and

accident

prevention

regulations,

-

knowledge

of

the

relevant

electrical

regulations,

-

trained

in

the

use

and

care

of

appropriate

safety

equipment,

-

capable

of

recognising

the

dangers

associated

with

electricity.

lnstructions

for

installation

and

connection

-The

controls

must

be

disconnected

from

the

electricity

supply

before

carrying

out

electrical

works.

After

the

disconnection

there

will

be

a

residual

voltage

.

Therefore

a

safety

period

of

180

seconds

must

be

adhered

to.

During

the

works

the

electricity

supply

must

rema

in

disconnected.

-

Local

protective

regulations

must

be

complied

with.

-

Mains

cables

and

control

cables

must

be

laid

separately

.

Regulations

and

bases

for

testing

For

connecting,

programming

and

servicing,

the

following

regulations

must

be

observed

(the

list

is

not

exhaustive).

eonstruction

product

standards

-

EN

13241-1

(Products

without

fire

resistance

or

smoke

control

characteristics)

-

EN

12445

(Safety

in

use

of

power

operated

doors-

Test

methods)

-

EN

12453

(Safety

in

use

of

power

operated

doors

-

Requirements)

-

EN

12978

(Safety

devices

for

power

operated

doors

and

gates

-

Requirements

and

test

methods)

Electromagnetic

compatibility

-

EN

55014-1

(Radio

disturbance,

household

appliances)

-

EN

61000-3-2

(Disturbances

in

supply

systems-

harmonic

currents)

-EN

61000-3-3

(Disturbances

in

supply

systems-

voltage

fluctuations)

-

EN

61

000-6-2

(Eiectromagnetic

compatibility

(EMe)

-

Part

6-2:

Gen

eric

standards-

lmmunity

for

industrial

environments)

-

EN

61000-6-3

(Eiectromagnetic

compatibility

(EMe)-

Part

6-3:

Generic

standards-

Emission

standard

for

residential,

commercial

and

light-industrial

environments)

Machinery

guidelines

-

EN

60204-1

(Safety

of

machinery,

electrical

equipment

of

machines,

part

1:

general

requirements)

-

EN

12100-1

(Safety

of

machinery

.

Basic

concepts,

general

principles

for

design.

Basic

terminology,

methodology)

Low

voltage

-

EN

60335-1

(Household

and

similar

electrical

appliances

-

Safety)

-

EN

60335-2-103

(Particular

requirements

for

drives

for

gates,

doors

and

windows)

Professional

association

(D)

-

BGR

232

(Directive

for

Power-driven

Windows,

Doors

and

Gates)

';·

~

".'

4.1

Various

options

eS300

FU

controls

can

be

supplied

with

the

option

of

a

frequency

converter

module

integrated

in

the

control

housing

(model

es

300

FU-E)

or

a

frequency

converter

integrated

in

the

door

or

gate

operator

(model

es

300

FU-l).

The

following

package

options

are

available

for

both

versions

of

the

es

300

FU

control:

-es

300

FU

control

with

LeD

monitor

-

es

300

FU

control

with

LCD

monitor

in

housing

-es

300

FU

controls

without

LCD

monitor

(monitor

is

required

for

adjusting

the

settings)

All

the

above

options

can

be

fitted

with

a

plug-in

weekly

timer

and

a

plug-in

radio

receiver.

The

following

options

are

available

for

the

housing.

-

housing

with

es

3-button

input

switch

-

housing

with

OPEN-STOP-eLOSE

-button

input

unit

-

housing

with

key

switch

ON/OFF

-

housing

with

ma

in

switch

-

housing

with

emergency

off

switch

The

operating

instructions

describe

the

connection

possibili-

ties

and

programming

procedures

for

the

different

models:

-

es

300

FU-E

control

with

attached

LCD

display

board

-

es

300

FU-l

control

with

attached

LeD

display

board

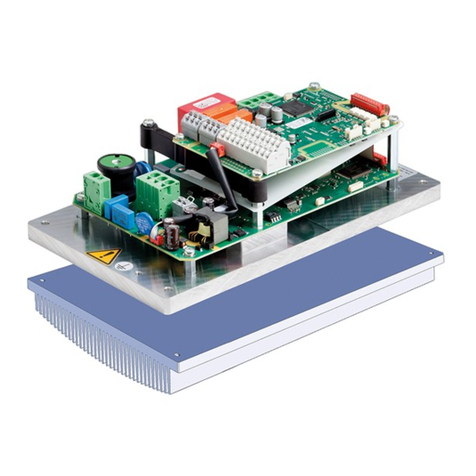

4.3

CS

300

FU

0,75

basic

board

(with

attached

LCD

display

monitor)

Key:

X1:

mains

connection

(mains)

terminal

block

1

power

supply

frequency

converter

(FC)

X2

:

terminal

block

for

FC

data

cable

=

X3:

terminal

block

command

devices

X4

:

terminal

block

Xll

1

r··········

·

········~·

·

r~

IXlo®

~

:

@j

t..

.

-----

-

-----------

- ~

f

·rn

~12

g

1 o

X6[j]

'rn

X7 g

1 g

safety

elements

X5:

terminal

block

relay

X6:

sockets

for

interna!

ON-OFF

switch

X7

:

sockets

for

interna!

3-button

input

unit

X8:

socket

for

monitor

(under

monitor)

X9:

sockets

for

radio

receiver

X10:

sockets

for

weekly

timer

D

X11:

sockets

for

digital

limit

switch

Xl

CJ

ID I

CJ

CJ

I

CJ

I

CJ

CJ

i

c::::J

I

CJ

CJICJ

I

CJ

1

~1~

1

~

1

~

:

~

1

~

1

~

1

~

1

~

~1~

1

~1

1 1

11 11 11

o

=:

I

::J

I

:J

iz

1

~

1

~

~

~

1

~

1

=:

I

::J

1

:3

1z

system

with

safety

circuit

(STOP

CIRCUIT)

X12:

socket

for

external

radio

receiver

X13:

terminal

block

for

es

three-

button

input

unit

H4:

status

display

for

safety

edge

protection

(SEP)-

illuminated

when

SEP

is

working

H5

:

status

display

frequency

converter

(FC)

-

lights

up

when

the

FC

is

ready

H6

:

Safety

circu

it

status

message

-

lights

up

when

the

safety

circuit

is

closed

·, .

General

The

frequency

control

system

allows

the

door

speed

to

be

adjusted

separately

for

the

OPEN

and

CLOSE

directions.

The

acceleration

and

retardation

times

(SPEED

UP

1

SLOW

DOWN)

ensure

a

gentle

start

and

stop

at

the

end

positions.

The

frequency

of

the

converter

determines

the

operator

speed

.

Adjustable

Values

The

following

values

can

be

adjusted

in

the

input

menu.

SPEED

UP

Acceleration

time

from

minimum

speed

to

maximum

speed.

SLOW

DOWN

Retardation

time

from

maximum

speed

to

minimum

speed.

MIN

SPEED

OPEN

Minimum

speed

of

the

drive

for

the

OPEN

run

(creep

speed).

MAX

SPEED

OPEN

Maximum

speed

of

the

drive

for

the

OPEN

run.

MIN

SPEED

CLOSE

Minimum

speed

of

the

drive

for

the

CLOSE

run

(creep

speed).

MAX

SPEED

CLOSE

Maximum

speed

of

the

drive

for

the

CLOSE

run

.

BRAKE

POINT

OPEN

The

bra

ke

point

for

the

OPEN

run

lies

before

the

OPEN

limit

switch

value

.

When

the

OPEN

brake

point

is

passed,

the

retardation

time

SLOW

DOWN

is

triggered.

BRAKE

POINT

CLOSE

The

bra

ke

point

for

the

CLOSE

run

lies

before

the

CLOSE

limit

switch

value

.

When

the

CLOSE

brake

point

is

passed,

the

retardation

time

SLOW

DOWN

is

triggered.

U

START

The

start-up

voltage

increases

the

performance

of

the

door

operators

at

low

rotational

speeds.

lf

the

start-up

voltage

is

set

too

high

or

too

low,

the

door

or

gate

may

not

run

properly.

The

start-up

voltage

can

be

set

between

OV

and

42V.

lf

the

start-up

voltage

is

too

high,

this

will

result

in

an

over-

current

fault

(FU2).

The

start-up

voltage

must

be

reduced

in

this

case.

lf

the

start-up

voltage

is

too

low,

then

the

motor

will

not

have

sufficient

power

to

move

the

door.

The

start-up

voltage

must

be

increased

in

this

case.

Due

to

the

variety

of

different

types

of

doors

and

gates,

the

correct

start-up

voltage

setting

must

be

obtained

through

practical

trials.

BRAKE

RETARDATION

ln

the

case

of

drives

with

a

bra

ke

and

low

self-locking

(high

speed

door

drives},

the

brake

release

must

be

retarded

when

the

door

or

gate

starts

moving

to

prevent

the

door

from

dropping

.

This

parameter

can

be

ignored

in

the

case

of

weight

counter-

balanced

doors

and

gates.

RATED

FREQUENCY

The

frequency

rating

parameter

must

be

set

to

the

rated

frequency

of

the

motor.

There

are

three

modes

available

.

Opening

Run

of

the

Door/Gate

Hz

E

2 1 1

6

181

4

1 3 5 7 9

Fl

n

A

MIN

SPEED

OPEN

B

MAX

SPEED

OPEN

C

SPEED

UP

D

E

1.

2.

3.

4.

5.

6.

7.

8.

9.

SLOW

DOWN

OPEN

brake

point

The

door/gate

moves

in

the

OPEN

direction.

nie

frequency

converter

accelerates

over

an

accelera-

tion

period

SPEED

UP

(C)

to

reach

its

maximum

speed

MA

X

SPEED

OPEN

(B).

The

door/gate

reaches

its

maximum

speed

MAX

SPEED

OPEN

(B).

The

door/gate

travels

at

the

maximum

speed

MAX

SPEED

OPEN

(B)

.

The

OPEN

brake

point

(E)

is

triggered

and

activates

the

soft

run

in

the

OPEN

direction

.

The

frequency

converter

reduces

the

speed

over

the

retardation

period

SLOW

DOWN

(D)

to

reach

the

minimum

speed

MIN

SPEED

OPEN

(A).

The

door

/

gate

reaches

its

minimum

speed

MIN

SPEED

OPEN

(A).

The

door/gate

travels

at

the

minimum

speed

MIN

SPEED

OPEN

(A).

The

door/gate

stops

at

the

upper

end

position.

Closing

run

of

the

door/gate

Hz

J

1 1

2 4 6

181

1 3 5 7 9

n 1=1

F

MIN

SPEED

CLOSE

G

MAX

SPEED

CLOSE

H

SPEED

UP

1.

2.

3.

4.

5.

6.

7.

8.

9.

SLOW

DOWN

CLOSE

brake

point

The

door/gate

starts

to

move

in

the

CLOSE

direction.

The

frequency

converter

accelerates

over

an

accelera-

tion

period

SPEED

UP

(C)

to

reach

its

maximum

speed

MAX

SPEED

OPEN

(B).

The

door/gate

reaches

its

maximum

speed

MAX

SPEED

CLOSE

(B).

The

door/gate

travels

at

the

maximum

speed

MAX

SPEED

CLOSE

(B).

The

CLOSE

brake

point

(E)

is

triggered

and

activates

the

soft

run

in

the

CLOSE

direction.

The

frequency

converter

reduces

the

speed

over

the

retardation

period

SLOW

DOWN

(D)

to

reach

the

minimum

speed

MIN

SPEED

CLOSE

(A)

.

The

door/gate

reaches

its

minimum

speed

MIN

SPEED

CLOSE

(A).

The

door/gate

travels

at

the

minimum

speed

MIN

SPEED

CLOSE

(A).

The

door/gate

stops

at

the

lower

end

position.

Effective

OPEN

DOOR

acceleration

time

-

Example

showing

change

of

frequency

setting

Hz

t =

seconds

Information:

The

time

values

set

for

SPEED

UP

1

SLOW

DOWN

a/ways

re/ate

to

the

maximum

values

of

O

Hz

to

1

OO

Hz.

The

drive

a/ways

starts

with

MIN

SPEED

OPEN.

The

values

set:

A

MIN

SPEED

OPEN

30Hz

B1

MAX

SPEED

OPEN

50

Hz

B2

MAX

SPEED

OPEN

90Hz

c

SPEED

UP

1

second

01

Effective

acceleration

time

1

02

Effective

acceleration

time

2

lf

the

time

for

SPE

ED

UP

(C)

is

set

to

1

second,

the

effective

acceleration

time

(01)

from

30Hz

to

50

Hz

is

0.2

seconds.

lf

the

setting

for

MAX

SPE

ED

OPEN

is

increased

to

90

Hz

(82),

the

resulting

effective

acceleration

time

(02)

is

0.6

seconds.

Effective

OPEN

DOOR

acceleration

time

-

Example

showing

change

of

time

setting

Hz

Cl

C2

100

90

80

70

60

50 /

40 /

/

30

20

10

o

t =

seconds

Information:

The

values

set

for

SPEED

UP

1

SLOW

DOWN

always

re/ate

to

the

maximum

values

ofO

Hz

to

100Hz.

The

drive

a!ways

starts

with

MIN

SPEED

OPEN.

The

values

set:

A

MIN

SPE

ED

OPEN

30

Hz

B

MAX

SPEED

OPEN

50

Hz

C1

SPEED

UP

1

second

C2

SPEED

UP

2

seconds

01

Effective

acceleration

time

1

02

Effective

acceleration

time

2

lf

the

time

for

SPE

ED

UP

(C)

is

set

to

1

second,

the

effective

acceleration

time

(C

1)

from

30

Hz

to

50

Hz

is

0.2

second

s.

lf

the

SPE

ED

UP

time

is

increased

to

2

seconds

(C2),

the

resulting

effective

acceleration

time

(02)

is

0.4

seconds.

6.1

General

Warning!

To

guarantee

that

the

equipment

functions

properly,

the

following

points

must

be

ensured:

-

The

gate

or

door

is

installed

and

operational.

-

The

com

mand

and

safety

devices

are

installed

and

ready

for

operation.

-

The

control

housing

with

the

CS

300

FU

control

is

installed.

Information:

For

the

installation

of

the

gate!door,

the

MFZ

drive

motor

and

the

command

and

safety

devices,

the

re

leva

nt

manufacturer's

instructions

are

to

be

adhered

to.

6.2

Connection

of

Drive

-

Controls

Model

CS300

FU-l,

frequency

converter

module

integrated

in

drive

A

B

c

D

E

F

G

A

AVE

plug

B

AVE

plug

terminal

C

Motor

output

FU

(U2,

V2,

W2),

Temperature

sensor,

optional

D

Plug

connection

for

data

cable

FU

E

LED

operation

FU

F

Connection

of

brake

resistance

(R-,

R+)

G

Power

supply

FU,

230V

(U

1,

N,

PE)

Connection

to

CS

300

FU

Controls:

o

Connect

power

supply

FU

(G)

at

terminal

Xl.

o

Connect

AVE

plug

(A)

at

terminal

X11.

O

Connect

data

cable

FU

(D)

at

terminal

X2.

Model

CS300

FU-E,

external

frequency

converter

module,

0.75

KW

G

F

E

Oo

1

~

l i

~i

l

~

~ ~

c

Motor

output

FU

(U2,

V2,

W2),

Temperature

sensor,

optional

D

Plug

connection

for

data

cable

FU

E

LED

operation

FU

F

Connection

of

bra

ke

resistance

(R-,

R+)

G

Power

supply

FU,

230V

(U

1,

N,

PE)

Model

CS300

FU-E,

external

frequency

converter

module,

1.5

KW

13

KW

Oo

-

1

li

il

--

-

~

~

~

-

c

Motor

output

FU

(U2,

V2,

W2),

Temperature

sensor,

optional

D

Plug

connection

for

data

cable

FU

E

LED

operation

FU

F

Connection

of

bra

ke

resistance

(R-,

R+)

G

Power

supply

FU,

400V

AC

6.3

Mains

connection

Danger!

To

guarantee

that

the

controls

function

pro-

perly,

the

following

points

must

be

ensured

:

-

The

mains

voltage

must

correspond

to

the

vo/tage

stated

on

the

type

plate

.

-

For

a

permanent

connection,

an

all-pole

main

switch

must

be

used.

-

The

drive

cover

must

be

closed.

Warning!

Before

switching

on

the

controls

for

the

first

time,

a

check

must

be

carried

out

after

com-

p/eting

the

wiring

to

ensure

that

all

the

motor

connections

at

the

motor

and

at

the

controls

are

securely

fixed.

All

control

voltage

inputs

are

galvanically

isolated

from

the

supply

For

all

components

to

be

connected

to

the

controls,

at

/east

one

additional

isolation

with

a

rated

voltage

of>

230

V

is

recommended

.

Detailed

circuit

diagram

for

mains

connection

(230

V

AC

1-phase

10.75

KW)

,1'

,IJ

Tl

Jf

2 4 6

lZJ:3

=1=1= = =

==

=1= = = =

1~

1

~

1

~

~ ~

~~~

~

~

~

~ ~ ~

1

.-i

INIM w w1w~

~

.-iN

M

_J _J _J

z

0....

o....

o...

0....

_J_J

_J

z

Detailed

circuit

diagram

for

mains

connection

(400

V

AC

3-phase

/1.5

KW

or

3

KW)

J,

,IJ

Tl

,r

2 4 6

lZJ:3

=1= = =1=1= =1

===

1=1=

1~

~

~

~

~

~

~

~

1

~

1

~1~

1

~

1

~1

1 1 1 1

.-i

NM

w

1

ww

l

~

l

.-i

i

N

I

M

I

_J

-l

-lZO....

0....0....

O...

-l-l

-l

Z

Key:

X1:

terminal

block

for

mains

connection

Connection:

O

Connect

the

control

to

the

mains.

o

Short

before

the

corresponding

screw

terminals,

groups

of

cables

should

be

make

safe

by

means

of

stra

ps

.

Information:

Technical

data

see

page

26

.

6.4

Allocation

of

connections

for

command

and

safety

devices

Com

mand

and

safety

devices

can

be

connected

to

termina

Is

X3,

X4

and

X5.

Terminal

block

X3

Terminal

block

X4

-

CLOSE

switch

-

impulse

switch

1

-OPEN

switch

-

STOP

switch,

Wicket

door

switch,

draw-in

protection

-

Emergency

off,

slack

rope

switch

(for

optoelectronic

safety

edge

protection)

1

sequence

control

2

button

or

selector

switch

3

effective

in

dawn

direction

-

PART-

OPEN

2

-

safety

edge

protection

OPTO

-

photoelectric

drive-through

barrier

3

-

24

V

DC

1

250

mN

4

for

external

switching

devices

(connection

to

terminals

1

and

2)

wt:

white

gr:

green

br:

brown

Terminal

block

X4

(for

8.2

kOhm

safety

edge

protection)

-

PART

-

OPEN

2

-

safety

edge

protection

-

photoelectric

drive-through

barrier

3

-

24

V

DC

1

250

mN

Terminal

block

X4

(for

pneumatic

safety

edge

protection

-

pressure

sensor

test:

- A

8.2

kO

hm

resistor

must

be

connected

in

series

-

The

input

parameter

SEP

TEST

must

be

switched

on)

-

PART-

OPEN

2

-

safety

edge

protection

-

photoelectric

drive-through

barrier

3

-

24

V

DC/

250

mN

Terminal

block

X4

(for

three-wire

photoelectric

barrier)

9

8

7

6

5

4

3 -

Three-wire

photoelectric

barrier

2

1

Terminal

block

X5

(potential

free

switch

contact)

6.5

Connection

examples

for

command

and

safety

devices

(terminal

block

X3)

OPEN

1

STOP

1

CLOSE

buttons

(6-lead

solution)

-

CLOSE

button

-

OPEN

button

-

STOP

button

OPEN

1

STOP

1

CLOSE

buttons

(4-lead

solution)

-

CLOSE

button

-

OPEN

button

-

STOP

button

Key

switch

OPEN

1

CLOSE

lmpulse

button

(sequence

control)

Connection:

-

CLOSE

-OPEN

-

impulse

button

D

Connect

the

com

mand

and

safety

devices

to

the

control.

'~)

7.1

Overview

of

the

LCD

monitor

H

A

-++---t+AUTOMATIC

8

RESTING

Key:

A:

B:

C:

D:

E:

F:

G:

H:

C D

mode

of

operation

1

diagnostic

info

parameter

1

diagnostic

info

(+)button

(-)button

(P)

button

value

1

status

value

1

status

jumper

E

0 -H---++ G

++-++

F

7.2

LCD

monitor,

mod

es

of

operation

The

control

has

four

modes

of

operation

with

the

LCD

monitor:

1.

AUTO

MATIC

2.

ADJUSTMENT

3.1NPUT

4.

DIAGNOSIS

When

the

jumper

H

is

pul

led,

the

+

button,

the

-

button

and

the

P

button

have

no

function.

The

display

stili

functions.

Operating

mode

1:

AUTO

MATIC

ln

the

AUTO

MATIC

operating

mode

the

door

system

is

operated.

Display:

-

displays

the

function

being

carried

out

-

displays

any

error

messages

lf

the

.,self

locking"

parameter

is

set

to

MOD2

or

MOD3

in

the

input

menu,

the

display

changes

from

AUTOMATIC

to

MANUAL

OPERATION.

Operating

mode

2:

ADJUSTMENT

ln

the

ADJUSTMENT

mode,

the

OPEN/CLOSED

end

position

settings

are

adjusted

.

Warning!

ln

the

ADJUSTMENT

mode

of

operation,

the

drive

does

not

switch

off

when

the

end

position

is

reached.

The

drive

moves

at

maximum

speed.

The

door

can

be

damaged

if

driven

beyond

the

end

position.

Fine

adjustments

can

be

made

in

the

INPUT

operating

mode

.

Display:

-

displays

the

end

position

value

Operating

mode

3:

INPUT

ln

the

INPUT

operating

mode,

the

values

of

various

parame-

ters

can

be

altered.

Display:

-

displays

the

selected

parameter

-

displays

the

program

med

value

/status

Operating

mode

4:

DIAGNOSIS

ln

the

DIAGNOSIS

operating

mode,

door-specific

checks

can

be

queried.

Display

-

displays

the

check

-

displays

the

checking

status

·.

----

!Ol

AUTOMATIC

~

RESTING

~

• ®

>1

Sec.

ADJUSTMENT

RESTING

• ® > 1

Sec.

1

~·1

'"'"'

J

0

->

Position

DOOR

OPEN

0

·>

Position

DOOR

CLOSED

0

and

Q > 2

Sec.~

ADJUSTMENT

MANUAL

UP

ADJUSTMENT

MANUAL DOWN

INPUT

GERMAN

INPUT

RUNNING TIME

INPUT

TIME OPEN

INPUT

FOREWARNING

INPUT TURN-

TURNAROUND TIME

INPUT

M1-3

RESTING

INPUT

QUICK

CLOSE

INPUT

RELAY

1

INPUT

RELAY

2

INPUT

RELAY

3

INPUT

RELAY

4

INPUT

SEP

TEST

INPUT

DELAY

OPEN

INPUT

FINE

OPEN

INPUT

FINE

CLOSE

INPUT

BES

OPEN

INPUT

BES

CLOSE

INPUT

ROTAT

ING

FIELD

INPUT

REVERSE

OFF

INPUT

A

UTO

LEVEL

Save

door position:

® Hold Ppressed and

0 > 1

Sec.

Save

door position:

® Hold Ppressed and

0

>1

Sec.

Scroll up through menu:

0 > 2

Sec.

60

Scroll dawn through menu:

O > 2

Sec.

o Select value:

o ®

>1

Sec.

Incr

ease

value:

0,3

0

Decrease value:

Mod1 o

OFF

Save

va

lue:

®

:

Mod6

Return to

INPUT

:

:

Mod7

0 and O > 1

Sec.

: Mod1

Mod14

:

OFF

:

OFF

4050

3950

4000

:

4000

:

RE

50

:

OFF

INPUT

SELF

LOCK

MOD1

INPUT

Sl:J/WI

MOD5

®>1

Sec.

INPUT

P/E

BARRIER

OPEN

MOD2

INPUT

P/E

BARRIER

CLOSED

:

MOD1

INPUT

SEP

LEADING

MOD1

INPUT

MAX

OPEN

SPE

ED

: 50

INPUT

MIN

OPEN

SPEED

: 20

INPUT

MAX

CLOSE

SPE

ED

50

INPUT

MIN

CLOSE

SPEED

: 20

INPUT

SPEED

UP

1.0

INPUT

SLOW

DOWN

: 150

INPUT

BRAKE

P

OPEN

250

INPUT

BRAKE

P

CLOSE

: 250

INPUT

F

START

:

3Hz

INPUT

U

START

: 20V

INPUT

BRAKE

RETARDATION

50

INPUT

RATED

FREQUENCY

MOD1

INPUT

P/E

BARRIER

300

[f!]

Scroll

up

through

menu:

DIAGNOSIS

@>2Sec.

Scroll

dawn through

menu:

OIAGNOSIS

: R2.0

O>

2

Sec.

011

00703

Return

to

AUTO

MATIC

DRAW-IN P

OPEN

ON

operating

mode:

DRAW-IN

P

CLOSE

:

ON

®

OPEN

BUTTON

OFF

PART

OPEN

OFF

CLOSE

BUTTON

OFF

Only

query

is

possible

SEP

:

ON

IM

PULS

OFF

TIMER

OFF

P/E

BARRIER

ON

STOP

CIRCUIT

ON

CYCLE

: 4

AVE

2599

9.1

Automatic operating

mode

Display

AUTO

MATIC

OPENING

AUTO

MATIC

CLOSING

AUTO

MATIC

RESTING

AUTO

MATIC

RESTING

AUTO

MATIC

RESTING

AUTO

MATIC

RESTING

AUTO

MAT

IC

RESTING

AUTO

MATIC

RESTING

o

o

u

Information:

Description

The

door

is

driven

to

the

OPEN*

end

position*

The

door

is

driven

to

the

CLOSED*

end

position

The

door

stands

between

the

end

positions

The

door

stands

at

the

OPEN

end

position

The

door

stands

at

the

position

PART

OPEN

("before-end

position"

up)

The

door

stands

at

the

CLOSED

end

position

The

door

stands

at

the

position

PART

CLOSE

(..before-end

position"

dawn)

The

door

stands

in

the

position

where

the

reversing

switches

off

ff

the

"self

/ocking"

parameter

is

set

to

MOD2

or

MOD3

in

the

input

menu,

the

display

changes

from

AUTOMATIC

to

MANUAL

OPERATION.

Display

MANUAL

MANUAL

UP

MANUAL

MANUAL

DOWN

MANUAL

RESTING

Description

The

door

is

driven

to

the

OPEN*

end

position*

The

door

is

driven

to

the

CLOSED*

end

position

The

door

stands

between

the

end

positions

*When

the

gate

is

being

driven

OPEN,

the

power

currently

being

used

is

displayed.

9.2 Input operating mode

Function

DEUTSCH

RUNNING

TIME

TIME

OPEN

FOREWARN-

ING

TURNA-

ROUND

TIME

MH

RESTING

QUICK

CLOSE

RELAIS

1

RELAIS

2

RELAIS

3

RELAIS

4

Description

Select

the

menu

language

Monitoring

the

max.

running

time

for

an

open

and

close

movement.

The

running

time

must

be

set

to

be

slightly

greater

than

the

effective

running

time

of

the

door.

After

the

door

has

opened,

it

runs

in

the

CLOSE

direction

aga

in

after

the

set

time

has

elapsed.

Ata

setting

OPEN

TIME>

O,

the

impulse

function

(X3

8/9)

only

generates

commands

in

the

OPEN

direction.

Before

the

door

starts

to

move

downwards,

the

traffic

light

flashes

during

the

forewarning

time

if

automatic

closing

is

activated,

or

in

the

case

of

impulse

operation.

Standing

time

at

every

change

of

direction

MOD1:

MOD2:

ON:

When

resting

relay

OFF

(door

closed)

When

resting

relay

ON

(door

closed)

The

open

time

is

cut

short

and

the

door

closes

immediately

after

the

photoelectric

barrier

(X4

3/4)

ha

s

been

activated.

This

function

is

also

active

if

the

open

time

=

O.

OFF:

The

open

time

continues

as

usu

al

All 4

relays

can

be

allocated

to

a

rela

is

mode

of

1-28.

The

parameter

M

1-3

TRAFFIC

LIGHT

REST

affects

the

red

traffic

light

(MOD

1-

3).

MOD1:

(Red

light

1)

flashes

du

ring

forewarning

and

is

on

when

door

is

running

MOD2:

(Red

light

2)

flashes

du

ring

forewarning

and

when

door

is

running

MOD3:

(Red

light

3)

is

on

du

ring

forewarning

and

when

door

is

running

MOD4:

lmpulse

signal

at

OPEN

command

MODS:

Error

message

(ln

the

case

of

stop

messages

and

error

messages,

please

refer

to

section

1

O)

MOD6:

OPEN

end

position

MOD?:

CLOSE

end

position

MOD8:

Final

position

OPEN

denied

MOD9:

Final

position

CLOSED

denied

MOD10:

Before-end

position

OPEN

Setting

options

DEUTSCH

ENGLISH

FRANCAIS

ES

PAN

OL

NEDERLANDS

POL

SKI

CE

SKY

ITALIANO

1-

250

Seconds

O-

600

Seconds

O-

120

Seconds

O,

1-

2,0

Seconds

(in

1110Sec)

MOD1

MOD2

ON

OFF

MOD1-

MOD13

MOD17-

MOD28

MOD1-

MOD13

MOD17-

MOD28

MOD1-

MOD13

MOD17-

MOD28

MOD1

-

MOD28

Factory

setting

DEUTSCH

60

Seconds

0=

Auto-close

off

0,3

Seconds

MOD1

OFF

MOD6

MOD?

MOD1

MOD14

~:r

~~

-

·l

Function

SEP

TEST

DELAY

OPEN

FINE

OPEN

FINE

CLOSE

BES

OPEN

BES

CLOSE

ROTATING

FIELD

REVERSE

OFF

AUTO

LEVEL

'

<~'

'

:~·..

,, j ,·

;;ft!'

..

Description

MOD11:

Before-end

position

CLOSE

MOD12:

From

before

CLOSE

position

to

CLOSE

position

MOD13:

Magnetic

locking

function

MOD14:

Bra

ke

MOD15:

Brake

negated

MOD16:

Bra

ke

MOD17:

SEP

activated

MOD18:

(Red

light

4)

flashes

du

ring

forewarning

and

is

off

when

door

is

running

MOD19

From

before-end

position

OPEN

to

OPEN

end

position

MOD20:

Activation

of

transmission

system

MOD21:

Test

mode

before

opening

run

MOD22:

Test

mode

before

closing

run

MOD23:

(Green

light)

is

on

du

ring

OPEN

end

position

and

OFF

du

ring

forewarning

and

OFF

when

door

is

running

MOD24:

Capacitor

circuit

for

230V

single

phase

drives

MOD25:

Yard

light

function

2

minutes

after

OPEN

com

mand

MOD26:

FREE

(continuously

ON)

MOD27:

lmpulse

signal

after

attaining

OPEN

end

position

MOD28:

Relay

OFF

ON:

PS

testing

is

active

OFF:

PS

testing

is

inactive

The

testing

of

the

PS

switch

ta

kes

place

in

the

CLOSE

end

position

.

To

achieve

this,

the

airswitch

contact

must

be

activated

briefly

when

the

door

eames

to

rest

on

the

ground

.

ON:

OFF:

Forewarning

also

before

opening

lmmediate

opening

Only

active

when

the

parameter

FOREWARNING

TIME

is>

O.

Fi

ne

adjustment

of

OPEN

end

position

Fi

ne

adjustment

of

CLOSE

end

position

Setting

of

cut-out

point

before-end

position

OPEN

1

PART

OPEN

Setting

the

before-end

position

switch

point

for

the

CLOSE

direction

MOD1:

MOD2:

Standard

assembly

(clockwise

rotating

field

1

increasing

AVE

values

during

opening

run)

Special

assembly

(anticlockwise

rotating

field

1

increasing

AVE

values

during

opening

run)

This

setting

may

only

be

altered

in

the

case

of

a

special

customised

drive

installation!

The

poin

t

where

the

re

v

ersing

switch

is

activated

before

the

CLOSE

end

position

is

reached

.

After

going

beyond

the

cut-out

point,

the

door

is

stopped

if

the

switching

strip

or

photoelectric

barrier

is

activated,

but

it

is

not

reversed.

The

value

must

not

exceed

a

maximum

of

5

cm

above

the

lower

end

position.

ON

:

OFF:

Align

with

gro

und,

ON

Align

with

ground,

OFF

Setting

options

ON

OFF

ON

OFF

O-

8190

(is

set

to

programmed

value

after

adjustment)

0-8190

o-

8190

o-

8190

MOD1

MOD2

10

-

250

ON

OFF

Factory

setting

OFF

OFF

4050

3950

4050

4000

c

50

MOD1

::·

Function

Description

Setting

options

Factory

setting

SELF

LOCK

MOD1:

Automatic

operation

MOD1-

MOD3

MOD1

MOD2:

Manual

operation

for

OPEN

and

CLOSE

MOD3

:

Manual

operation

for

CLOSE

SUIWI

Connection

to

terminal

strip

X4

(9

+ 1

O)

MOD1-

MOD7

MODS

MOD1:

(SUIWI

button

1)

When

the

button

is

pressed,

the

door

opens

as

far

as

the

intermediate

position

PART

OPEN.

There

is

no

automatic

closing

of

the

door

from

the

position

PART

OPEN.

MOD2:

(SU/WI

se

lectar

switch

1)

Closed:

all

OPEN

commands

lead

to

the

position

PART

OPEN.

Open:

all

OPEN

commands

lead

to

the

position

OPEN.

The

door

closes

automatically

from

both

positions

.

MOD3:

(SUIWI

se

lectar

switch

2)

Closed:

all

OPEN

commands

lead

to

the

position

PART

OPEN.

Open

:

all

OPEN

commands

lead

to

the

position

OPEN

.

The

door

closes

automatically

only

from

the

position

PART

OPEN.

MOD4:

(SUIWI

selector

switch

3)

Closed

:

all

OPEN

commands

lead

to

the

position

PART

OPEN

.

Open:

all

OPEN

commands

lead

to

the

position

OPEN.

The

door

closes

automatically

only

from

the

position

OPEN.

MODS:

(S

UIWI

button

2)

When

the

button

is

pressed,

the

door

opens

as

far

as

the

intermediate

position

PART

OPEN.

Automatic

closing

of

the

door

also

occurs

from

the

position

PART

OPEN

.

MOD6:

Activation

of

automatic

closing

Closed:

no

auto

matic

closing

of

the

door

Open

:

automatic

closing

of

the

door

is

acti

ve

MOD?:

External

input

for

clock

The

door

opens

ance

the

contact

closes

and

remains

in

the

position

OPEN

until

the

contact

opens.

The

door

then

closes

automatically.

This

function

can

be

aborted

by

pressing

the

CL

OSE

button.

The

door

then

closes.

P/E

BARRIER

MOD1:

Stop

when

activated

MOD

1

MOD

2

CLOSED

MOD2:

Stop

and

reverse

when

activated

MOD

2

P/E

BARRIER

MOD1:

Photoelectric

barrier

not

active

MOD

1

MOD1

OPEN

MOD2:

When

the

photoelectric

barrier

is

activated

between

the

CLOSED

end

MOD

2

position

and

the

pre-limit

switch

CLOSE,

the

door

stops.

The

red

light

is

on.

The

pre

-

limit

switch

CLOSE

goes

automatically

to

CLOSED

end

position

+

600.

SEP

MOD1:

No

function

MOD1

MOD1

LEADING

MOD2:

Leading

photoelectric

barrier

(MFZ)

MOD

2

MAX

SPEED

Sets

the

frequency

that

regulates

the

speed

for

the

OPEN

door

run.

10Hz-100Hz

SO

Hz

OPEN

-

Maximum

speed

of

the

drive

for

the

OPEN

door

run

MIN

SPEED

Sets

the

frequency

that

regulates

the

speed

for

the

OPEN

door

run

.

10H

z-

SO

Hz

25Hz

OPEN

-

Minimum

speed

of

the

drive

for

the

OPEN

door

run

(creep

s

peed)

MAX

SPE

ED

Sets

the

frequency

that

regulates

the

speed

for

the

CLOSE

door

run.

10Hz

-

100H

z

SO

Hz

CL

OSE

-

Maximum

speed

of

the

drive

for

the

CL

OSE

door

run

MIN

SPEED

Sets

the

frequency

that

regulates

the

speed

for

the

CLOSE

door

run.

10Hz

-

50Hz

25Hz

CL

OSE

-

Minimum

speed

of

the

drive

for

the

CLOSE

door

run

(creep

speed)

SPEED

UP

Acceleration

time

from

minimum

speed

to

maximum

speed

.

O,

1Sec.- 2

Sec.

1,0

Sec.

f ' ·

..

j

-:.

Function

Description

Setting

options

Factory

setting

SLOW

Retardation

time

from

maximum

speed

to

minimum

speed.

O,

1

Sec.

- 2

Sec.

1,0

Sec.

DOWN

BRAKE

P

The

OPEN

bra

ke

point

lies

before

the

OPEN

limit

switch

value.

When

the

OPEN

brake

0-999

250

OPEN

point

is

passed,

the

retardation

time

SLOW

DOWN

is

activated.

The

adjustable

value

is

based

on

the

distance

from

the

OPEN

limit

switch.

BRAKE

P

The

CLOSE

bra

ke

point

lies

before

the

CLOSE

limit

switch

value.

When

the

CLOSE

o

-999

250

CLOSE

bra

ke

point

is

passed,

the

retardation

time

SLOW

DOWN

is

activated.

The

adjustable

value

is

based

on

the

distance

from

the

CLOSE

limit

switch.

U

START

The

start-up

voltage

increases

the

performance

of

the

door

operators

at

low

rotational

0-42V

20V

speeds.

F

START

The

start-up

frequency

increases

the

performance

of

the

door

operators

at

low

O-10Hz

3Hz

rotational

speeds.

BRAKE

The

bra

ke

retardation

delays

the

falling

off

of

the

bra

ke

when

the

door

operator

starts

0-500

50

RETARDATION

up.

RA

TED

This

is

the

frequency

rating

of

the

motor

MOD1=

50

HZ,

Set

to

match

the

FREQUENCY

MOD2=87

Hz,

motor

supplied

MOD3=100

Hz

P/E

BARRIER

The

photoelectric

harrier

signal

is

not

evaluated

between

the

CLOSED

end

position

o

...

999

300

and

the

photoelectric

harrier.

This

function

masks

the

photoelectric

barrier

signal

at

low

rotational

speeds

to

avo

id

interference

resulting,

for

instance,

from

spiral

cables.

Explanation

of

the

relay

modes:

A.

Traffic

light

functions

MOD

Description

CLOSED

end

OPEN

end

Forewarning

Door

run

position position

MOD1

Red

traffic

light

1

ON

1

OFF*

OFF

Flashing

ON

MOD

2

Red

traffic

light

2

ON

1

OFF*

OFF

Flashing

Flashing

MOD3

Red

traffic

light

3

ON

1

OFF*

OFF

ON ON

MOD

18

Red

traffic

light

4

OFF

OFF

Flashing

OFF

MOD

23

Green

traffic

light

OFF

ON

OFF

OFF

*

depending

upon

parameter

MOD1-3

RESTING

Table of contents

Popular Controllers manuals by other brands

Parker

Parker ACR9000 installation guide

Rockwell Automation

Rockwell Automation Allen-Bradley CompactLogix 5370 L2 Series Product information

BFT

BFT Magistro ROLL quick guide

Norac

Norac UC4+ installation manual

Johnson Controls

Johnson Controls NAE35 installation guide

DRAGONFRAME

DRAGONFRAME DDMX-S2 user guide