2

VAP Series balancing valve actuator -Installation Instructions

VAP系列平衡阀执行器 -安装说明

601U-B01A-NC-Issue Date 11 2013

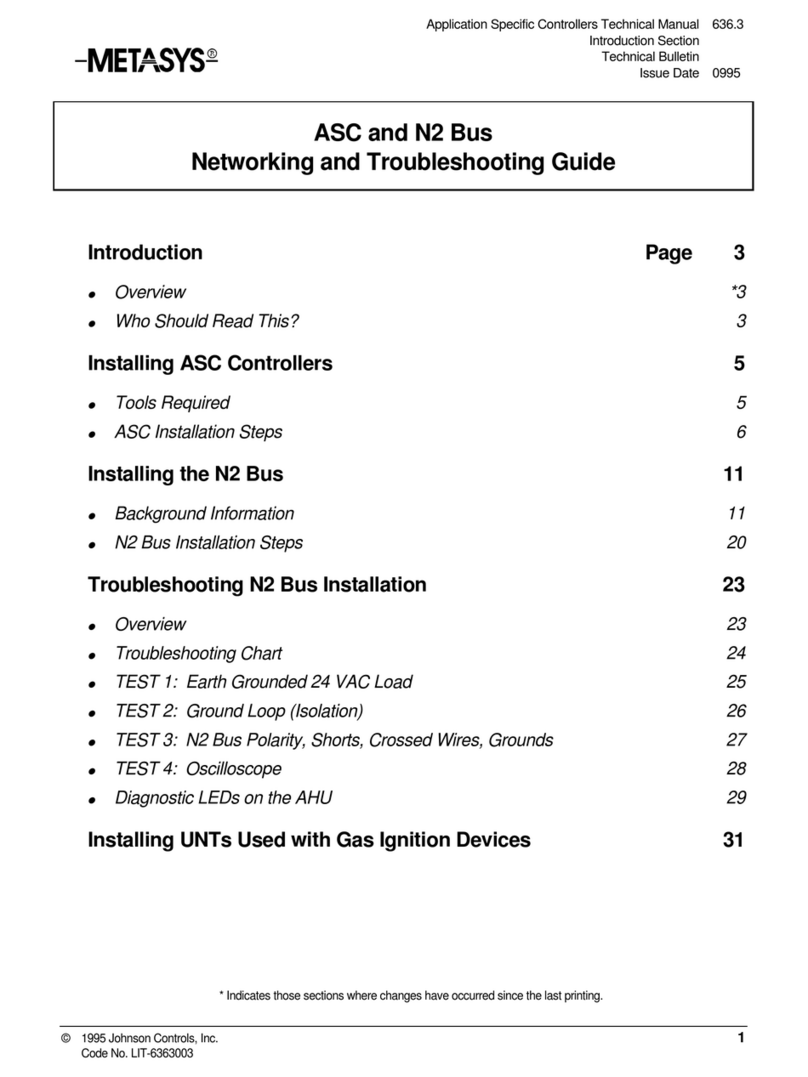

23 4

1

ON

OFF

S2

23 4

1

S3

控制信号 Control signal:0~10VDC

阀位反馈信号 Feedback signal:0~10VDC

工作模式 Operating mode:RA

断信号模式 Losing control signal mode:DW

控制信号 Control signal:4~20mA

阀位反馈信号 Feedback signal:4~20mA

工作模式 Operating mode:RA

断信号模式 Losing control signal mode:DW

例1

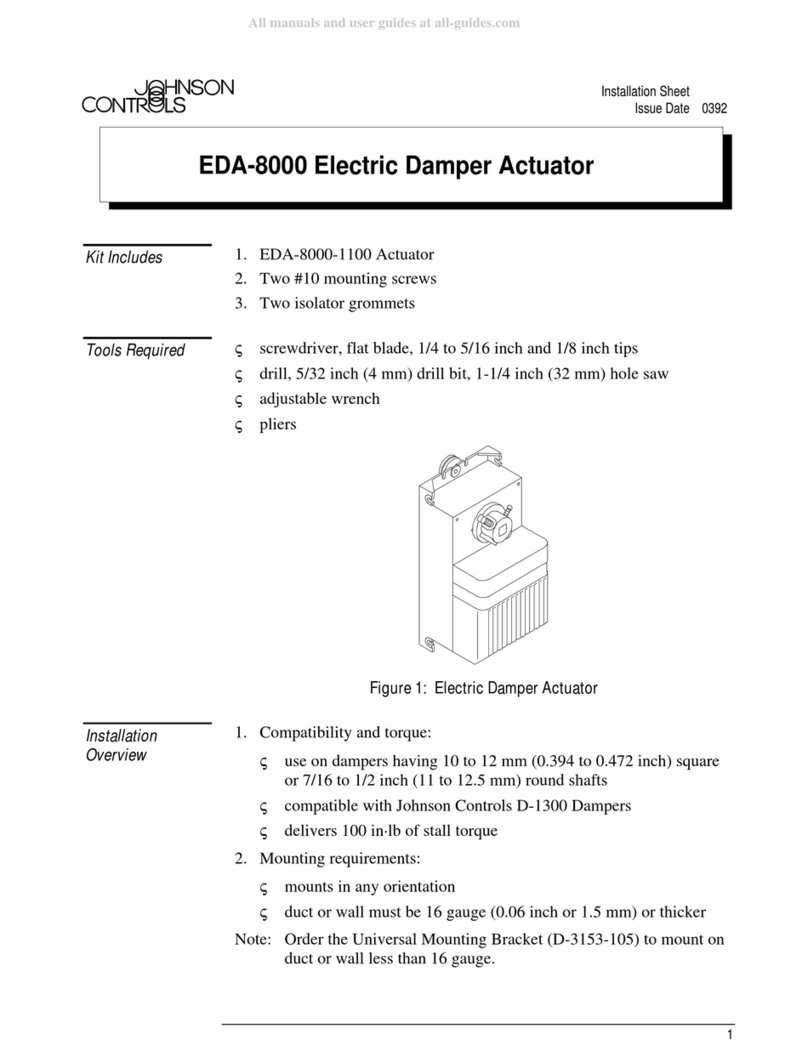

S2、S3拨码开关设定 S2, S3 DIP Switch Setting

拨码

DIP

功能

Function

设定值功能描述

Description

S2

1

控制/阀位反馈信号起始点

设定

Starting of control /

feedback signal

ON 20%: 控制/阀位反馈信号起始点为20%(适用于控制/阀位反馈信号为4~20mA或2~10VDC)

20%: The starting control / feedback signal is 20% (namely 4~20mA or 2~10VDC)

OFF 0: 控制/阀位反馈信号起始点为0(适用于控制/阀位反馈信号为0~20mA或0~10VDC)(出厂默认设定)

0: The starting control / feedback signal is 0 (namely 0~20mA or 0~10VDC) (factory setting)

2控制信号类型 设定

Type of control signal

ON II: 控制信号为电流型

II: current signal

OFF UI: 控制信号为电压型(出厂默认设定)

UI: voltage signal (factory setting)

3输入信号阻抗匹配 设定

Selection of control signal

ON UI: 控制信号为电压型(出厂默认设定)

UI: voltage signal (factory setting)

OFF II: 控制信号为电流型

II: current signal

4阀位反馈信号类型 设定

Type of feedback signal

ON IO: 阀位反馈信号为电流型

IO: current signal

OFF UO: 阀位反馈信号为电压型(出厂默认设定)

UO: voltage signal (factory setting)

S3

1工作模式 设定

Operating mode

ON DA: 控制信号增大时执行器轴伸出运行,控制信号减小时执行器主轴缩进运行

DA: when control signal is increasing, the actuator axes extends

OFF RA: 控制信号增大时执行器轴缩进运行,控制信号减小时执行器主轴伸出运行 (出厂默认设定)

RA: when controls signal is increasing, the actuator axes retracts (factory setting)

2

断信号模式 设定

Losing control signal

mode

ON

DW: 当控制信号类型设定为电压型或电流型时,此时如果信号线被切断,执行器内部会自动提供一个最小控制信号。

(出厂默认设定)

DW: When lose control signal (voltage type), the minimum control signal (will be applied automatically)

When lose control signal (current type), the minimum control signal (will be applied automatically) (factory setting)

OFF

UP: 1) 当控制信号类型设定为电压型时,此时如果信号线被切断,执行器内部会自动提供一个最大控制信号。

2) 当控制信号类型设定为电流型时,此时如果信号线被切断,执行器内部会自动提供一个最小控制信号。

UP: When lose control signal (voltage type), the maximum control signal (will be applied automatically)

When lose control signal (current type), the minimum control signal (will be applied automatically)

3自适应模式设定

Self-stroking mode

ON DF: 执行器为上电自适应模式(出厂默认设定)。

DF: Power up each time, self-stroking starts automatically (factory setting)

OFF RF: 执行器为手动自适应模式。

RF: Self-stroking starts only when press the red self-stroking button manually

4

灵敏度设定

Sensitivity

ON

HS: VAP500-24-C/VAP1000-24-C控制信号高灵敏度≤1.0% (100%~40%) ; ≤1.5% (40%~30%)

VAP3000-24-C控制信号高灵敏度≤1.5% (100%~40%) ; ≤2% (40%~30%)

HS: The high sensitivity of control signal (VAP500-24-C/VAP1000-24-C) ≤1.0% (100%~40%) ; ≤1.5% (40%~30%)

The high sensitivity of control signal (VAP3000-24-C) ≤1.5% (100%~40%) ; ≤2% (40%~30%)

OFF

LS: VAP500-24-C/VAP1000-24-C控制信号低灵敏度≤1.5% (100%~30%) (出厂默认设定)

VAP3000-24-C控制信号低灵敏度≤2% (100%~30%) (出厂默认设定)

LS: The low sensitivity of control signal (VAP500-24-C/VAP1000-24-C) ≤1.5% (100%~30%) (factory setting)

The low sensitivity of control signal (VAP3000-24-C) ≤2% (100%~30%) (factory setting)

S2、S3拨码开关设定示例 S2, S3Setting Example

例2

数码管功能说明(仅限VAP3000-24-C)

标配功能:

—运行指示灯(RUN):此指示灯为红绿双色灯,当执行器轴缩进运行的时候,运

行指示灯的红灯亮;执行器轴伸出运行的时候,运行指示灯绿灯亮,当进行自适

应操作时,红绿双色灯同时闪烁(频率为1Hz)。

—故障指示灯(ERR):当执行器出现故障时,故障指示灯亮。

—数码管:(从左至右四位数码管,第一位为功能位,第2,3,4位为数字位)

1)数码管显示及含义:

Additional Function (Only for VAP3000-24-C)

Basic function:

—Running light(RUN):Red and green double color light. When actuator axes retracts,

running light shows red; when actuator axes extends, running light shows green.; when do

"self-stroking", running light flickering both red and green (1Hz).

—Warning light(ERR):When actuator has problem, warning light will be lighting.

—LED:(from left to right, the first one is function bit, the second to the forth are numerical bits)

1) Description of LED:

出厂默认设定 factory setting 用户设定 user setting

功能位

Function Bit

含义

Description

数字位

Numerical Bit

含义

Description

A开度百分数

Show aperture value

30-100之间连续变化

Number between 30-100

当前开度值,其显示值为百分数

Present aperture value (percent)

C

数字位显示值为输入信号

Show control signal on

Numerical bit

0~100之间数值

Number between 0~100

输入信号值,其显示值为百分数,例如输入信号0~10V,当输入信号为1V时,此时的显示值为

1/10*100=10

Control signal (percent) 0~10V. For example, control signal type is 0~10V, When control signal is 1V, there

will be shown 1/10*100=10

F

数字位显示值为反馈信号

Show feedback signal on

Numerical bit

0~100之间数值

Number between 0~100

反馈信号值,其显示值为百分数,例如反馈信号为0~10V,当反馈信号为1V时,此时 的显示值为

1/10*100=10

Feedback signal (percent) 0~10V. For example, feedback signal type is 0~10V, When control signal is 1V,

there will be shown 1/10*100=10

23 4

1

S3

ON

OFF 23 4

1

S2