Sturtevant Richmont TCV User manual

Sturtevant Richmont

Global Reach. Local Support.

Sturtevant Richmont Div. of Ryeson Corp.

3203 N. Wolf Road Franklin Park, IL 60131

Phones: 847/455-8677 800/877-1347

Fax: 847/455-0347

E-Mail: [email protected]

Web Site: www.srtorque.com

Operating Instructions

Torque Control Verifier 2.4 GHZ

S/R Part No. 10467

Manual P/N: 857269 Rev. B

Date: 9/1/09

This product is not RoHS compliant.

Table of Contents

Contents Page

Chapter 1 - Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Chapter 2 - Domestic Warnings (USA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Chapter 3 - TCV Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Chapter 4 - Tool Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Chapter 5 - Using Device Programmer Software to Program the TCV. . . . . . . . . . . . . . . . .

Page 1

1 Introduction

The TCV/FM Switch Wrench System is designed to assist the manufacturer in closing sev-

eral gaps in the quality system that have hindered their quality improvement efforts. The

key capabilities this system enables are:

1. The ability to integrate manual torque wrenches into the automated line control system.

2. The ability to attain control of the actual torque wrench use process, not just the

wrench calibration process.

3. The ability to provide rapid and effective training in proper torque wrench use through

reinforcement of proper technique with every cycle of the wrench.

1.1 Control Concepts

The TCV works with the FM Switch Wrenches to bring systematized control to the use of

manual torque wrenches. The control is applied as follows:

1. There are three ways to use a clicker-type torque wrench. When used properly, a steadi-

ly increasing force is applied until the wrench clicks and the pressure is immediately

released and the tool resets. One improper use technique consists of applying force too

quickly (”jerking” the wrench). The other improper technique is to continue to apply force

after the click and overtorque the fastener.

2. When the correct technique is used the torque wrench spends a certain amount of time

in the “clicked” position. When the wrench is used too quickly it spends less time in the

clicked position. When it is rotated past the click it spends more time in the clicked posi-

tion.

3. The FM Switch Wrench is a preset clicker-type torque wrench. The torque is preset using

a torque tester to assure the wrench is accurately set. The torque setting is then locked

in.

4. The FM Switch Wrench has a timer that measures the duration of a click (cycle) of the

wrench. once the wrench has been accurately adjusted on the tester, variation in tech-

nique can be controlled by measuring and controlling the duration of the click.

5. An experiment is conducted to determine the correct use of the torque wrench (duration

of time in the clicked position) to obtain the correct torque on the joint. The accurately-

preset torque wrench is used to tighten the fastener(s) on the joint and an indicating

torque wrench is used to check the torque after the tightening. The experiment deter-

mines the minimum and maximum click duration to attain proper torque.

6. The minimum and maximum duration of a proper click is programmed into the TCV.

[Time Minimum or TMIN and Time Maximum of TMAX]

Page 2

7. In use, the FM Switch Wrench tightens a fastener. As soon as the wrench clicks a timer

on the wrench starts measuring time.

8. When pressure on the wrench is released and the wrench resets, the timer stops and the

duration of the click is transmitted to the TCV. The TCV compares the duration of the

click to the TMIN and TMAX specification limits.

9. The TCV immediately communicates to the operator the acceptability of that use of the

wrench. Light emitting diodes (LED’s) and a buzzer inform the operator whether or not

the wrench was used properly and the click accepted.

10. The TCV also uses the Input/Output Relays to communicate to programmable logic con-

trollers or other peripheral devices the acceptability, or lack of acceptability, of each use

of the wrench.

1.2 Component Nomenclature

1Cabinet

The Cabinet houses all of the electronic components in the unit. On the left and right sides

of the Cabinet there are flanges with holes for mounting the unit to an appropriate support.

2Antenna Housing

The Antenna Housing protects the antenna for the 2.4Ghz band receiver.

3. Power Light

Emitting Diode

(LED)

The power LED

lights and

remains lit

when electric

power is sup-

plied to the unit

and the power

switch is in the

“On” position.

4Accept Light Emitting Diode (LED)

The Accept LED emits a green light to notify the operator when a wrench cycle meets the

duration specification.

5Reject Light Emitting Diode (LED)

The Reject LED emits a red light to notify the operator when a wrench cycle has been

rejected.

Page 3

6Strength/Prog Light Emitting Diode (LED)

In normal operation this Light Emitting Diode (LED) will emit green, yellow, or red light. If

the LED is green, the TCV is receiving a strong radio signal from the FM Switch Wrench

that it is working with. If it is yellow the signal strength is marginal. If this LED is red than

the signal strength is inadequate and the distance from the tool to the TCV should be

reduced. During programming this LED will be lit continuously to indicate the unit is in pro-

gramming mode.

7Key Lock

The Key Lock permits and denies access to programming the unit. When

the Key lock is in the PROG position, programming functions are

enabled. When the Key Lock is in the LOCK position, the unit is in the

normal operating mode and only those functions are accessible.

8Power Entry Module

The Power Entry Module houses the Receptacle

for the Power Cord, the Voltage Selector and Fuse

Holder, and the Power Switch.

9Receptacle

The Receptacle accepts the female end of the

supplied Power Cord. The pronged end must be

plugged into a grounded outlet.

10 Power Switch

The Power Switch permits and denies electric

power to the TCV.

11 Voltage Selector/Fuse Holder

The Voltage Selector/Fuse Holder permits using

the TCV with either 115 VAC or 230 VAC electric

power sources. The correct power source must be

selected during the installation process and before electric power is supplied to the unit.

12 RS232 Communications Port

This port provides connection for the RS232 cable supplied

with the unit. The TCV is programmed with the supplied

software, and must be connected to the computer through

this port.

13 5-Pin Communication Receptacle

This receptacle mates with the supplied 5-pin connector,

and is used to communicate with programmable logic con-

trollers (PLC) and other devices.

Page 4

14 5-Pin Connector

This male connector connects wires from PLC’s and other line control

devices to the pins on the mating receptacle on the TCV. The system is

designed to work with 24VDC I/O devices.

15 9-Pin Serial Convertor

This device attaches to the serial port on the computer that will run

the software used to program the TCV. It permits use of the sup-

plied serial cable to connect to the TCV when programming the

unit.

16 Serial Cable

This cable connects the RS232 port to the 9-Pin Serial

Convertor to the computer when programming the unit.

17 Power Cable

The Power Cable connects the TCV to the electric

power source. This is a standard pc-type cable, and any

cable of this type with a rated capacity of 120 VAC and

10 Amperes may be used.

18 TCV Software

The TCV software is supplied on the enclosed cd. It must be installed on

the computer that will be used to program the TCV before the TCV can

be programmed and used.

2 Domestic (USA) Warnings

INSTRUCTION TO THE USER

This equipment has been tested and found to comply with the limits for a class B digital

Contains FCC ID: OUR-XBEE

The enclosed devise complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful interference and (2)

this device must accept any interference received, including interference that may cause

delayed operation.

Page 5

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reason-

able protection against harmful interference in a residential installation. This equipment gener-

ates, uses and can radiate radio frequency energy and if not installed and used in accor-

dance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of thefollowing measures:

* Reorient or relocate the receiving antenna.

* Increase the separation between the equipment and receiver.

* Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

* Consult the dealer or an experienced radio/TV technician for help.

This equipment has been certified to comply with the limits for a class B computing

device, pursuant to FCC Rules. Operation with non-approved equipment is likely to result in

interference to radio and TV reception. The user is cautioned that changes and modifications

made to the equipment without the approval of manufacturer could void the user's authority to

operate this equipment.

3 Installation

There are two separate processes for installation; the TCV must be installed in the location

where it will be used and the software must be installed on the computer.

3.1 Installation Electric Safety

It is mandatory that the national, state, and local safety and wiring standards be

adhered to during installation. There standards take precedence over any information

presented in this section.

To avoid the hazard of electrical shock or burn, the following instructions must be

adhered to. Failure to follow these instructions may also cause damage to your unit and void

existing warranties.

• Do not energize (supply electric energy to) the unit until all connections have been

properly made.

• Equipment must be properly grounded before applying power. Units energized by cord

and plug must be connected to an approved and properly grounded receptacle.

• Ensure the power switch is in the “off” position before applying power.

Page 6

3.2 Mounting the TCV

This unit may be wall mounted, table mounted, beam mounted, suspended overhead,

pedestal mounted, or used without mounting. Mounting tabs are located on flanges on the

rear of the cabinet.

The mounting location should be in a stable, secure area so as to avoid damage to the unit

and avoid injury to the operator due to an inconvenient mounting. Locate the unit so that

ambient air can circulate freely around the cabinet.

This unit should be located to allow access to the front panel and connectors. The location

should allow for unrestricted and comfortable viewing of the front panel. The unit may be

remotely mounted, but should still be accessible.

3.3 Source Power

CAUTION! This unit is capable of being powered by 115 VAC

or 230 VAC (both 50 and 60Hz). Before powering up the

unit for the first time, make sure the voltage selection on

the power entry module matches the type of power being

applied.

1. The voltage setting for the unit is always displayed in a

window above the power switch, shown as #1 in the

image to the right. Always check the voltage for compati-

bility before supplying electric power to the unit. For this

example the voltage will be changed from 115VAC to

230VAC.

2. If the setting needs to be changed because it does not match

the power to be supplied, open the access door marked as #2

in the prior image by prying outward gently with a fingernail or

small screwdriver. Slide the red voltage selector/fuse holder

out of the module.

Page 7

3. Turn the red voltage selector/fuse holder over so the voltage

matching that of the power to be supplied has the top of the printed

voltage facing upwards.

4. Reinsert the red voltage selector/fuse holder into the module.

The face of the voltage selector/fuse holder will be slightly

recessed in the module when it has been properly reinserted.

5. Close the door over the voltage selector/fuse holder. The cor-

rect voltage, that which matches the voltage of the power to be

supplied to the unit, should now show through the window.

The TCV is fused at 1 Amp for 115VAC. The TCV is fused at

1 Amp for 230 VAC. The fuses are located on the sides of the

voltage selector/fuse holder, as shown in the accompanying

photograph.

6. Use the Power Cord to bring electric power from the source to the TCV. Check the Power

Switch and make certain that it is in the “Off” or de-energized position. Connect one end of

the cord to the TCV at the Power Entry Module and plug the other end into the electric

outlet.

3.4 Connecting Peripheral Devices

The TCV has relay outputs and an optically isolated RESET input. All of the relays can be

accessed through the 5-Pin Connector on the bottom of the Cabinet. The TCV also has a

serial port labeled “RS232”. The serial port is used to connect to a personal computer or lap-

top computer running the TCV software to accomplish programming of TCV parameters.

The circuit diagram below is that for the relays.

Page 8

The TCV Input/Output control

system is designed primarily for use with 24VDC systems. Follow all national and state elec-

trical codes and regulations when connecting peripheral devices to the TCV. Do

not exceed the voltages and amperages shown above.

Connect the wires from the peripheral devices to the TCV via the external 5-Pin

Connector. This connector has screw clamps for the wire for each pin.

3.5 Software Installation and Computer Connection

A compact disk packaged with each TCV contains the software required to program the unit.

The software must be installed and used to program the TCV before the unit is placed in ser-

vice.

This software will work on machines using the Windows XP Professional operating system.

Close all programs not necessary to computer operation before executing the installation pro-

cedure below.

1. Insert the Device Programmer compact disk into the compact disk drive on the computer

that will be used to control the settings on the TCV.

2. Use “My Computer” or “Windows Explorer” to open the compact disk drive containing the

compact disk.

3. When the files on the compact disk are displayed, double-click the left mouse button on

the “Setup” file. This will start an automated program installation and setup routine.

4. Follow the instructions displayed on screen to install the program.

5. Remove the compact disk and store in a safe location.

Page 9

4 Tool Communications

Each TCV unit can work with one SLTC-FM 2.4 GHz preset torque wrench at a time. The unit

and tool each use the identitfication number of the transceiver in the other to assure that

there is no crosstalk or erroneous reporting during radio communications.

For the association of individual tool and individual TCV unit to exist, the tool and the TCV

must learn each other's identities before the system can be used.

Since the TCV can only work with one torque wrench at a time, if a tool has already been

learned by the unit the memory of that tool must be cleared should it become necessary for it

to be used with a different wrench.

Both the memory clearing procedure and the learning procedure are given here. There are

several items that should be taken care of before engaging in the procedures.

1. It is usually advisable to preset the torque on the SLTC_FM 2.4 GHz torque wrench before

starting the learning procedure. While the tool can be removed from the vicinity of the TCV

for calibration or unlearned before calibration and relearned after, it is often easier to pre-

set the tool before starting the procedure.

2. Make sure that a battery of sufficient charge is installed in the tool before beginning the

learning procedure. Insufficient battery charge for tool communications can cause confus-

tion and difficulty.

3. Insure that no other TCV unit is undergoing this process at the same time. If two TCV's

and two wrenches must undergo the process, perform the process on one unit and do not

start the process on the second unit until the process is complete on the first unit.

Clearing the Tool Memory

To remove the identification of the TV unit from the tool memory, click the wrench and hold it

in the clicked position until the LED on the wrench flashes. This will take about 5 seconds.

Release the pressure on the tool and allow it to return to the normal position.

The flashing of the LED occurs when the memory of which TCV unit the tool was associated

with has been erased. The tool is now ready to be associated with another TCV unit.

Note that when the battery has been removed and replaced in the wrench the LED will alter-

nate between emitting red and green light several times very quickly. If the alternating color

emission stops and then a red light pulse is emitted, the tool is not associated with a specific

TCV and can be associated with whatever unit is desired. If the alternating color emission

stops and then a green light pulse is emitted, the tool has a specific TCV unit in memory and

is ready to be used with that unit.

Page 10

Creating the TCV Unit and Tool Association

1. Enable power to the TCV unit.

2. Assure that the tool to be used with the TCV is nearby.

3. Insert the key into the lock on the side of the TCV.

4. Rotate the key from the "LOCK" position to the "PROG" position.

5. Click the wrench to be used with this TCV one time.

6. The ACCEPT LED on the TCV will illuminate to indicate that the procedure was performed

successfully.

7. Rotate the key back to the "LOCK" position.

The wrench and the TCV are now associated.

If the initial attempt to associate the TCV and wrench were not successful, check the battery

in the tool to assure that it is charged, then repeat steps 4 - 7. The Device Programmer soft-

ware shipped with the TCV can also be used to associate the wrench with the TCV.

RF Channels

The TCV and SLTC-FM 2.4 GHz wrenches can operate on any one of 12 channels. If the

channel is changed after a torque wrench has been associated with the TCV, the Clearing the

Tool Memory procedure must be performed and the wrench must then again be put through

the Creating the TCV Unit and Tool Association procedure above. When these are performed

the unit and tool will communicate on the newly-selected channel.

The radio modules in the TCV and the S/R torque wrenches used with it comply with the

IEEE 802.15.4 standard. The channel numbers loosely match the channels used by the IEEE

802.11b/g WLAN standard. It may be beneficial to use channels that do not match the chan-

nels used by a nearby wireless network. The graph below depicts both standards and illus-

trates the center frequencies and channel overlap for each standard. Notice that the channels

we use leave a much smaller footprint than WLAN. Also notice that one WLAN channel radi-

ates a significant amount of energy onto several of the adjacent WLAN and PTV channels.

For the most reliable communication between the unit and the tool in a 802.11b/g LAN envi-

ronment, it is usually best to choose a channel for the RFE and tool that is separated from

the channel of the LAN.

Page 11

Unlike IEEE 802.15.1 (Bluetooth) radios, the

RFE 2.4GHz radio modules do not frequency

hop, use less power and have faster response

times with less impact on other wireless devices.

A wrench only transmits a small packet of data

after each torque operation, and each transmis-

sion lasts about 30ms (0.03 seconds).

The 2.4GHz radio used by the unit and the tool

is certified in the United States (FCC), Canada

(IC), and Europe (CE).

Torque wrench output power: 1mw

TCV 2.4GHz output power: 10-60mw

Typical 802.11b/g output power: 100mw

Using Device Programmer Software to Program the TCV

Device Programmer software is designed to work with most of the advanced torque products

offered by Sturtevant Richmont. It provides rapid and efficient programming of the varying

specifications required to obtain the most from the products.

1. To use the software, connect the serial port of the computer to the serial port of the TCV

via the supplied cable and adapter.

2. Ensure that power to the TCV is enabled (On).

3. Start the Device programmer software.

4. Insure that the serial port on the computer is selected in the Tools menu on the software;

usually this will be the COM 1 port.

5. Use the pulldown menu for the Product window to select the TCV. Once this has been

done the window will appear as it does on the following page. Use the mouse to click

inside any of the specification entry areas to make it the active area. NOTE: The current

settings on the TCV can now be retireved using the Retrieve Settings button in the lower

right-hand corner of the window.

6. Set the Tmin specification by typing in the minimum time, in seconds, that the torque

wrench must be in the clicked position for this application.

7. Set the Tmax specification by typing in the maximum time, in seconds, that the torque

wrench may be in the clicked position for this application.

Frequency Map of 802.15.4 vs. 802.11b/g

Center Frequency (GHz)

Channel 802.15.4 802.11b/g

1 2.410 2.412

2 2.415 2.417

3 2.420 2.422

4 2.425 2.427

5 2.430 2.432

6 2.435 2.437

7 2.440 2.442

8 2.445 2.447

9 2.450 2.452

10 2.455 2.457

11 2.460 2.462

12 2.465

Page 12

8. Set the Time Between

Cycles specification by typ-

ing in the minimum time, in

seconds, that must elapse

between one cycle of the

tool and the next.

9. Set the Relay Mode to

either Latching or

Momentary, as desired.

10.If the Relay Mode is set to

Momentary, it is necessary

to set the amount of time

each relay will be closed

using the ACC (Accept)

Relay Timer and REJ

(Reject) Relay Timer. Type

the time each relay is to be

closed, in 10 ms incre-

ments, into each of the

areas provided.

11.Use the pulldown menu for

Beep Settings to select how

the beeper on the TCV is to

operate. There are four

options available.

12.Total is the total number of cycles since the unit was placed in service or last reset to zero.

To reset the count to zero, type zero in the entry area.

13.The RF Channel may be selected by typing in any number between 1 and 12. As stated

earlier, any tool that is associated with the unit will have to undergo the two procedures

delineated in the section on RF Communications.

14.Wrench Radio ID is the identification number of the currently-associated tool. This can be

typed in or the tool can be associated with the unit using the procedure in the prior section

of this manual.

15.The Low Battery Warn Level can be set to alert the user to the need for battery replace-

ment. Type in any number between 20 and 99; the lower the number the more discharged

the battery will be before the user is alerted to the need to replace the battery.

Page 13

Once all of the specifications have been typed into the appropriate areas, click on the Write

Settings button in the lower right-hand corner of the window to send the settings to the TCV.

When the transmission is complete, the software can be closed and the computer disconnect-

ed from the TCV.

Additional Information

For additional information on the TCV or any of the components of the system, contact your

S/R Representative or the factory using the information on the front of this document.

Other manuals for TCV

2

Table of contents

Other Sturtevant Richmont Controllers manuals

Popular Controllers manuals by other brands

Maxcess

Maxcess FIFE D-MAXE 1 operating instructions

Emerson

Emerson Fisher LS200 Series instruction manual

emz

emz smart Econ HCW 1620 Operating and installation instructions

SKYDANCE

SKYDANCE VP quick start guide

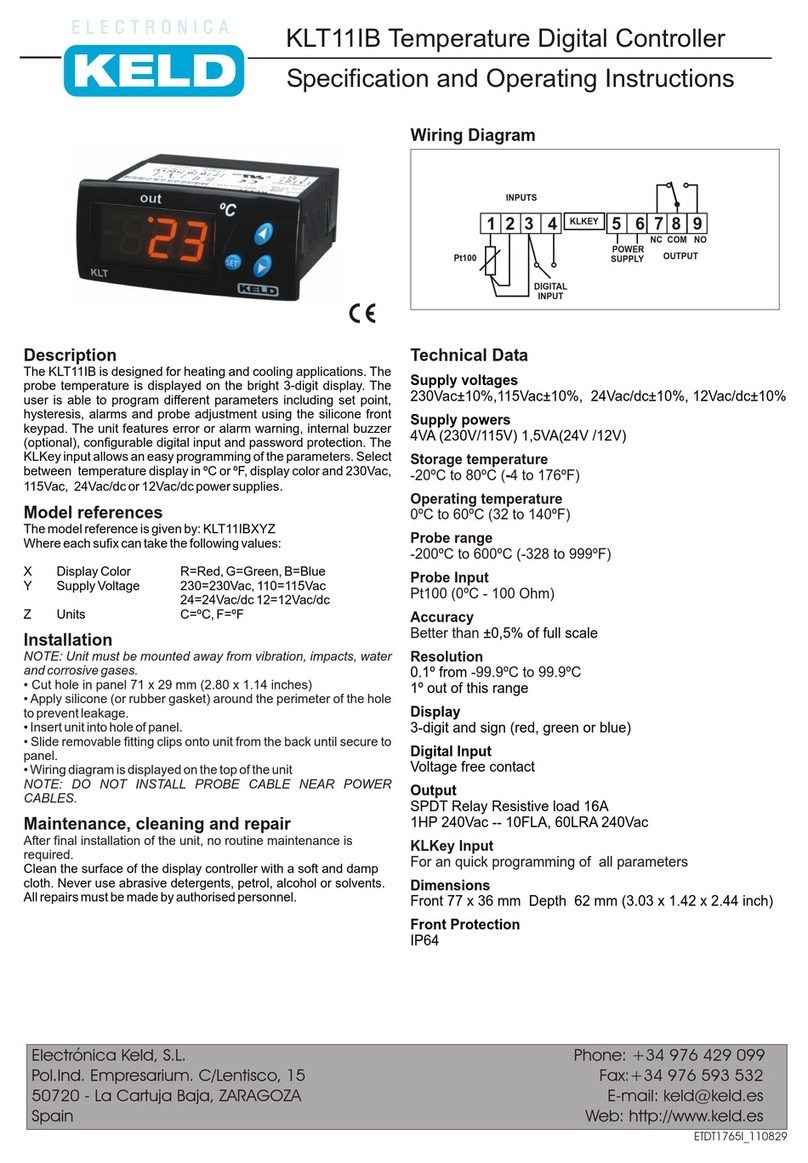

KELD

KELD KLT11IB Specification and operating instructions

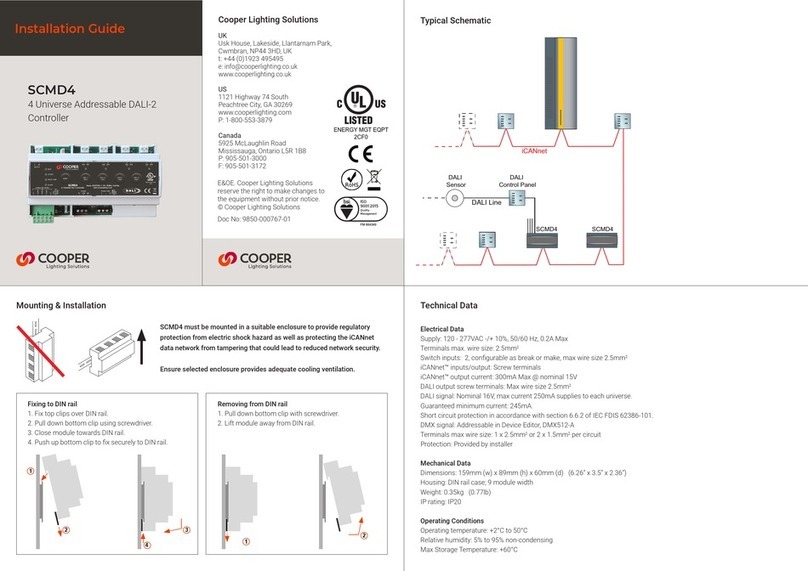

Cooper

Cooper SCMD4 installation guide

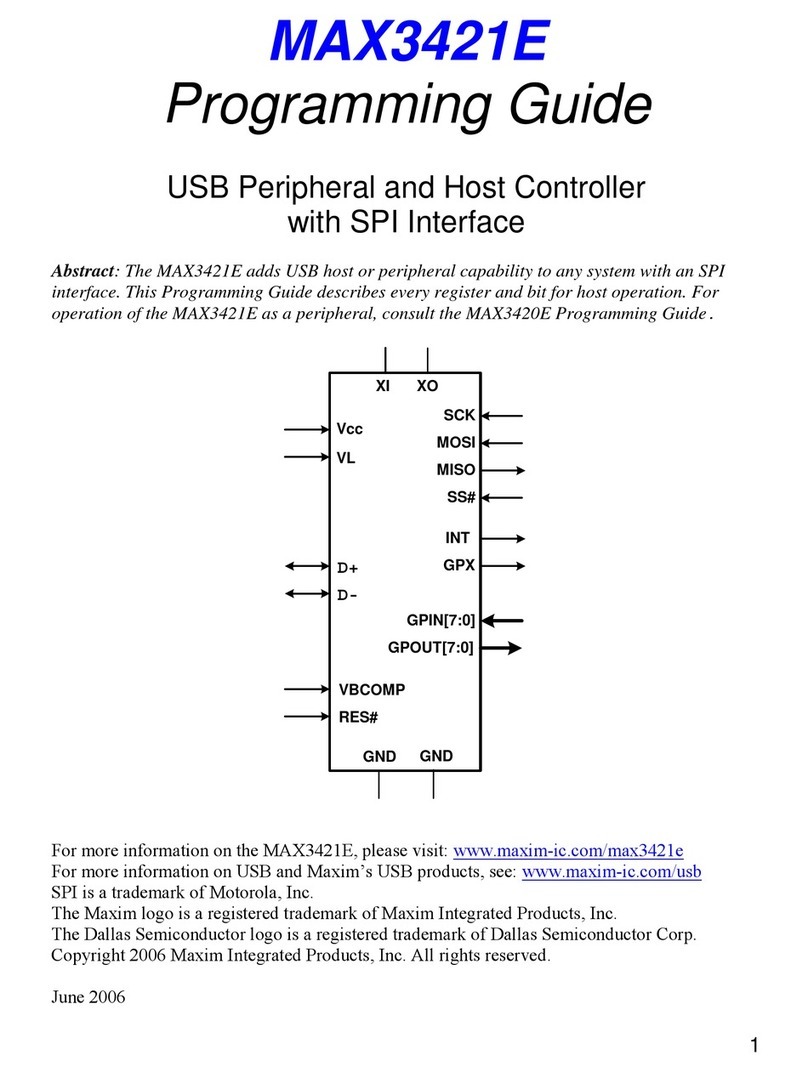

Maxim

Maxim MAX3421E Programming guide

elsner elektronik

elsner elektronik KNX RF S1R-B2 compact Installation and adjustment

Fantom

Fantom FR-10 ESC user manual

HP

HP StorageWorks 2312 installation instructions

Galil Motion Control

Galil Motion Control RIO-47120 user manual

Magnum Energy

Magnum Energy PT-100 owner's manual