ProArc TR-3500B User manual

OWNER’S MANUAL

Important

:

Read these instructions before installing, operating or servicing this product.

MODEL

:

TR-3500B / TR-6000B

Digital Turning Rollers

Serial number

:

1401013 ~ later

Date

:

Feb. 27, 2014

UNITED PROARC CORPORATION

No. 3 Gungye 10th Road, Pingjen Ind. Park, Tel No:88634696600

Pingjen City, Taoyuan 324, Taiwan Fax No:88634694499

http://www.proarc.com.tw E-Mail:customerservice@proarc.com.tw

RD-8428E

PRIMARY POWER CONNECTION

Read and understand this entire manual regarding the rules for users’

safety before installing, operating, or servicing the equipment.

Please read this owner’s manual carefully before connection of the wires to AC power. Wrong connection

may damage the equipment.

Before connecting primary power, check the data plate to verify the voltage required by the TR-XX. Check

the power supply line that corresponds to the machine’s specification.

WARNING

TABLE OF CONTENTS

Introduction

General information

Installation

Operation

Troubleshooting

Parts list

Circuit diagram

Appendix

Circuit

Instruction..............................................................................................................i

Safety precautions................................................................................................ii

Limited warranty ...................................................................................................iii

1.1 Introduction.....................................................................................................1

1.2 Specification ...................................................................................................2

2.1 Installation & adjustment.................................................................................3

3.1 Operation instruction.......................................................................................4

3.2 Remote control instruction ..............................................................................6

4.1 Troubleshooting guide ....................................................................................8

5.1 Control box .....................................................................................................9

5.2 TR-3500BP / 6000BP ....................................................................................10

5.3 TR-3500BI / 6000BI.......................................................................................11

5.4 TR-3500BP / 6000BP (Main wheel)...............................................................12

5.5 TR-3500BI / 6000BI (Idler wheel)...................................................................13

6.1 Control circuit.................................................................................................15

6.2 Control system box........................................................................................16

6.3 Inside input / output connect interface ...........................................................18

6.4 Input/output connect interface........................................................................23

Appendix A:Inverter settings .............................................................................24

Wiring diagram ....................................................................................................25

Revisions.............................................................................................................28

INSTRUCTION

A procedure, which if not properly followed, may cause injury to the

operator or others in the operating area.

Read and understand this entire manual regarding the rules for users’

safety before installing, operating, or servicing the equipment.

Equipment identification

Receipt of equipment

The identification number specification or part number, model, and serial

number of this unit usually appear on a nameplate attached to the control

panel record these numbers for future reference.

When you receive the equipment, check it against the shipping documents.

Make sure it is complete and inspect the equipment for possible damage

during shipping. If there is any damage, notify the carrier immediately to file a

claim.

Furnish complete information concerning damage claims or mistake(s) in

shipment to United ProArc Corporation: No. 3 Gungye 10th Road, Pingjen Ind.

Park, Pingjen City, Taoyuan 324, Taiwan. Include the equipment identification

number along with a description of the parts in question.

Move the equipment to the installation site before uncrating the unit. Use care

to avoid damaging the equipment when using bars, hammers, etc. to uncrate

the unit.

Falling machine due to lifting device failure may cause death or injury.

*Lifting device may fail when overloaded.

*Avoid sudden jerks, drops or swinging.

*Check lifting device components visually for looseness and signs of metal

fatigue.

*Before changing any hardware, check grade and size of bolts, and replace

with bolts of equal or higher size and grade.

*Falling object may potentially cause serious bodily harm, please keep a

safe distance away from any hanging objects

*Long working duration may cause lumbar back strain and sprain. Please

take caution and rest accordingly from time to time, or work in shifts to

prevent long working hours.

WARNING

WARNING

WARNING

i

SAFETY PRECAUTIONS

Operation and maintenance involves potential hazards. All operators

and personnel should be alerted to possible hazards and precautions

should be taken to prevent possible injury.

Electrical safety

Maintenance

Individual safety

Machine:

﹡The counter, safety device against excess current and electrical installation, are

compatible with its maximum power and its main voltage.

﹡The connection, single-phase or three-phase, is possible on a stand compatible

with the plug of its cable link.

﹡If the cable is connected with the electrical network, the earth must never be cut

by the protection device against electrical shocks.

Work Place:

﹡Be very careful to avoid contact between metal part and phase conductor and

the neutral of electric network.

﹡Electrical messes of different electrical machine and apparatus are connected

between themselves and with the terminal of earth neutral wire.

Interventions:

﹡Before control and repair, see the apparatus is switched off and insulated.

﹡Connection with fixed installation cable is impossible.

﹡It’s on “Stop” and connection is impossible.

﹡Some apparatus are provided with starting circuit HT HF (with a plate). Never

enter into the corresponding switch cupboard.

﹡Only qualified persons are authorized for intervention concerning electrical

instillation.

﹡Often check the insulation and connection good state of apparatus and electrical

accessories: taps, appliance cords, coatings, switch, extension cords, etc.

﹡Maintenance and repair of insulating coatings operations are very important.

﹡Do repair with a specialist or better replace defective accessories.

﹡Check regularly the right adjustment and the non-heating of electrical

connections.

﹡The operator must be dressed and protected in relation with his work.

﹡Avoid contacting metal parts connected or accidentally connected.

﹡Wear leather gloves with gauntlet.

﹡Safety clothes: gloves, apron, safety shoes protect the operator and his

assistants against burns of hot parts, projections and slag.

WARNING

ii

SAFETY PRECAUTIONS

Gases and fumes

Fire

Noise

protection goggle

﹡Gases and fumes produced during the plasma cutting or welding process can

be dangerous and hazardous to your health.

﹡Ventilation must be adequate to remove gases and fumes during operation.

﹡Keep all fumes and gases from the breathing area.

﹡Use an air supplied respirator if ventilation is not adequate to remove all fumes

and gases.

﹡Oil or grease in the presence of oxygen may ignite and burn violently. Keep

cylinders, valves, couplings, regulators, hoses, and other apparatus clean and

free from oil and grease. Oxygen cylinders and apparatus should not be

handled with oily hands or gloves. Do not allow an oxygen stream to contact

oily or greasy surfaces.

﹡Do not use oxygen as a substitute for compressed air.

﹡Fire can be caused by hot slag and sparks.

﹡Remove combustibles from working area or provide a fire watch.

﹡Do not cut containers that have held combustibles. Remove all flammable and

combustible materials in the operating area that may be ignited by sparks.

﹡Noise can cause permanent hearing loss.

﹡Wear proper protective ear muffs or plugs.

﹡Make sure others in the operating are protected from noise.

﹡Welding radiation may cause permanent sight damage

Eyes protection goggle recommended

ii

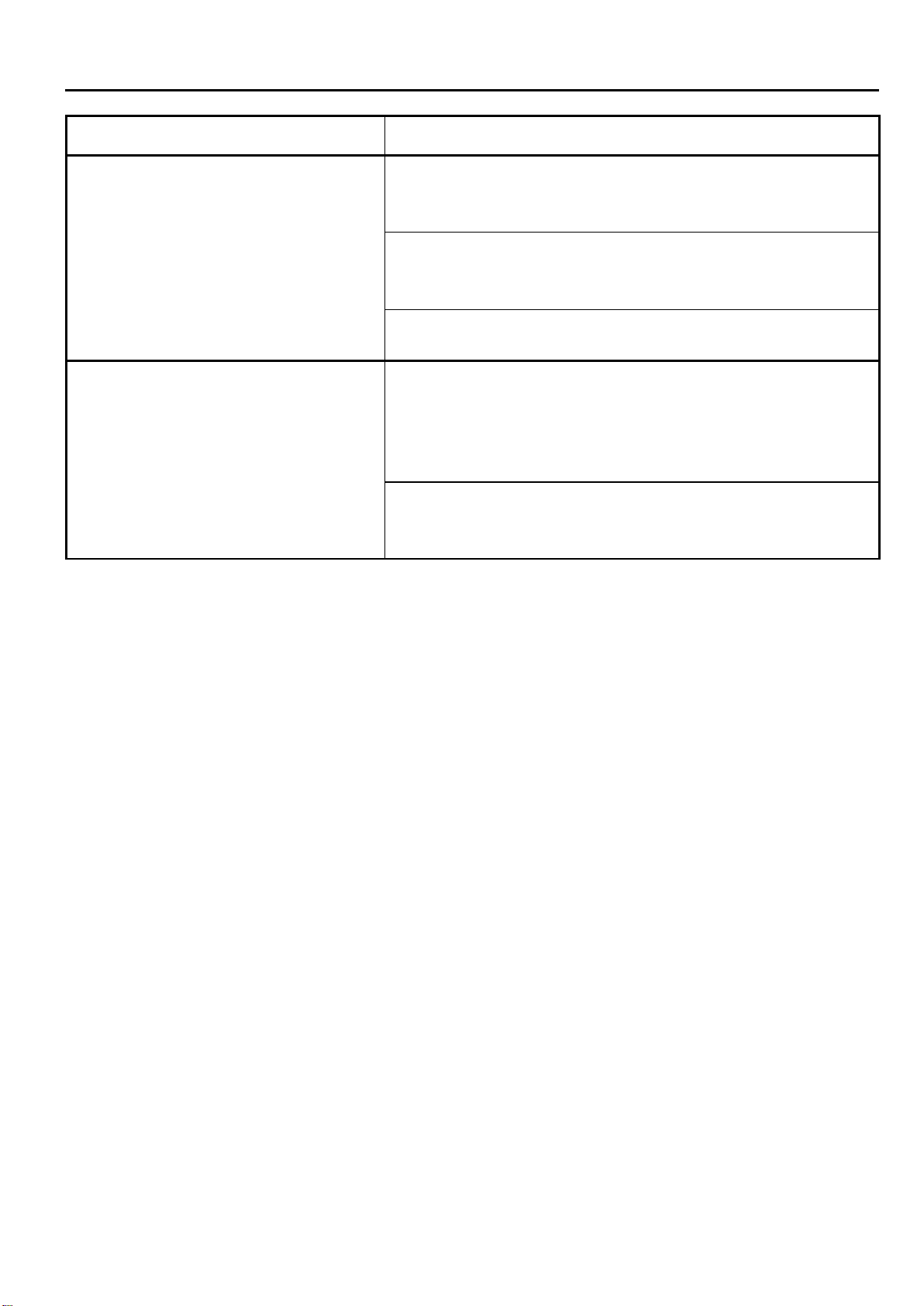

LIMITED WARRANTY

UNITED PROARC CORPORATION warrants all new equipment to be free from defects in material and

workmanship for a period of one (1) year, provided that the equipment is installed and operated according

to instructions stated in this manual.

UNITED PROARC’s obligation under this warranty policy is expressly limited to the replace or repair, at its

option, of the defected part only. ProArc’s option to repair or replacement of a defected part under this

warranty shall be based on FOB Taiwan basis.

The warranty period begins on the date of sale to the original-purchase user of the equipment.

UNITED PROARC CORPORATION shall not be liable for any loss or consequential damage or express

accruing directly or indirectly from the use of equipment covered by this warranty.

This warranty supersedes all previous ProArc warranties and is exclusive with no other guarantees or

warranties expressed or implied.

This warranty excludes the consumable parts that are used in normal operation.

iii

T

T

TH

H

HI

I

IS

S

S

P

P

PA

A

AG

G

GE

E

E

I

I

IS

S

S

B

B

BL

L

LA

A

AN

N

NK

K

K

iii

1.1 INTRODUCTION

Instruction

Features

﹡The turning rollers can be applied on round shaped work pieces, such as tanks,

drums, pressure and cylindrical vessels and pipe to do the sequential

circumferential rotation.

﹡The turning roller can be associated with manual welding or the automatic welding.

For example:manipulator.

﹡Suitable for various kinds of welding process:SMAW, MIG, TIG, Plasma welding.

﹡The machine is so designed that uses low-axial single-sided power rolls. The motor

drive uses a shaft mounted worm reducer coupled on axis producing high torque

and low clearances operation.

﹡The rolls are wrapped with heat resistant, anti-spalling rubber. It has good friction

and will minimize work piece slippage.

﹡Roll move method is done manually by hand with positioning-bar to lock.

﹡The option is adjusted roll manually by the L/R screw. The operator must refer to

3.1 Installation & Adjustment ( page 4 of this manual) for instruction to match the

diameters of work piece.

1

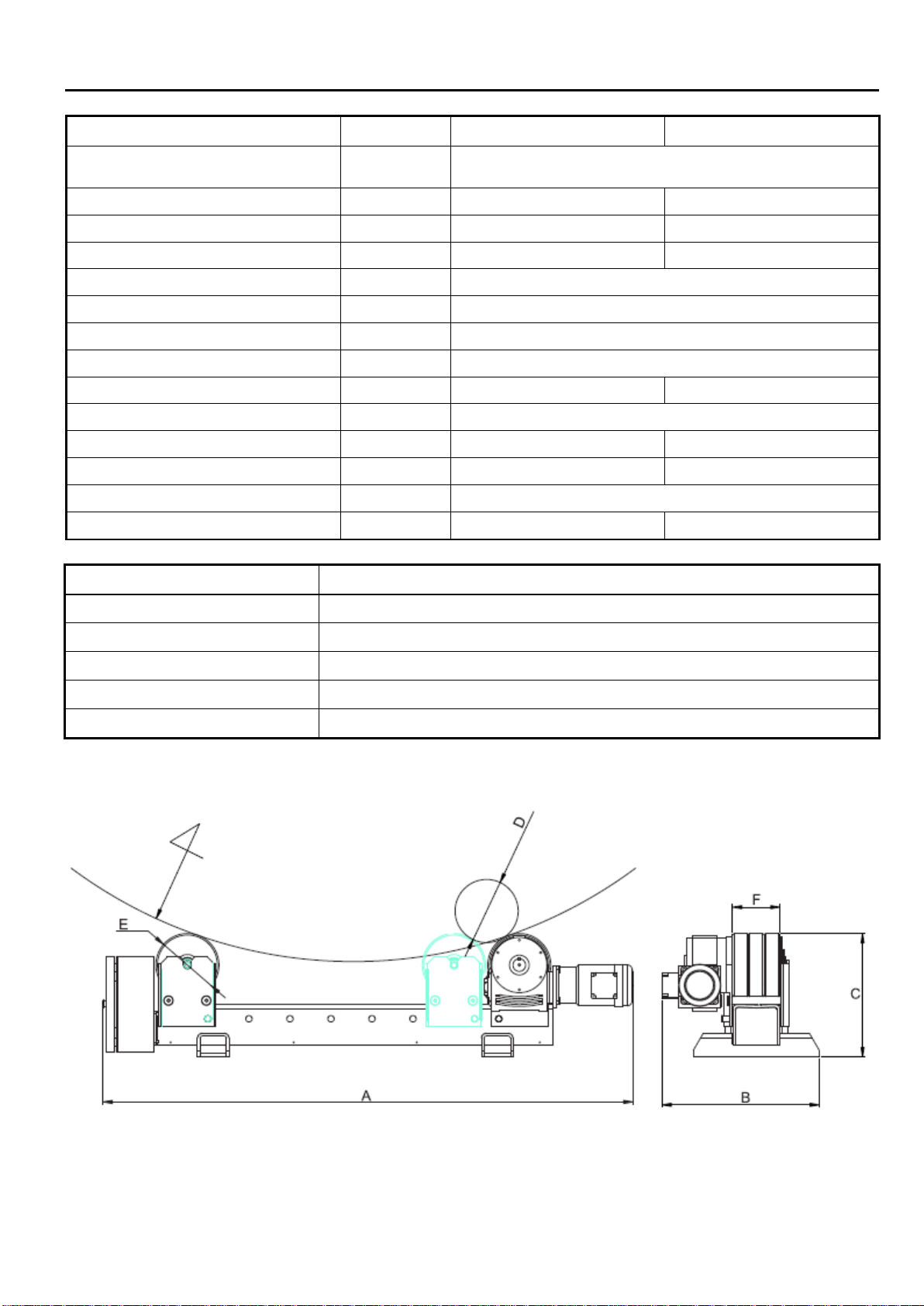

1.2 SPECIFICATION

MODEL UNIT TR-3500B TR-6000B

Power Input ~

1 Phase 220V ~ 240V 50 / 60Hz

3 Phase 460V 50 / 60Hz

Rated capacity

KVA

0.5

0.5

NFB capacity

A

6 / 2

6 / 2

Turning capacity kg 3500 6000

Diameter range (D)

mm

ψ

50 ~ 3000

Speed range mm/min 60 ~ 1200

Motor

Hp

1/2

Wheel Dia. (E)

mm

ψ

200

Wheel width (F) mm 100 150

Roller type

-

PU

Overall length (A) (Drive / Idler) mm 1520 / 1260 1670 / 1260

Overall width (B) (Drive / Idler)

mm

500 / 400

500 / 400

Overall height (C) (Drive / Idler)

mm

391

Weight(Drive / Idler) kg 171 (102 / 69) 242 (150 / 92)

Installation location Altitude 1000M or below , Free from corrosive gas and liquid.

Ambient temperature 0~+40℃(non-condensing and not frozen)

Ambient humidity Below 90%RH(non-condensing)

Storage temperature -20~+60℃(non-condensing and not frozen)

Storage humidity Below 90%RH(non-condensing)

International projection IP 22

2

2.1 INSTALLATION & ADJUSTMENT

Instruction During installation, please pay attention to the parallelism and horizontal height of the

bed of drive / idler.

﹡When the ground is rugged, please adjust the screw of the base to make the

height of bed horizontal and to prevent vibrations. Bed needs to be fixed on the

ground to prevent any movement caused by vibration during operation.

﹡The correct installation method is as the following figure:

Faulty installation method:

The following 3 installation methods should be avoided to prevent the work piece from

falling down or prevent the turning roller from being damaged by the outside unusual

force.

3

3.1 OPERATION INSTRUCTION

Instruction ﹡Correct loading angle --- 40º~ 60º. When the loading angle is incorrect, the

following situations would occur:

A. When the contact angle between work piece and turning roller is more than

60º, the roller would suffer from the improper squeeze or the work piece

would be stuck between the rollers, which would cause the damage of the

roller and shaft. The drive motor would burn down as well.

B. When the contact angle between work piece and turning roller is less than

40º, the work piece would slip or fall off. Before putting the work piece, the

correct loading angle should be identified in advance to make the machine

run normally.

﹡The calculation method of the loading angle and turning roller C-C:

C-C = [ (Sinθ/ 2) ×( r + D) ] ×2

Ex:Diameter of work piece (D) =ψ500mm

Radius of roller (r) = 202.5mm

Loading angle = θ

Hence, roller C-C = 702.5

Please check this table before loading work pieces

:

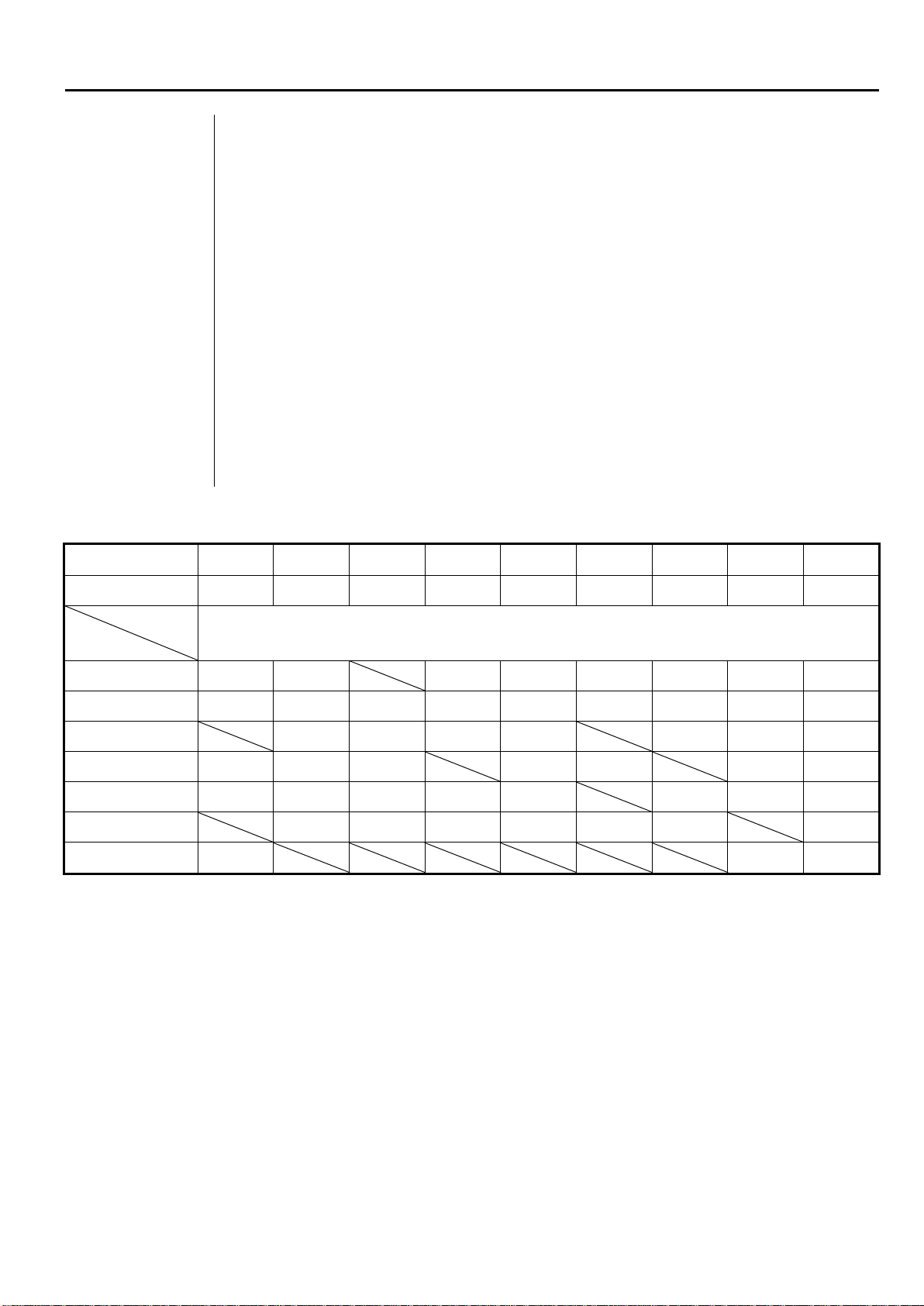

Roll-Roll A-A B-B C-C D-D E-E F-F G-G H-H I-I

C-C 207 272 337 402 532 662 792 922 1052

Work-pieces Dimension (B)

38.36~40.22 400 600 1000 1400 1800 2200 2600 3000

41.04~44.06 350 550 750 900 1300 1600 2000 2400 2800

44.10~47.32 500 650 800 1200 1800 2200 2600

47.70~49.32 300 450 600 1100 1400 2000 2400

51.96~54.52 250 400 550 700 1000 1600 1800 2200

57.08~60.18 350 500 600 900 1100 1400 2000

61.68~61.98 200 1600 1850

Angle (A)

4

3.1 OPERATION INSTRUCTION

5

3.2 REMOTE CONTROL INSTRUCTION

1. System power switch:System’s main power - NFB switch (circuit breaker).

2. “Start” switch:Press to start the system – green light.

3. While HP mode, the wheel speed is controlled by the adjustment knob on the remote pendent. The foot

switch is only used to start / stop the rotation.

While RP mode, the maximum wheel speed is set by the remote pendent adjustment knob. The foot

switch controls speed between 0 and the maximum speed.

4. Remote control device:

A. Speed meter

Shows the speed data (Hz.)

B. Speed knob

To increase speed, turn clockwise.

To decrease speed, turn counter clockwise.

C.Forward / Reverse

Indicates forward and reverse direction of the turning rollers.

CAUTION: [WHILE TURNING, PLEASE AVOID CHANGING DIRECTION.]

D.Run / Stop

Set the “Forward / Reverse” direction followed by pressing the “Run” button to turn the rollers

continuously. Press “Stop” button to stop the turning.

E. Jog / Reset

While the machine is not in motion, you can adjust to desired position slowly by pressing “Jog”

function. When the inverter driver displays an error message, press “Reset” to clear the error and

reset the system.

F. E-stop button

Press the emergency stop button to terminate the driver circuit.

5. Line speed meter:

Display 0 when the wheel is completely stopped. The line speed is displayed to facilitate the wheel

speed adjustment.

﹡

Please remove the external cover in order to set the RPM meter.

6

T

T

TH

H

HI

I

IS

S

S

P

P

PA

A

AG

G

GE

E

E

I

I

IS

S

S

B

B

BL

L

LA

A

AN

N

NK

K

K

7

4. 1 TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE / REMEDY

(1.) After switch on, the power light

doesn't lit A. NFB jumps off.

To check the main circuit-disconnect or short.

B. No power input.

To inspect the AC power input voltage and phase.

C. DC24V no output

1. To inspect and make sure the switching power supply

input voltage is correct or not ?

2. To Check the Fuse was burn down or not? If yes, please

replace new one.

D. Control PC board.

Please refer the item (2.)

E. The indicator light breaks down.

1. To make sure the voltage of indicator-DC24V.

2. To inspect the indicator.

(2.) Control PC board indicator (LED

lamp) wasn't illuminated or

damaged.

A. AC or DC power input disconnected.

To inspect power input voltage and phase.

B. Fuse burn down.

To inspect the F1 & F2 fuse working or not, If damaged,

please replace a new one.

(3.) Inverter – no display.

A. Inverter has no power input.

Check if magnetic contactor is defective (replace).

B. Inverter has power input.

Check if inverter’s digital remote panel is defective (replace).

(4.) Inverter – displays ALM. A. Inverter driver display" ALM "data.

To make sure the d

isplay status, and refer the inverter driver

Trouble shooting.

(5.) The turntable has no movement. A. Remote control breaks down.

Please refer the item (6.)

B. Control PC board.

Please refer the item (2.)

C. Inverter breaks down, no output.

Please refer the item 3 & 4.

D. Failed motor

Check / change a new motor.

E. The reducer is damaged.

Replace a new reducer.

8

4.1 TROUBLE SHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE / REMEDY

(6.) Remote switch has no action or

speed control knob disable. A. Snap switch damaged.

To check the snap switch connector is normal or not? And

replace it.

B. Potentiometer damaged.

To measuring the potentiometer resistance (5KΩ) is normal

or not? If yes, please change a new one.

C. Indicator was no work.

To change the indicator.

(7.) Remote foot control has no

response, or cannot control speed. A. Remote foot control limited switch failed

1. Check the limited switch and its connector. Replace

when required.

2. To make sure the activating position in the dog is

correct. Adjust its position if required.

B. Potentiometer damaged.

Measure the resistance of the potentiometer – should be

about 5KΩ. Replace when necessary.

9

5.1 PARTS LIST ─CONTROL BOX

Fig No.

Part No.

Description

Q’ty.

Remark

1

3061-1006

Line speed meter

1

2

3214-2002

ES Push Button

1

3214-1005

Contact

1

3

3214-4006

Push button (w/ light)

1

PB1

4

3216-1003

Rotaryes switch

1

5

*

3323-0005

Power supply

1

PS

*

5015-5090000-30

Power supply clamping plate

1

PS

6

*

3224-1005

Magnetic contactor

1

MC

7

3221-2001

No Fuse Breaker

1

220VAC

3221-3008

No Fuse Breaker

1

460VAC

8

*

6652-1221

PC Board

1

PCB

9

**

3021-2001

Inverter

1

INV

**

3021-4003

Inverter

1

INV

10

**

3311-0018

Transformer

1

AC460V

11

3071-2201

Fan

1

12

3211-4105

Select switch

1

SW1

13

3122-7002

Socket female 17 Pin

1

JN4

14

3122-4003

Female male connector 7 Pin

1

JN2

15

3534-3005

Cable clamp

1

P1

16

3122-4004

Metal connector socket 10Pin

1

JN5

17

3023-0003

Remote control 7.5M

1

18

3534-3003

Nylon cable gland

1

* Recommended spare parts

** Options

10

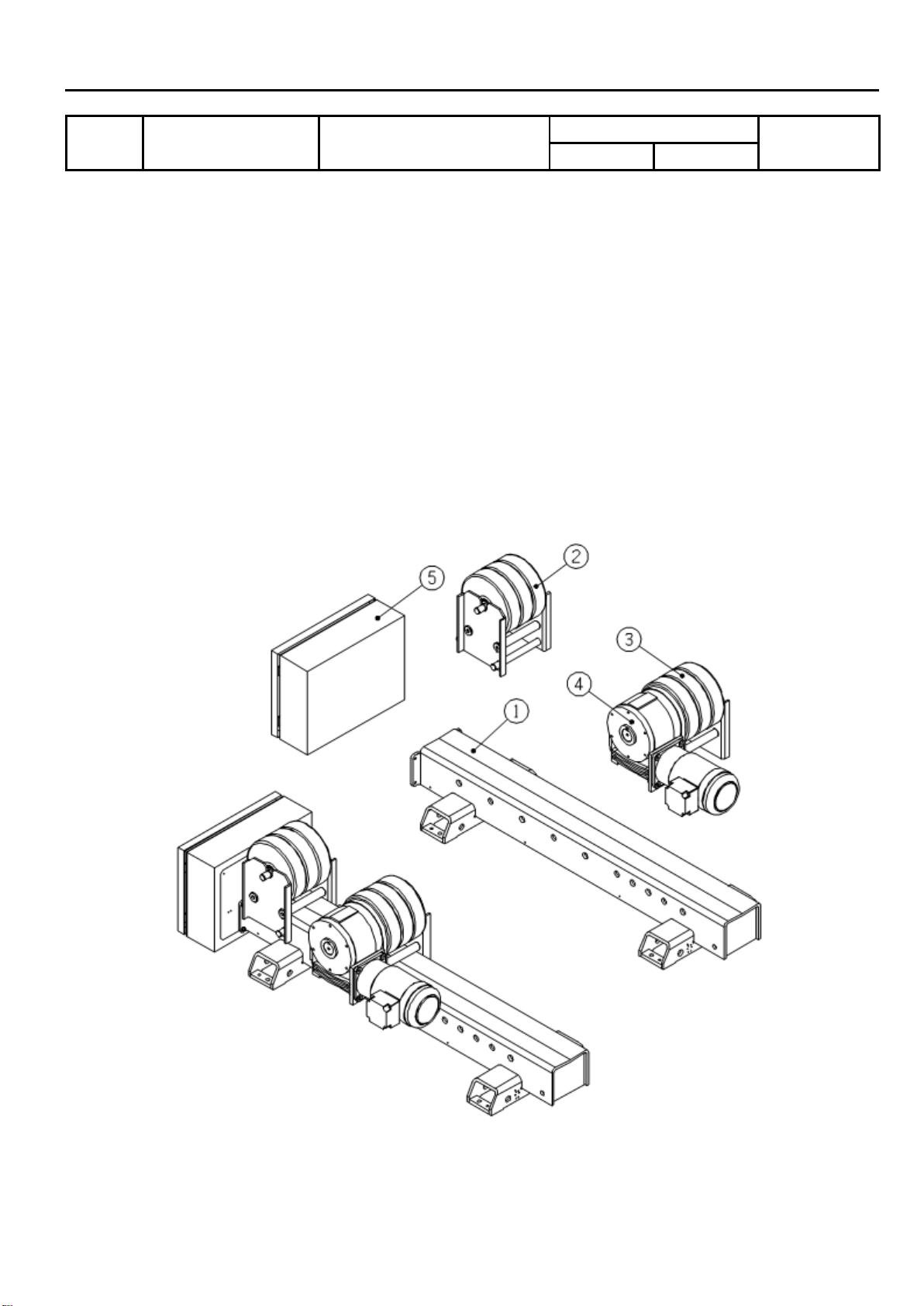

5.2 PARTS LIST ─TR-3500BP / TR-6000BP

Fig No. Part No. Description

Q’ty.

Remark

TR-3500BP

TR-6000BP

1

5041-4010000-24

Machine bed

1

1

2

**

5041-3700010-20

Idler wheel

1

**

5041-4030010-20

Idler wheel

1

3

**

5041-3600010-22

Main wheel

1

**

5041-4060010-22

Main wheel

1

4

**

0353-0111

Worm reducer

1

**

0353-0114

Worm reducer

1

*

0350-0019

Gear Motor

1

1

5

**

6501-0520

Control box

1

1

AC 220V

**

6501-0550

Control box

1

1

AC 460V

* Recommended spare parts

** Options

11

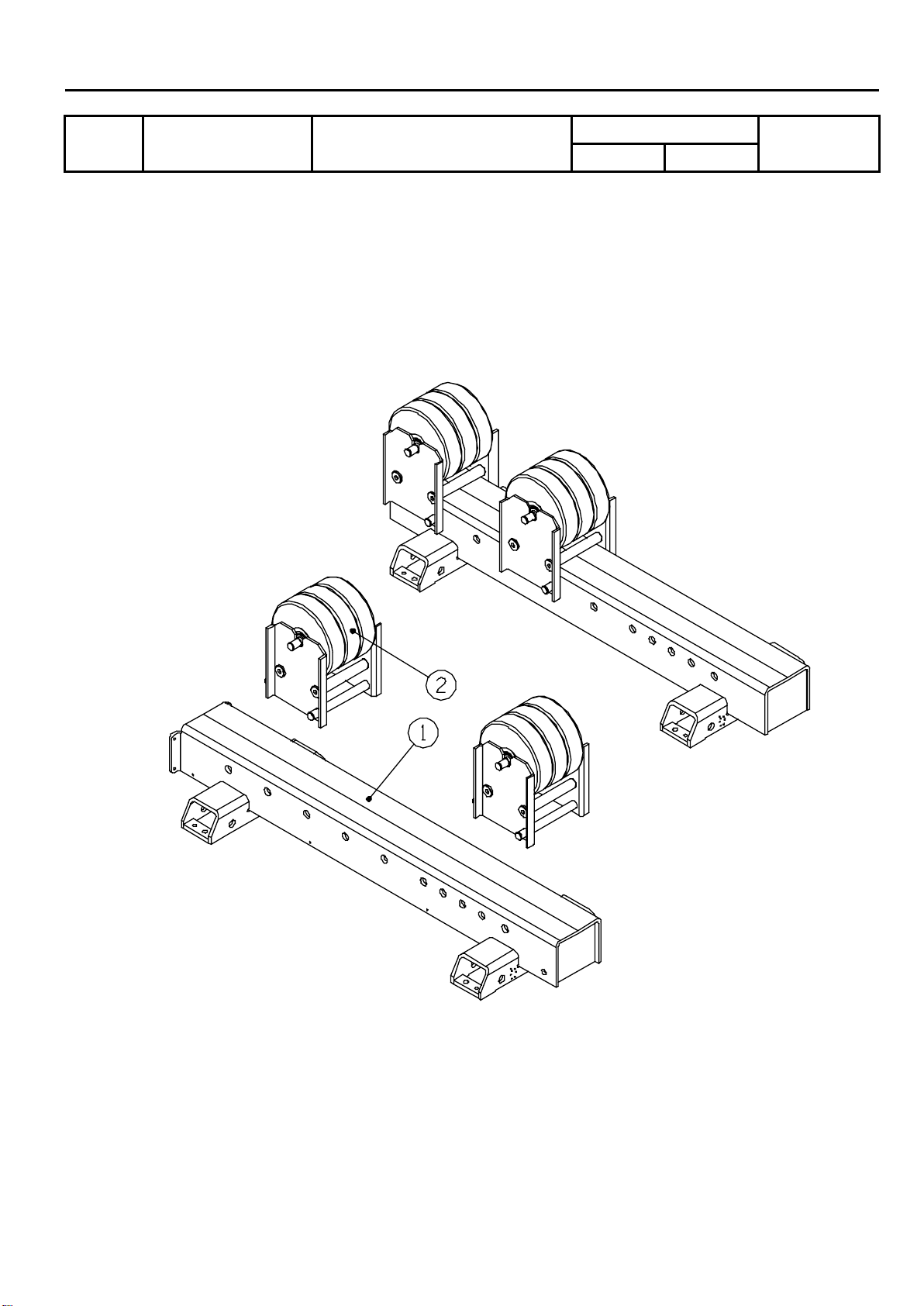

5.3 PARTS LIST ─TR-3500BI / TR-6000BI

Fig No. Part No. Description Q’ty. Remark

TR-3500BI

TR-6000BI

1

5041-4190000-10

Machine bed

1

1

2

**

5041-3700010-21

Idler wheel

2

**

5041-4030010-21

Idler wheel

2

* Recommended spare parts

** Options

12

This manual suits for next models

5

Table of contents

Other ProArc Industrial Equipment manuals